Promoting Socially Responsible Procurement Across Supply Chains

- Goals and Achievements of Major Initiatives

- Basic Approach to Sustainable Procurement

- Ascertaining and Improving Suppliers’ Sustainability

- Human Rights Due Diligence in Supply Chains

- Responsible Procurement of Minerals

- Advance Assessments of New Raw Materials

- Ensuring the Sustainable Procurement and Use of Raw Materials

- Internal Configuration and Employee Training

Goals and Achievements of Major Initiatives

Promote sustainable procurement.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 | Advance initiatives aimed at expanding sustainable procurement over the medium to long term, including evaluating the CO2 emissions reduction targets and promoting awareness of the need for improvements, assessing CO2 emissions associated with raw materials, and searching for bioderived and recycled raw materials. |

|

★★ |

| Continue conducting sustainability assessments of suppliers in Japan and Sun Chemical suppliers using the EcoVadis platform or another tool and promote related efforts across the DIC Group by expanding the scope of this initiative to include Greater China and the Asia–Pacific region. |

|

★★★ | |

| ― | ― | ― | |

| 2025 | Advance initiatives aimed at expanding sustainable procurement over the medium to long term, including promoting suppliers’ awareness of the importance of reducing CO2 emissions and collecting data on CO2 emissions associated with key raw materials. | ― | ― |

| Take steps to ensure sustainable procurement over the medium to long term, including promoting the use of bioderived raw materials and recycled materials, including bioderived raw materials for which the mass balance approach has been adopted and chemically recycled raw materials. | |||

| Continue conducting sustainability assessments of suppliers worldwide using the EcoVadis platform or another tool and promote related efforts across the DIC Group by expanding the scope of this initiative to include the PRC and the Asia– Pacific region. | ― | ― | |

| Advance human rights due diligence across the supply chain using the EcoVadis platform or another tool. Promote respect for human rights internally and among business partners and implement a system for terminating use of raw materials the sourcing of which may involve human rights violations. |

― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Basic Approach to Sustainable Procurement

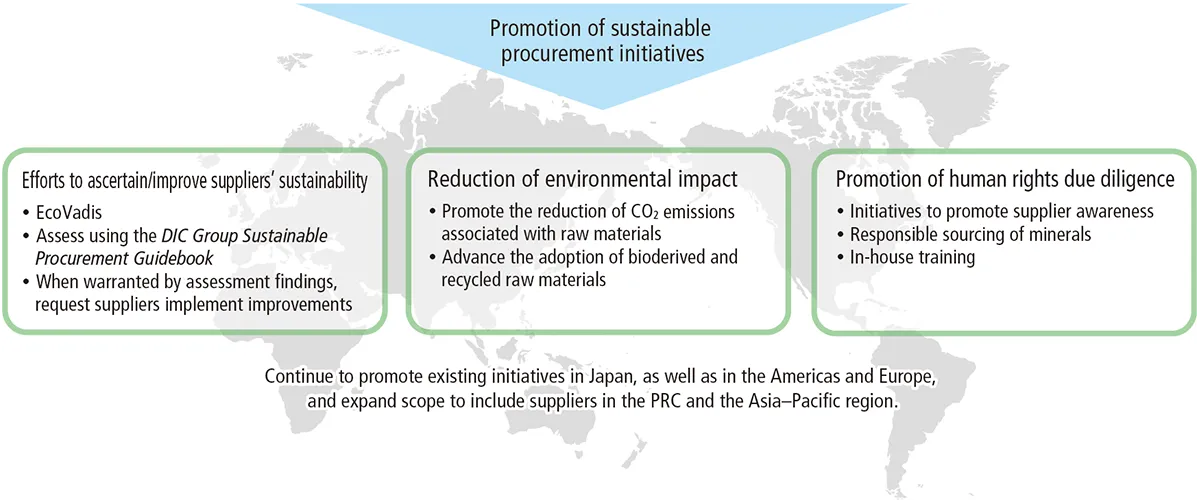

Having recognized the increasing importance of addressing issues essential to sustainable procurement, including compliance with laws and social norms, consideration for the environment and respect for human rights, the DIC Group formulated the DIC Group Universal Purchasing Policy and continues to advance related initiatives on a global scale. Based on this policy, the Group also established the DIC Group Sustainable Procurement Guidelines, which clarifies its expectations of suppliers, and advances sustainable procurement across its supply chains by ensuring assessments are conducted to ascertain the status of suppliers’ sustainability and by encouraging awareness-raising efforts.

The DIC Group Universal Purchasing Policy

1. Fair and transparent business practices

The DIC Group will implement fair and open purchasing activities with suppliers based on global perspectives, without the constraints of conventional commercial customs.

2. An appropriate purchasing process and the building of relationships of mutual trust

The DIC Group, as a good partner for suppliers, will build long-lasting, mutually trusted relationships with suppliers and work together with them for mutual harmony and benefit, while complying with relevant regulations/ social norms, domestic and overseas, and pursuing adequate quality and prices.

3. Satisfying environmental/safety needs

The DIC Group will take responsibility as an exemplary corporate citizen for environmental affairs, occupational safety, human health and product quality, always take into account changes in society and implement environment-friendly purchasing activities.

4. Challenge the creation of new value

In order to respond at a high level to a new value sought by society, the DIC Group will proactively challenge the creation of such value together with suppliers, with whom the same goal can be shared, and strive to grow together with them in a sustainable manner.

Additional Information:

- 1. This Policy has been in effect since July, 2008

- 2. This Policy is confirmed as of Dec. 1, 2025

Document download

The DIC Group Universal Purchasing Policy

- Fair and transparent business practices

The DIC Group will implement fair and open purchasing activities with suppliers based on global perspectives, without the constraints of conventional commercial customs. - An appropriate purchasing process and the building of relationships of mutual trust

The DIC Group, as a good partner for suppliers, will build long-lasting, mutually trusted relationships with suppliers and work together with them for mutual harmony and benefit, while complying with relevant regulations/social norms, domestic and overseas, and pursuing adequate quality and prices. - Satisfying environmental/safety needs

The DIC Group will take responsibility as an exemplary corporate citizen for environmental affairs, occupational safety, human health and product quality, always take into account changes in society and implement environment-friendly purchasing activities. - Challenge the creation of new value

In order to respond at a high level to a new value sought by society, the DIC Group will proactively challenge the creation of such value together with suppliers, with whom the same goal can be shared, and strive to grow together with them in a sustainable manner.

The DIC Group Sustainable Procurement Guidelines

- Compliance with laws/social norms

- Human rights and work environments

- Safety and health

- Consideration for the environment

- Information security

- Appropriate quality and safety and technological improvements

- Stable supplies and flexible responses to change

- Promotion of sustainability and sustainable procurement initiatives

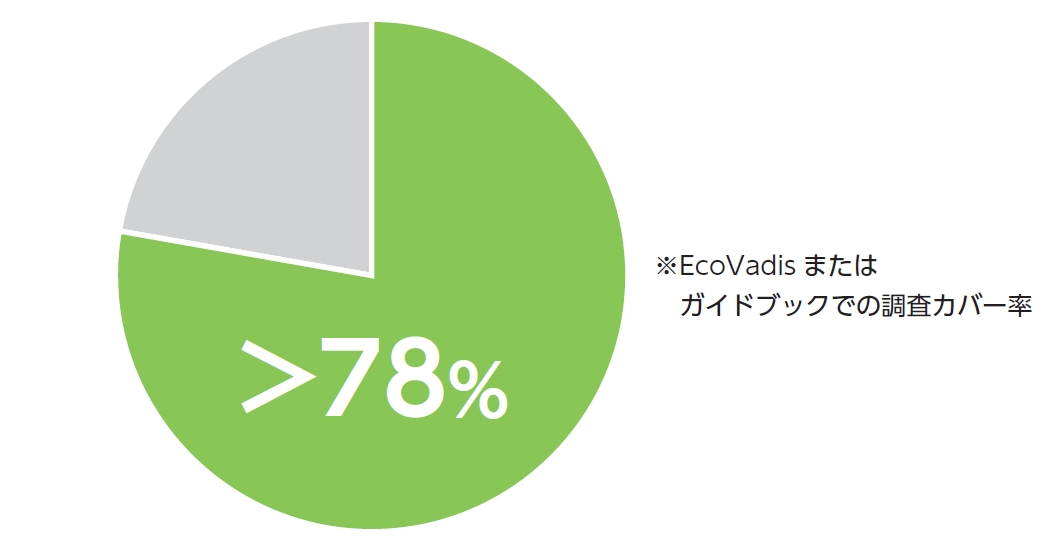

Ascertaining and Improving Suppliers’ Sustainability

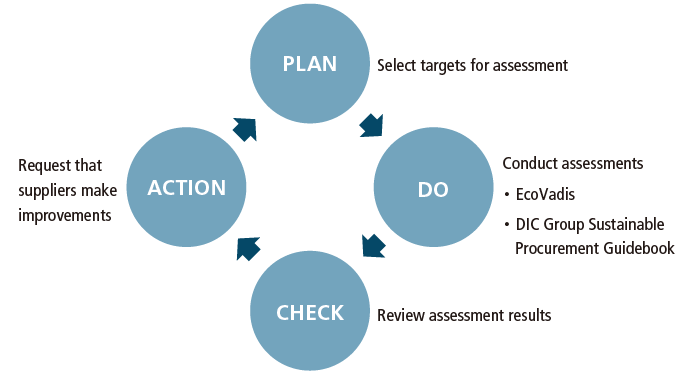

The DIC Group uses EcoVadis and the DIC Group Sustainable Procurement Guidebook, capitalizing on the distinctive features of each, to assess the sustainability of its suppliers and encourage related efforts. As of the end of fiscal year 2024, the Group had completed assessments using one or the other for suppliers accounting for 78% of its procurement spending and made recommendations for improvements as necessary based on the results thereof. In addition, the Group regularly applies the PDCA cycle to evaluate the implementation of improvements, thereby helping bolster sustainability across its supply chains.

Use of the PDCA Cycle in Assessing Suppliers’ Sustainability

EcoVadis

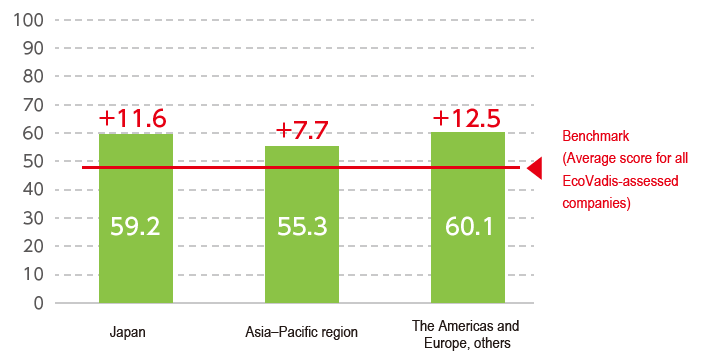

EcoVadis is a third-party web-based sustainability rating platform that assesses the sustainability of companies. EcoVadis experts conduct evidence-based analysis of supplier information collected, facilitating the provision of objective and highly reliable assessments. In fiscal year 2023, the DIC Group transitioned to deploying this platform across the global DIC Group, with results shared with suppliers to further enhance their sustainability. At present, the average EcoVadis score for suppliers in each of our geographic operating regions is higher than the average score for all EcoVadis-assessed companies. The Group has also introduced EcoVadis IQ Plus, a supplier risk assessment tool, which it is using to screen out high-risk suppliers.

Average EcoVadis Score for Suppliers in Each of the DIC Group’s Geographic Operating Regions

DIC Group Sustainable Procurement Guidebook

The DIC Group Sustainable Procurement Guidebook is used to encourage awareness of the Group’s expectations of suppliers, which are outlined in the DIC Group Sustainable Procurement Guidelines, and includes a self-evaluation sheet to ascertain the status of suppliers’ sustainability efforts. In addition to providing feedback to suppliers on assessment results, the Group follows up as required with on-site inquiries or other measures to help suppliers improve their sustainability. The guidebook also includes the DIC Group Green Procurement Guidelines, which oblige suppliers to ensure the stringent management of chemical substances and compliance with pertinent laws and regulations, as well as to promote the reduction of environmental impact. The Group also uses the self-evaluation sheet as necessary to ascertain the status of suppliers’ efforts to comply with these guidelines and follows up as necessary.

Document Download

Global Sustainable Procurement Efforts

・Japan

In fiscal year 2024, the DIC Group collected evaluations from suppliers accounting for more than 90% of its domestic procurement spending using EcoVadis and the DIC Group Sustainable Procurement Guidebook. In instances where the supplier surveyed is a trading company, an additional survey was conducted for the actual producer. Feedback was provided to all responding suppliers and producers and follow-up, in the form of a direct interview, was provided to encourage remedial measures for suppliers who fall short of the minimum standard. (In fiscal year 2024, such interviews were launched for six suppliers.) To date, on-site inquiries have been conducted for a total of 102 companies.

・PRC and the Asia–Pacific Region

In the period under review, the DIC Group commenced full-scale surveys of principal suppliers in the PRC and the Asia–Pacific region using EcoVadis and the DIC Group Sustainable Procurement Guidebook. In fiscal year 2025, the Group plans to continue conducting these surveys, as well as to begin providing feedback based on survey results to promote remedial measures.

・The Americas and Europe

In the Americas and Europe, EcoVadis has been used by Sun Chemical to assess the sustainability of and encourage initiatives by its suppliers since fiscal year 2020. The company has completed assessments of suppliers accounting for more than 80% of its procurement spending and will continue working to expand implementation. Looking ahead, the company also intends to deploy the screening function of EcoVadis IQ Plus to conduct risk assessments for a broader range of suppliers.

Human Rights Due Diligence in Supply Chains

Recognizing the importance of respect for human rights in supply chains, the DIC Group works with its suppliers to promote initiatives across its own supply chains.

Initiatives Targeting Suppliers

In accordance with the DIC Group Sustainable Procurement Guidebook, the Group compels its suppliers to respect the human rights of their employees by, among others, providing equal opportunities, prohibiting forced labor, preventing harassment, paying appropriate wages, appropriately managing working hours, ensuring freedom of association and guaranteeing the right to engage in collective bargaining. Having grasped the status of suppliers’ efforts through sustainability assessments, described above, the Group also encourages awareness of the need for improvement.

Preventing the Procurement of Materials for Which There Are Human Rights Concerns

In Japan, the DIC Group provides training for purchasing and technical department employees on the importance of respect for human rights in the supply chain. The Group has also set up checkpoints to identify any concerns regarding human rights violations for raw materials used beginning at the product development stage.

Responsible Procurement of Minerals

The DIC Group has formulated the Basic Approach to the Responsible Procurement of Minerals and conducts surveys to ensure its ability to procure these critical resources in a responsible manner.

Basic Approach to the Responsible Procurement of Minerals

To avoid any complicity in the funding of armed groups, or in child labor or other human rights abuses, in areas of conflict—including the Democratic Republic of Congo and its neighboring countries—or high-risk areas,* the DIC Group surveys suppliers of minerals such as tin, tantalum, tungsten and gold to ensure the responsible procurement thereof across its entire supply chain. Should it discover the use of minerals mined in conditions of conflict or as a result of human rights abuses, the Group will take immediate corrective actions.

- The EU Conflict Minerals initiative defines high-risk areas as areas in a state of armed conflict or a fragile post-conflict state, as well as areas witnessing weak or non-existent governance and security, such as failed states, and widespread and systematic violations of international law, including human rights abuses.

The DIC Group ascertains the status of suppliers’ efforts to ensure the responsible procurement of minerals using EcoVadis and the DIC Group Sustainable Procurement Guidebook. The Group also surveys smelters using the conflict minerals reporting template (CMRT) and the extended minerals reporting template (EMRT)* to evaluate minerals contained in procured raw materials. To date, surveys using the CMRT have been secured regarding more than 90% of the raw materials the Group currently procures in Japan. Surveys using the EMRT have also been conducted for major raw materials containing target minerals. The Group will continue to expand and update its surveys in the future, as well as to respond—to the extent possible— for requests for disclosure from customers and other stakeholders.

In addition, Sun Chemical is a founding member of the Responsible Mica Initiative, which seeks to eradicate child labor and unacceptable working conditions in India’s mica supply chain, and is working to improve the soundness of that country’s mica mining industry.

- The CMRT and EMRT are standardized reporting templates developed by the Responsible Minerals Initiative (RMI) to survey smelters and refineries used for minerals contained in raw materials, with the CMRT targeting tin, tantalum, tungsten and gold and the EMRT targeting cobalt and mica.

Initiatives to Reduce the Environmental Impact of Raw Materials

The DIC Group promotes initiatives aimed at reducing the impact of procurement of raw materials from a medium- to long-term perspective.

Reducing CO2 Emissions Associated with Raw Materials

The DIC Group seeks to work with its suppliers to encourage the reduction of CO2 emissions associated with purchased raw materials with the goal of lowering climate change risk and achieving Science Based Targets initiative (SBTi) certification of its target for lowering Scope 3 remissions. To this end, the Group has confirmed the status of efforts to set medium- to long-term CO2 emissions reduction targets by suppliers accounting for approximately 90% of its procurement spending in Japan, and has been publicizing and raising awareness of these efforts.

In response to social imperatives and the expectations of its customers, the DIC Group surveys CO2 emissions associated with raw materials to calculate the carbon footprint of its products, that is, total CO2 emitted over its products’ life cycles. The Group will continue to keep abreast of industry trends, as well as to conduct surveys with the objective of accurately calculating and helping reduce its products’ carbon footprint.

Promoting the Use of Bioderived and Recycled Raw Materials

With the aim of reducing its environmental impact, the DIC Group actively promotes the procurement of plant-derived raw materials, bioderived raw materials for which the mass balance approach has been adopted, and chemically recycled materials. This includes using the Group’s global supply chain to conduct raw material surveys and sharing survey results with technical groups to encourage product design reviews.

Ensuring Legal and Regulatory Compliance with and Safety Management in Raw Materials Procurement

The DIC Group conducts advance assessments of new raw materials to confirm that there are no issues regarding legal or regulatory compliance, safety or other issues related to the sustainable procurement of raw materials. In Japan, for example, the Group mandates the submission of a DIC Raw Materials Survey,*1 a safety data sheet (SDS), chemSHERPA*2 and the CMRT.

- A DIC Raw Materials Survey is a questionnaire the aim of which is to confirm basic information on the constituents of raw materials and their compliance with pertinent laws and regulations.

- An acronym for “chemical information sharing and exchange under reporting partnership in supply chain,” chemSHERPA is a scheme developed in Japan for the transfer of information on raw materials across supply chains.

Internal Configuration and Employee Training

Internal Configuration

A dedicated team has been established within DIC’s Purchasing Department that is responsible for sustainability in the DIC Group’s supply chains and has devoloped KPIs to track the progress of related efforts. DIC Group global meetings and other initiatives are used to promote the sharing of information among different regions regarding region-specific initiatives, underscoring the Group’s robust commitment to advancing sustainable procurement. Thanks to these efforts, in fiscal year 2024 the Group as a whole scored an outstanding 80 points in the “Sustainable Procurement” category of the EcoVadis assessment.

Employee Training

To promote understanding across the DIC Group, training on sustainable procurement is provided to individuals involved in purchasing at point of hire, when joining a Group company and otherwise as appropriate. This training is provided to all employees in DIC’s Purchasing Department. The Group also provides relevant training, including an e-learning program on respect for human rights in the supply chain, to employees Groupwide.

Related Link