Special Feature SEPAREL® Hollow-Fiber Membranes and Membrane Modules

Hollow-fber membranes that facilitate the removal of gas from and dissolving of gas into liquids

Social Imperative Eliminate gases dissolved in liquids, which can adversely impact various processes

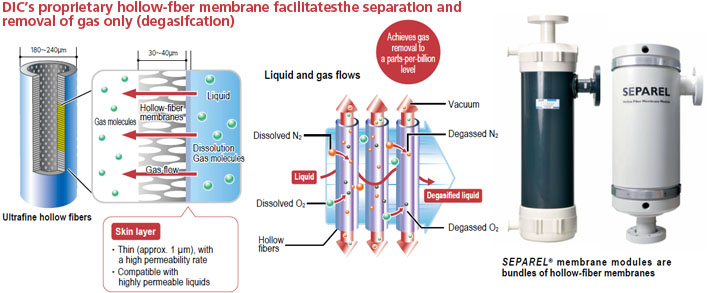

From daily life to industrial production, water pipes play a key role in a truly diverse range of situations. However, oxygen, nitrogen, carbon dioxide and other gases dissolved in water can have many negative consequences. One of these is rust, formed when iron and oxygen react in the presence of water, which can shorten the useful life of plumbing pipes. Oxygen can be removed with chemicals, but some contain substances that present health hazards, and so they pose a risk to individuals using them.

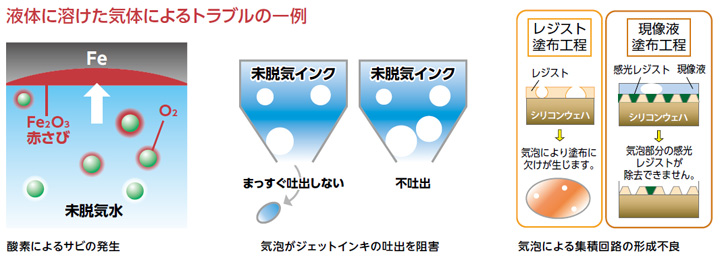

Another consequence of oxygen in liquid is the formation of bubbles, a result of fluctuations in pressure, which may adversely affect the operation of precision equipment. For example, bubbles forming in jet inks can hamper ejection from nozzles, damaging print quality, while in semiconductor fabrication bubbles in photoresists and developers can impede the formation of circuit patterns, causing defects.

As these examples indicate, there is a clear need for effective and environment-friendly ways to remove gases dissolved in liquids, thereby reducing related resource and energy losses, as well as waste arising from product quality issues attributable thereto.

DIC’s Response Hollow-fber membranes for degasifcation (removal of gasesdissolved in liquid) and aeration (dissolving of gases into liquid)

DIC developed a proprietary hollow-fber membrane with groundbreaking gas separation capabilities approximately 30 years ago.

In the late 1980s, DIC developed a proprietary hollow-fber membrane made from a polyolefn.

-

Compatibility with highly permeable liquids

DIC’s hollow-fber membrane consists of a porous inner supporting layer and a nonporous outer layer called a skin layer, making it compatible with highly permeable liquids.

-

High gas permeability

Owing to its molecular structure, the raw material used in the hollow fbers—poly (4-methyl-1-pentene) (PMP)—boasts a high level of gas permeability. In addition, at approximately 1 µm the skin layer is exceptionally thin, as a result of which the membrane delivers an excellent degassing performance.

-

Ultrafne hollow fbers

The minimum outer diameter of DIC’s hollow-fber membranes is around 180 µm, the smallest possible for a degasifcation membrane. This structure, made possible by the use of ultrafne hollow-fber membranes, maximizes membrane surface in small spaces.

Applications for DIC’s hollow-fiber Membranes are Found in Medicine, Everyday Life and Industry

One of the earliest applications for DIC’s hollow-fber membranes was oxygenators, which are used to dissolve oxygen into and remove carbon dioxide from blood during surgical procedures. Subsequently, DIC commercialized these membranes in SEPAREL® hollow-fber membrane degasification and aeration modules. Uses for SEPAREL® modules include removing oxygen from pipes in power plants, factories, office buildings and condominium complexes to protect against rust, thereby pronging their useful lives. In the area of inkjet printing, these modules are used to remove oxygen from jet inks, which helps enhance print quality. SEPAREL® modules also boast outstanding aeration capabilities. In semiconductor fabrication, for example, they are used to dissolve carbon dioxide into ultrapure water, which facilitates control of the water’s specifc resistance value, preventing dust from readhering due to static electricity and the electrostatic destruction of substrate patterns.

DIC’s proprietary hollow-fber membrane facilitatesthe separation and removal of gas only (degasifcation)

KEY PERSON of DIC

Our goal is to provide products that customers cannot do without.

SEPAREL® membrane modules are light and compact and can be installed simply by lining them up, making them far more fexible and easy to move around than the degasifcation towers commonly seen at production facilities. Moreover, unlike with chemical degasifcation these units are not hazardous to human health or the environment. Because the hollow-fiber membranes used in these modules are made from resin, there are constraints in terms of heat-, pressure- and solvent-resistance. We recognize that if we can improve the performance of membranes on these fronts, applications will be almost limitless. Recognition of the SEPAREL® name is still low. As I believe there are potential customers around the world who are troubled by dissolved gas and gas bubbles who would beneft from these products, we will continue working with DIC Group companies overseas to promote awareness of SEPAREL® among such customers. I am confdent that once they try our membrane modules, they won’t be able to do without them!

Assistant Manager in Charge of Membranes Sales Department, Application Materials Product Division Ken Tamaoki

The secret is an exclusive dual-layer structure with a skin layer.

All aspects of the SEPAREL® membrane business—including production of hollow fbers, development of modules, commercialization and module production—are centered at the Chiba Plant. These products are a prime example of the comprehensive capabilities of the DIC Group. These modules are currently used in diverse felds, including ink production, water treatment, medicine and semiconductor fabrication, and we constantly receive inquiries regarding the possibility of deployment in other felds. The fact that my predecessors were able to develop something so revolutionary 30 years ago is a source of tremendous pride, as is the technological prowess that made it possible. Our team is committed to working hard to further refne and improve product performance. With recent advances in the speed and precision of semiconductor fabrication systems and printers and a commensurate increase in degasifcation levels, customers’ quality expectations have become increasingly exacting. The higher the requirements for the removal of gases dissolved in liquid or for the dissolving of gases into liquid, the greater the value realized by SEPAREL® modules.

Head Researcher, Polymer Processing Technical Group 5, Polymer Processing Technical Division Shigeaki Fujieda

TOPICS

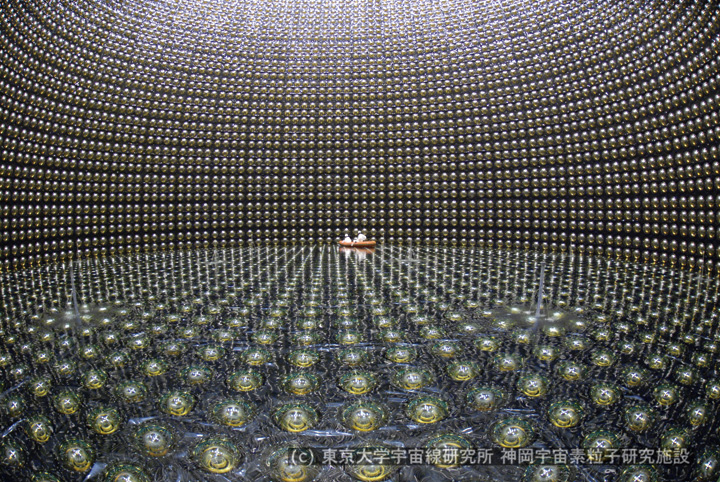

DIC’s SEPAREL® hollow-fier membrane module is used as an ultrapure water degasifcation device in the Super-Kamiokande neutrino detector

In 2002, Masatoshi Koshiba, Professor Emeritus of the University of Tokyo was awarded the Nobel Prize in Physics for the first real-time observation of neutrinos from a supernova explosion. A key factor in Professor Koshiba’s achievement was the Kamiokande detector, part of the University of Tokyo’s Institute for Cosmic Ray Research (ICRR), which is located in Gifu Prefecture. The Super-Kamiokande detector, a super-high sensitivity detector that operates on the same principle as its predecessor, consists of a cylindrical stainless steel tank, which holds 50,000 tons of ultrapure water, and approximately 11,200 photomultiplier tubes, which are installed on the tank wall. A SEPAREL® hollow-fber membrane module is used as an ultrapure water degasifcation device in the Super-Kamiokande’s water purification system, its outstanding performance contributing to research carried out at the detector. The Super-Kamoikande detector was also used by Professor Takaaki Kajita, director of the ICRR, who received the 2015 Nobel Prize in Physics for his discovery of neutrino oscillations.

(c) Kamioka Observatory, ICRR(Institute for Cosmic Ray Research), The University of Tokyo

For more information, visit the Super-Kamiokande offcial website.

http://www-sk.icrr.u-tokyo.ac.jp/sk/sk/neutrino.html

Special Topics 2016

Inkjet Inks for Industrial and Office Printer

Color solutions for customers in filds ranging from outdoor signage to textiles

SEPAREL® Hollow-Fiber Membranes and Membrane Modules

Hollow-fber membranes that facilitate the removal of gas from and dissolving of gas into liquids

Pigments for Cosmetics

Rich color and superior safety contribute to the cosmetics industry

TOPICS

Aquacure Inkjet Inks Technology Delivers the Positive Print Characteristics of a Water-Based Ink

Sun Chemical Promotes Initiatives Aimed at Addressing an Important Social Imperative