Occupational Safety and Health/Disaster Prevention

- Goals and Achievements of Major Initiatives

- Occupational Safety and Health

Basic Approach - Framework for Promotion

- Principal Initiatives in Fiscal Year 2024

- Infrastructure for Preventing Occupational Accidents

- Hands-On Safety Training

- Efforts to Foster a Safety-Conscious Corporate Culture

- Disaster Prevention

Basic Approach - Framework for Promotion

- Principal Initiatives in Fiscal Year 2024

Goals and Achievements of Major Initiatives

Ensure occupational safety and health.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Global | 2024 | Reduce TRIR. Targets: DIC Group in Japan: 1.90 PRC: 1.00 Asia–Pacific region: 1.00 Sun Chemical Group: 8.00 |

DIC Group in Japan: 1.93 PRC: 0.90 Asia–Pacific region: 1.28 Sun Chemical Group: 5.70 |

★★ |

| 2025 | Reduce TRIR. Targets: DIC Group in Japan: 1.60 PRC: 1.00 Asia–Pacific region: 1.00 Sun Chemical Group: 5.30 |

― | ― |

Prevent disasters.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Japan | 2024 | Maintain 0 major accidents. Process safety accident frequency rate: 0.110 (maintain at fiscal year 2023 level) |

Process safety accident frequency rate: 0.229 | ★ |

| 2025 | Maintain 0 major accidents. Process safety accident frequency rate: 0.110 (maintain at fiscal year 2024 level) |

― | ― |

- Note: TRIR is calculated as (Number of fatalities due to occupational accidents + Number of injuries due to occupational accidents resulting in workdays lost + Number of injuries due to occupational accidents not resulting in workdays lost) / Million work hours.

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Occupational Safety and Health

Policies

Basic Approach

Viewing the prioritization of operational safety as a core management tenet, the DIC Group works tirelessly to prevent occupational accidents and disasters, as well as to bolster occupational health and safety levels.

The DIC Group recognizes operational safety both as fundamental to its businesses and the core component of Responsible Care. The Group thus promotes active occupational safety and health, security and disaster prevention measures to foster a “Safety First” approach Groupwide and involving every employee.

Groupwide Occupational Safety and Health

The DIC Group has numerous processes that use hazardous and toxic materials, as well as rotating devices, not all of which involve chemical reactions. Any accident using such materials or devices has the potential to significantly impact neighbors in general and damage the health of Group and/or partner company employees and local residents. With the aim of preventing such accidents, the Group operates occupational health and safety management systems for Group employees (regular and temporary) in accordance with the laws and regulations of the countries and territories in which it operates. The DIC Group also encourages individual Group companies in the Asia–Pacific region to obtain certification under ISO 45001, the International Organization for Standardization’s benchmark for occupational health and safety management systems. As of December 31, 2024, 96% of Group companies in the region had obtained ISO 45001 certification. Based on the results of risk assessments, the Group places a priority on reducing risks in the workplace, adhering to basic safety procedures and training safety-conscious employees, and strives to reinforce its safety infrastructure and create a safety-oriented corporate culture.

Framework for Promotion

Under the supervision of the Sustainability Committee chair (DIC’s president and CEO), the Responsible Care Department promotes a variety of occupational safety and health initiatives in collaboration with sites via individual regional headquarters. In Japan, the Responsible Care Department meets regularly with site environment, safety and health (ESH) officers to confirm the status of priority issues and the achievement of targets, as well as to manage the progress of related efforts. Elsewhere, the Responsible Care Department and individual regional headquarters work together to set regional targets, while regional ESH officers conduct site risk assessments, analyze accidents and promote remedial measures to improve the continuous improvement of occupational safety and health. (For more information, please see “Policies, Targets and Framework.”)

Principal Initiatives in Fiscal Year 2024

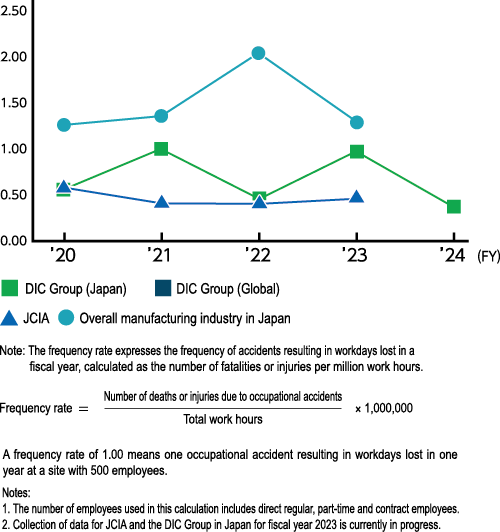

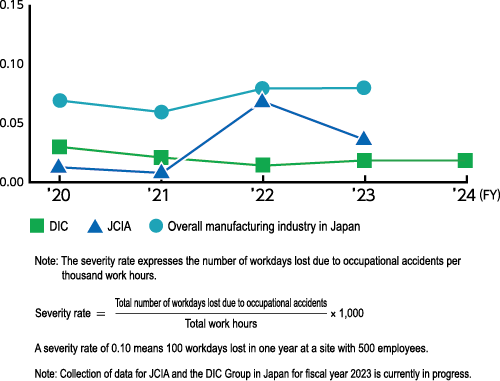

1. Global DIC Group

The DIC Group sets regional targets and promotes a variety of initiatives around the world with the aim of eliminating occupational accidents. Occupational accident frequency rate—the frequency of occupational accidents resulting in workdays lost—is generally used as an indicator. This is calculated as the number of fatalities or injuries due to occupational accidents per million work hours. DIC Group companies in Japan, the People’s Republic of China (PRC) and the Asia–Pacific region, as well as Sun Chemical Corporation, use total recordable incident rate (TRIR), an even more stringent indicator. TRIR is calculated as the number of casualties (fatalities and injuries) due to occupational accidents, both those resulting in workdays lost and those not resulting in workdays lost, per million work hours. The number of employees used to calculate TRIR is the number of direct, regular, part-time and contract employees. Employees of on-site and outside contractors are not included.

In fiscal year 2024, the TRIR for the global DIC Group was 3.51, below its 4.47 goal. None of the occupational accidents at global Group sites resulted in fatalities. A total of 83 injuries resulting in workdays lost were reported, while injuries not resulting in workdays lost numbered 63. Looking ahead, the Group will continue working to reduce occupational accidents by promoting the sharing of information on accidents and disasters, conducting risk assessments, analyzing the causes of accidents and formulating countermeasures, and providing occupational safety and health–related education and training. Some of these efforts are described in this website.

TRIR and Injuries Due to Occupational Accidents (FY2020–2024) (Focusing only on the main regions)

Japan

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| TRIR | 2.51 | 3.60 | 2.23 | 2.09 | 1.93 |

| Injuries resulting in workdays lost | 5 | 12 | 4 | 9 | 3 |

| Injuries not resulting in workdays lost | 18 | 21 | 16 | 10 | 13 |

PRC

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| TRIR | 2.29 | 1.94 | 0.79 | 2.06 | 0.90 |

| Injuries resulting in workdays lost | 5 | 6 | 2 | 7 | 2 |

| Injuries not resulting in workdays lost | 4 | 2 | 1 | 4 | 2 |

Asia–Pacific region

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| TRIR | 1.02 | 0.90 | 1.21 | 1.11 | 1.28 |

| Injuries resulting in workdays lost | 7 | 7 | 9 | 9 | 10 |

| Injuries not resulting in workdays lost | 2 | 1 | 2 | 1 | 1 |

Sun Chemical Group

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| TRIR | 5.63 | 5.33 | 6.33 | 4.53 | 5.70 |

| Injuries resulting in workdays lost | 50 | 45 | 70 | 50 | 67 |

| Injuries not resulting in workdays lost | 45 | 44 | 62 | 41 | 47 |

- TRIR = (Number of fatalities due to occupational accidents + Number of injuries due to occupational accidents resulting in workdays lost + Number of injuries due to occupational accidents not resulting in workdays lost) / Million work hours

2. DIC Group in Japan

In fiscal year 2024, the DIC Group in Japan achieved a TRIR of 1.93, which fell short of the Company’s target of 1.90 but was an improvement from 2.09 in the previous fiscal year. No occupational accidents resulting in fatalities were reported. There were three injuries resulting in workdays lost and 13 injuries not resulting in workdays lost. These numbers are broken down in the table.

DIC Group (Japan)

| Injuries | Illnesses/Ill health | Total | |

|---|---|---|---|

| Fatalities | 0 | 0 | 0 |

| Injuries resulting in workdays lost | 3 | 0 | 3 |

| Injuries not resulting in workdays lost | 12 | 1 | 13 |

| Total | 15 | 1 | 16 |

3. DIC Group in Other Countries and Territories

The TRIR for the Sun Chemical Group in fiscal year 2024 was 5.70, significantly better than the target of 8.00. The TRIR for the PRC was 0.90, better than its target of 1.00, while the Asia–Pacific region fell short of its 1.00 target, reporting a TRIR of 1.28. No occupational accidents resulting in fatalities were reported. There were 80 injuries resulting in workdays lost and 50 injuries not resulting in workdays lost.(For more information, please see “Key Data.”)

TOPIC

Nantong DIC Color Implements “One-Day Safety Officer” Activity

From May through November 2024, DIC Group company Nantong DIC Color Co., Ltd., in the PRC implemented an activity it dubbed “One-Day Safety Officer.” This activity has five principal components.

- Prior preparation: An activity plan was formulated, a “one-day safety officer on duty” roster created and all participants notified via email.

- Checklist: A duty record checklist was prepared that was divided into six safety issue categories: dress code, work environment, equipment and facilities, frontline work, fire safety management and other. Individual elements to be checked are listed in each category and safety officers record any instances of failure to meet standards.

- One-day safety officer duties: The one-day safety officer on duty wore a tag identifying them as a safety officer, recorded any issues they found and reported them to the pertinent department manager.

- Collation of information: Departments compiled issues recorded by the one-day safety officer before the second business day of each month and submitted them to the Environment and Safety Department , which oversaw subsequent corrective measures.

- Evaluation: Having collected all of the one-day safety officer records from the individual departments, the Environment and Safety Department tallies up reported issues and classifies each as either a safety risk or a 5S problem. (“5S” is workplace organization methodology based on five Japanese words: seiri (“sort”), seiton (“set in order”), seiso (“shine”), seiketsu (“standardize) and shitsuke (“sustain”).

Infrastructure for Preventing Occupational Accidents

1. Monthly Occupational Safety and Health Data

The DIC Group conducts its diverse businesses in accordance with a wide range of national and regional legal systems, working conditions and practices. However, to raise the level of occupational safety and health of the entire Group, it is crucial to establish common standards and benchmarks and to align regional initiatives. The DIC Group promotes the sharing of information related to occupational safety and health across the global Group by aggregating regional statistical data on a monthly basis. Specifically, local data is gathered by DIC (China) Co., Ltd., for Greater China, DIC Asia Pacific Pte Ltd for the Asia–Pacific region, and Sun Chemical for the Americas and Europe. This data is then collated and analyzed by the Responsible Care Department. This makes it possible for each Group company to objectively compare and evaluate their own operational safety, which assists in the establishment of precise targets for individual countries and regions, and the formulation of programs for making improvements. In fiscal year 2019, the Group introduced the cloud-based DIC ESH Data Collection System (DECS) in Japan, Greater China and the Asia–Pacific region to improve the efficiency of data collection. (For more information, please see “Key Data.”)

- Number of employees

- Number of casualties due to occupational accidents resulting in workdays lost and not resulting in workdays lost

- Number of workdays lost

- TRIR

- Total work hours

- Number of accidents involving fires/explosions

- Occupational accident frequency rate

Statistical Occupational Safety and Health Data

2. Analyzing Accidents and Disasters and Providing Information

In the event of an accident or disaster at a DIC Group site, the site in question and the corporate headquarters’ department in charge of safety work together to analyze the causes thereof and implement appropriate countermeasures. The department in charge of safety and site Safety and Environment groups organizes regular meetings to determine the root cause of accidents and to confirm the effectiveness of countermeasures. Findings are deployed horizontally to Group sites and companies with the aim of preventing recurrence, as well as shared with DIC Group companies worldwide. DIC has compiled such information to create Accident Case Studies and Occupational Accident Case Study databases, which are used in safety education for Group companies in Japan.

3. Principles of Safe Conduct

Using resources such as case studies of accidents and disasters in the past, DIC has created rules and procedures to ensure operational safety for DIC Group companies in Japan, the PRC and the Asia–Pacific region, which it has published as a guidebook titled Principles of Safe Conduct. The fifth edition of this guidebook was published in fiscal year 2019 in Japanese, English and Chinese.

TOPIC

Sun Chemical follows the basic principles of the Occupational Safety and Health Administration (OSHA)’s Stop Work Authority program, which gives workers the authority to stop work if the safety thereof is in question. The company views “If you see something, say something” as a rule of thumb and encourages workers, whether employees or contractors, to immediately stop work if they observe any unsafe conditions or behaviors. The exercise of stop work authority is recognized and valued. Sun Chemical expects its teams to stop working, think, assess the situation and take any action necessary to improve safety and to refuse to resume work until it is deemed safe to do so. We have adopted “STOP–THINK–ASSESS–REACT (S.T.A.R.)” as a mantra to promote awareness of everyday workplace safety and work as one to create safe work environments and ensure its employees go home safely at the end of the day.

4. Conducting Risk Assessments

The DIC Group identifies potential risks to occupational safety and health and implements initiatives to prevent accidents and occupational injuries. In Japan, the Group is working to further reduce risks posed by chemical substances by revamping its risk assessment procedures and lowering the impact of such substances on the health of employees. Of particular note, in fiscal year 2023 DIC updated its risk assessment guidelines, including those for assessment procedures. After providing appropriate training on the implementation of the revised guidelines to management-level employees at domestic DIC Group plants, DIC evaluates the hazards and toxicity of chemicals designated under Japan’s Poisonous and Deleterious Substances Control Act, and considers measures to mitigate related risks, such as revising handling procedures and upgrading facilities.

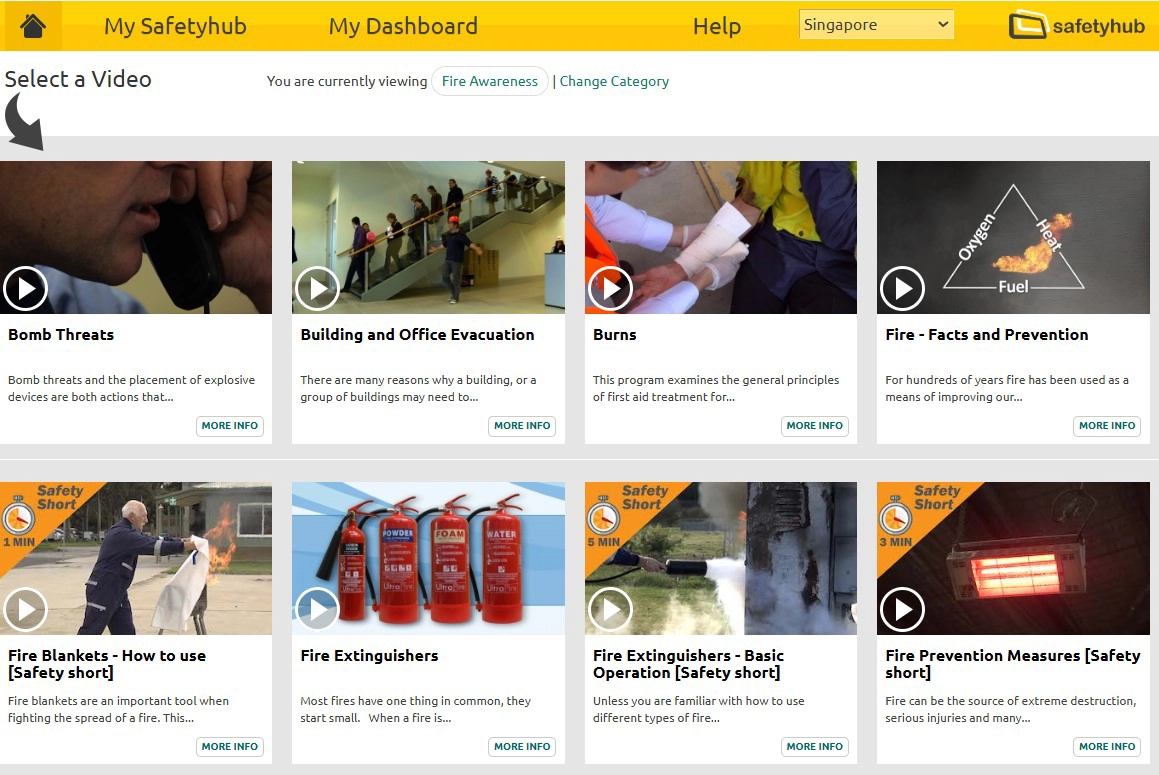

5. Promoting E-Learning–Based Safety and ESH Training at Production Facilities

To enhance its capabilities in the area of occupational safety and health, and in disaster prevention, the DIC Group recognizes the importance of ensuring that all of its employees gain a broad understanding of chemical substances, production processes, and pertinent laws and regulations. In fiscal year 2016, the Group introduced an e-learning program in Japan. Initially structured around laws and regulations pertinent to the operational safety of production facilities, including Japan’s Fire Service Act, Air Pollution Control Law and High Pressure Gas Safety Act, the e-learning program’s focus was later expanded to include non-regulatory components such as static electricity, with the appropriateness of the program’s training materials verified from the perspective of Responsible Care Department specialists, site ESH officers and production departments. Employees are able to take up to 16 classes. Competence is confirmed through testing. In fiscal year 2024, 193 employees participated in this program. Since fiscal year 2022, the Group has deployed an online occupational safety and health education service from Tokyo-based LaKeel, Inc., that centers on the distribution of short films on the subject.

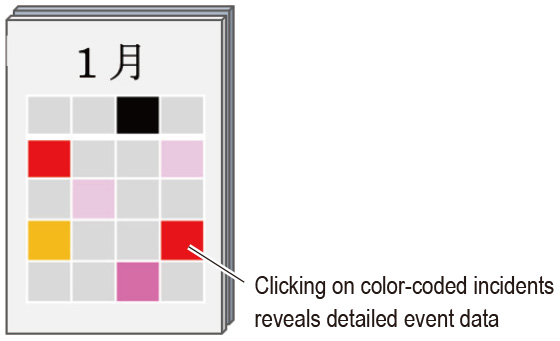

6. Accident and Disaster Calendar

Since fiscal year 2022, the DIC Group has compiled information on past accidents and disasters into case studies in the form of a monthly calendar that is visible to all employees on the first page of the DIC Group portal site. In addition to date of occurrence, information posted includes site, type of event (e.g., heatstroke, chemical injury or other) and impact (i.e., resulted in workdays lost or did not result in workdays lost). This allows users to identify incidents of concern to them and view detailed data summarizing conditions surrounding occurrence and the effectiveness of countermeasures. Displaying data for all accidents and disasters on a monthly basis also sheds light on trends. Employees looking at the calendar on any given day are able to learn about accidents or disasters that occurred on that day in the past, bolstering awareness of safety and disaster prevention across the Group.

TOPICS

DIC Asia Pacific Launches Back-2-Basics Program

Safety is deeply ingrained in DIC Asia Pacific’s operations and the company works hard to foster a culture of excellence in which all employees are empowered to maintain the highest safety standards. To strengthen this vision, the company has launched the Back-2-Basics program, an ongoing effort to reinforce fundamental safety principles and practices at all DIC Group sites across the Asia–Pacific region. The program serves as both a learning tool and a refresher, promoting consistent employee adherence to basic safe conduct and standards. A key element of this initiative is continuous self-learning. Each year, 12 e-learning modules are assigned to more than 1,500 employees across all locations in the region. Topics for 2025 include:

- the human factor;

- introduction to safety data sheets (SDSs);

- responding to chemical burns;

- preventing eye injuries;

- cuts and bleeding;

- noise-induced hearing loss;

- safe use of ladders;

- display screen equipment;

- building and office evacuation;

- cardiopulmonary resuscitation (CPR);

- prevention and control of spills; and

- contractor management.

Going forward, DIC Asia Pacific plans to further strengthen its Back-2-Basics program and incorporate themes such as promoting leadership visibility and creating a safety management structure. The company will continue to promote the continuous improvement of safety culture and the further clarification of responsibility at all of its sites.

Hands-On Safety Training

The DIC Group provides hands-on safety training in Japan, Greater China and the Asia–Pacific region. The purpose of such training is to reduce employees’ risk acceptance and foster their ability to recognize danger by simulating actual accidents. This began as a domestic initiative in 2012, after which deployment was expanded to include Greater China and the Asia–Pacific region. In Japan, hands-on safety training has helped to almost halve the occupational accident frequency rate at Group sites.

The DIC Group’s hands-on safety training program focuses on simulating common production floor accidents—including those involving entanglement in rotating devices, falls from high places and incised wounds caused by cutting equipment. The objective of this format is to transform the mindset of employees by encouraging them to think and act on their own to protect themselves and each other from latent dangers.

1. DIC Group Companies in Japan

In fiscal year 2014, the DIC Group opened the Saitama Hands-On Safety Center, a training facility that fosters skilled safety personnel by incorporating hierarchical hands-on safety training. In the same year, DIC and DIC Graphics Corporation began including hands-on safety training and Kiken Yochi Training (KYT) (“hazard prediction training”) in the training curricula for new employees. The Chiba, Sakai, Hokuriku, Tokyo, Kashima and other plants have also established their own hands-on safety training equipment and curricula to further ingrain a safety-conscious culture. In fiscal year 2015, the Group created six types of hands-on training equipment for lending to individual sites as part of a mobile training initiative. The Responsible Care Department trains employees at individual sites to serve as training instructors and has established an instructor licensing system.

Training for new employees at the Saitama Plant

Hands-on safety training simulating an accident involving a fall at the Saitama Hands-On Safety Center

2. DIC Group Companies in Other Countries and Territories

DIC Group companies in other countries and territories are also introducing hands-on safety training equipment. In Greater China, hands-on safety training equipment has been installed at Nantong DIC Color, DIC Graphics (Guangzhou) Ltd. and Changzhou Huari New Material Co., Ltd., in the PRC and DIC Graphics Chia Lung Corp. in Taiwan. In the Asia–Pacific region, equipment has been installed at DIC Compounds (Malaysia) Sdn. Bhd., PT. DIC ASTRA Chemicals in Indonesia, Thailand’s DIC Siam Chemical Industry Co., Ltd., and DIC India Limited’s Noida Plant. These companies also provide hands-on safety training for employees of affiliated companies, as well as training for instructors, in their respective regions.

Efforts to Foster a Safety-Conscious Corporate Culture

1. Safe Corporate Culture Cultivation Working Groups

In line with its “Safety First” approach, the DIC Group works to foster a safety-conscious culture. In fiscal year 2011, ESH members at plants belonging to DIC and DIC Graphics created Safe Corporate Climate Cultivation working groups, which meet regularly to discuss and exchange proposals regarding safety policies and measures, which are incorporated into Responsible Care initiatives.

2. DIC Safety Pledge Day

DIC has declared September 6 “DIC Safety Pledge Day,” an annual occasion for all of the DIC Group employees to pledge their commitment to ensuring safe operations and not repeating past serious accidents and disasters. On this day, each employee makes their pledge by writing a personal declaration on a special card.

| Fiscal year | Working group initiatives |

|---|---|

| 2012 | Working groups presented recommendations on safety policies and produced warning stickers to enhance awareness of workplace hazards. |

| 2013 | Working groups prepared safety posters featuring the president and CEO and started reading out key passages from Principles of Safe Conduct in workplaces with the aim of making the practices therein routine. |

| 2014 | Working groups prepared an illustrated version of Principles of Safe Conduct for reading out in workplaces. |

| 2015 | Working groups edited Principles of Safe Conduct into a tear-off calendar version for workplace reading circles, which was distributed to sites. The calendar version was also translated into English and Chinese. |

| 2016 | Working groups in the PRC began reading out key passages from Principles of Safe Conduct to foster a culture of safety. |

| 2017 | Working groups updated Principles of Safe Conduct. |

| 2018 | Working groups published the fifth edition of Principles of Safe Conduct. |

| 2019 | Working groups commenced production of a version of the fifth edition of Principles of Safe Conduct for workplace reading circles. |

| 2020 | The publication of a version of the fifth edition of Principles of Safe Conduct for workplace reading circles was scheduled, but was postponed until 2021 as a result of COVID-19. |

| 2021 | Site meetings were held at production facilities, with the president and vice present of DIC and the general manager of the Production Management Unit visiting each site to meet with frontline employees. A version of the fifth edition of Principles of Safe Conduct for workplace reading circles was published. |

| 2022 | Manual for protective equipment was revised. |

| 2023 | Accident records were revised to promote the effective horizonal dissemination of pertinent information and prevent the recurrence of past accidents. |

| 2024 | The revision of past accident records was completed and the revised records were brought into use. |

VOICE

We created a framework for the autonomous management of chemical substances that won a 2024 JCIA Responsible Care Award Grand Prix.

DIC took a variety of steps as part of a project to achieve the autonomous management of chemical substances, including revising rules for handling chemical substances used by domestic DIC Group companies and clarifying management workflows. We also assigned key personnel, such as chemical substance managers, to each department, which entailed collating all in-house management guidelines and risk assessment methods and developing an in-house training program that complied with pertinent regulations. This enabled us to establish a system that facilitates the appropriate management of chemical substances across the entire Group in Japan.

This project was conducted by selected members of major domestic Group site Safety and Environment groups and the Responsible Care Department. I am one of the latter. I joined the project partway through and was put in charge of administrative tasks, including documenting relevant regulations discussed, developing original DIC risk assessment tools, and designing and administering training programs at all domestic Group sites There were few role models to follow, either in-house or outside the Group, and many challenges. Thanks to thoughtful discussions with fellow project members I was able to better define my responsibilities and we succeeded in seeing the project through despite various challenges.

Safety and Environment Group, Responsible Care Department, Production Management Unit, DIC Corporation

Yosuke Kato

Disaster Prevention

Policies

Basic Approach

In addition to establishing a safety management system to prevent major accidents, the DIC Group implements prompt, effective countermeasures in the event an accident occurs.

Any fire, explosion or leakage of a hazardous substance from a chemicals plant could have a tremendous impact on local residents and the rest of the community and damage the health of employees, including those of our partner companies. As well as operating and maintaining its facilities in line with pertinent laws and regulations, the DIC Group regularly conducts emergency drills and has earthquake and other response measures in place in the event a major incident occurs.

Framework for Promotion

(For more information, please see “Policies, Targets and Framework.”)

Principal Initiatives in Fiscal Year 2024

1. Process Safety Accidents

The International Council of Chemical Associations (ICCA) formulated criteria for chemical process safety accidents that require reporting in line with these standards. In fiscal year 2018, the DIC Group began reporting process safety accidents for the DIC Group in Japan in line with these standards. Since fiscal year 2022, the Group has set targets based on results for the immediately preceding three years and implements measures to ensure their achievement.

In fiscal year 2024, the DIC Group reported 12 process safety accidents. The process safety accident frequency rate—the number of such accidents per 200,000 work hours—was 0.229, falling short of the Group’s target of 0.11. The principal reason for the Group’s suboptimal performance was the leakage of chemicals, which happened several times. Looking ahead, the Group will assess risks associated with production processes and make necessary improvements.

- Note: In Japan, a process safety accident requires reporting if the four criteria listed below are met. (These apply primarily to fires, explosions and the leakage of hazardous substances related to manufacturing processes.)

- (1) The accident was related directly to a chemical substance or a chemical process.

- (2) The accident involved production, logistics, storage, utilities or pilot plants.

- (3) The accident caused the release of material or energy (e.g., a fire, explosion or implosion) from a process unit.

- (4) The accident resulted in any of the following events: Occupational accident, equipment damage, evacuation or the release of substances included in the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

| Fiscal year 2020 |

Fiscal year 2021 |

Fiscal year 2022 |

Fiscal year 2023 |

Fiscal year 2024 |

|

|---|---|---|---|---|---|

| Number of ICCA process safety accidents |

4 | 7 | 3 | 7 | 12 |

| Process safety accident frequency rate |

0.073 | 0.128 | 0.055 | 0.124 | 0.229 |

2. Risk Assessments at Chemicals Production Facilities

The DIC Group’s production facilities have an array of application-specific equipment, ranging from units where chemical reactions are conducted to machine presses and other processing equipment. In 2013, the Group formulated the DIC Process Risk Management (PRM) Guidelines, which it uses to conduct systematic risk assessments at individual sites. These guidelines outline timetables and implementation frameworks for assessing risks associated with chemical substances handled, production processes, production formulas, machinery and work practices. Since fiscal year 2020, the Group has also used hazard and operability (HAZOP) studies developed to assess the risk of accidents such as the leakage of hazardous substances, fire or explosions at chemicals production facilities. The Group has already deployed HAZOP studies to assess risks at facilities that have chemical reaction equipment, including the Yokkaichi, Chiba, Kashima, Sakai and Hokuriku plants, and in fiscal year 2025 plans to establish uniform guidelines for such assessments across Japan.

3. The DIC BC Portal

Because of its location, topography and climate, Japan is vulnerable to a variety of natural disasters, including typhoons, heavy rains, floods, earthquakes and tsunami. An accident at, for example, a chemicals production facility involving a fire, explosion or the leakage of hazardous substances, can also have a significant impact on local communities. In such a situation, it is necessary to collect, comprehend and share accurate information to facilitate appropriate decision making and prompt action. DIC has introduced the DIC BC Portal disaster information system, a web-based system facilitating the collection and sharing of information when an accident or disaster occurs.

A recent natural disaster that underscored the benefits of the DIC BC Portal was the 2024 Noto Peninsula Earthquake, a magnitude 7.6 earthquake that struck the Noto Peninsula of Ishikawa Prefecture on January 1, 2024, at approximately 4:10 pm. An intensity of 7 on the Japan Meteorological Agency (JMA) Seismic Intensity Scale was recorded in the cities of Shika and Wajima, while an intensity of 5 Lower was recorded in the city of Hakusan, where DIC’s Hokuriku Plant is located. The plant was fortunately not operating at the time and there was no major damage. The safety of employees was confirmed and damage to structures were reported via the portal. Previously, information on accidents, disasters and resulting damage were made by telephone and email, among others, using an emergency contact network, but there were issues with the speed, precision and the scope of information sharing. The DIC BC Portal has thus allowed the Company to create a system for sharing information swiftly and exactly, positioning it better to make effective decisions.

4. Emergency Response Drills

In addition to daily security patrols and periodic equipment checks, the DIC Group conducts regular emergency response drills based on business continuity plans (BCPs) at production sites in Japan.