Special Feature

Employing Chemical Recycling to Realize a Closed-Loop

Recycling System for Polystyrene Food Containers

Value Creation Closed-loop recycling of polystyrene to reduce the use of resources and energy, and the discharge of waste

Given the increasingly critical nature of the issue of waste plastic, the need to reinforce recycling systems is an increasingly urgent imperative.

Polystyrene food containers are widely used because they are light and easy

to carry, easy to process and color, and protect food by preventing moisture

ingress. In Japan, municipalities separate and collect appropriately disposed-of

post-consumer polystyrene food containers, turning them over to recycling firms

to be transformed back into raw materials, but a significant amount is discarded

improperly as general waste and ends up being incinerated or sent to landfills.

Another problem is illegally dumped waste plastic, which often ends up in

rivers and the ocean, becoming a major cause of environmental pollution in

rivers and oceans, harming ecosystems, disrupting ship navigation, hindering

tourism and fishing, and damaging coastal areas. A particular cause for concern

is microplastics, fragments of plastics 5mm or less, and superfine nanoplastics,

which are ingested by marine organisms, persisting throughout the food chain

to eventually harm the health of humans.

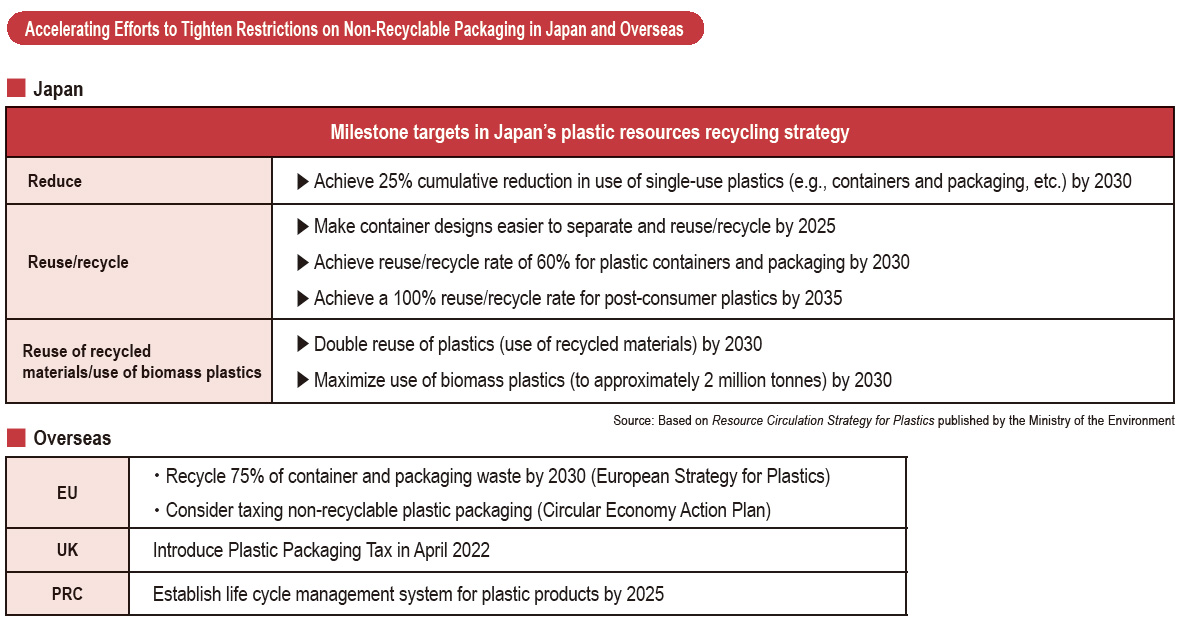

With countries tightening restrictions on waste plastic imports, exports

are no longer a disposal route for Japan, which had previously exported a

portion of the waste plastic it generates as materials for recycling. Accordingly,

establishing an infrastructure for the recycling of waste plastic within the

country is an increasingly urgent imperative. Critical to addressing this

imperative is reducing the volume of waste plastic generated. To this end, it is

necessary to reconsider single-use plastics, promote the development of new

plastic resource recycling technologies and systems, and pare consumption of

petroleum-derived resources and energy.

DIC and FPCO: Building a Closed-Loop Recycling System for Polystyrene

DIC was the first company to succeed in developing and mass producing

hyperbranched polystyrene, which it markets in Japan under the name

Hybranch. Approximately 80% of the polystyrene manufactured and sold by

the Company is currently used in the production of food containers. At present,

DIC is participating in a project to realize advanced plastic resource recycling

systems that involves collaboration among industry, government and academia.

The Company also conducts research regarding the infl uence of polystyrene,

films, inks, adhesives and other materials on recyclability in an effort to develop

products that exert less of an impact on the environment.

FP Corporation (FPCO), based in the city of Fukuyama, Hiroshima Prefecture,

is Japan’s largest food container manufacturer and a major destination for DIC

polystyrene. The company boasts a nationwide network of 9,600 collection

centers and three recycling plants, through which it recovers and transforms

post-consumer foamed polystyrene food containers into new food containers

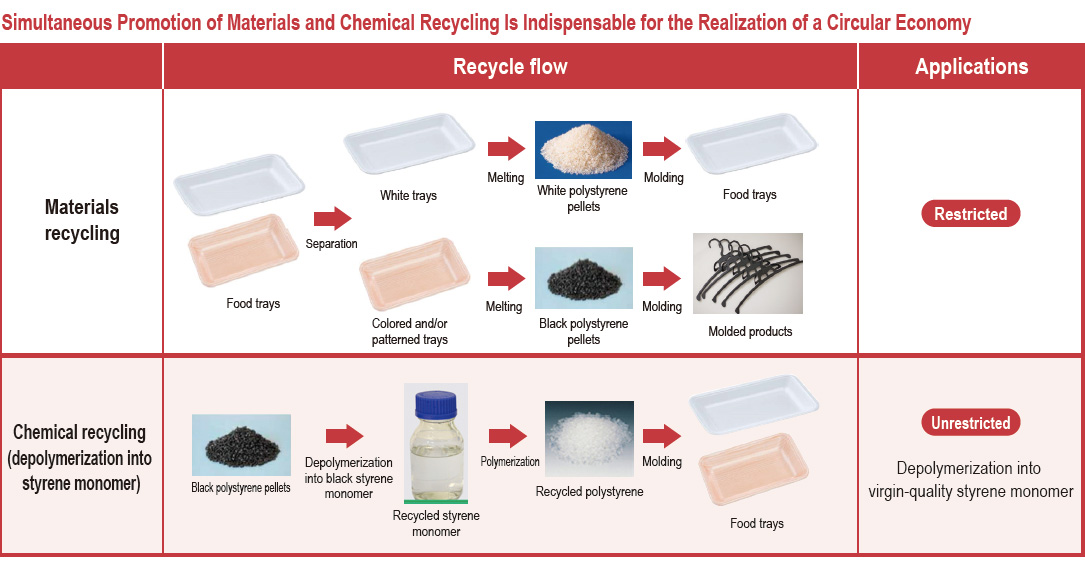

using materials recycling. Currently, the company pulverizes and melts these

containers into polystyrene pellets, with those from white containers recycled

into new environment-friendly Eco Tray containers (“tray-to-tray recycling”) and

those from colored and/or patterned containers recycled into clothes hangers

and other household items.

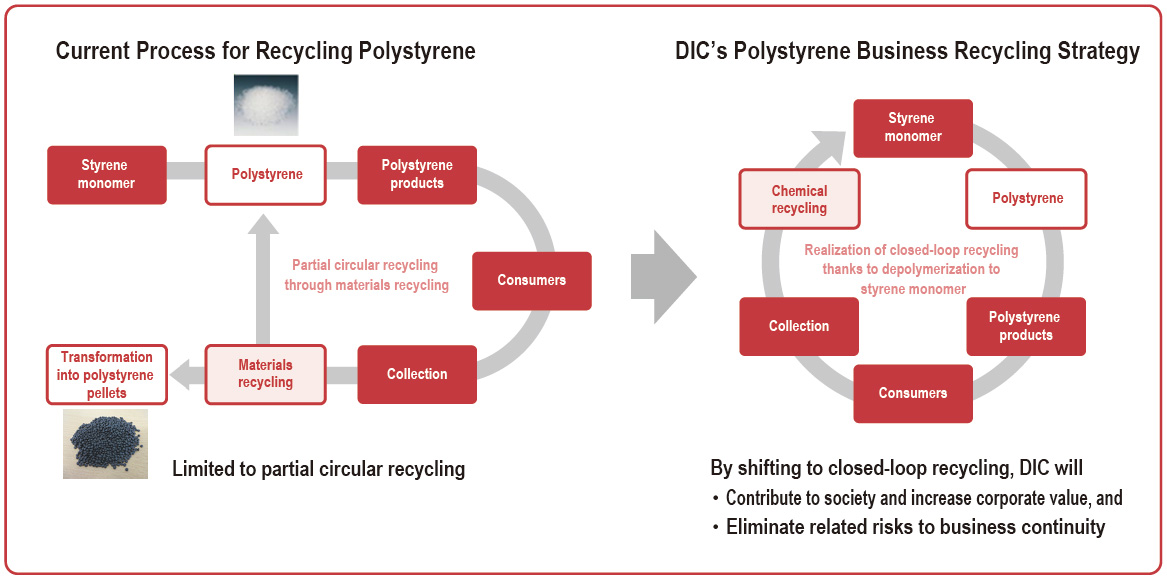

In November 2020, DIC and FPCO announced a new model of circular

recycling system that will maximize the two companies’ technologies, and

collection and recycling configurations, with the aim of achieving the practical

implementation of advanced resource recycling. This initiative also seeks to

facilitate the use of chemical recycling to transform colored and/or patterned

polystyrene, which to date could not be recycled into food containers, facilitating

fully closed-loop recycling of all types of polystyrene products.

A Distinctively DIC Response Using depolymerization through chemical recycling to realize closed-loop recycling of polystyrene food containers

Introducing third-party technologies and launching a testing plant in 2022

In addition to polystyrene, colored and/or patterned food trays contain ink

and adhesives. As a result, using materials recycling, which pulverizes

and melts the entire tray, yields black pellets and causes the deterioration

of physical properties, so the commercial value thereof is significantly

reduced. Such pellets also cannot be used for food-contact surfaces. In

contrast, polystyrene is suited to chemical recycling because it can be easily

depolymerized back into its precursor—styrene monomer—with only minimal

energy using pyrolysis, also known as thermal degradation. Because

polystyrene made with chemically recycled styrene monomer delivers the

same performance and safety levels as that made with petroleum-derived

virgin raw material, there are no limits to potential applications.

DIC thus plans to introduce third-party technologies and equipment for

depolymerizing polystyrene back into styrene monomer and to build a testing

facility at its Yokkaichi Plant, in Mie Prefecture, the Company’s principal

polystyrene production facility. The testing facility is expected to begin

operations in 2022. Through this, the Company aims to establish control

technologies that increase yields by evaluating depolymerization efficiency,

energy consumption and cost, among other factors, at annual production

levels of several thousand tonnes.

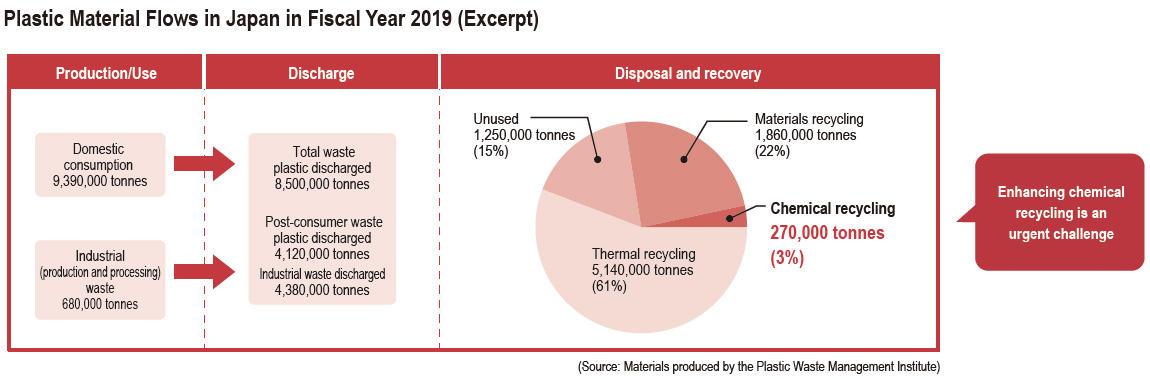

The challenge of chemical recycling: A process with outstanding potential

Materials recycling is the principal method used to recycle plastics in

Japan. The use of chemical recycling, which leverages a chemical reaction

to recycle resources, remains rare. However, given the limits of materials

recycling, the progress and expansion of chemical recycling is essential

to realizing the sort of advanced recycling-oriented society envisioned by

people around the world. The new closed-loop recycling system launched

by DIC and FPCO can be said to be a litmus test of the potential of chemical

recycling in the future. The DIC team expects the establishment of new

technologies for depolymerizing polystyrene into styrene monomer to

facilitate expansion of the initiative’s focus to include biomass inks and

adhesives and is thus committed to boldly taking the steps necessary to

ensure commercialization as quickly as possible.

KEY PERSON from DIC

A sense of crisis shared by both DIC and FPCO led to this initiative.

Over many years working together, DIC and FPCO have come to share an awareness of key imperatives. We launched this initiative because of a shared sense of crisis derived from the recognition that given the overall trend toward resource recycling, the survival of related businesses in the future depends on moving away from single-use food containers. Depolymerization back to styrene monomer is key to the closed-loop recycling of polystyrene. The ability to achieve closed-loop recycling will be a critical measure of fine chemical manufacturers’ corporate value. We look forward to building an optimal chemical recycling–based model system that contributes to a substantial reduction of waste and CO₂ emissions by choosing and integrating superior basic technologies.

Manager, Polystyrene Sales Group, Packaging Material Products Division, DIC Corporation Ken suke Shinya

We are working to make the best use of the existing collection and recycling infrastructure to achieve early commercialization.

A number of chemicals manufacturers have begun to explore chemical recycling of polystyrene. The fully closed-loop model that we are working on makes the best use of the infrastructure built by FPCO in 1990 for what it calls “FPCO-method” circular recycling, which involves the collection and transformation of post-consumer containers using materials recycling. We are enhancing this already essentially complete recycling system by adding chemical recycling. Decomposing colored and/or patterned polystyrene into styrene monomer to facilitate the efficient recovery of resources is not an easy proposition, but we are committed to mobilizing DIC’s extensive know-how to facilitate the practical implementation of a system that helps resolve plastics-related environmental issues.

Manager, Polystyrene Sales Group, Packaging Material Products Division, DIC Corporation Ryou Minakuchi

Stakeholder Perspective

COMMENT

We look forward to the early establishment of chemical recycling technologies that balance greenhouse gas emissions reduction and economic efficiency.

Using “FPCO-method” circular recycling, we collect post-consumer foamed polystyrene containers and transform

them into new food containers. We also recycle colored and/or patterned foamed polystyrene into a variety of

other items. Our desire to be able to recycle these latter containers inspired efforts to begin research in the area

of chemical recycling.

The challenge with chemical recycling technologies is that they will not be sustainable unless they help reduce

greenhouse gas emissions as well as make sense economically. We are confident that DIC will be able to clear

both of these hurdles to swiftly establish the best and most appropriate technologies.

Currently, colored and/or patterned polystyrene food containers are not the only type currently in use that

cannot be recycled into food containers. With this in mind, we look forward to increasing the range of input

materials we can recycle to bolster consumer recognition of the fact that polystyrene is an easy-to-recycle,

environment-friendly plastic and in so doing to expand the market for such containers.

Executive Director,

Executive General Manager of

Purchasing Division, FP Corporation

Hiroshi Ogawa

Special topics 2021

Employing Chemical Recycling to Realize a Closed-Loop Recycling System for Polystyrene Food Containers

Fine chemicals manufacturer DIC and food container manufacturer FPCO collaborate to implement closed-loop recycling system for polystyrene that employs chemical recycling.

Nashiji Film Made with Biomass Plastic (DIFAREN® A7440Bio)

DIC has developed a new food packaging film that is refined and visually appealing while at the same time reduces CO₂ emissions.

An FFC that Improves the Skin’s Barrier Function from the Inside Out (PHYCONA Skin Moistlifting Tablets)

DIC has developed a new “edible” skin-care product, made with phycocyanin extracted from Spirulina blue-green algae, that addresses various skin problems.