Special Feature Nashiji Film Made with Biomass Plastic (DIFAREN® A7440Bio)

Value Creation Expansion of applications for biomass plastics to advance decarbonization

DIC is taking decisive steps to help Japan become carbon neutral by 2050.

Curbing global warming is an urgent challenge facing the world. Japan has set a

target for reducing overall greenhouse gas emissions to zero by 2050. The country’s

government has positioned the creation of a mass production configuration to

advance the popularity of biomass plastics as a key theme in its plan for achieving

this goal and is encouraging the industrial sector to promote related efforts.

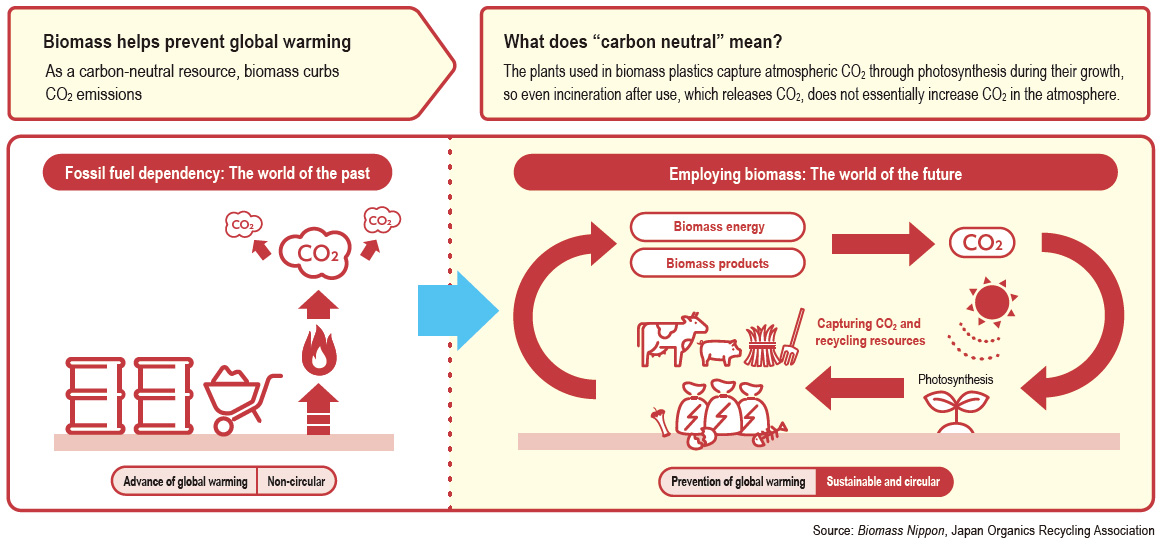

The plants that account for a portion of the raw materials used in biomass

plastics capture atmospheric CO₂ through photosynthesis during their growth,

so even incineration after use, which releases CO₂, does not essentially

increase CO₂ in the atmosphere. By leveraging the carbon-neutral nature of

biomass plastics, we are working to reduce our dependence on petroleum

resources, as well as to contribute to the prevention of global warming and

accelerate resource recycling.

Developing DIFAREN® A7440Bio, which boasts a 20% biomass content

In addition to protecting contents and offering suitability for packaging,

films used in food packaging must deliver, among others, heat

resistance, heat sealability, rigidity, flexibility, cold resistance, and easypeel

and easy-open properties.

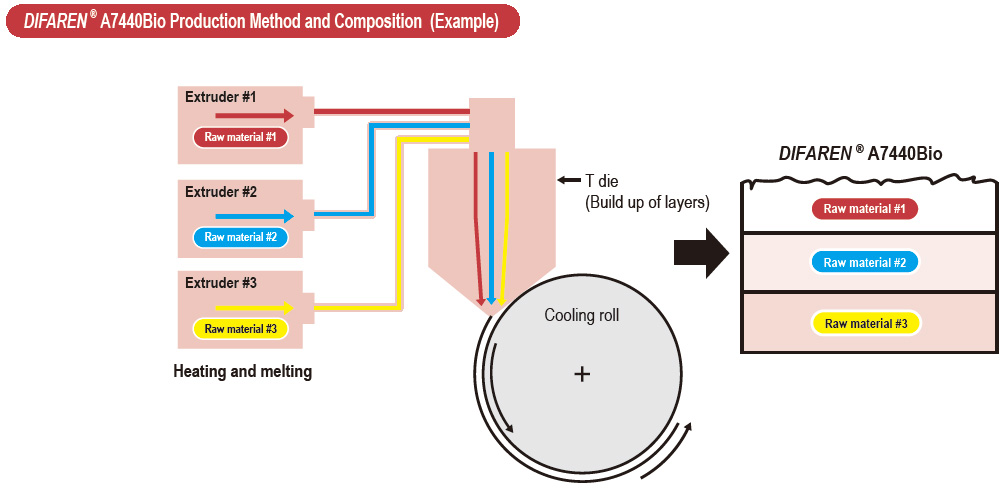

In 1970, DIC developed coextruded multilayer films for packaging

in which multiple resins with different characteristics are laminated

together in a single process. Using the same manufacturing process,

the Company has also developed the DIFAREN® A7440 series of

Nashiji (pear-skin textured) highly attractive embossed matte films with

a surface feel reminiscent of traditional Japanese paper, which has

earned high marks in the area of food packaging. A recent addition

to this lineup, developed in line with our commitment to promoting

decarbonization, is DIFAREN® A7440Bio, made with biomass plastic and resin. This new film, the first in the DIFAREN® lineup to be certified

from the Japan Organics Recycling Association, was launched in

August 2020.

A Distinctively DIC Response Achieving a visually appealing film with a 20% biomass content using existing production equipment

Pursuing a balanced combination of the physical properties of petroleum-based and biomass plastics

Nashiji film has a surface feel reminiscent of paper, but produces no paper dust and so is hygienic, as a result of which it is attracting a great deal of attention not only in Japan but also across Asia, the Americas and Europe. Unfortunately, producing Nashiji film with biomass plastics and maintaining its performance properties and visual appeal has proven difficult. Adding biomass to principal petroleum-based raw materials upsets the balance of properties, causing a variety of issues. To overcome this, DIC engineers studied the microstructure of the film and searched for the optimal resin–biomass formulation through a process of trial and error. Then, making full use of multilayer film forming technology cultivated over many years of collaboration with CAST FILM JAPAN CO., LTD., DIC succeeded in producing DIFAREN® A7440Bio, which boasts a 20% biomass content. The Company also achieved mass production of this Nashiji film, made with biomass, which delivers the same functionality and texture as petroleum-based Nashiji film, without having to modify existing equipment in any way.

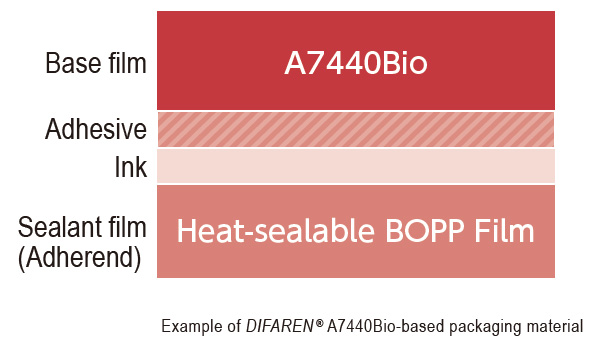

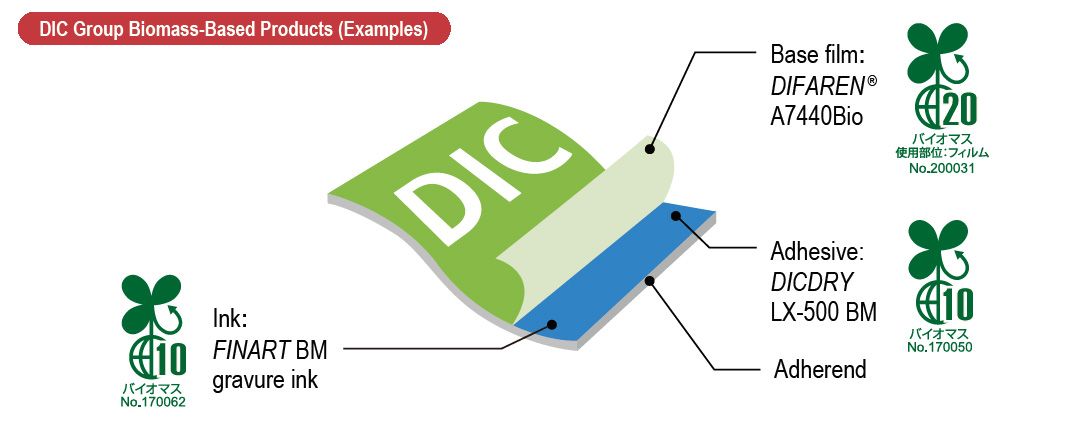

Increasing biomass content of packaging material by using environment-friendly inks and adhesives

In addition to DIFAREN ® A7440Bio, numerous other environmentfriendly DIC Group products have earned certification from the Japan Organics Recycling Association. These include biomass inks, including FINART BM gravure inks for lamination developed by DIC Graphics, and adhesives such as DICDRY LX-500 BM, underscoring DIC’s ability to provide inks, adhesives and films that support environment-friendly packaging. Use of heat-sealable biaxially oriented polypropylene (BOPP) sealant film, inks and adhesives made with biomass-derived raw materials on a DIFAREN® A7440Bio base makes it possible to create a packaging film with an even higher overall biomass content. The ability to provide a full range of biomass packaging materials is a distinctive competitive strength enjoyed by the DIC Group, which develops and manufactures inks, adhesives and films for packaging applications.

KEY PERSON from DIC

This is a groundbreaking product that responds to the needs of customers who want to differentiate their products in terms of environment-friendly performance.

Food products manufacturers and other customers are constantly conducting research to uncover packaging materials that differentiate them from other companies. To date, DIC has earned high marks for its refined and visually appealing Nashiji films. I am particularly pleased at the addition to our lineup of DIFAREN ® A7440Bio, which uses biomass plastic. The reaction to this new product at a recent packaging materials exhibition was tremendously positive. Initially, I had thought it would be difficult to raise biomass content, so I am particularly grateful to technology and manufacturing teams for their work to make this possible. I look forward to building on this groundbreaking product to actively promote our environment-friendly offerings both in Japan and overseas.

Manager, Films Sales Group, Packaging & Graphic Business Group, DIC Corporation Masaharu Ito

Building on this biomass Nashiji film to expand the use of biomass-derived materials will be a key challenge going forward.

The project to replace petroleum-derived raw materials with bioplastics while recreating the Nashiji texture was a series of stumbling blocks. Everything would be fine at the lab level, but on the production line problems would arise. And this didn’t happen just once or twice, but many times. So, when we finally achieved stable production it was pretty emotional! That said, we are not resting on our laurels. There are many environmentfriendly raw materials in the world and it is our mission as a manufacturer of fine chemicals to master their use. Another challenge in the years ahead will be to reduce the thickness of this film below 1μm, which will contribute to the reduction of waste. Both are high hurdles, but we will capitalize on our experience to strive for an even higher level of sustainability.

Packaging Materials Technical Group 4, Packaging Materials Technical Division, DIC Corporation Tomohisa Kida

Special topics 2021

Employing Chemical Recycling to Realize a Closed-Loop Recycling System for Polystyrene Food Containers

Fine chemicals manufacturer DIC and food container manufacturer FPCO collaborate to implement closed-loop recycling system for polystyrene that employs chemical recycling.

Nashiji Film Made with Biomass Plastic (DIFAREN® A7440Bio)

DIC has developed a new food packaging film that is refined and visually appealing while at the same time reduces CO₂ emissions.

An FFC that Improves the Skin’s Barrier Function from the Inside Out (PHYCONA Skin Moistlifting Tablets)

DIC has developed a new “edible” skin-care product, made with phycocyanin extracted from Spirulina blue-green algae, that addresses various skin problems.