Sustainable Technology and Product Development

Proposing Solutions that Leverage Core Technologies

Goals and Achievements of Major Initiatives

Enhance ability to develop products and technologies that facilitate contribution to a sustainable society.

| Goals for fiscal year 2022 |

|

|---|---|

| Achievements in fiscal year 2022 |

|

| Evaluation | ★★ |

| Goals for fiscal year 2023 |

|

Accelerate efforts to develop products that contribute to sustainability.

| Goals for fiscal year 2022 | Accelerate efforts to develop products that contribute to sustainability. |

|---|---|

| Achievements in fiscal year 2022 | Efforts led to the launch of multiple new biomass products, including a polyester plasticizer, UV-curable clear varnish and packaging materials suitable for recycling. |

| Evaluation | ★★ |

| Goals for fiscal year 2023 | Accelerate efforts to develop products that contribute to sustainability. |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Achieving Sustainable Growth

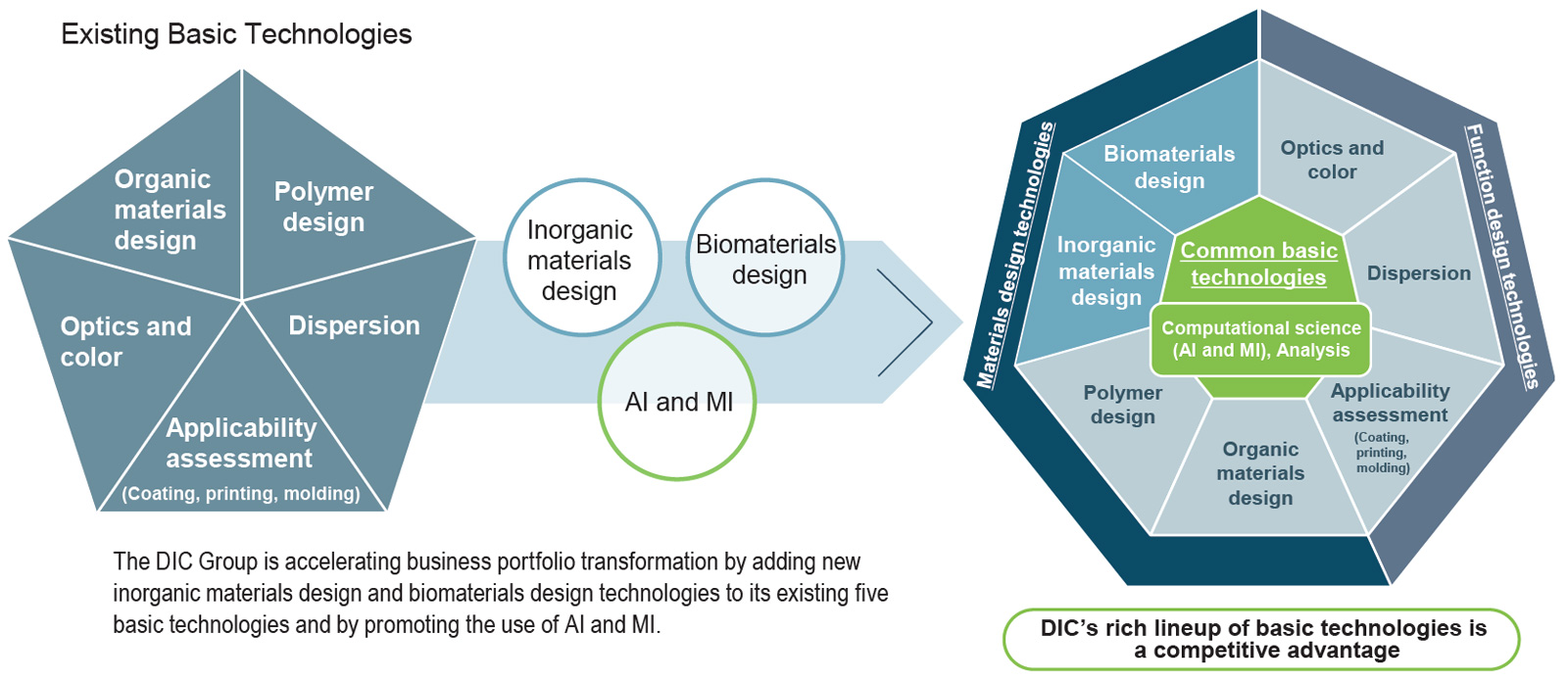

With the aim of realizing its redefined vision statement, “We improve the human condition by safely delivering color and comfort for sustainable prosperity—Color & Comfort,” the DIC Group strives to add depth to its existing basic technologies in the areas of optics and color, organic materials design, polymer design and dispersion, and to foster new technologies in the areas of inorganic materials design and biomaterials design. The Group also actively promotes the use of AI and materials informatics (MI), as well as the training of AI specialists.

Sustainable Packaging

Highlights in the area of printing inks include the development and launch of a new series of low temperature–drying web offset inks that reduce associated CO₂ emissions attributable to use because less gas is required for drying, a series of UV-curable clear varnishes that earned the Biomass Mark from the Japan Organics Recycling Association (JORA), and antibacterial and antiviral overprint varnishes. In materials for packaging, the DIC Group expanded its lineup of products, introducing adhesives with barrier properties, ordinary coatings and heat-resistant coatings that are compatible with recyclable mono-material packaging. The Group also worked to expand sales of products that contribute to the reduction of food loss, including easy-peel films for the lids of prepared food containers used by convenience stores and pulp molded containers for home-delivery frozen lunch boxes.

In response to market demand and sustainability trends in the regions in which it operates, the Sun Chemical Group focused on developing new integrated solutions for making packaging more recyclable, including barrier, temperature-resistant and protective coatings, adhesives, sealants and recycle-friendly inks. These technologies are enablers for recyclability, for reducing weight and for transitioning from plastic to paper packaging.

Color Science

As well as the development of new products in the area of pigments for color filters used in displays, the DIC Group’s achievements in the area of color materials included the commercialization of pigments for water-based flexo inks with reduced concentrations of harmful primary aromatic amines. The Group also developed and began shipping samples of a new UV dispersing ingredient for sunscreen, an active cosmetic ingredient containing polysaccharide SACRAN™, extracted from Suizenji nori, a fresh-water bluegreen algae.

Overseas, the Sun Chemical Group inaugurated sales of a range of new products. Among these were two new orange and eight new plant-derived natural effect pigments for cosmetics, as well as eight new effect pigments for automobile coatings that expand color choices available for use on vehicles.

Smart Living

R&D in the area of synthetic resins centered on low-dielectric materials for electronic circuit boards for 5G/6G-enabled communications devices and biomass resins such as an all-sustainable alkyd resin composed of biobased and recycled monomers and bioderived solvents. In metal carboxylates, the DIC Group embarked on the provision of a new cobalt-free drier for coatings in the particularly environment-conscious European market. In addition, DIC’s 100% biomass-based polyester plasticizer was accredited as a Certified Biobased Product under the USDA’s BioPreferred Program, which is expected to help boost its adoption by a broad range of industries, including in the United States, Europe and the PRC, while in industrial adhesive tapes the Group expanded its lineup of products for attaching smartphone components and fixing panels in the production of computers that deliver excellent removability and reworkability.

A Global R&D Configuration that Underpins Product Development

The Group’s R&D organization in Japan comprises the Technical Management Unit, which is responsible for product development and modification connected directly to businesses; DIC Graphics Corporation’s Technical Division; the R&D Management Unit, which is responsible for adding depth to existing basic technologies and fostering new basic technologies; and the New Business Development Headquarters, which is charged with creating strategic new businesses and commercializing business units’ next-generation products. Overseas, the Group’s R&D is conducted by the Sun Chemical Group’s research centers in the United States, the United Kingdom and Germany; Qingdao DIC Finechemicals Co., Ltd., in the PRC; printing inks technical centers, polymer technical centers, solid compound technical centers and pigment technical centers in the PRC and the Asia–Pacific region; the Fine Chemical Technical Center–Korea; and an algae research center in the United States. These facilities are working as one with the new Tape Technical Center–China, established in 2023, to promote the global development of products and technologies.

Accelerating the Expansion of Sustainable Products

DIC has introduced the proprietary DIC Sustainability Index. (For more information, please see page 36.) This index is used to simultaneously assess all DIC Group products from the perspectives of environmental impact and social contribution. The Group defines products that will help it address key social imperatives as sustainable. The index is also used in R&D to determine the focus of research and product development themes, including the modification of products to reduce environmental impact.

Product Stewardship

The DIC Group views product stewardship as a key aspect of its operations. The Group has established a global product stewardship team for printing inks, adhesives and other products used in food packaging, which it supplies to customers around the world. The team shares information on regulations and relevant topics from various markets, as well as advances awareness thereof and provides training. Knowledge thus gained is incorporated into product design and is used to produce compliance certificates across the supply chain, which are sought by customers worldwide.

The DIC Group also strives to maintain a solid grasp of laws and regulations in different countries and territories, and of trends in environmental initiatives, to ensure its ability to design products that comply with diverse controls on the use of chemical substances. In addition, the Group conducts environmental assessments on a continuous basis.

Innovation through Compounding

Building on its fundamental pigment and resin dispersion and formulating technologies, realized through the production of printing inks, the DIC Group has succeeded in combining materials with different properties and performance characteristics to develop groundbreaking products and create new value. In the area of compounds for 3D printing, the Group’s antiviral and antibacterial thermoplastic polyurethane resin (TPU) filament for additive manufacturing became the first such material to earn certification from the Society of International sustaining growth for Antimicrobial Articles (SIAA). In PPS compounds, the Group promoted the development of products with outstanding insulating properties and thermal conductivity for use in motor components for electric vehicles (EVs) and e-bikes. The Group will continue to harness its distinctive compounding capabilities to transform its diverse technologies into competitive advantages with the aim of driving innovation.

Responding to a Circular Economy

The DIC Group views product stewardship as a key aspect of its operations. The Group has established a global product In line with the “5Rs” (Reuse, Reduce, Renew, Recycle and Redisign), which seeks to advance the circular use of resources, the DIC Group is working to expand its lineup of biomass products, crucial to the achievement of carbon neutrality, shift to recyclable materials, and develop biodegradable and compostable materials. In addition, the Group is promoting the development of production processes using algae and bacteria, and of biopolymers, as well as the realization of a closed-loop chemical recycling process for polystyrene and an innovative deinking agent. The Group is also taking active steps to help reduce waste plastic and marine plastics, recognizing these as challenges that, as a manufacturer of fine chemicals, it has a responsibility to address.

Innovation through Compounding

Building on its fundamental pigment and resin dispersion and formulating technologies, realized through the production of printing inks, DIC has succeeded in combining materials with different properties and performance characteristics to develop groundbreaking products and create new value. Newly launched products include a PPS alloy compound that responds to needs arising from the increased use of electronic components in vehicles and a non-aluminum compound for vehicle sensors that delivers outstanding electrical insulation. The DIC Group is also developing a wide range of new products, including a high–biomass content plasticizer that improves the flexibility of biodegradable resins containing a large amount of inorganic filler. The Group will continue to harness its distinctive compounding capabilities to transform its diverse technologies into competitive advantages with the aim of driving innovation.

Responding to a Circular Economy

In line with the “5Rs” (Reuse, Reduce, Recycle, Redesign and Reduce CO₂), which seek to advance the circular use of resources, the DIC Group is working to expand its lineup of biomass products, crucial to the achievement of carbon neutrality, shift to recyclable materials, and develop biodegradable and compostable materials. In addition, the Group is promoting the development of production processes using algae and bacteria and biopolymers, as well as the realization of a closed-loop chemical recycling process for polystyrene and an innovative dekinking agents. The Group is also taking active steps to help reduce waste plastic and marine plastics, recognizing these as challenges that, as a manufacturer of fine chemicals, it has a responsibility to address.

Intellectual Property

Basic Approach

The DIC Group recognizes intellectual property as an important management resource and advances related initiatives, including the development of new technologies and branding, that are in conformance with its business and technology strategies, with the goal of building valuable intangible assets.

Actively Promoting Intellectual Property Strategies in Priority Business Areas in Line with DIC Vision 2030

The analysis of patent information, a treasure trove of big data that plays a key role in the formulation of business strategies, using DX is emerging as a mainstay of intellectual property strategies. With the aim of establishing new basic technologies and creating new sustainabilityrelated and other businesses, the DIC Group is promoting more extensive use of patent landscapes, which combine analyses of patent data with business information, yielding insights that assist its efforts to promote new businesses, in tandem with marketing activities conducted by business groups and technical teams.

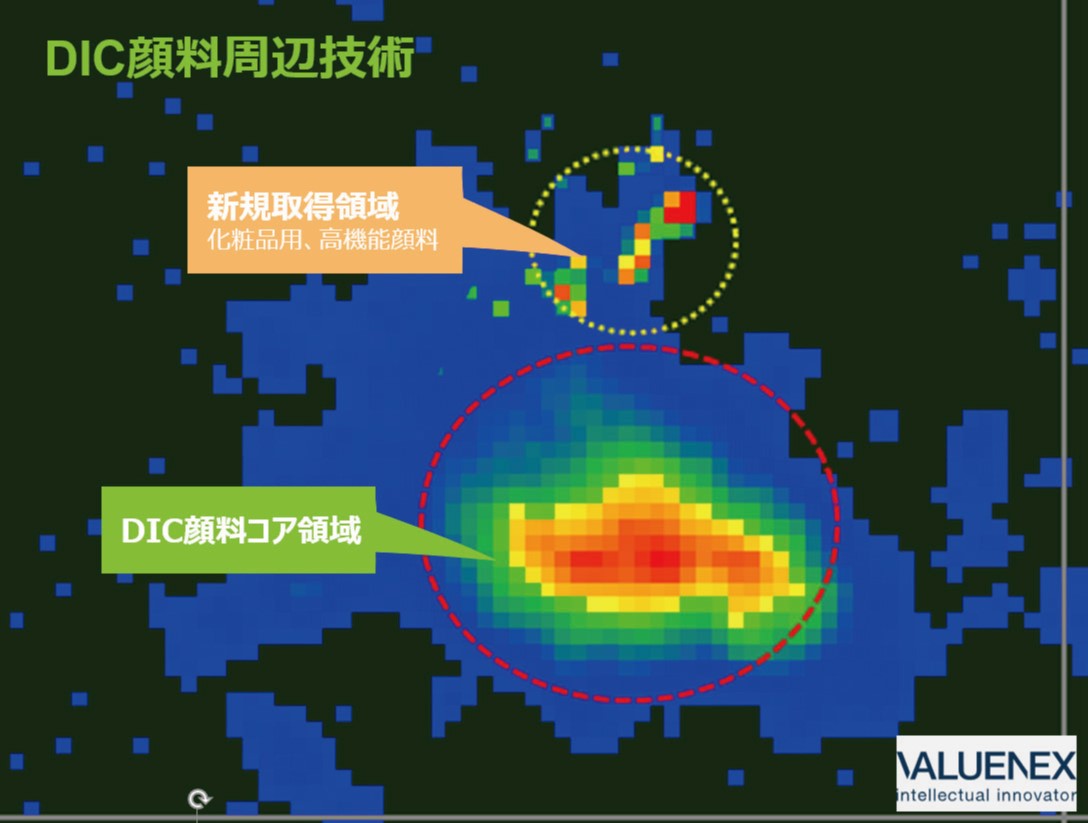

With the focus of its core business areas shifting toward sustainabilityrelated areas, the DIC Group will also broaden its use of patent landscapes to add depth to these businesses by identifying areas in which it can demonstrate core competencies, evaluating potential M&A targets in terms of ability to bolster business scale and analyzing the strategies of competitors. One such areas is pigments, where patent landscapes have enabled the Group to not only reinforce existing businesses but also diversify into new areas such as cosmetics. Patent landscapes also increased the effectiveness of M&A activities by clarifying to what degree the acquisition of the Colors & Effects pigments business would be beneficial in expanding the Group’s intellectual property portfolio in this area, as is shown in the image at the top of the next column.

The DIC Group is also capitalizing on AI and MI to actively implement its intellectual property strategies, as well as to transform its intellectual property portfolio by swiftly applying for related patents. To these ends, the Group is working closely with its Data Science Center.

Protecting Corporate Value by Managing Intellectual Property Risks

In line with its basic policy on compliance, the DIC Group works to protect business earnings and minimize intellectual property risks by conducting exhaustive patent clearance searches in new markets and for new technologies, promoting contract management, effectively managing confidential information and advancing initiatives to prevent counterfeiting, patent infringement and the use of similar trademarks. Accordingly, the Group is building a configuration for intellectual property management that conforms closely with business and product development strategies and fostering greater awareness of intellectual property and related risks by providing training, including e-learning programs offered at Group sites both in Japan and overseas.

Improving Corporate Value through Effective Intellectual Property Governance

The DIC Group strives to bolster its corporate value by enhancing the visibility of its intangible assets, as well as by accurately evaluating its competitiveness and ensuring compliance with Japan’s revised Corporate Governance Code. DIC’s intellectual property initiatives are also attracting notice from external observers. The Company is regularly among the top companies in the chemicals industry in Japan in terms of patent assets owned in a ranking conducted by an independent firm.*

- Patent Result Co., Ltd.; in the 2022 ranking, DIC was the eighth

Promoting Environment-Friendly Products

The DIC Group is committed to effective stewardship of the products it provides. Conscious always of the importance of ensuring its products are friendly to the environment, DIC promotes the development of products and new technologies that are useful to society and works to increase the weighting of environment-friendly products in its portfolio, by reducing the volume of hazardous substances it uses, focusing on products that are less hazardous and products that facilitate recycling, and realizing safer production processes that generate less waste and use less energy.

VOICE

We developed antibacterial and antiviral overprint varnishes that contribute to a better QOL.

With the aim of helping ensure that the targets of DIC Vision 2030 are met, DIC Graphics’ Paste Ink Technical Group is focusing its efforts on developing sustainable ink products that will help make society greener and more QOL-oriented. We recently developed a series of overprint varnishes with antibacterial and antiviral properties that can be cured even with energy-efficient LED-based UV curing systems. In addition to the superb performance of a conventional product in terms of imparting decorative properties and protective coatings, these products earned certification from SIAA for their ability to suppress the growth of bacteria and inactivate viruses.

Paste Ink Technical Group, DIC Graphics Corporation Tomokazu Yamada

We developed an easy-to-remove adhesive tape that aligns with the 3Rs.

In recent years, we have seen increasing demand for DIC to provide solutions that will contribute to the achievement of the SDGs, a critical global challenge. My group developed an easy-to-remove adhesive tape that delivers the outstanding adhesion required in manufacturing and can be removed easily simply by stretching. In addition to ensuring highly reliable adhesion without peeling off when in use, this tape’s easy removability helps improve the materials recycling rate for devices in which it is used, aligning with the originals 3Rs—Reduce, Reuse and Recycle—for customers and society in general. Adoption by television and mobile device manufacturers continues to increase and we plan to expand our focus to include other markets going forward.

Processing Technical Group 2, Processing Technical Division, DIC Corporation Daisuke Watanabe

We developed an adhesive for packaging materials made from recovered PET bottles.

With companies’ growing awareness of the need to contribute to the achievement of the SDGs, the importance of actively promoting environmental protection and reducing the waste they generate have taken on greater importance. In line with the sustainability policy outlined in DIC111, we recently developed the environmentfriendly DICDRY LX-RP series of adhesives, which are made from recovered post-consumer PET bottles. This new series follows the development of biomass-based adhesives in fiscal year 2019. In addition to polymer design, which was a process of trial and error, we worked to improve product value from a customer perspective through meticulous inspections of PET bottle recycling processes, safety and recycling facilities. Looking forward, we will apply technologies developed in this effort to further expand our product lineup.

Packaging Materials Technical Group 1, Packaging Materials Technical Division, DIC Corporation Tsukiko Takashima

We developed a 100% biomass-derived polyester plasticizer.

Our group has developed an extensive range of polymer modifiers that includes plasticizers, stabilizers and highly functional modifiers. In recent years, we have worked to add value to the DIC Group’s modifiers with the aim of contributing to the realization of the SDGs and to sustainability. In fiscal year 2019, we succeeded in developing Polycizer W-1810-BIO, a polyester plasticizer that satisfies all the basic performance requirements of polyester plasticizers yet is derived entirely from biomass resources. This product earned Biomass 100% Biomass Mark certification from the Japan Organics Recycling Association (JORA). The reaction to this new product has been extremely positive and it has earned solid marks in a variety of applications.

Assistant Manager, Polymer Technical Group 10, Polymer Technical Division 2, DIC Corporation Takafumi Noguchi

We are promoting the development of waterborne polyurethane resins that will contribute to the success of the SDGs.

Amid rising environmental concerns, including climate change, and increasingly urgent social imperatives, companies today face an ever-more diverse array of challenges. DIC is working to develop products that take into account the global environment, ecosystems, socioeconomic systems and other factors, with the aim of contributing to sustainability. Our group focuses on polyurethane resins that impart both texture and durability to solvent-based artificial and synthetic leathers used in automotive interiors, furniture and clothing, which DIC supplies to customers around the world. We are also contributing to the circular economy by developing production processes that achieve significantly improved efficiency and adopting bio-derived raw materials.

Assistant Manager, Polymer Technical Group 6, Polymer Technical Division 2 Tomohiro Tetsui