Overview of Materiality

- Material Issues and Related Initiatives

- Identifying Material Issues

- DIC Group Company Opens New Facility for Cultivating Algae with the Goal of Realizing Sustainable Smart Farming

- DIC Develops Antifoaming Agent for Use in Lubricating Oils for EVs that Is PFAS-Free and Delivers an Outstanding Performance

- Digital Twins Technology Is Deployed to Automate the Operations of Synthetic Resins Production Facilities

- Establishment of the Global Innovation Center and the Global HR Department

- Other Management Issue

The DIC Group has abstracted and defined a number of issues as being material and requiring its attention. The Group continues promoting a variety of measures to address these issues.

Material Issues and Related Initiatives

1.Qualitative transformation to a business portfolio that contributes to sustainable prosperity for society

Promote a qualitative transformation to a business portfolio that emphasizes social value and sustainability.

(Focus on the five priority business areas set forth in DIC Vision 2030 that deliver social value.)

2.Contribution to the realization of carbon neutrality

Advance CO₂ emission reductions in the market and provide products and services that contribute to decarbonization.

(Announce goal of achieving carbon neutrality by fiscal year 2050, work to reduce Scope 1 and 2 CO₂ emissions and to provide information on product carbon footprint.)

3.Creation of new businesses with the potential to become mainstays

Ensure a better future for people’s lives and the environment and realize greater social benefits that enhance shareholder value.

(Identify areas at the intersection of ESH-related issues and social changes and the DIC Group’s core competencies and foster new businesses.)

4.Promotion of efforts to maximize the value of human capital

Build a strategic human resources portfolio that maximizes the value of human capital over the medium to long term.

(Ensure mobility, improve engagement and organizational cohesiveness, and encourage ongoing efforts to increase diversity and reform work styles.)

5.Establishment of a more robust global management configuration

Accelerate global expansion in priority business areas.

(Advance global management governance, foster and strengthen management personnel, and create a global enterprise resource planning (ERP) system.)

6.Promotion of DX

Leverage digital technologies and data to provide new added value and strengthen the DIC Group’s business structure.

(Innovate business processes, work styles and business models, and revamp the DIC Group’s corporate culture and business structure.)

7.Response to a circular economy

Contribute to the realization of a waste-free society that does not depend on resource consumption as part of a greater global effort to address climate change.

(Foster products that help reduce CO₂ emissions in categories 1 and 12 of Scope 3, and advance chemical and material recycling.)

8.Creation of a sustainable supply chain

Encourage responsible procurement that takes into account global human rights issues, as well as environmental issues such as climate change and water risk.

(Promote awareness of the current status of raw materials and appropriate responses to country risk and various supply disruption risks, and to issues regarding environmental soundness.)

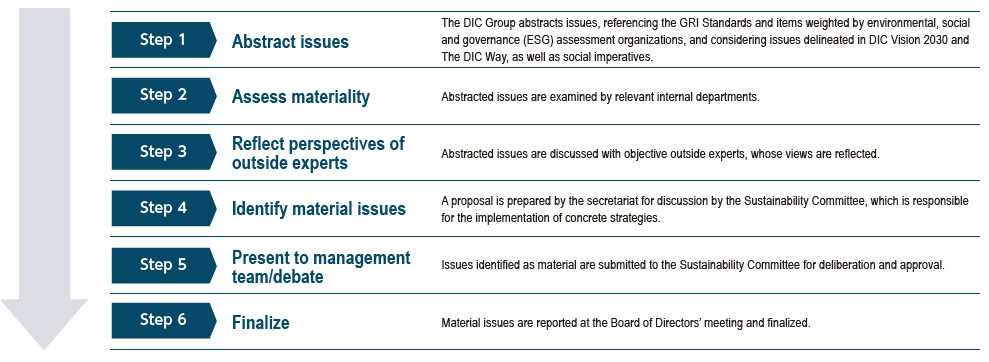

Identifying Material Issues

DIC Group Company Opens New Facility for Cultivating Algae with the Goal of Realizing Sustainable Smart Farming

In March 2025, Group company Earthrise Nutritionals, LLC, commenced operations at a new edible algae cultivation facility that was built with the goal of realizing sustainable smart farming. As a photosynthetic organism, Spirulina carries out photosynthesis, that is, it converts CO₂ into the chemical energy necessary to fuel its growth. Earthrise’s new facility uses more than 1,200 tonnes of refined CO₂ procured from external sources annually to cultivate Spirulina and satisfies more than 50% of its energy needs with renewable energy procured in an environment-friendly manner. The facility also uses state-of-the-art technologies to produce Linablue®, a natural blue food coloring made with a pigment extracted from Spirulina using water, enabling it to achieve zero discharge of industrial wastewater off-site. Going forward, the Group will continue striving to provide superior environment-friendly products to its customers around the world.

Ceremony celebrating completion of the new plant (April 2025) (left) and an overview of the new facility

DIC Develops Antifoaming Agent for Use in Lubricating Oils for EVs that Is PFAS-Free and Delivers an Outstanding Performance

Despite excellent antifoaming properties, thermal stability and durability (shear stability) when used in lubricating oil, concerns regarding latent environmental risks associated with PFASs have prompted debate, particularly in Europe and the United States, over the need to further regulate the use of these substances. At the same time, achieving a level of performance comparable to PFAS-based surfactants with ordinary silicone-based alternatives has proven challenging. DIC has been working to develop an environment-friendly alternative PFAS-free surfactant. In fiscal year 2024, the Company succeeded in developing the MEGAFACE™ EFS series of surfactants that are PFAS-free but deliver a performance that rivals that of PFAS-based products. Looking ahead, DIC will continue to expand its operations, focusing on sustainable products. The Company will augment its selection of PFAS-free products that help address social imperatives, thereby helping promote the sustainability of industry and the reduction of environmental risks.

Digital Twins Technology Is Deployed to Automate the Operations of Synthetic Resins Production Facilities

DIC and Hitachi, Ltd., recently achieved the practical deployment of digital twins technology that leverages process informatics to automate the operations of a synthetic resins production facility. The system developed by the two companies, which leverages AI to build reaction prediction models that can determine optimal operating conditions, is expected to ensure stable quality and improve work efficiency. Having conducted joint demonstration tests since fiscal year 2021, in January 2025 DIC and Hitachi commenced full-scale deployment of the new system at DIC synthetic resins production facilities in Japan, with a view to rolling it out at other sites in Japan and overseas going forward.

The DIC Group is advancing the use of the IoT and AI to improve efficiency at its sites and realize smart factories. DIC will continue to promote digitalization within its own production facilities, focusing on ensuring it has the right people in the right places, enabling it to respond effectively to the needs of customers and at the same time to streamline supply chains, thereby taking its production capabilities to a new level.

Establishment of the Global Innovation Center and the Global HR Department

The DIC Group is a multinational organization with operations in Japan and other parts of Asia, as well as in the Americas and Europe. In January 2025, DIC established the Global Innovation Center to leverage capabilities Groupwide to advance the development of new technologies and products that support nextgeneration businesses. The Company also recently established the Global HR Department to promote the exploration, selection and deployment of human resources management systems that contribute to more effective integrated management of the DIC Group as a whole. With these two new organizational components, the Group aims to transcend regional boundaries to further fortify its global competitiveness and achieve sustainable growth.

Other Management Issue

In the process of identifying material issues, the DIC Group also recognized the following as issues with the potential to significantly impact its management. The Group will continue working to address/strengthen its response to these issues through its business activities.

| Environmental | Product stewardship, reduction of environmental impact, intellectual property strategies |

| Environmental and social | Strengthening of partnerships |

| Social | Communication with customers and markets, contribution to local communities, response to pandemics |

| Governance | Ability to optimize capital efficiency, business continuity, political and geopolitical change, information security, response to tax-related risks, response to currency fluctuations |

| Other | Ability to help realize colorful and comfortable lifestyles |