Special Feature Pigments for Color Filters Used in LCDs and OLED Displays(Functional Pigments)

Value Creation Global market-leading pigments that deliver outstanding brightness and picture quality

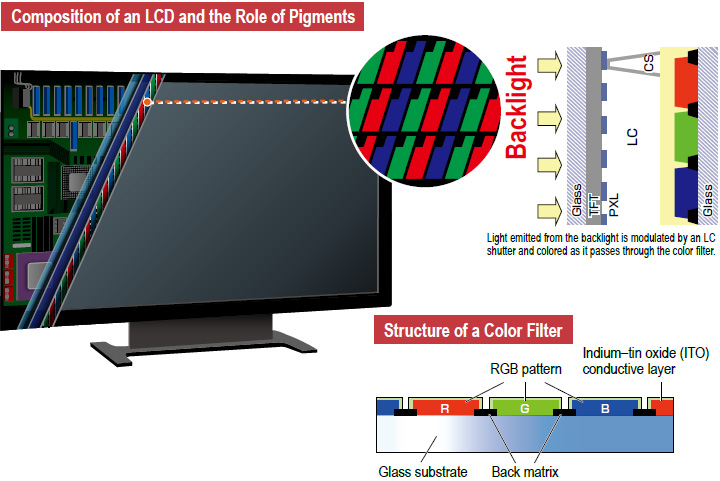

Color images on liquid crystal displays (LCDs) used in LCD televisions, computers and smartphones are produced using the three primary colors of light—red (R), green (G) and blue (B). These colors are created using pigments. LCDs produce images by transmitting light emitted from a backlight lamp through a color filter to which an RGB pattern has been applied. As a consequence, the pigments used in the color filter are crucial to picture quality.

With Japan’s shift to digital terrestrial television driving up demand for flatpanel LCD televisions and the popularity of smartphones increasing, in 2007 DIC launched the G58 series of green pigments, which achieved a remarkable increase in brightness. The series includes FASTOGEN GREEN A350, a green pigment characterized by outstanding brightness and contrast that ensures excellent picture quality even with little light from the backlight. In fiscal year 2014, DIC developed the G59 series of green pigments for wide color gamut color filters, which deliver superior brightness and color reproduction, making them suitable for use in filters for next-generation high-definition displays, including those for ultra-high-definition (UHD) televisions. DIC currently enjoys an 85%- plus share of the global market for green pigments for color filters, making its products the de facto standard. DIC also manufactures blue pigments for color filters. In 2012, the Company developed the A series, which boasts a superb balance between brightness and contrast. The optical properties of pigments in this series have earned high marks from smartphone manufacturers and boosted DIC’s share of the global market for blue pigments to approximately 50%.

DIC’s pigments for color filters, which satisfy the diverse performance requirements of displays used in LCD televisions, smartphones, tablets and notebook computers while at the same time adding value, have been adopted for use by many color filter manufacturers. In addition to improving picture quality, these pigments reduce energy consumption and, by extension, lower emissions of CO₂. Having positioned pigments for color filters as a business that it expects to drive growth, DIC continues working to reinforce its development and product supply capabilities.

A Distinctively

DIC Response

Applying technologies amassed through the production of printing inks to the development and expansion of functional pigments that have become the de facto standard worldwide

DIC first succeeded in developing offset printing inks in-house in 1915 and 10 years later began production of organic pigments for its own use. Over subsequent years, the Company amassed development and design capabilities, as well as production technologies, crucial to the manufacture of fine chemicals and in 1973 commercialized revolutionary high-performance, long-lasting nematic LCs, which were adopted by Sharp Corporation for use in the world’s first pocket calculator incorporating an LCD. DIC’s passion and development prowess are also evident in its pigments for color filters.

Large-screen LCD televisions are expected to deliver superbly realistic and accurate color reproduction. The small LCDs used in smartphones and other devices must be clear, easy to read and bright enough to ensure legibility even with less light. This is because reduced light requirements results in longer battery life. Increasing brightness requires making color filters thinner and more transparent, but this alone will not deliver vivid colors and resolution. With the question of how best to realize both high brightness and vivid colors on ongoing challenge for display manufacturers, DIC has responded by developing innovative pigments for this application.

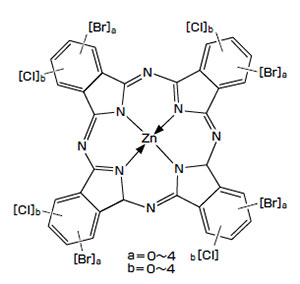

Copper has traditionally been the central material used in green pigments. In developing its green pigments for color filters, DIC defied conventional wisdom by exploring the use of a different central material with the goal of further enhancing performance characteristics. Through a process of trial and error, the Company narrowed down the list of suitable materials from a wide range of candidates, eventually choosing zinc. DIC also significantly improved transparency by reducing the size of pigment particles, thereby achieving a dramatic increase in contrast, which ensures a bright, clear picture quality even with less light. The outcome of these efforts was the groundbreaking G58 series.

Picture quality is influenced significantly by the brightness and contrast of the pigment used in the color filter. (Left: High brightness and high contrast; Right: Low brightness and low contrast)

In the area of blue pigments for color filters, DIC also leveraged its superior molecular design capabilities to achieve outstanding tinting strength and precise particle size control. To develop the A series of blue pigments for color filters, the Company also employed specialty particle surface processing to ensure highly stable dispersion, realizing an excellent balance between brightness and contrast. Products in the A series currently dominate the market for blue pigments for color filters, delivering excellent optical properties that continue to earn solid marks from smartphone manufacturers.

DIC’s success in developing a steady stream of pioneering functional pigments is supported by the seamless integration of basic technologies amassed in various fields as a manufacturer of color materials, the crossbusiness R&D configuration of its Central Research Laboratories and production technologies that facilitate the mass production of products with performance characteristics realized in the laboratory.

KEY PERSON of DIC

We are making full use of the DIC Group’s global network at all stages, from the promotion of product strategies through to the expansion of sales channels.

The value chain extending from functional pigments through to color filters for LCDs encompasses manufacturers of pigments, pigment dispersions, resist inks, color filters and LCDs. In developing pigments for color filters, we gather information on the latest trends from LCD manufacturers, which we apply to the formulation of nextgeneration product strategies.

Production of pigment dispersions, color filters and LCDs is concentrated primarily in East Asia. Recent years have seen a particularly sharp increase in the People’s Republic of China (PRC), which is on the verge of overtaking the Republic of Korea (ROK) as No. 1 in terms of volume produced. We are making full use of the DIC Group’s global network by working closely with local Group companies to bolster the adoption of DIC pigments for color filters for use in LCDs.

Manager, Pigments Sales Department 2, Pigments Product Division Naoto Akiyama

We are capitalizing on the substantial growth potential of pigments for color filters by realizing new optical properties.

Since joining DIC, I have been involved in the development of green pigments. The chemical structure of our market-leading G58 and G59 pigments is extremely complex, but with both series it is possible to dramatically transform optical properties simply by making minor adjustments. The growth potential of this business is all the more significant for this reason and our ability to make continuous improvements and modifications means that the sky really is the limit.

The evolution of display backlight technology from light-emitting diodes (LEDs) to organic light-emitting diodes (OLEDs) to quantum dots (light-emitting semiconductor nanoparticles) is also a key factor underscoring changes in the performance requirements of pigment customers. At the Central Research Laboratories, dedicated molecular design, analysis, simulation and other technical groups promote cross-collaboration with the goal of accelerating all stages of the development of products with new optical properties, from planning through to commercialization.

Fine Synthesis Technical Group 5, Fine Synthesis Technical Division 1, Central Research Laboratories Keisuke Sakamoto

TOPICS

Responding to Global Needs by Expanding Production Capacity for Blue Pigments for Color Filters

DIC aims to boost sales of blue pigments for color filters to 1.5 times the fiscal year 2016 level by fiscal year 2021

In June 2017, DIC announced that plans to expand the production capacity for blue pigments for color filters of its Kashima Plant, in Ibaraki Prefecture, to 1.5 times the current level by fiscal year 2021. In light of growing demand—underpinned by growth in emerging economies— and an increase in the volume of pigments used attributable to the trend toward larger displays, DIC estimates that the global display market will continue to expand at a rate of approximately 3.5% annually between now and fiscal year 2025. Demand for A series blue pigments for color filters has risen sharply since launch, reflecting a steady increase in the number of customers adopting these pigments for use. DIC will capitalize on the expansion of its production capacity to boost sales of these pigments to 1.5 times the fiscal year 2016 level by fiscal year 2021, to solidify its top share of the global market for blue pigments for color filters, as it has done for its green pigments for this application, which are currently recognized as the de facto standard worldwide.

Related Link

2018 Special Feature

Pigments for Color Filters Used in LCDs and OLED Displays(Functional Pigments)

Securing the top share of the global market for pigments for color filters by offering products with unrivaled optical properties with unrivaled optical properties

Adhesive Primers for Optical and Packaging Films

Outstanding adhesion improves the reliability of LCDs and the safety of food products

TOPICS

Efforts to Reduce Environmental Impact by Using Water-based Biomass Ink Made with Plant-Based Packaging Resin

Sun Chemical Promotes Initiatives Aimed at Addressing an Important Social Imperative