Managing Water Resources

Goals and Achievements of Major Initiatives

Assess and manage water risks at production facilities.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Global | 2024 | Target implementation rate for countermeasures at high-risk sites: 100% by fiscal year 2024 | The implementation rate for countermeasures at high-risk sites was 100%. |

★★★ |

| 2025 | Revise road map for fiscal year 2026 forward. | ― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Policies and Organization

Basic Approach

The DIC Group maintains a firm grasp of water risks relevant to Group operations and promotes a variety of initiatives to ensure the effective use of water resources.

Policies and Organization

Finding effective ways to conserve and manage water resources is a crucial global challenge. The DIC Group withdraws fresh water from multiple sources for cooling production equipment, as well as for use in products and as drinking water for employees. The Group also discharges wastewater—after purifying it in accordance with internal standards that exceed official standards in the countries and territories in which it has operations—into rivers and other freshwater bodies. In addition to evaluating water risks at each of its production sites around the world and implementing countermeasures, the Group works to ensure the effective use of water resources.

Principal Initiatives in Fiscal Year 2024

01Assessing Water Risks

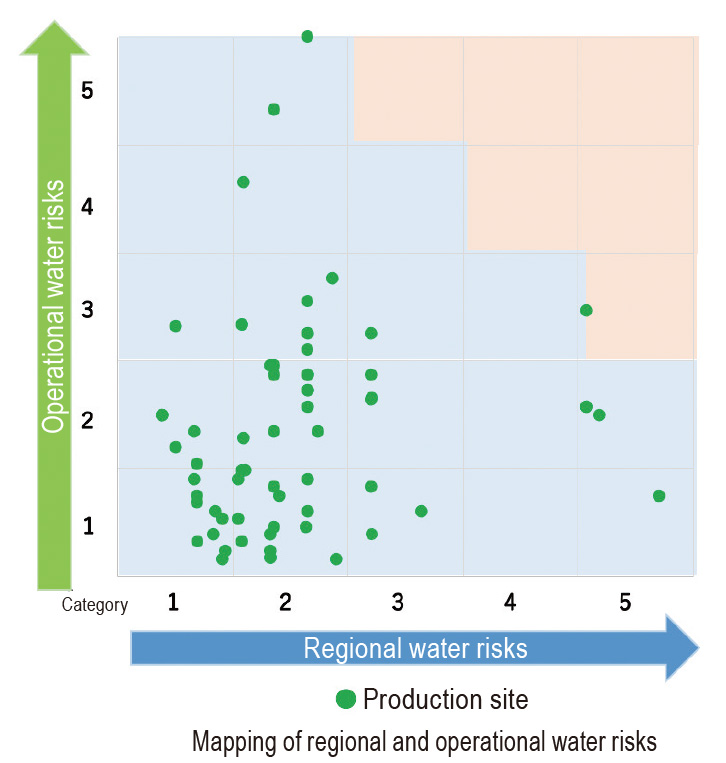

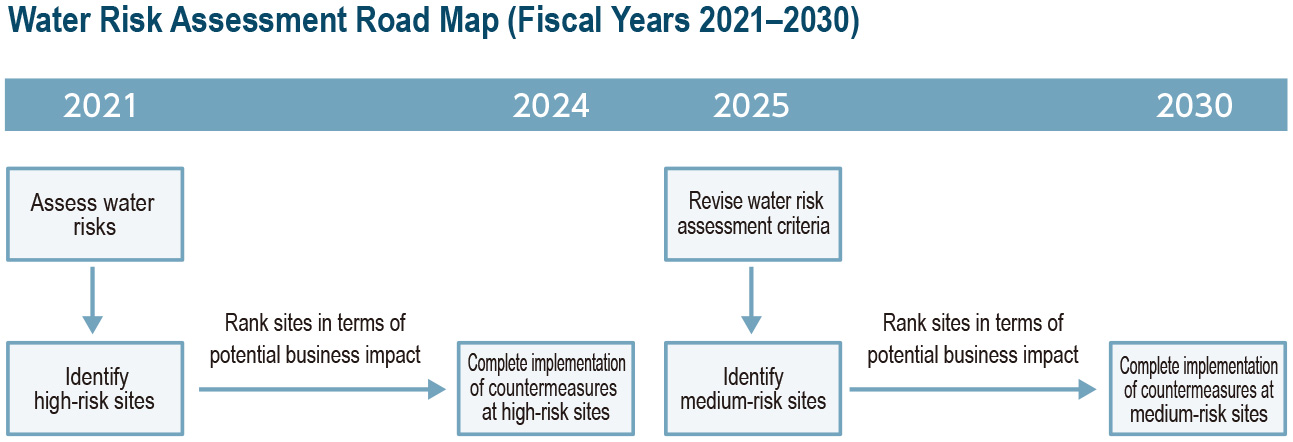

In recognition of the fact that water risks, which include drought, floods and water quality, vary greatly from region to region, companies are increasingly expected to set targets that take into account local water conditions in line with regional challenges as outlined in recent years by the World Wide Fund for Nature (WWF).*1 In fiscal year 2016, the DIC Group began using the World Resources Institute (WRI)’s Aqueduct Water Risk Atlas,*2 a popular water risk assessment tool, at each of its sites around the world to assess regional water risks, that is, risks associated with site location, which are caused by external factors. (Figure 1) Under the guidance of a third-party organization, Group companies—particularly those in Japan, the People’s Republic of China (PRC) and the Asia–Pacific region—also undertook an assessment that took into account operational water risks, which are attributable to internal factors. Specifically, water risks were classified into categories such as drought, floods and water quality, and mapped using two scales, namely, “regional water risks” and “operational water risks,” designating those sites registering at the upper end of both scales as being high risk. (Figure 2) Regional water risks were assessed using the Aqueduct Water Risk Atlas, while operational water risks were evaluated using a questionnaire developed in-house. Screening thus identified 16 sites as being high risk. Countermeasures were determined for all 16 high-risk sites and a target was set for implementation rate thereof from fiscal year 2021 through fiscal year 2024.

The DIC Group has implemented countermeasures at all high-risk sites, completing work at four sites each in fiscal years 2021 and 2022, three sites in fiscal year 2023 and four sites in fiscal year 2024. (One of these sites closed in late fiscal year 2023, as a result of which the actual number is currently 15.)

- Targets were published in the WWF’s Setting Site Water Targets Informed by Catchment Context: A Guide for Companies.

- The DIC Group uses the WRI’s Aqueduct Water Risk Atlas to map water risks such as water stress, drought and floods, among others, at 186 sites worldwide.

02Managing the Withdrawal of Water at and Discharge of Wastewater from Sites

Since fiscal year 2017, the DIC Group has used the Global Reporting Initiative (GRI)’s guideline* for collecting data on fresh water withdrawn at and wastewater discharged from each of its sites. In fiscal year 2024, the global DIC Group withdrew a total of 36,558,000 m³ of fresh water, down 23% from fiscal year 2023, and discharged a total of 33,778,000 m³ of wastewater, a decline of 22%. Fresh water withdrawn at Group sites in Japan amounted to 13,085,000 m³, a decrease of 49%, while wastewater discharged from these sites, at 11,473,000 m³, was down 52%. The principal factor behind these results was the divestiture of subsidiary SEIKO PMC CORPORATION, resulting, in a change in the scope of data collected. Fresh water withdrawn at and wastewater discharged from DIC Group sites in other countries and territories rose 8%, to 23,473,000 m³, and 14%, to 22,305,000 m³, respectively. The Group will continue to advance the effective management of water resources.

- This guideline is included in the GRI’s G4 Sustainability Reporting Guidelines.

03Efforts to Reduce Use of Water Resources and Address Risks Related to the Discharge of Wastewater

Most of the water used by the DIC Group is for the cooling of equipment. Accordingly, the Group uses cooling towers, among others, to recycle water and reduce use of water resources. To lower risks associated with wastewater generated by its production facilities, the Group purifies such wastewater to a level that exceeds that mandated by law. For example, plant domestic wastewater (gray water) undergoes primary treatment using a process such as oil–water separation before being discharged off-site. Wastewater from production processes also goes through secondary treatment—for example, an activated sludge process—before being cooled to a normal room temperature, undergoing oil–water separation and being discharged. In some cases, a tertiary process such as activated carbon treatment is further employed to remove harmful substances.

DIC’s Central Research Laboratories in Chiba Prefecture, Japan, and subsidiary DIC Siam Chemical Industry Co., Ltd., in Thailand have achieved zero discharge of wastewater. Both continue working to further reduce their impact on water resources. At the Central Research Laboratories, groundwater is used to supply the approximately 60 m³ of water used by the site daily. The facility has established a fully closed system, which means all water is treated and reused or is disposed of on-site. The Central Research Laboratories has also formulated a plan to install additional water purification equipment with the aim of improving the quality of treated wastewater, thereby reducing the amount of water it withdraws.

04Reporting to the CDP’s Water Security Program in 2024

In fiscal year 2024, the DIC Group received a score of B– in the CDP’s* water security program. Going forward, the Group will continue working to strengthen its water security initiatives and earn a higher evaluation.

- The CDP is a nonprofit organization (NPO) that operates a global disclosure system that seeks to promote greenhouse gas emissions reductions, water resources management and forest conservation.