Digital Transformation (DX)

Driving Business Model and Portfolio Transformation

Goals and Achievements of Major Initiatives

Promote process innovation and business model transformation.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 | Create processes and guidelines for confirming/verifying effectiveness and work with business units to prioritize and implement key DX initiatives. |

|

★★★ |

| Continue to explore and implement digital initiatives crucial to business model transformation and thus to achieving the targets of DIC Vision 2030. |

|

★★★ | |

| 2025 | Create processes and guidelines for confirming/verifying effectiveness and work with business units to prioritize and implement key DX initiatives. | ― | ― |

| Continue to explore and implement digital initiatives crucial to business model transformation and thus to achieving the targets of DIC Vision 2030. | ― | ― |

Create/firmly establish a data-driven corporate culture and foster related human resources.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 | Advance awareness of the need for and importance of realizing data-driven management and data-driven operations (cultivate a corporate culture in which these concepts are firmly established) and continue strengthening efforts to foster human resources with advanced digital capabilities. |

|

★★ |

| 2025 | Cultivate/firmly establish a data-driven corporate culture through new and ongoing projects and foster human resources with the necessary advanced digital capabilities | ― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Basic Policy

The DIC Group promotes DX with the objective of providing new value and reinforcing its corporate structure and competitive advantages through the use of digital technologies and data. Initiatives are being advanced Groupwide, beginning with measures to expedite the growth strategies outlined in the DIC Vision 2030 long-term management plan in four key areas: Market,* production, R&D and technology, and supply chain management (SCM). The Group is also working to maximize a next-generation digital integrated platform, as well as to secure and foster human resources, to establish the infrastructure necessary to advance DX.

- “Market” is used here in the sense of sales and marketing functions.

Framework for Promotion

The IT Strategy Unit’s Information Systems Department and DX Promotion Department capitalize on data and digital technologies, eliminating boundaries between IT and DX, to promote process optimization, work style reforms and the innovation of business models over the short term, as well as the medium to long term. Looking ahead, the Company expects to see an increase in the promotion of independent DX initiatives by individual business units and functional departments. Accordingly, the IT Strategy Unit provides support for and conducts post-implementation monitoring of such initiatives to ensure optimization from a Groupwide perspective. Efforts to develop an IT governance scheme for the entire DIC Group, including the formulation of guidelines for promotion and the establishment of a management system, are also underway.

Market

Through DX, the DIC Group seeks to bolster brand strength by creating high-level customer experiences, as well as to achieve business model transformation. The Group has launched an initiative aimed at enhancing use of the existing sales support system and expanding deployment to additional departments, thereby improving the efficiency of sales efforts while also improving customer experiences. A new digital marketing initiative has also been inaugurated that seeks to identify and effectively approach customers with specific needs based on time series analyses of online search data. This is enabling the Group to extend a variety of proposals to customers who may have previously been unfamiliar with Group products, thereby generating new business opportunities. U.S.-based Sun Chemical is leveraging its website chat feature and digital marketing tools to connect customer inquiries to sales representatives, improving customer experiences and making the sales process more efficient. In fiscal year 2025, the Group will continue taking steps to further promote digital marketing initiatives and enhance use of its sales support system with the goal of providing new and better customer experiences.

Production

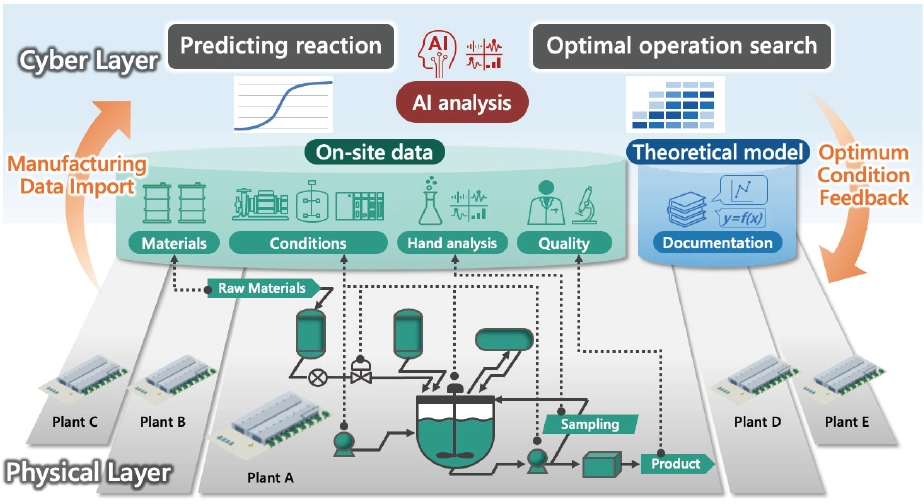

In the area of production, the DIC Group is working to create smart factories. Because the business environment varies for different products, the Group is advancing a concept that takes diversity into consideration. As part of this effort, DIC has developed process informatics (PI)*1 technologies that are suited to batch reaction*2 production, typically used for high-value-added products. Group company Sun Chemical successfully demonstrated the use of Machine Vision AI,*3 improving the reliability of its drum consolidation robot in correctly identifying drum closure points. Sun Chemical also introduced autonomous guided vehicles (AGVs)*4 at several locations, marking a significant step forward in its use of robotics for materials handling and logistics and further driving operational excellence. Looking ahead, the Group will continue to advance PI technologies, as well as its proprietary smart factory concept, with the objective of achieving chemicals production sites that are not dependent on human capabilities and at the same time achieving outstanding reliability and productivity across safety, quality, environmental performance, cost competitiveness and other key areas.

- PI is defined as an approach to leveraging data and AI to optimize manufacturing processes.

- Batch reaction is a production method whereby all reactants (raw materials) are added to a reactor at the start of the reaction and products are removed at the end once the reaction is complete.

- Machine Vision AI technologies involve machines using cameras and sensors to analyze images and video, and to automatically identify, inspect and measure objects.

- AGVs are used to autonomously transport freight and materials along designated routes in production facilities and warehouses, among others.

R&D and Technology

On the technology side, the DIC Group continues seeking to accelerate the creation of new value and products by shifting the focus of its efforts to computational and data science, which use AI and material informatics (MI). Through the Data Science Center, a specialized organization that makes use of AI, including MI, the Group is stepping up efforts to create greater value, including by significantly shortening development periods for new products and realizing ideas that exceed the boundaries of the human imagination. In fiscal year 2024, the Group implemented laboratory automation, expanded molecular simulation technologies, advanced the use of internal and external data, and promoted the deployment of generative AI–based analytical technologies. In addition, the use of AI to formulate testing plans made it possible to conduct highly efficient experiments narrowly tailored to specific objectives. In fiscal year 2025, DIC will seek to add depth to its fiscal year 2024 achievements, leveraging large-scale language models (LLMs) in marketing and document management, among others, to promote the fundamental transformation of business processes. The Company will also collaborate with the global DIC Group, including Sun Chemical, to promote the use of data science. Sun Chemical effectively employs AI and machine learning to enhance the effectiveness of its vision system, used for challenging visual inspection of certain products to assure quality and consistency. Machine learning is also being used for spectral analysis and verification of printed artwork in a manner that is not achievable by conventional methods. Machine learning technology has also been successfully deployed in a proprietary measurement device for specific security inks, among others.

SCM

As well as improving the visibility of the flow of goods and information through its supply chains, the DIC Group is promoting related reforms designed to optimize supply chains spanning multiple regions, businesses and organizational constituents. To this end, the Group has made use of digital technologies that can be automatically linked Groupwide to build a digital SCM platform that facilitates planning online and in real time based on up-to-date demand data, which it began full-scale operation of in the color materials and performance materials business in fiscal year 2023. Sun Chemical is capitalizing on digitalization to drive various products aimed at improving its ability to enhance the efficiency, optimization, transparency and visibility of its businesses. Going forward, the DIC Group will continue to expand deployment of this platform in additional regions and businesses as part of its effort to achieve supply chain reform.

Updating Core Business Systems and Establishing a Global Digital Integration Platform

In July 2024, the DIC Group in the Asia–Pacific region completed an update of its core business systems and built an integrated digital platform. Beginning in fiscal year 2025, Sun Chemical will upgrade its core business systems, aiming to build a global digital infrastructure and operational framework. The company is also focusing on leveraging advanced analytics and cloud technologies to provide better decision-making capabilities to ensure it remains agile in a rapidly evolving market.

Securing and Fostering Human Resources

Both DIC and Sun Chemical are focusing on taking advantage of digital technologies and data to create a foundation for analyzing, evaluating and executing problem-solving measures and business reforms in its various businesses. In addition to training for individuals whose jobs require the use of data or AI, practical training is provided to foster human resources who grasp both business strategy and frontline challenges and equipping them to lead digital initiatives, thereby improving the digital literacy of all employees. Moreover, as part of its effort to reinforce its framework for swiftly implementing measures that fully leverage digital technologies, the Group is actively recruiting new graduates and mid-career hires in the areas of IT and DX.