Special

Feature

Thermoresponsive Cell Cultureware that Facilitates the Harvest of Cells Without Enzyme Treatment or Damage (Cepallet®)

Value Creation Development of revolutionary cell cultureware that minimizes damage to iPS and ES cells during harvest

Reduced survival rates for cultured cells owing to damage from enzyme treatment and scraping

Research in induced pluripotent stem (iPS) and embryonic stem (ES) cells, which hold promise in such fields as regenerative medicine

and drug discovery, continues to gain momentum worldwide. Demand for the culture of high-quality cells for use in research is driving the need for sophisticated iPS and ES cell culture processes.

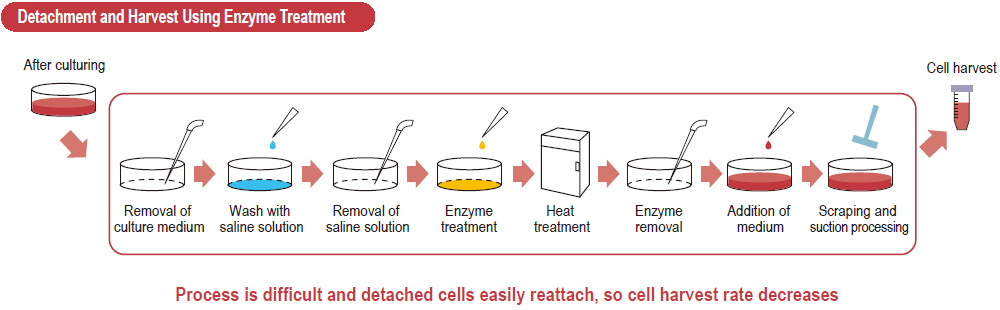

Conventional cell culturing begins with the attachment of adherent cells to the base of cultureware that has been coated with an extracellular matrix. A culture medium provides nutrients necessary for cell proliferation. To harvest the cultured cells, it is necessary to use an enzyme treatment to detach the cells and then to employ a scraper to lift them from the base. However, enzyme treatment and scraping results in some cells dissolving, while scraping causes physical stress, reducing survival rates and impeding efficient harvest. These issues have posed significant challenges to ensuring the quality of cultured cells.

Development of the revolutionary Cepallet® series of thermoresponsive cell cultureware that enhances cell detachment

In fiscal year 2018, DIC succeeded in developing the Cepallet® series of revolutionary cell cultureware that facilitates harvest without the use of enzymes or a scraper. This greatly simplifies the process, increasing both the efficiency of harvest and cell survival rates.

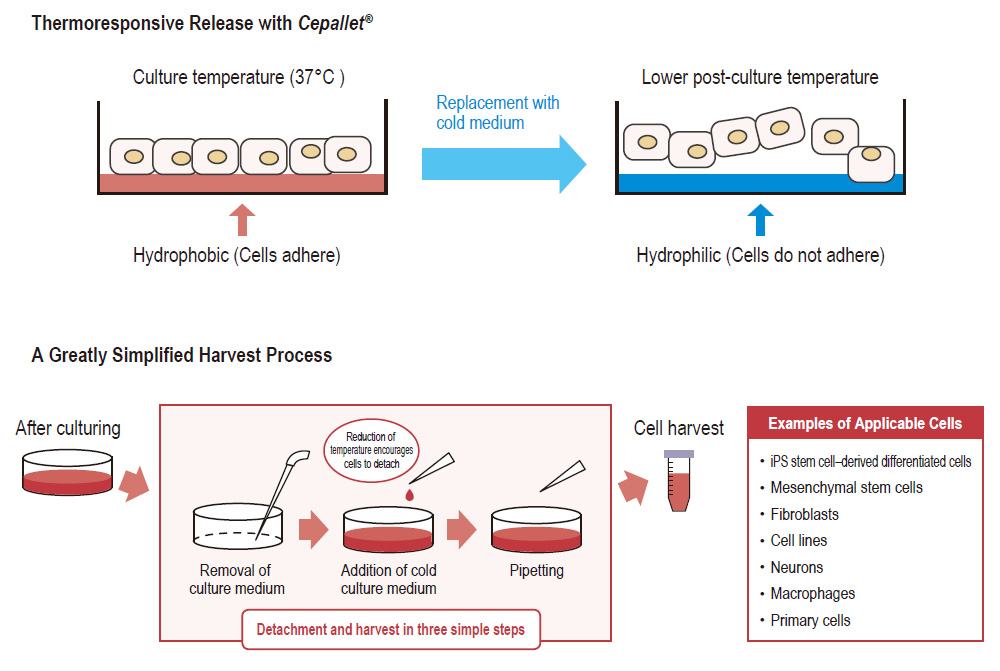

The base of DIC’s newly developed cell cultureware is coated with a proprietary thermoresponsive polymer that shows hydrophobic–hydrophilic transition—i.e, changes from promoting attachment to promoting release— upon cooling to a certain temperature (transition temperature). Accordingly, replacing the 37ºC culture medium after culturing with fresh and cold (below room temperature) medium lowers the temperature, encouraging cells to detach gently from the base (thermoresponsive release), thereby minimizing damage during harvest. Because thermoresponsive release eliminates the need for scraping, the Cepallet® series is suited for automated cell culture systems. Going forward, Cepallet® cell cultureware is thus expected to contribute to the more efficient culturing of higherquality cells in the research laboratories of pharmaceuticals manufacturers, universities and public research organizations.

A Distinctively

DIC Response

Capitalizing on proprietary polymer technologies to develop high-performance containers for culturing cells in laboratories

Leveraging DIC know-how to address needs for laboratory research

DIC embarked on the development of Cepallet® in 2013, the year that Japan introduced a new national revitalization plan, a strategic priority of which is to advance regenerative medicine. Recognizing the existence of both market needs and research seeds in this area that would allow DIC to capitalize on its expertise and experience as a chemicals manufacturer, sales and R&D personnel worked together to gather information, visiting pharmaceuticals manufacturers, universities and public research organizations, among others. This led to the recognition of a need for industrial quality control for cell culturing in laboratories conducting research related to regenerative medicine and drug discovery, which use multiple different types of equipment and devices.

Many laboratories use plastic containers to culture cells. DIC thus saw potential to leverage its specialized high-performance polymer design technologies

and industrial know-how to develop high-value-added products for use in this area. This led to the formation of a project team made up of R&D and technical personnel. The team began by identifying issues affecting the cell culturing process, resolving to help improve process efficiency and increase the quality of cultured cells by developing revolutionary high-performance cell cultureware.

During this period, DIC launched its DIC108 medium-term management plan, which positioned healthcare as a key focus of its efforts to cultivate nextgeneration businesses. As a result, expectations were high for the Company to enter the life sciences field.

A thermoresponsive polymer coating and the debut of the Cepallet® series

A detailed analysis of cell culture processes prompted the team to focus their efforts on the structural design of the polymer used to coat the base. What functional features were needed? What did the polymer need to do? Team members sifted through DIC’s vast accumulation of basic research data to determine a course of action for designing a new polymer. “In a process of trial and error, we narrowed the focus of our research to thermoresponsive polymers,” explains one member of the team. “Damage to cells during harvest from cultureware is caused by the use of enzymes to detach the cells and a scraper to lift them from the container base,” he continues. “We realized that if we could develop a polymer the adhesive properties of which would change according to temperature, it would bring us significantly closer to commercialization.” Technical and R&D departments thus commenced work toward realizing something that originally seemed impractical.

“Setting the temperatures for culture and detachment at, respectively, the temperature at which cells can be cultivated (37°C) and the temperature at which they can be harvested (below room temperature), thereby designing a polymer with adhesive properties that could be controlled within that range to encourage detachment, was the central challenge we faced,” recalls the leader of the project. “Even if we achieved positive results in a laboratory setting, designing a container that delivered stable results on an industrial scale was difficult. By capitalizing on accumulated technologies and expertise, we succeeded in commercializing a new thermoresponsive polymer coating. This achievement led to the development of the Cepallet® series, which features a surface that has been coated with this proprietary polymer using nanolevel coating technology. This eliminates the need for enzyme treatment and scraping, minimizing damage to cultured cells and dramatically improving the harvest process.

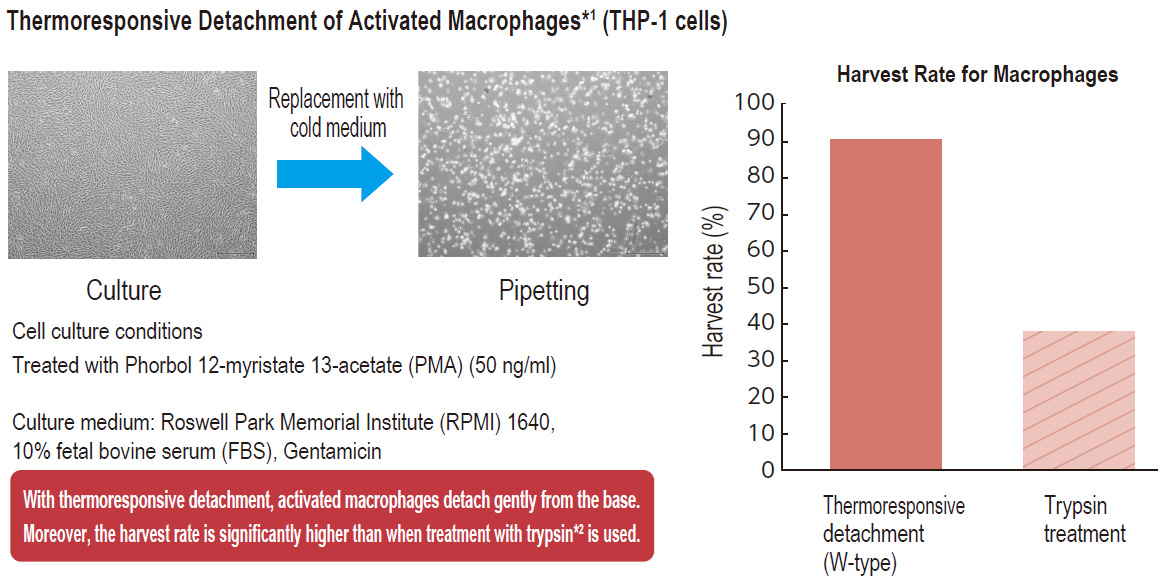

- A macrophage is a type of white blood cell of the immune system.

- Trypsin is an enzyme that breaks down proteins.

KEY PERSON from DIC

We are entering a new era of personalized healthcare, in which order-made treatments will be mainstream.

Progress in the area of regenerative medicine has ushered in an era of personalized healthcare, in which treatments are order-made, that is, tailored to the individual’s unique cellular and genetic traits. A key focus for DIC today is providing breakthrough products in the healthcare field by integrating expertise accumulated in such areas as pharmaceuticals, agrichemicals and health foods with industrial technologies cultivated in the development and production of polymers. Cepallet® is the first such product to reach commercialization. Going forward, we will capitalize on this groundbreaking product to promote a wider understanding of DIC’s development capabilities and to deepen collaboration with people in various fields with the aim of adding a new dimension to this exciting market.

Product Manager, Health Care Foods Produc t Group, Color Material Products Division, DIC Corporation Taro Ichimoto

The sense of achievement when we announced Cepallet® at an academic conference on regenerative medicine and commenced sales was extraordinary.

A wide range of cells are used in regenerative medicine and drug discovery, and various factors including the condition of cells, type of culture medium used and nutrients provided vary from one pharmaceuticals manufacturer, public research organization or university laboratory to another. Accordingly, even when we reached the point where prospects for commercialization were clear, it took another full year to have the new container evaluated by various laboratories. I think this is why when we announced Cepallet® at an academic conference on regenerative medicine and commenced sales in 2018, we were overwhelmed with pride that our new product had earned global recognition.

Project Manager, H -2 Project, Health Care Business Unit, New Business Development Headquarters, DIC Corporation Yoshinobu Sakurai

We sought to leverage key DIC technologies specifically to improve the efficiency of cell culture processes.

Cell culturing demands delicate, seasoned skills. While robots are used for some processes, the fact is that many processes still rely on human hands. The full automation of these processes would facilitate the culture of high-quality cells uniformly and in large volumes. This is an opportunity for DIC, which to date has capitalized on its synthesis technologies to industrialize and automate complex manufacturing processes. Cepallet® makes use of such uniquely DIC technologies and know-how to realize the highly efficient culture of high-quality cells. We will take advantage of the foothold we have established in this area to promote product development that contributes to the further automation of cell culture processes.

Group Manager, Health Care Products Business Development Group, Color Material Products Division, DIC Corporation Hiroyasu Asakura

Underscoring high marks from laboratory personnel, Cepallet® was first adopted by a university research laboratory.

A professor studying regenerative medicine visited DIC’s booth at an academic conference on medicine held in autumn 2018. I gave him a sample of Cepallet® , which his assistants, who are in charge of culturing cells, promptly tried out. Their verdict was that the container was easy to work with, efficient and most importantly greatly improved the cell survival rate. This professor, who works closely with cultured cells and is well aware of the difficulty of culturing, made the decision to purchase Cepallet® on the spot. Looking ahead, we will continue to actively introduce such examples of organizations that have decided to use Cepallet® and of efforts to help improve culturing processes.

Manager, Health Care Products Business Development Group, Color Material Products Division, DIC Corporation Satoko Mimura

Special Topics 2020

Thermoresponsive Cell Cultureware that Facilitates the Harvest of Cells Without Enzyme Treatment or Damage (Cepallet®)

Providing Novel Cell Cultureware that Enhances Cell Detachment Simply by Lowering the Temperature, Thereby Significantly Shortening the Harvest Process

Fast-Curing Solvent-Free Adhesive DUALAM™

DUALAM™: Inaugurating a New Era in Solvent-Free Lamination that Will Revolutionize the World of Packaging