Topic Aquacure Inkjet Inks Technology Delivers the Positive Print Characteristics of a Water-Based Ink

The Sun Chemical Group, a core member of the DIC Group, is the leading manufacturer of printing inksin terms of market share in both the Americas and Europe.

Social Imperative

Today’s core inkjet technologies—aqueous, solvent and UV-curable—perform perfectly well across a wide variety of products and applications. However, there are fundamental pros and cons with each chemistry. Being water-based, aqueous inks have strong environmental credentials, provide a wide color gamut, offer excellent resolution and are relatively inexpensive. However, printheads require increased maintenance, substrates need to be coated, which can cost more, and agueous inks require lamination in order to be suitable for outdoor use.

UV-curable inks have superb media flexibility, offer high durability and can adhere to both uncoated stocks and other challenging materials such as vinyl, glass and wood. They cure almost instantly, enhancing image quality, reducing energy consumption and improving productivity. On the downside, UV-curable inks have a limited color gamut, the structured ink film produces a noticeably raised finish, and they need greater care in handling and transportation.

Solvent inks produce exceptionally durable finishes that are ideal for demanding outdoor applications. Nonetheless, the VOCs released as the solvent evaporates require a ventilated environment, making these inks the least environment-friendly option. They are also difficult to handle in a single-pass printer architecture, owing to the rate of evaporation at elevated temperatures and the inability to exercise inactive nozzles during printing.

In an ideal world, inkjet users want a solution that combines the characteristics of aqueous and UV-curable inks while at the same time providing consistent high-quality output with an extended color gamut. Such a hybrid composition would deliver odor-free prints, provide excellent adhesion to a wide range of media, and offer enhanced resistance and high flexibility. It would also be environment-friendly, with a reduced film weight, and have low migration properties.

Sun Chemical’s Response

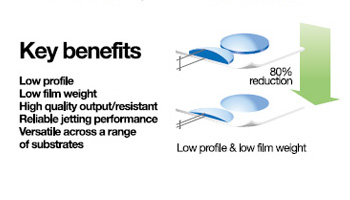

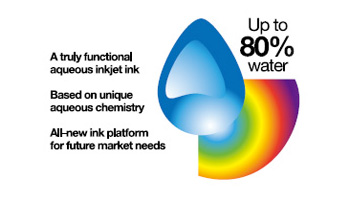

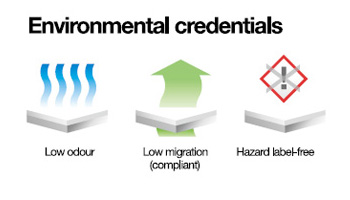

Sun Chemical addressed this imperative with the introduction of Aquacure, a functional aqueous technology combining water-based and UV-curable solutions. Comprised of 60–90% water, Aquacure inkjet inks deliver the positive print characteristics of a water-based ink, including low film weights, lack of odor, and an impeccable health, safety and environmental profile. The UV-curable component provides the ink’s versatility and durability, as well as ensuring reliable jetting through the printhead. Aquacure technology delivers adhesion to a broad range of media, offers superb flexibility and has an extensive color gamut. The technology delivers significant advantages in the graphics sector, but can also achieve migration limits and compliance for primary food packaging in combination with the appropriate press design. Unlike 100% solids UV-curable inkjet inks, Aquacure can produce low film weights similar to those in conventional print processes.

VOICE from the DIC Group

Aquacure provides a look and feel that converters and brand owners demand.

This newly developed aqueous chemistry offers functionality that digital printers have wanted from water-based technology and will have a positive impact on both well-established and emerging inkjet market segments. Most importantly, Aquacure uses between 70–80% renewable materials, is hazard- and odor-free, and is compliant for low migration packaging. Aquacure provides a look and feel that converters and brand owners demand. To date, tests involving key manufacturers have proven to be highly successful.

Business Director, Digital, Sun Chemical Peter Saunders

Related Link

Special Topics 2016

Inkjet Inks for Industrial and Office Printer

Color solutions for customers in filds ranging from outdoor signage to textiles

SEPAREL® Hollow-Fiber Membranes and Membrane Modules

Hollow-fber membranes that facilitate the removal of gas from and dissolving of gas into liquids

Pigments for Cosmetics

Rich color and superior safety contribute to the cosmetics industry

TOPICS

Aquacure Inkjet Inks Technology Delivers the Positive Print Characteristics of a Water-Based Ink