Toward the Achievement of a Sustainable Society

Toward the Achievement of a Sustainable Society

Basic Approach

The DIC Group promotes a broad range of ESH initiatives through its Responsible Care® program.

Initiatives to Date

As a global organization that manufactures and sells chemical substances, the DIC Group promotes a broad range of ESH initiatives through its Responsible Care* program. Having established its Principle and Policy for the Environment, Safety and Health in 1992, in 1995 DIC pledged to implement the precepts of Responsible Care. Since reaffirming its support for Responsible Care management in January 2006 by signing the CEO’s Declaration of Support for the Responsible Care Global Charter, the Company has promoted constant improvements. Today, the Group manages its Responsible Care program in a uniform manner using standardized codes, guided by its Environment, Safety and Health Policy, and works to implement initiatives that exceed regulatory requirements, in line with annual Responsible Care activity plans, and to fully disclose the results thereof.

- Responsible Care describes voluntary management initiatives undertaken by companies that manufacture or otherwise handle chemical substances, in line with the principles of autonomous action and self-assessment, pledging in their management policies to protecting the environment and ensuring health and safety across the entire life cycle of products, from development to manufacturing, distribution, use, recycling and end-of-life disposal, as well as to disclosing related information and promoting improvements.

Policy for Environment, Safety and Health

As a responsible corporate citizen and a company group that manufactures, distributes and sells chemical materials, the DIC Group recognizes its commitment to the environment, to safety, and to health, as fundamental to its business.

With this philosophy assured in all aspects of its business activities, the DIC Group contributes to the development of society through products and technology that are harmonized with the global environment, including biodiversity, under the concept of “sustainable development.”

- Take responsibility for the environment, safety, and health throughout all product lifecycles.

- Set goals and targets regarding the environment, safety and health, and work on continuous improvement.

- Comply with laws, regulations, and conventions associated with the environment, safety, and health. In countries where such laws and regulations are not sufficiently developed, DIC’s business will be conducted based on the concept of safe operation as the highest priority and the protection of the global environment.

- Plan and conduct education programs and training on the environment, safety, and health.

- Consolidate the system and conduct internal audits to ensure the protection of the environment, safety, and health.

This Policy is to be published inside and outside the Group. Each company of the DIC Group is required to comply with this Policy. “Safety” as described above includes security and disaster prevention.

Additional Information:

- 1. This Policy is confirmed as of Apr. 1, 2024

Document download

Responsible Care Codes

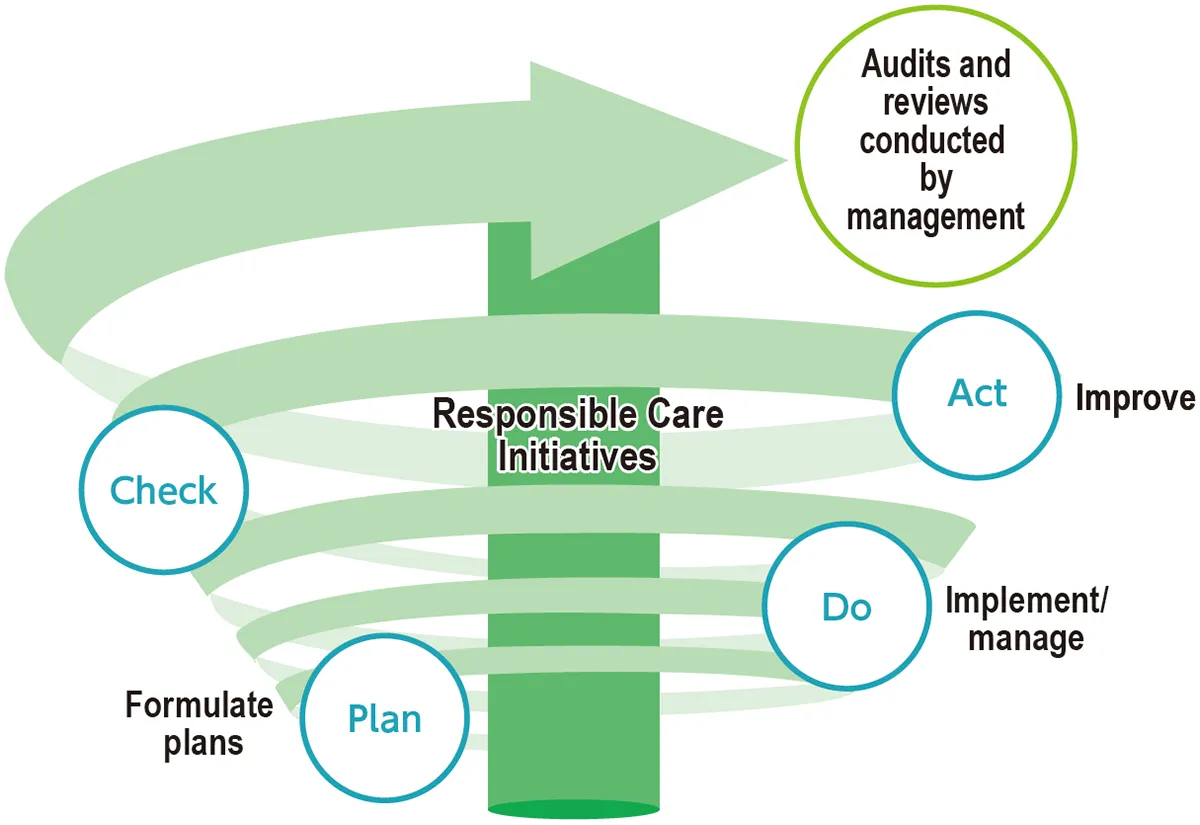

The DIC Group manages its Responsible Care program in accordance with seven codes:* “Occupational safety and health” (protection of the safety and health of employees), “disaster prevention” (prevention of fires, explosions and the discharge of chemicals), “environmental protection” (continuous reduction of chemical emissions and the discharge of waste), “safety in logistics” (reduction of chemical risks associated with the distribution of chemicals), “ensuring the safety of chemical substances” (management of risks associated with chemicals), “engaging with society” (communication with local communities regarding ESH) and “management systems” (ensure the uniform administration of the first six codes). In line with these codes, the Group applies the plan-do-check-act (PDCA) cycle and conducts annual ESH audits and management reviews to evaluate initiatives.

- The seven Responsible Care codes were developed by the Japan Responsible Care Council (JRCC), which is part of the Japan Chemical Industry Association (JCIA), as a framework for Responsible Care programs with the goal of helping achieve a society that supports efforts to address ESH-related initiatives.

Message from the President

DIC’s president prepares a message for employees for Environment Month and National Safety Week.

VOICE

We have narrowed the focus of our safety KPIs to three key areas.

Key performance indicators (KPIs) are essential in assessing current safety performance and identifying areas where safety program improvements are needed to strengthen a company’s culture of safety. At Sun Chemical, in the United States, we reviewed our safety KPIs in 2024 and narrowed the focus of our efforts to three key areas: Human safety, fire prevention and spills.

We also resolved to focus not only on lagging indicators such as total recordable incident rate (TRIR) but also on leading indicators, including training completion rate. In addition to providing training regarding these KPIs at production facilities, we have set a goal of having all Sun Chemical plants track these metrics monthly in 2025 and promote various safety measures. To address some of the most critical challenges faced at such facilities, we have also simplified injury classifications and taken steps to expedite identification of trends in the root causes of injuries.

Vice President, Environmental, Health and Safety, Sun Chemical Corporation Daniel Grell

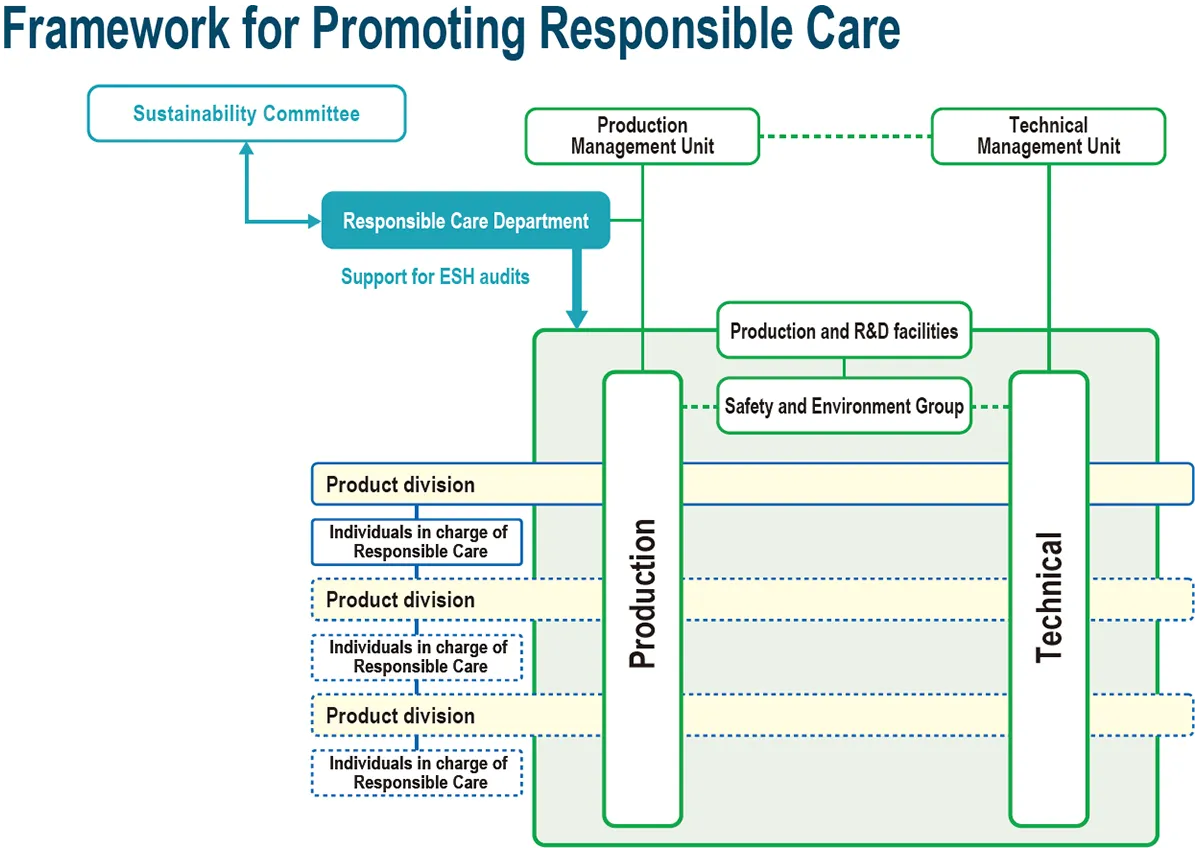

Framework for Promoting Responsible Care

The Sustainability Committee, which reports directly to the president and CEO, is responsible for deliberating and approving Responsible Care initiatives. Chaired by the president and CEO, the committee currently includes business group presidents, administrative unit general managers /heads, managing directors of regional headquarters and a member of the Audit & Supervisory Board. The committee approves Groupwide sustainability targets and policies, as well as deliberates and evaluates medium-term sustainability policies and annual sustainability activity plans. The PDCA cycle is used to evaluate voluntary Responsible Care initiatives implemented by Group companies, plants and R&D facilities in line with these policies and plans in collaboration with the Safety and Environment Group. The Responsible Care Department provides support to ensure the smooth progress of these initiatives and conducts audits to ensure compliance and improve safety and environmental performance.

Deployment of Responsible Care Initiatives at Group Companies

The Responsible Care Department provides wide-ranging support to DIC Group companies worldwide, regardless of operating scale, with the goal of enhancing Responsible Care initiatives Groupwide. In particular, we are focusing on supporting regional activities and developing human resources at the regional headquarters in China and the Asia–Pacific region.

1. Initiatives in Japan

The DIC Group has nine companies and 27 production and R&D sites in Japan. Safety and Environment groups have been established at each site, which are overseen by the Responsible Care Department. DIC and DIC Graphics hold group manager (GM) conferences four times a year. These conferences are gatherings of appointed group managers from principal sites. Other domestic Group companies participate in biannual Responsible Care conferences. These various conferences facilitate the discussion of efforts to prevent accidents and disasters, share information on environmental challenges and ensure common awareness of Groupwide rules.

TOPICS

DIC Safe Future Conference Held

With the aim of preventing serious accidents and occupational injuries, the DIC Safe Future Conference formulates common safety rules for all DIC Group companies in Japan. In fiscal year 2024, this conference, which comprises members of the Safety and Environment GM Conference, formulated guidelines for work in confined spaces, a set of uniform rules that govern work involving risks such as oxygen deficiency, which are now being deployed at all domestic sites, including those of consolidated subsidiaries. Audits are being conducted to confirm that each site has implemented these guidelines smoothly.

2. Initiatives in the Asia–Pacific region

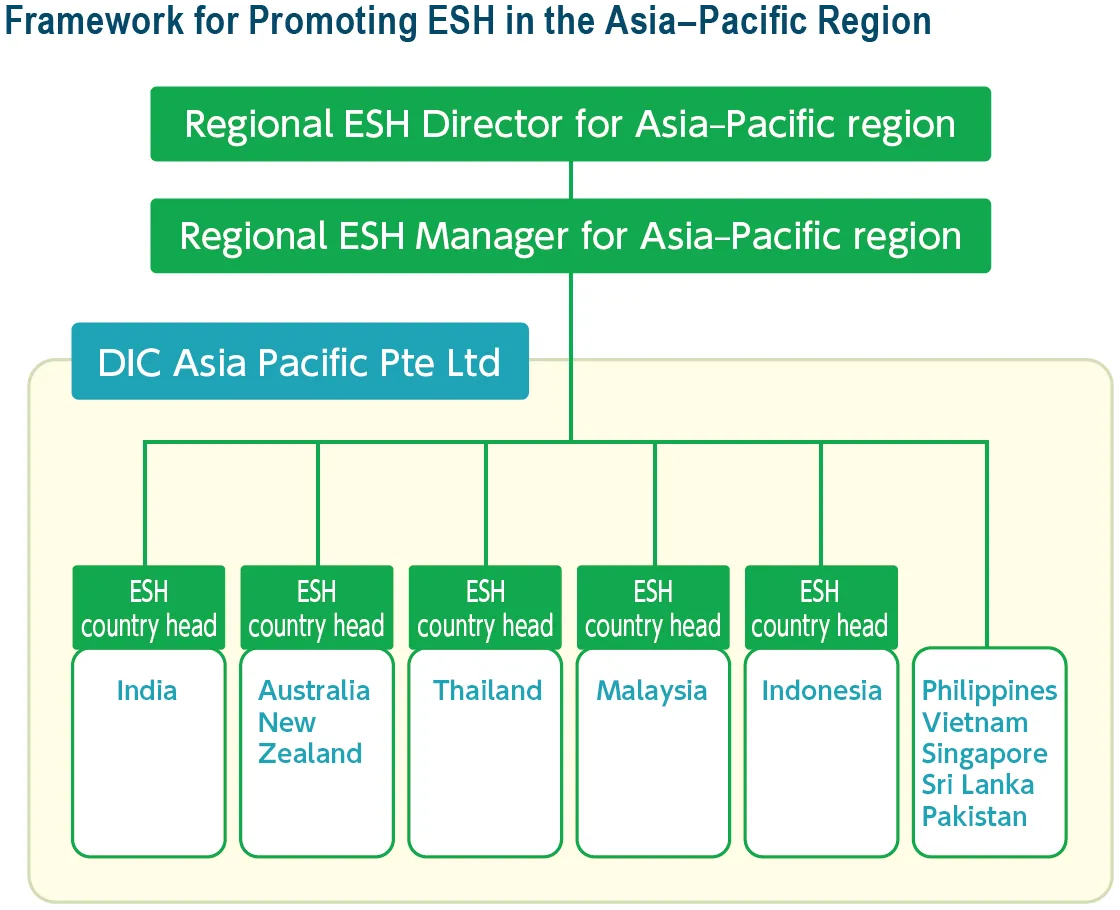

The DIC Group has 18 companies and 21 production sites across the Asia–Pacific region. A regional ESH director has been installed at DIC Asia Pacific, the Group’s regional headquarters, in Singapore, who supervises ESH country heads (individuals in charge of ESH initiatives) in key countries and territories in the region. In addition to an annual regional conference that is also attended by the Responsible Care Department, monthly meetings are held with the Chemical Substance Information Management Group, established in fiscal year 2023, to reinforce communication. Country heads hold regular country- and territory-specific meetings, convening representatives of local subsidiaries and sites to discuss initiatives, targets and challenges.

TOPICS

DIC Asia Pacific Holds Annual Safety Day to Promote a Culture of Safety

Recognizing the critical importance of safety at all of its operations, DIC Asia Pacific holds an annual regional Safety Day, after which it carefully reviews the day’s activities. The company’s 2024 Safety Day was held on April 30 under the theme of “COACH for Safety.” Effective safety coaching involves leadership engaging actively with employees to encourage the identification and correction of risky behaviors and situations. Activities at the 2024 event were divided into the following two main events:

Annual safety speeches: DIC Asia Pacific Managing Director Paul Koek and Responsible Care Department General Manager Shinobu Yamaguchi spoke about identifying risk situations and practicing employee safety. Site-led activities: Various activities aimed at reinforcing safety, including a poster contest, safety skits, a safe forklift driving challenge and emergency response training, were held prior to and after Safety Day.

3. Initiatives in Greater China

In Greater China, the DIC Group has 13 companies and 14 sites. To fortify the Group’s regional ESH framework, DIC has assigned a regional ESH director to DIC (China), the Group’s regional headquarters, and ESH coordinators to the southern and eastern parts of the country. In addition to an annual regional conference that is also attended by the Responsible Care Department, monthly meetings are held with the newly established Chemical Substance Information Management Group to reinforce communication.

TOPIC

DIC China Holds Employee Safety Knowledge and Forklift Skills Competitions

Ensuring outstanding safety awareness and skills helps create a solid foundation that underpins a company’s steady advance. At DIC China, the DIC Group’s local human resources and ESH departments worked together to hold safety knowledge and forklift skills competitions on October 22, 2024. A total of 42 competitors from nine Group companies in the PRC participated, with 28 taking part in the safety knowledge competition and 14 in the forklift skills competition. The safety knowledge competition involved a written test and a buzzer quiz, with points awarded based on the question’s difficulty, and required both general knowledge and strategy. The forklift skills competition comprised slalom driving, nut loading and double needle driving. Going forward, the DIC Group in the PRC will continue to hold skills and safety knowledge competitions to provide opportunities for employees to display their capabilities and for communication among local Group companies, thereby helping to bolster overall skill and safety awareness levels.

4. Initiatives in the Americas, Europe and Africa

The Sun Chemical Group oversees all Responsible Care initiatives by DIC Group companies in the Americas, Europe and Africa. Periodic regional conferences and online meetings are held between local ESH staff and the Responsible Care Department to ensure the DIC Group’s ESH policy and its values are shared by all.

Annual Activity Plans

The DIC Group formulates an annual Responsible Care Activity Plan and oversees Groupwide initiatives. Based on the Group’s annual plan, which is prepared by the Responsible Care Department, regional headquarters develop their own region-specific activity plans, while individual Group companies, in line with the concept of management by objectives (MBO), translate these plans into reality by promoting a variety of Responsible Care initiatives.

The DIC Group’s Annual Responsible Care Activity Plan for Fiscal Year 2024

-

Occupational safety and health

- The DIC Group’s fundamental objective remains the achievement of accident-free workplaces worldwide. With this in mind, we set regional targets for TRIR in fiscal year 2024 and implement related initiatives.

- Promote safety and health awareness among all employees.

-

Disaster prevention

- Encourage the horizontal deployment of measures based on the lessons learned from past major accidents and take steps to prevent their recurrence.

- Conduct risk assessments with the aim of reducing process risks.

- To reduce the number or severity of process safety accidents, continue calculating such accidents in accordance with the ICCA guidelines.

-

Environmental protection

- Maintain/lower the impact of production activities on air and wastewater quality.

- Reduce the generation of and maintain/increase the resource recycling rate* for industrial waste.

- Assess water risks impacted by production activities. Continue to monitor water consumption.

- Implement initiatives aimed at assuring environmental compliance.

-

Safety in logistics

- Continue to provide information pertinent to the safe transport of chemicals.

-

Ensuring the safety of Chemicals

- Complete the creation and promote the stable deployment of a new global system for managing chemicals information.

- Further expand deployment of the Wercs and Atrion at DIC Group companies overseas.

- Increase understanding of domestic and overseas laws and regulations governing chemical substances and prevent violations thereof by further enhancing in-house legal and regulatory training, including at overseas Group companies.

-

Engaging with society

- Publicize the results of Responsible Care activities.

- Continue working to secure ratings from ESG assessment organizations.

-

Management systems

- Strengthen the global sharing of ESH data.

- Reinforce relations between corporate headquarters and regional headquarters to prevent accidents/disasters in Greater China and the Asia–Pacific region.

- Promote environment- and safety-related training.

- Resource recycling rate: (Volume of industrial waste recycled + Waste heat recovered) / Volume of industrial waste generated