Special Feature Inkjet Inks for Industrial and Office Printer

Color solutions for customers in filds ranging from outdoor signage to textiles

Social Imperative Reduce environmental impact through on-demand printing

Outdoor display graphics, including billboards, posters and banners, product packaging, printed materials in the workplace, and textiles used in garments, bedding and interior decorating are just a few of the many things that make our lives colorful. However, in this era of mass consumption the use of resources and energy and the generation of waste in these and other areas are just a few of the many critical issues facing manufacturers and consumers. At the same time, with manual work the only way to satisfy low volume diversified orders, problems remain in terms of speed, quality and cost.

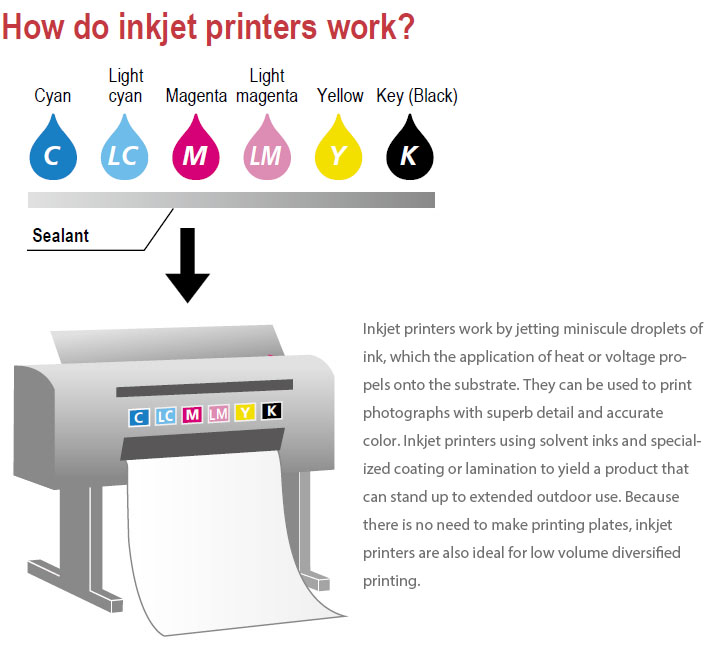

In recent years, the emergence of digital printers has fueled the popularity of on-demand printing, which allows items to be printed in the quantity desired at the time needed, making it possible to respond promptly to low volume diversified needs while also reducing both resources and energy use and waste emissions. In particular, inkjet printers—which work by jetting miniscule droplets of ink onto a substrate, are smaller and more energy-efficient than laser printers and can reproduce images and text with superb precision without the print heads ever touching the print surface—have gained popularity in many different fields.

The quality of images recreated by inkjet printers is infuenced greatly by the characteristics of the inks. In addition to durabirity, image quality and weatherability, i.e., resistance to moisture and UV light, inks must maximize the performance of increasingly high-speed, high-precision inkjet printers. The development and supply of inks optimally suited to different types of inkjet printers continue to drive the expansion of on-demand printing to an ever-broader variety of media and are thus expected to help reduce the environmental impact of on-demand printing in various felds.

DIC’s Response Aqueous inkjet inks that help reduce environmental impact for a variety of industries

DIC uses its proprietary pigment dispersion technologies to develop inkjet inks that provide water-and light-fastness with excellent color gamut and gloss

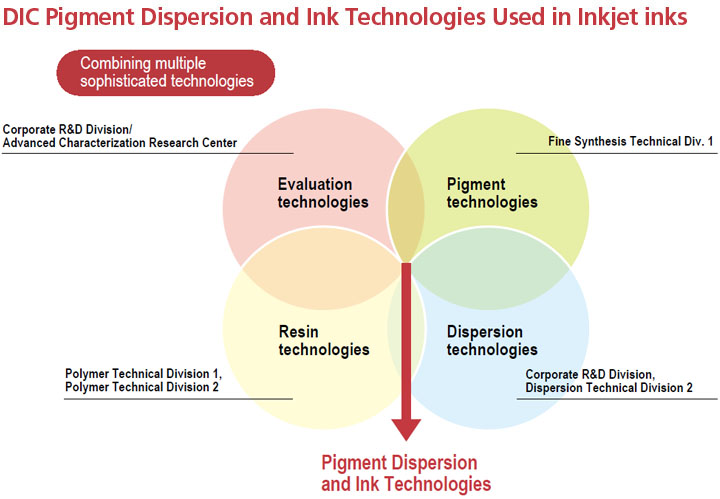

Large-format inkjet printers for industrial and office applications use a variety of different inks. The DIC Group, including both DIC and Sun Chemical, supply printer manufacturers with a broad range of global market-leading UV-curable*, solvent and aqueous inkjet inks. The Group has earned particularly high praise for its environmentally friendly aqueous inkjet inks, which are formulated with pigments dispersed in water. While aqueous inkjet inks exert less of an impact on the environment than solvent-based products, obtaining a stable dispersion of pigments in water has traditionally been problematic, making it difficult to realize excellent color gamut and gloss. DIC utilized its proprietary pigment dispersion technologies to resolve this challenge, creating inkjet inks that combine the inherent water-and light-fastness of pigments with the superb color gamut and gloss required for the printing of posters and photographs.

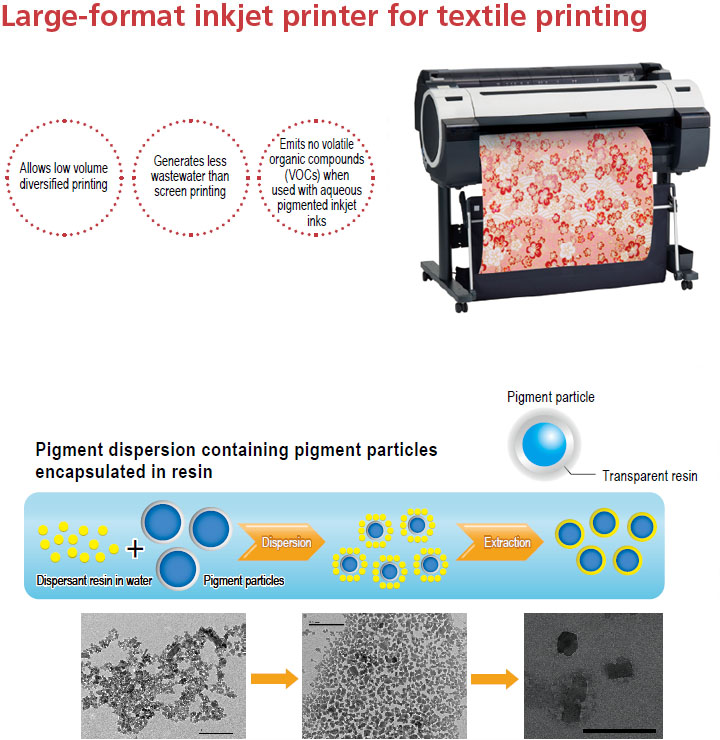

The combination of digital printers and aqueous pigmented inks is also attracting attention from manufacturers of textiles used in garments, bedding and interior decorating. Conventional textile printing requires the production of printing plates for each design, making this a laborious, costly and time-consuming process that uses a significant amount of electricity and generates a considerable amount of wastewater. In contrast, inkjet printers can print digital data directly onto fabrics, eliminating the need for plates, thereby facilitating low volume diversified printing and reducing electricity use. Moreover, pigment inks are compatible with many fabric types, substantially reducing wastewater generated.

The DIC Group's inkjet inks lineup includes UV-curable inks that use light-entitling diode (LED) light sources and solvent inks formulated with environment-friendly solvents.

- Inks cured (dried) using high-intensity UV light

KEY PERSON of DIC

We are providing integrated solutions that leverage DIC Group capabilities and meet advanced requirements.

Inkjet inks must meet the complicated requirements of printer and printhead manufacturers and as such we need to control the properties of picoliter-level droplets. Our competitive edge reflects our ability to provide integrated solutions that leverage the DIC Group’s pigment dispersion and stabilization processes, as well as to design raw materials such as synthetic resins.

Industrial and office printers are rapidly improving in terms of speed and accuracy, providing an opportunity for us to extend value by optimizing our products, an effort that is supported by the evolution of resins and pigments and advanced evaluation techniques.

General Manager, Dispersion Technical Division 2 Satoshi Idemura

We are collaborating with Sun Chemical and working to expand markets for the Group’s inkjet inks.

In 2013, DIC and Sun Chemical consolidated their respective lines of printing inks for industrial inkjet printers under the SunJet brand name. DIC excels at aqueous dispersions and inks, while Sun Chemical’s forte is UV-curable and solvent-based inks. By combining these strengths, which DIC and Sun Chemical have cultivated independently by developing unique technologies and accumulating know-how, we are working to propose effective solutions that meet customers’ needs.

We recognize that customers’ needs have shifted to include the reduction of energy and resource use, prompt delivery and the elimination of production waste, as well as high product quality. I believe that inkjet ink technology offers a particularly promising solution to these and other social imperatives.

Today, we are seeing a dramatic shift to on-demand printers for office use and textile printing, among others, and we are expecting rapid growth for packaging applications—one of our focus areas—in the next few years. By expanding this business, we will also continue helping to reduce the environmental impact of our customers’ operations.

Manager in charge of jet ink products, Imaging and Reprographic Products Sales Department, Liquid Compounds Product Division Yoshiyuki Koizumi

Special Topics 2016

Inkjet Inks for Industrial and Office Printer

Color solutions for customers in filds ranging from outdoor signage to textiles

SEPAREL® Hollow-Fiber Membranes and Membrane Modules

Hollow-fber membranes that facilitate the removal of gas from and dissolving of gas into liquids

Pigments for Cosmetics

Rich color and superior safety contribute to the cosmetics industry

TOPICS

Aquacure Inkjet Inks Technology Delivers the Positive Print Characteristics of a Water-Based Ink