Special Feature

Functional black pigments that combine outstanding LiDAR

signal response and visual appeal

Spectrasense™ Black EH 8082, Spectrasense™ Black L 0086

and Sicopal® Black L 0095

The DIC Group has pioneered key NIR-management solutions that will help automotive coating systems ensure safe, secure and richly colored vehicles.

Value Creation Leveraging functional pigments to assist autonomous driving and enhance visual appeal

The benefits and drawbacks of using carbon black in automotive coatings

Automakers the world over are focused on developing next-generation mobility

technologies for the smart society of the future that will facilitate autonomous driving,

which will make it possible for anyone and everyone to get around safely and securely.

Leading the charge is light detection and ranging (LiDAR), which detects the shape

and distance of surrounding objects by irradiating them with a near-infrared (NIR) laser

and measuring the light reflected back to the system’s detector, enabling autonomous

driving vehicles to “see” where they are going and preventing them from bumping

into or colliding with other vehicles or obstacles. However, conventional automotive

coatings contain carbon black, a material consisting of fine carbon particles, which

largely absorbs the NIR wavelengths of LiDAR signals and incident sunlight, causing

heat build-up and significant reduction of object detection capabilities.

The obvious question is that if LiDAR object detection capabilities are the priority,

why not just use something other than carbon black? Unfortunately, it’s not that

simple. In addition to providing excellent coverage, carbon black increases the

durability and conductivity of coatings, making its replacement with another material

difficult. Carbon black also plays an important role in body color, a key consideration for consumers’ decision making when purchasing a vehicle. Without using carbon

black, it is difficult to produce dark colors, including deep blacks, greens, blues and

reds, or neutral colors such as metallic grays. Accordingly, automakers have faced

a challenge in that the more they emphasize LiDAR signal response, the less color

design freedom they retain.

The NIR wavelengths of LiDAR signals are absorbed by the carbon black pigment of automotive coatings, significantly hindering signal response.

Developing a color formulation approach that produces clean, deep colors without hindering LiDAR detection

In March 2021, Colors & Effects, the pigments business of Germany’s BASF, one of the

world’s leading chemicals manufacturers, succeeded in developing a color formulation

approach that produces clean, deep colors without the use of LiDAR signal–absorbing

carbon black. (Colors & Effects was acquired by DIC in July 2021.)

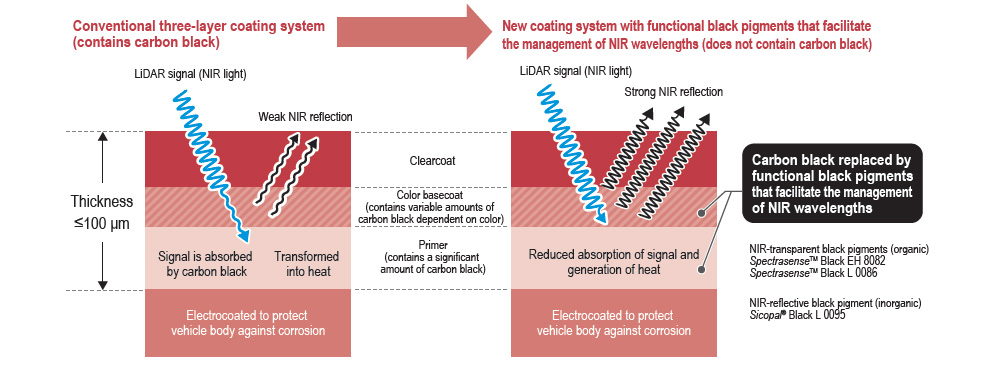

The conventional automotive coating process involves three key layers: A primer, which

evens out surface irregularities and protects the electrocoat; a basecoat, which imparts the main color; and a clearcoat, which seals everything, providing shine and protection against

external elements. It is in the primer and the basecoat that carbon black, which absorbs

NIR wavelengths in LiDAR signals, is typically used. Similar pigmentation considerations

can be used if the paint system omits the conventional primer and instead uses a

combination of two modified basecoat layers to fulfill the combined roles of the primer and

the basecoat.

Colors & Effects sought to address the problem of carbon black as a pigment in coatings

for autonomous driving vehicles by embarking on the development of color formulations that

enable the management of NIR wavelengths in automotive coatings by using a primer and

a basecoat containing NIR-transparent and NIR-reflective functional black pigments that

selectively transmit and reflect back NIR wavelengths while ensuring the high performance

required for each coating layer. By using NIR functional pigments as replacement for

carbon black—NIR-transparent black pigments from the Spectrasense™ Black product

range (Spectrasense™ Black L 0086 and the new Spectrasense™ Black EH 8082) or an

NIR-reflective black pigment from the Sicopal® Black product range (Sicopal® Black L

0095)—formulations were created which allowed LiDAR signals to penetrate through and

reflect back, instead of being absorbed, while at the same time achieving the depth of color

needed for high-end vehicles.

This new color formulation approach makes it possible for manufacturers of coatings for

autonomous driving vehicles, which will be indispensable to the smart society of the future,

to break free from dependence on carbon black and deliver both outstanding sensing

performance and visual appeal. Because this approach is suitable not only for automobiles

but also for a variety of industrial products where sensors are used, potential applications

span multiple scenarios.

A Distinctively DIC Respon Realizing a revolutionary perylene black pigment that improves jetness and enhances neutral colors

An issue that cannot be resolved simply by reflecting NIR

The impetus behind Colors & Effects’ efforts to develop a new color formulation

approach was a project to develop LiDAR-based positional mapping technologies for

use in advanced driver assistance systems (ADAS). A major challenge for developers

was of course the presence of carbon black.

The fact that carbon black absorbs and stores NIR light is well known. Colors

& Effects had previously developed pigments that reduced the absorption of NIR

wavelengths—thus exerting a heat-shielding effect—for coatings used in building

materials for roofs and outer walls and enjoyed a significant share of the global

market for pigments used in coatings for energy-efficient building materials. However, simply applying existing technologies would not resolve all the issues for automotive

coatings. Automakers and coatings manufacturers alike demanded a coating system

that would ensure LiDAR object detection capabilities while at the same time enabling

the creation of dark colors with improved jetness, as well as metallic grays and other

neutral colors. To this end, it was necessary to develop a new functional black pigment

to replace carbon black that was also easy to incorporate into coating systems that

take LiDAR transmission, absorption and reflection into account, and was optimized

for the composition of automotive coatings.

Helping realize innovative coating systems through the optimal combination of pigments that facilitate the management of NIR wavelengths

Colors & Effects commenced full-scale development in 2018 by thoroughly analyzing and

evaluating the impact of carbon black on LiDAR signals, including examining the scattering,

absorption and reflection of NIR light and performing colorimetric assays. Narrowing its

focus to perylene black, an organic compound that possesses multiple hues, the company

developed Spectrasense™ Black EH 8082, an innovative perylene black pigment that

improves transmission of the NIR wavelengths in LiDAR signals and enhances jetness by

absorbing visible light better than other NIR management black pigments on the market. By

using this new neutral colored black pigment in combination with other NIR reflective or nonabsorbing

pigments, formulations were created for the primer and basecoat layers which not

only provided excellent LiDAR reflectivity but also allowed desirable colors from the whole

color palette to be formulated. Due to the neutral color and high jetness of SpectrasenseTM

Black EH 8082, for the first time neutral gray and black colors were achievable simply by use

of the black pigment in combination with other reduction pigments. No additional tinting or adjustment is needed unless a color shift is required to achieve the design color.

Completed in March 2021, the new, improved NIR-transparent black pigment,

Spectrasense™ Black EH 8082 immediately earned acclaim from both coatings

manufacturers and automakers, for the potential it offers in eliminating dependence on

carbon black pigments and opening the way to the realization of a smart society.

DIC’s decision to acquire the Colors & Effects business, a business partner of wholly

owned U.S. subsidiary Sun Chemical Corporation, was prompted by the German company’s

advanced pigment development technologies and experience as a key supplier to all the

leading global automotive coatings manufacturers, both of which it believes are essential to

the realization of the targets it has set, which are outlined under its DIC Vision 2030 longterm

management plan. As

this new color formulation approach shows, the acquisition has already proved highly fruitful.

Message

The reaction from automakers and the coatings industry has been tremendous!

Development of a quantitative measuring method through modification of a UV/Vis/NIR spectrophotometer

Colors & Effects had experience dealing with heat-management applications through the development of pigments with heatshielding

functions. Nonetheless, undertaking a project to develop pigments for automotive coatings compatible with autonomous

driving systems that would both enhance LiDAR signal responsiveness and improve dark and neutral colors was a major challenge.

In the initial phase of this project, the focus was to understand how LiDAR signals behaved at various angles of incidence

when encountering a coating stack comprising three layers formulated with functional pigments. The tools needed to make such

measurements were not readily available for experiments under reproducible lab conditions, so assistance was sought from a

leading equipment manufacturer. With this company’s help, modifications were made to a commercial ultraviolet–visible/NIR (UV/

Vis/NIR) spectrophotometer, enabling measurements to be made across a 300–2,500 nm wavelength range while varying the

incidence angle of the measured sample. This allowed comparative measurements of coated objects, to determine the degree to

which carbon black negatively affects LiDAR signal response at different incidence angles and how much this improves with NIRtransparent

black pigments, the outcome of which played a key role in subsequent pigment development efforts.

Global Innovation Manager–

Organic Pigments,

Color Materials,

Sun Chemical Corporation

Dr. Paul Brown

The difficulty of producing neutral metallic grays

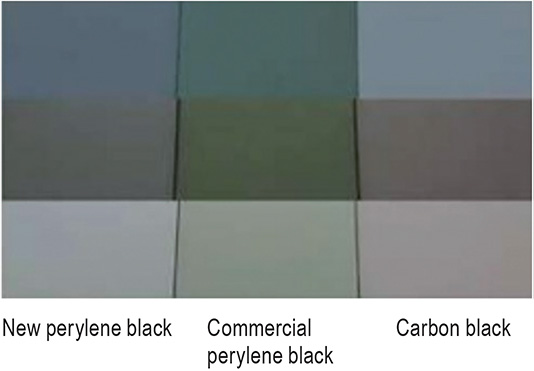

One of the most difficult tasks when using alternative pigments—including existing commercial

NIR-transparent black pigments from the Spectrasense™ Black range—as replacement for

carbon black was to facilitate the production of neutral metallic grays. When combining existing

Spectrasense™ Black products with neutral pigments such as titanium dioxide, silver mica and

aluminum, the color shifts into the green or reddish-blue color space, requiring the addition of

other color pigments to counter the undesired undertone.

To overcome this issue, information available in related literature was combined with internal

expertise to develop a method for controlling the crystal structure of the perylene, thereby

controlling the pigment color. This enabled the development of a new perylene black that

produces neutral colors in pigment reductions and fulfills the NIR transparency requirements

for LiDAR-detectable color formulations at all viewing angles. Importantly, the approach was

effective not only in the laboratory but also when scaled up to commercial production level. This

breakthrough makes it possible to achieve NIR-reflective neutral metallic grays (solid and effect

shades) without the need for color correction with another pigments.

LiDAR Signal Response: Carbon Black vs. Functional Black Pigments

Commercialization and production during a global pandemic

Technological development had progressed considerably before COVID-19 spread to Europe and by the time it was declared a pandemic, development was

already at the stage where advanced prototypes were being sampled to major customers with whom active nondisclosure agreements were in place. Given the

global situation, however, significant challenges remained in finding an effective way to obtain detailed feedback on the testing of the prototypes so that any final

adjustments could be made to the pigment prior to commercialization in 2021.

Under normal circumstances, face-to-face meetings with customers, and with pertinent in-house groups, would have taken place. However, given the pandemic

all communications had to be conducted via online meetings. In general, limited experience existed in conducting in-depth discussions remotely, but despite

some initial frustrations, effective communication was achieved, resulting in successful completion of the project and the subsequent launch in the market in

2021. Everyone involved in the development, commercialization and production of the new pigment, as well as our customers, deserves a big thank you.

Earning the best presentation award at the FOCUS conference

The Detroit Society of Coatings Technology (DSCT) holds an annual Future of Coatings Under Study (FOCUS) conference for the discussion of notable themes

and urgent issues. This event is attended by original and contracted coatings manufacturers from around the world, as well as by leading global automakers.

More than 250 people took part in the May 2021 conference, which was held remotely to curb the spread of COVID-19. During the conference, Colors & Effects

gave a presentation on the reflectivity of coatings and LiDAR detection during which it detailed its success in realizing a method for measuring variable angle

intensities of reflected LiDAR radiation and developing a new perylene black pigment with neutral coloristics. The messages delivered in the presentation were

well received by the organizing committee and Colors & Effects was pleased to receive the best presentation award.

The extremely positive response to our FOCUS presentation confirms that Colors & Effects’ pigments technologies are seen as leaders in the area of pigments

for LiDAR-detectable colors. Further R&D will continue in this area with the aim of contributing to increased design freedom.

KEY PERSON of DIC

This new pigment yields a true black and offers great potential.

When the development personnel first showed me a panel coated with the prototype pigment, I was really excited and recognized that it had the

potential to become a massively important new product. We have introduced perylene black to manufacturers of automobile coatings many times in

the past, but have not been able to break into the area of color creation for automobiles, which requires the production of clean, deep colors with a

coating thickness of only 15 μm. The reaction from customers has always been the same: “It looks black, but it’s not a true black.”

We have received many favorable and encouraging comments in response to samples of Spectrasense™ Black EH 8082, and the physical

characteristics of coatings containing the new pigment have also earned positive reviews. Recently, stricter energy efficiency standards for

automobiles have prompted demand for pigments with heat-management capabilities, underscoring our belief in our ability to grow this new

business without waiting for the full-scale arrival of autonomous driving. This is a new functional pigment that enables the creation of a true black

coating, and I can feel confident in recommending for a wide range of applications.

Manager, Pigment Global Operation Strategy Planning Group, Color Material Products Division, Osaka Branch, DIC Corporation Shintaro Gomyo

The potential for pigments that can replace carbon black is unlimited.

To improve the safety of autonomous driving vehicles, it is essential to ensure that vehicles are able to detect things around them that they could possibly run into, from the clothes worn by pedestrians to bicycles, walls and construction cones. Many such objects feature colorants containing carbon black. In all of these cases, we need to replace carbon black with functional pigments that do not interfere with an autonomous driving vehicles’ ability to detect LiDAR signals. The potential applications for Colors & Effects’ functional black pigments really are innumerable. Moreover, carbon black absorbs NIR light in incident sunlight, causing heat build-up, so we also expect heat-management applications for these pigments to expand further.

Technical Industry Manager–Automotive, Sun Chemical Corporation Andre Bendo

This is another great example of how we advance technical and scientific expertise.

The influence of color pigments on coatings is not restricted solely to the visual regime. Despite the name, they also impact properties apart from color, defined in regions hidden to the human eye. One of these regions is NIR, which is relevant to both solar heat management and LiDAR. Control over the advanced properties of pigments is a key characteristic underscoring our position as one of the largest pigment producers and a global leader at the forefront of technological understanding and research. Our expertise led to the recent development of an outstanding functional black pigment, offering a multitude of possible usages by enabling targeted tuning of the NIR behavior of coatings. The new Spectrasense™ Black EH 8082 pigment is a clear demonstration of our deep knowledge of pigment chemistry and physics, as well as our highly skilled engineering capabilities.

Team Leader, Colorimetry & Pigment Physics, Color Materials, Sun Chemical Corporation Dr. Max Mussotter

Bringing together the know-how, technologies and sales channels of three companies is key to expanding sales of sustainable products.

With Colors & Effects, the operations of which focus on Europe, becoming a member of the DIC Group, we have implemented a threepronged

global color materials business management framework comprising this company, U.S. subsidiary Sun Chemical and DIC, which

oversees Group operation in Asia.

The new functional black pigments featured herein represent a pioneering sensing-related application for pigments that have long been

sold for use in heat-management applications. These sustainable products are evidence of Colors & Effects’ advanced technologies

and marketing capabilities. Looking ahead, we will work not only to expand sales of Colors & Effects’ functional color materials through

our global sales channels, but also to expand our product portfolio of products that contribute to sustainability by leveraging DIC’s R&D

capabilities to further enhance added value.

Manager, Color & Display Business Planning Department, DIC Corporation Mineo Yoda

Special topics 2022

Functional black pigments that combine outstanding LiDAR

signal response and visual appeal

Spectrasense™ Black EH 8082, Spectrasense™ Black L 0086

and Sicopal® Black L 0095

The DIC Group has pioneered key NIR-management solutions that will help automotive coating systems ensure safe, secure and richly colored vehicles.

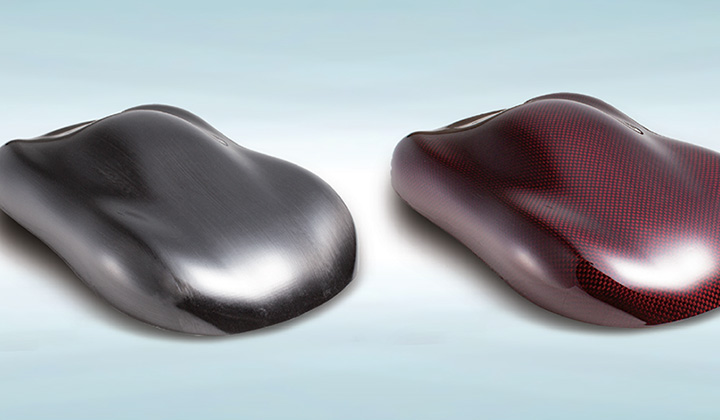

World’s fastest-curing carbon fiber–reinforced prepreg

DICARBO® LF series

The DIC Group has developed a revolutionary method for producing CFRP—essential to lowering the weight and increasing the durability of vehicles—that significantly reduces CO₂ emissions and energy consumption attributable to production.