Special Feature

World’s fastest-curing carbon fiber–reinforced prepreg

DICARBO® LF series

The DIC Group has developed a revolutionary method for producing CFRP—essential to lowering the weight and increasing the durability of vehicles—that significantly reduces CO₂ emissions and energy consumption attributable to production.

Value Creation Contributing to improved fuel efficiency for vehicles, among others, by improving productivity for CFRP

Production processes that hinder the broad adoption of CFRP, a superior composite material

As its name indicates, carbon fiber–reinforced plastic (CFRP) is a fiberreinforced

composite material containing carbon fibers reinforced with resin.

To use reinforced concrete as a metaphor, carbon fiber corresponds to rebar,

while resin corresponds to concrete. CFRP’s principal properties include its

outstanding strength and lightness. Originally used in golf clubs and fishing

rods, CFRP today is finding increased application in aircraft, automobiles,

buildings, bridges, satellites and wind power generating equipment. In the

mobility field, in particular, with fuel efficiency a key theme as the world seeks to

decarbonize, CFRP is seeing further growth in demand as a functional material

that helps reduce vehicle weight.

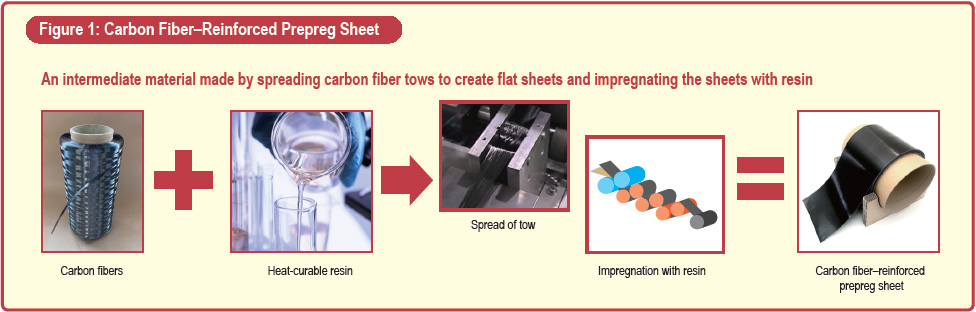

One production process for CFRP uses prepreg sheet, a carbon fiber–

reinforced sheet-form intermediate material made by spreading bundles of

carbon fibers (tows) to create fl at sheets and impregnating the sheets with resin

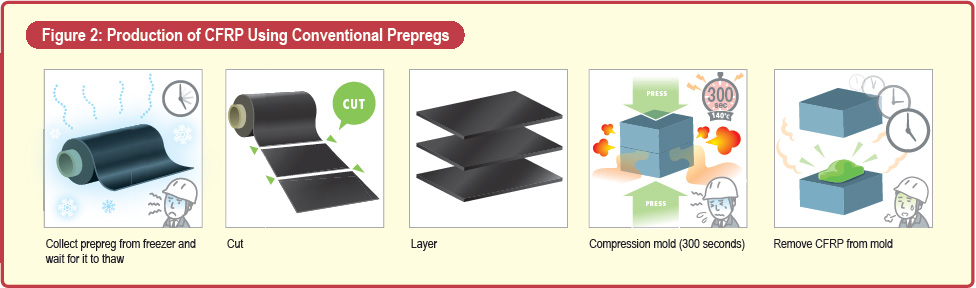

(figure 1). The sheets are then layered into a heated mold cavity, compression

molded and cured. A major drawback is that conventional prepreg sheet—

made with epoxy resin—must be refrigerated or frozen for storage and thawed

for use, as a result of which this has traditionally been a costly, complex and

low-productivity process (figure 2).

Realizing a fast-curing carbon fiber–reinforced prepreg that greatly improves productivity

With the aim of improving the productivity and cost of CFRP production, in

fiscal year 2018 DIC commenced full-scale development of a fast-curing

resin for prepreg, leveraging its polymer design technologies, and launched a

research project aimed at commercializing fast-curing prepreg sheets made

with this resin in partnership with the Industrial Technology Center of Fukui

Prefecture, which owns a high-speed tow spreading technology, and Fukuibased

comprehensive fibers manufacturer Seiren Co., Ltd., which boasts highprecision

impregnation technologies that capitalize on its resin film–forming

and coating capabilities. This project was chosen as a major research project

by Japan’s New Energy and Industrial Development Organization (NEDO)

under its Strategic Innovation Program for Energy Conservation Technologies

as a practical application development project aiming at commercialization for automotive applications within three years.

The three project partners proceeded with R&D in their respective areas of

specialty and cooperated closely to integrate new technologies. In summer

2021, they succeeded in the practical development of a fast-curing prepreg

sheet that boasts the world’s fastest curing time and can be stored at room

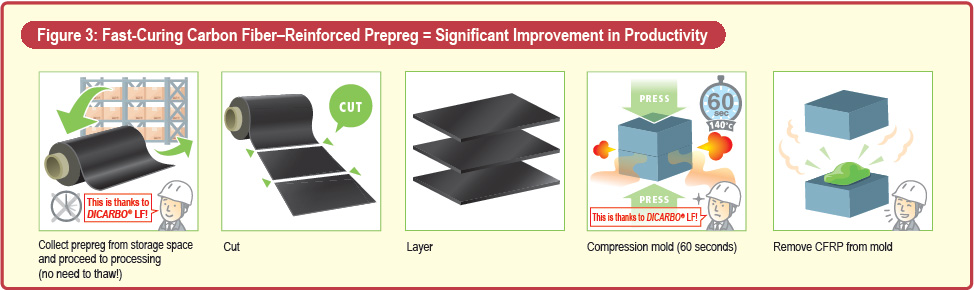

temperature (around 23°C). By shortening the minimum curing time to between

1/3 and 1/5 that of conventional prepreg sheet—i.e., to approximately 30

seconds—and eliminating the need to refrigerate or freeze for storage and

then subsequently thaw for use, productivity is improved by up to five times.

Production costs are also lowered because there is no need to install and

maintain refrigerated or frozen storage facilities (figure 3).

A Distinctively

DIC Response

Developing a radical curing resin that delivers both high-speed curing and normal temperature stability

Many challenges were faced, including the need to control viscosity, achieve thin sheets and ensure suitability to each process

DIC’s role in the joint project centered on developing a new resin that cured

quickly and could be stored easily. While the Company has extensive experience

in the area of molding resins, a number of breakthroughs were necessary to

realize a resin conducive to spreading and loosening carbon fiber bundles into

single tapes that are then arranged evenly into thin sheets.

DIC’s technical staff began by selecting several fast-curing candidate resins it

saw as having the potential to boost productivity, but found determining a design

and formulation that allowed changes in curing status depending on the process

extremely challenging. They realized that what they needed to develop was a

resin that reaches a semi-cured state during the process of impregnating each

ultrafine carbon fiber and then fully cures at a high speed when heated. In other

words, a resin that would reach optimum viscosity during each process, i.e.,

coating, impregnation, winding, storage and compression molding. Design and formulation was further complicated by the need to ensure the resin could be

stored at room temperature, rather than requiring refrigeration or freezing.

To address these issues, technical staff analyzed changes in physical

properties caused by viscosity and resin temperature required at each stage and

pressed ahead with polymer design while conducting repeated simulations. At the

same time, DIC’s Sakai Plant, where the Company conducts resin development,

produced multiple prototype resins in a process of trial-and-error to realize

the precise resin characteristics as designed. These prototypes were taken

to the Industrial Technology Center of Fukui Prefecture, which was in charge

of developing tow spreading equipment, and Seiren, which was responsible

for resin coating and impregnation equipment, where repeated additional

refinements and adjustments were made.

The debut of DICARBO® LF, a carbon fiber–reinforced prepreg that boasts the world’s fastest curing time and can be stored at room temperature

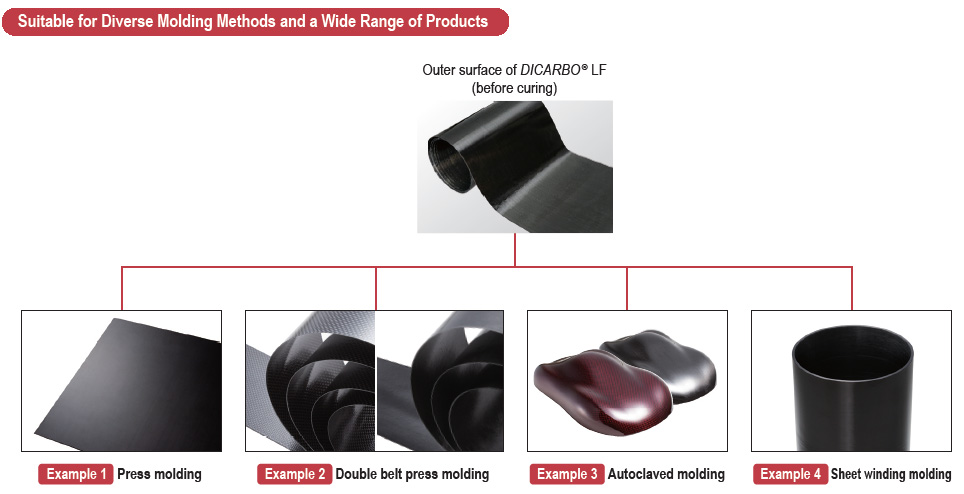

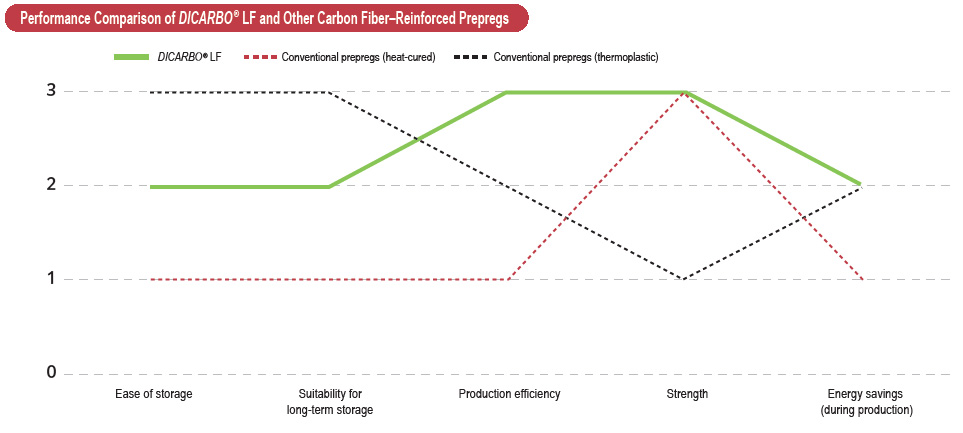

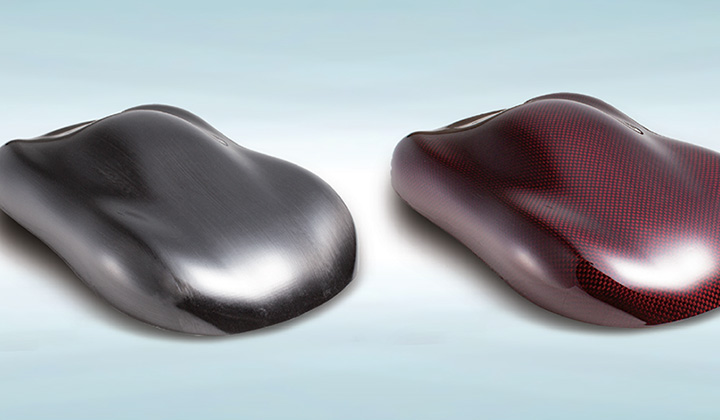

Through repeated trial production and constant modification, the project partners succeeded in gradually improving resin characteristics. They also incorporated an original idea into the impregnating process that greatly enhanced prepreg production. In spring 2021, with the NEDO program’s development deadline looming, the partners completed fast-curing carbon fiber–reinforced prepreg DICARBO® LF, which not only boats the world’s fastest curing time but can also be stored at room temperature and is compatible with a wide range of molding methods. The three entities subsequently developed a mass production process for this innovative product, announced simultaneously in July 2021, after which they began providing samples produced using a demonstration plant operated by Seiren. DIC displayed DICARBO® LF at the Society for the Advancement of Material and Process Engineering (SAMPE)’s Japan Exhibition 2021 in December 2021. The product was well received across a broad range of industries and the department in charge was busy for weeks responding to inquiries. Nonetheless, DIC does not see this as the end of the project, believing it has a mission to promote DICARBO® LF as a replacement for conventional carbon fiber–reinforced prepregs and to encourage its adoption to facilitate the development of exciting new CFRP products. The Company is confident that the increasing use of DICARBO® LF will further advance the popularity of CFRP and in so doing help lower the weight, improve the fuel economy and reduce the energy consumption of finished products in diverse fields.

Demonstration plant at Seiren

KEY PERSON of DIC

Six years after its proposal, we were able to overcome the biggest obstacle and achieve commercialization.

We put together an in-house proposal for entering the highly promising carbon fiber–reinforced prepreg market as part of a new product planning

effort and commenced development. We soon realized that the road to commercialization would be a long one if DIC was to go it alone. We

approached the Industrial Technology Center of Fukui Prefecture in 2016 and Seiren in 2017 to undertake a joint project with the aim of accelerating

development. Even with two partners, however, the way forward was anything but flat. There even came a point when, staring at the mountain of

prototype resins that had come to nothing, I felt pretty bleak about the future of the project. For that reason, I was truly pleased when the work of so

many colleagues to make improvements enabled us to begin providing samples in 2021.

Currently, we are working hard to realize the official launch of DICARBO® LF, sharing information on challenges faced by customers in multiple industries.

I am confident that we will soon be able to show CFRP automotive parts and other products made with DICARBO® LF at exhibitions and elsewhere.

Manager, A-1 Project, Automotive Business Unit, Sakai Plant, DIC Corporation Tomoaki Shinchi

We are striving to encourage the widespread adoption of CFRP by focusing on reducing energy consumption attributable to production.

The response to our news releases, as well as to our participation in exhibitions and digital marketing efforts, has been immense from both the

domestic and overseas markets. In addition to mobility, we are promoting sales to sports equipment, electronics and electrical appliances, civil

engineering and multiple other industries. DIC is a latecomer to the market for carbon fiber–reinforced prepreg, so it is not easy for us to encourage

companies to switch from conventional products to DICARBO® LF, but our customers have generally been interested in saving energy so this is the

angle we have used to propose this product.

DICARBO® LF is also a strategic choice for customers who are considering using carbon fiber–reinforced prepreg to develop new CFRP products

and we will provide whatever support we can by leveraging the technologies and personal connections we have cultivated in the development of

this innovative product. We are determined to clear the obstacles ahead to realize the official launch of DICARBO® LF and look forward to the day

when it becomes the dominant next-generation carbon fiber–reinforced prepreg.

Manager, A-1 Project, Automotive Business Unit, New Business Development Headquar ers, DIC Corporation Naoko Nakajima

Stakeholder Perspective

I look forward to this achievement leading to the realization of new molded products made with CFRP.

When DIC approached us, we had been working to develop carbon fiber–reinforced prepreg sheets that leverage

our tow spreading technologies for many years but had not done anything in the area of resin development. For this

reason, we were pleased with DIC’s proposal for producing these sheets with a novel resin and that the joint project

would also involve a company based in Fukui Prefecture.

In terms of the resin’s behavior, obtaining stable, high-quality prepreg sheets was a challenge, but the researchers

involved in the project were tenacious and positive and succeeded in achieving commercialization. On behalf of the

Industrial Technology Center of Fukui Prefecture, I am delighted at this achievement. We are confident that this will

lead to the realization of a wide range of new molded products made with CFRP.

General Manager,

New I ndustrial Creation R&D De part ment,

Industrial Tech nol ogy Center of Fukui

Prefecture

Ka zumasa Kawabe

Special topics 2022

World’s fastest-curing carbon fiber–reinforced prepreg

The DIC Group has pioneered key NIR-management solutions that will help automotive coating systems ensure safe, secure and richly colored vehicles.

World’s fastest-curing carbon fiber–reinforced prepreg

DICARBO® LF series

The DIC Group has developed a revolutionary method for producing CFRP—essential to lowering the weight and increasing the durability of vehicles—that significantly reduces CO₂ emissions and energy consumption attributable to production.