With Customers

Goals and Achievements of Major Initiatives

Create businesses with the potential to become new pillars.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 | Having designated business areas where ESH-related issues/social changes intersect with DIC’s core competencies as priorities, identify areas that are expected to be commercially viable and profitable and strive to swiftly launch next-generation businesses. |

|

★★★ |

| Actively use external resources, including through CVC and advanced research in collaboration with academic institutions, as well as work with other companies, with the aim of driving the creation of new businesses and products that will contribute to a society that is increasingly green, digital and QOL-oriented. |

|

||

| 2025 | Designate business areas where ESH-related issues/social changes intersect with DIC’s core competencies as priorities and work to build next-generation businesses that deliver social and economic value. | ― | ― |

| Actively use open innovation and strategic investments with the aim of driving the creation of new businesses and products that will contribute to a society that is increasingly green, digital and QOL-oriented. | ― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Creating New Value

The DIC Group’s vision statement expresses its goals of improving the human condition to realize sustainable prosperity. Seeing its mission as being to achieve sustainable growth for itself and society, the Group is pursuing various initiatives aimed at helping realize carbon neutrality, in line with its policy of providing greater social benefits that enhance shareholder value and achieving sustainable growth for both society and the DIC Group.

Seeking to fulfill its mission, the DIC Group is expanding businesses in growth markets and creating new businesses to promote the transformation of its business portfolio, guided by DIC Vision 2030. Through these efforts, the Group strives to contribute to the realization of a society that is increasingly green, digital and quality of life (QOL)-oriented. The Group has also established the new Global Innovation Center (GIC), which is charged with contributing to globally focused efforts to create next-generation businesses, and will continue working to expedite development by maximizing its overall global assets.

In light of recent changes in the business environment, the DIC Group will periodically review related themes, emphasizing effective time management with clearly defined targets and milestones. The Group will also continue working to create new value that will drive its growth going forward.

Portfolio Transformation

The COVID-19 pandemic created a new normal that has significantly accelerated the transition to a digital society and fundamentally altered consumer behavior. Recent years have also heightened corporate awareness of the importance of achieving carbon neutrality by 2050. Amid these paradigm shifts, the DIC Group has identified five priority business areas where ESH-related issues/social changes intersect with its core competencies: Sustainable energy, healthcare, smart living, color science and sustainable packaging.

Over the short term, the DIC Group will concentrate management resources on smart living, which focuses on chemitronics,* with the aim of swiftly creating new businesses. The R&D Management Unit will focus its efforts in the smart living area by leveraging new design technologies for inorganic materials and biomaterials, among others, as well as its polymer design and organic materials design technologies. The New Business Development Headquarters is charged with transferring those new business concepts or proposals thus developed that are seen as likely to yield synergies to the business groups, reinforcing collaboration with the business groups to realize opportunities with the potential to quickly achieve viability and profitability.

Next-generation and growth businesses are highly competitive and evolve rapidly. In addition to strengthening internal cooperation to promote the commercialization of new products in such areas, the DIC Group will make active use of external resources by promoting open innovation by, among others, leveraging corporate venture capital (CVC) and connections in other industries, investing in start-ups, and collaborating with academic institutions and other companies.

- DIC has selected the term “chemitronics” to designate businesses centered on chemicals and materials for electronics applications.

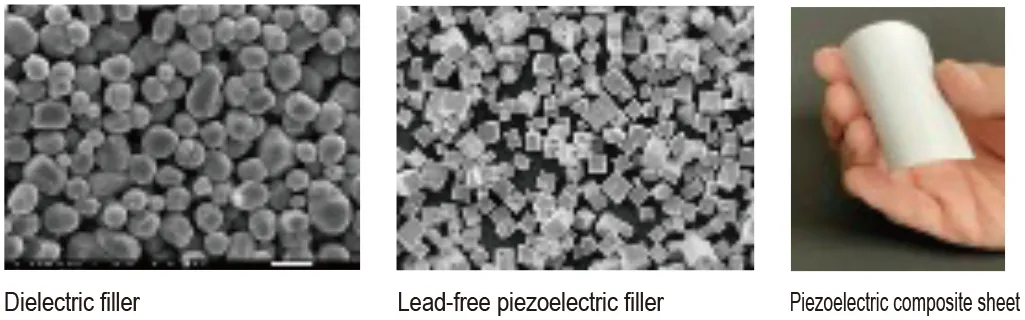

01Development of Inorganic Fillers for a New Era in High-Speed Communications, IoT and Robotics

Amid advances in high-speed communications, as well as in IoT-related areas and robotics, and other fields, increasing demand for materials with superior performance features, DIC succeeded in developing high-grade defect-free inorganic fillers through a proprietary synthesis method. Compounding these inorganic fillers with resin enables the creation of high-performance materials. The Company is working to scale up production with the aim of achieving mass production of these fillers in fiscal year 2027. In the area of high-speed communications, for example, the Company has developed a dielectric filler boasting permittivity and dissipating properties unmatched by conventional fillers, facilitating antennas that are both smaller and more efficient. In IoT-related areas and robotics, the Company developed a piezoelectric filler that generates voltage when it detects force or vibration, which it compounded with resin to produce a piezoelectric composite sheet for use in flexible and highly sensitive sensors. The sheet’s ability to be processed into any size and/ or shape, including those with curved surfaces, will allow the production of devices with more precise vital sign sensing and the fabrication of soft robots with a sense of touch. In addition, unlike conventional ceramic materials, which contain lead, this new sheet is lead-free, leading to a better environmental profile.

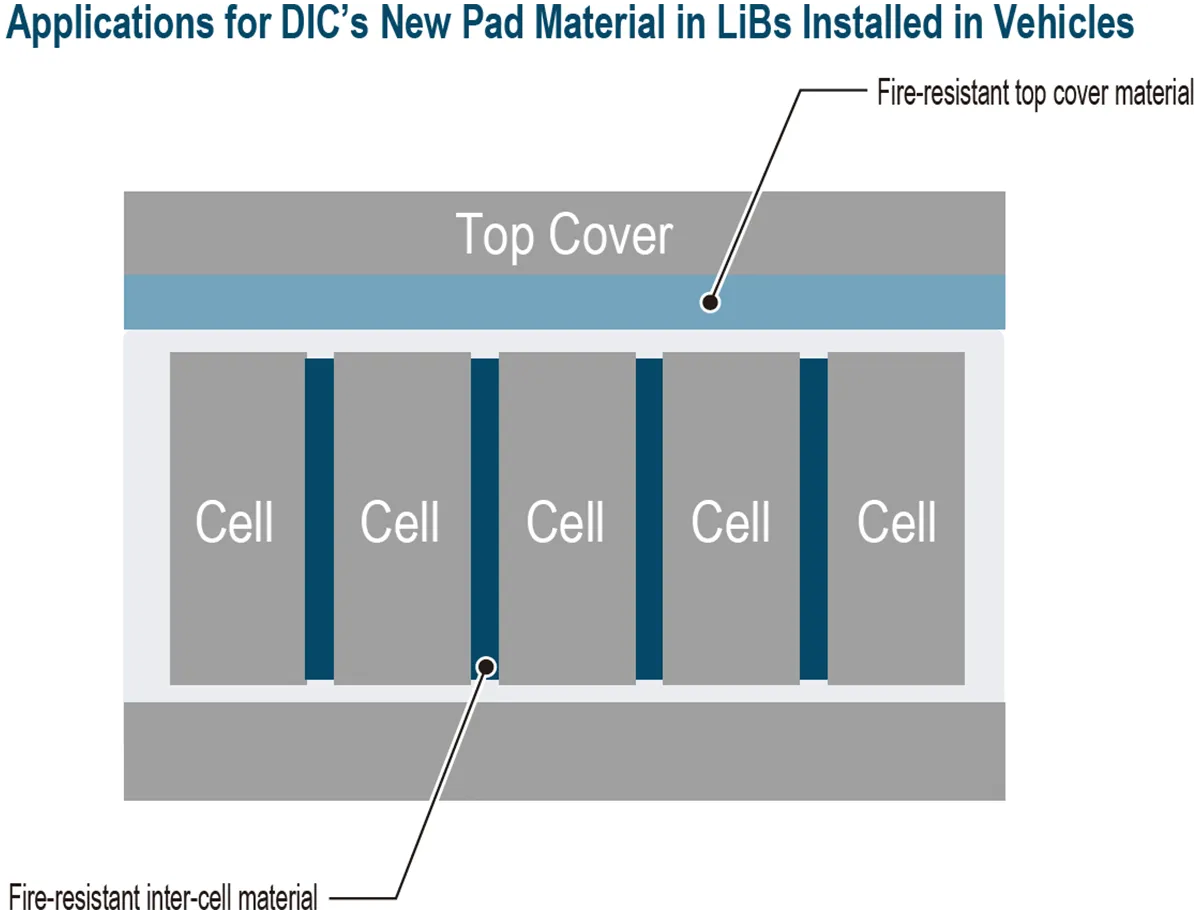

02Development of Fire-Resistant Materials for Lithium-Ion Batteries (LiB): Endothermic Pad that Prevents Fires from Spreading

With the use of LiBs continuing to expand, particularly in EVs, preventing battery fires due to thermal runaway has become a major challenge. This continues to drive efforts worldwide to develop fire-resistant battery insulation materials. Seeking an even more effective solution, DIC succeeded in developing a fire-resistant battery pad material. In addition to the thermal endothermic insulation properties, it absorbs heat generated by thermal runaway, thereby suppressing temperature rise and reducing the impact of fire beyond the LiB. Several automobile and battery manufacturers are currently exploring adoption of this new pad material for use in LiBs installed in vehicles, with expected uses being on battery pack top covers and as an inter-cell material.

Attaching DIC’s new pad material to the top cover of an LiB pack effectively suppresses the transfer of heat to the battery pack and outside the battery in the event of thermal runaway. In testing, while thermal runaway caused the battery’s internal temperature to rise to 1,300°C, heat was largely absorbed by the pad and the temperature on the top surface of the battery remained below 80°C. The pad material also has a mechanism whereby it becomes a hard sheet at high temperatures, providing protection against flying debris. Used between cells, this new pad material absorbs shocks under normal conditions thanks to its excellent elasticity, while in the event of thermal runaway it absorbs heat from cells that have ignited, suppressing the transfer of heat to other cells and significantly delaying explosion. (In-house testing of inter-cell materials has shown that with aerosilica gel it takes seven minutes to reach a temperature of 150°C, while with DIC’s new pad material it takes 25 minutes.)

DIC is currently evaluating its new pad material with pouch LiBs. Going forward, the Company will adjust specifications with a view to expanding its target market to include small batteries for electronic devices and stationery batteries for renewable energy–related applications.

03Promotion of Skincare Business by Leveraging Bioresources Native to Japan

Through its Spirulina business, the DIC Group has honed extensive algae cultivation and extraction technologies. The Group was the first in the world to succeed in the indoor mass cultivation of Suizenji nori (scientific name: Aphanothece sacrum), a rare edible blue-green algae indigenous to Japan that has been a traditional ingredient in high-end Japanese cuisine since the Edo period (1603–1867).

Skincare products are expected to address specific skin issues, as well as to protect the skin against external stimuli. Suizenji nori produces a macromolecular polysaccharide that when used in skincare products forms a high-density, mesh-like veil on the skin, enhancing the skin barrier, while boasting a moisture-retention capacity five times that of hyaluronic acid, commonly used as a moisturizer in skincare and cosmetic products, helping reduce the appearance of fine lines, sagging skin and enlarged pores.

Looking ahead, DIC will capitalize on a new grade of the macromolecular polysaccharide extracted from high-quality Suizenji nori mass produced indoors under the brand name SACRANEX™ to promote its own skincare business globally, as well as to expand applications for this material in multiple other areas.

04Additional Investment in Vaxa

DIC recently made an additional investment in Israeli biotech start-up Vaxa Technologies Ltd. Vaxa possesses proprietary LED-based photobioreactors and advanced algae cultivation technologies and is advancing the development and commercialization of clean, high-value-added algae products not offered by any other companies. Vaxa’s cultivation process employs renewable energy and achieves excellent productivity while consuming less land and fresh water than conventional methods. This process also converts discharged CO2 into useful materials, making it carbon negative and thus highly sustainable.

With the aim of bringing together its many years of accumulated experience in algae cultivation with Vaxa’s carbon-negative algae-based product technologies to develop skincare materials that contribute to a more sustainable, healthier society, in January 2025 DIC followed up its initial investment in Vaxa (fiscal year 2021) with an additional investment in the company.

05Use of DIC Tactile Samples to Recreate the Texture of Objects in the AR Space

Augmented reality (AR) is a technology that has become widely known thanks to smartphone AR applications and wearable AR smart glasses. Traditionally, the focus has been to enhance the user’s view of the physical world by overlaying what the user sees with digital visual information. However, simultaneous feedback of synthetic haptic information into the user’s perception can increase their ability to interact with virtual objects. Japan’s Saitama University recently published a paper on research conducted into reproducing the texture of objects in the AR space using tactile samples developed by DIC’s Packaging Materials Technical Division.

Saitama University’s paper proposes a visuo-haptic AR system that allows users to perceive the texture and shape of virtual objects by touching a overlaid with a projected image tangible object. A finger-mounted device provides feedback from a tactile sample no matter what part of the tangible object the user touches, thus making it possible to reproduce tactile sensations at a low cost. This configuration largely meets the requirements for an effectively functioning visuo-haptic AR system, underscoring the system’s potential for deployment going forward.

TOPIC

Development of the HAGAMOSphere™ Omnidirectional Multicopter and Expansion of this New Business

In fiscal year 2024, DIC inaugurated a new next-generation business by unveiling the new HAGAMOSphere™ omnidirectional multicopter. A prototype of this new drone was showcased at CES 2025, one of the world’s most powerful technology events, held in the United States in early 2025, where it earned designation as a CES Innovation Award⪚ 2025 Honoree. The HAGAMOSphere™ features a cubic frame and diagonally mounted propellers, allowing it to move both horizontally and vertically while maintaining its balance, something impossible with conventional drones. The frame is housed in a robust spherical guard that allows the drone to roll on the ground and move by itself. These unique features of the HAGAMOSphere™ are expected to further its adoption for use in, among others, disaster relief, inspection and measurement, the shooting of videos and photographs, and the entertainment industry. At CES 2025, visitors from around the world stopped by the DIC booth, enhancing the Company’s understanding of market requirements and latent needs and encouraging it to explore a multifaceted entry into the drone business.

Guided by DIC’s “Direct to Society” business creation mechanism, employees gave careful consideration to the needs of society, using its findings to develop appropriate specifications, and created a prototype that tests confirmed was capable of omnidirectional flight. The Company is confident that this approach will enable it to add depth to this new business. In other words, in addition to selling the HAGAMOSphere™ itself, the Company will promote the development of materials that enhance performance by reducing the drone’s weight, increasing battery output and useful life, and enhancing the spherical guard’s flame retardancy and impact resistance. DIC will also continue developing drones and other devices, which it will aim to incorporate into new offerings in “soft” areas, including services, software and solutions, in line with its Color & Comfort value proposition.

Ties with Customers

The DIC Group works to strengthen communication with its customers, placing a priority on gaining their understanding of its efforts and initiatives, in line with the basic policy of the DIC Vision 2030 long-term management plan. Principal avenues of communication include exhibitions and events, lectures for business partners, websites and social media.

Exhibitions

In 2024, we actively participated in in-person exhibitions both in Japan and in other countries and territories, while also staging online exhibitions, which has become a well-established format.

Japan

- In April 2024, DIC participated in the 33rd New Environment Exposition 2024, the first time it has taken part in this annual exhibition, which seeks to raise awareness of environmental conservation by displaying and disseminating information on a variety of technologies and services that help address environmental issues, thereby contributing to environmentally stable lifestyles and the expansion of environment-related industries. DIC’s exhibit at this event included environment-friendly containers and other products made with dyeable recycled plastic.

- In September 2024, DIC took part in SENSOR EXPO JAPAN 2024, which focuses on sensors and sensing technologies, both of which are critical for society to effectively leverage digital transformation going forward. This exhibition showcased advanced products, technologies and information from around the world while also introducing pioneering technologies expected to play key roles in the next generation. DIC exhibited two unique sensor materials for the first time.

- Another highlight of the period was Chemitronics Online, which DIC held in October 2024. The goal of this event was to offer solutions to issues in the area of electronics from two perspectives: Devices and objectives.

Other Countries and Territories

- Sun Chemical Corporation, which oversees DIC Group operations in the Americas and Europe, participated in in-Cosmetics Global 2024, a four-day event held in April in Paris, France. The company showcased a wide range of offerings, including groundbreaking effect pigments for use in personal care products, naturally derived pigments and raw materials.

- DIC South Asia Private Limited and Sun Chemical partnered to exhibit at PAINTINDIA 2024, one of India’s largest exhibitions of paints and related raw materials. The two companies presented a wide range of polymers and pigments for a variety of applications.

Websites

To bolster communication with customers, the DIC Group expanded the content of its global website, as well as of its official People’s Republic of China (PRC) and Asia–Pacific region websites. Improvements to these websites were also made to ensure that information shared by the Group is conveyed in an appropriate manner. Group company Sun Chemical also upgraded its website, improving links to information about products it sells in global markets, and promoted cooperation in responding to inquiries, with the goal of bolstering customer satisfaction. The Group also made use of social media, including X (formerly Twitter), LinkedIn and Instagram, as a tool to attract more website traffic.

Related link