Preventing Global Warming(2022)

Principal Initiatives in Fiscal Year 2022

01Energy Consumption and CO₂ Emissions by the Global DIC Group (Scope 1 and 2)

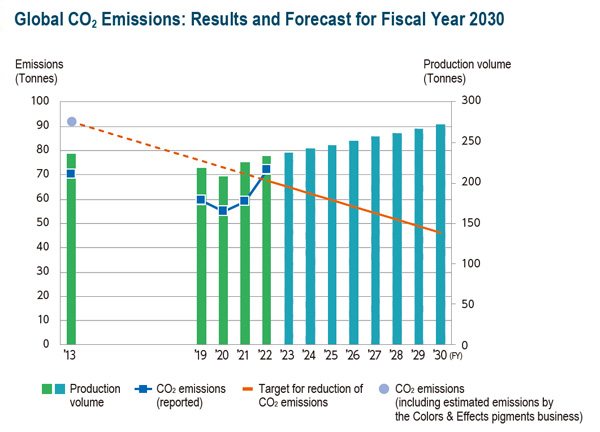

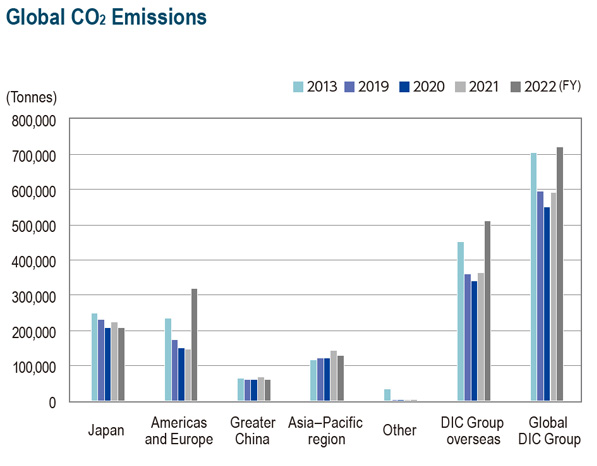

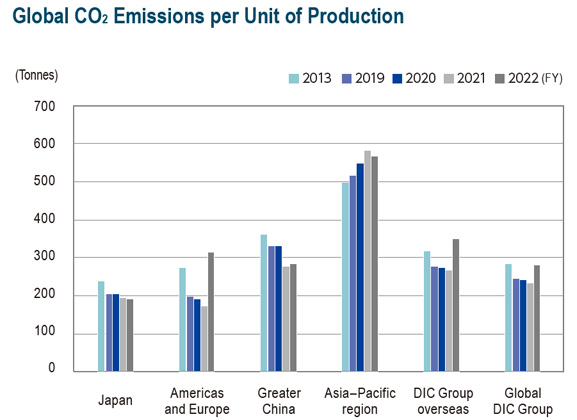

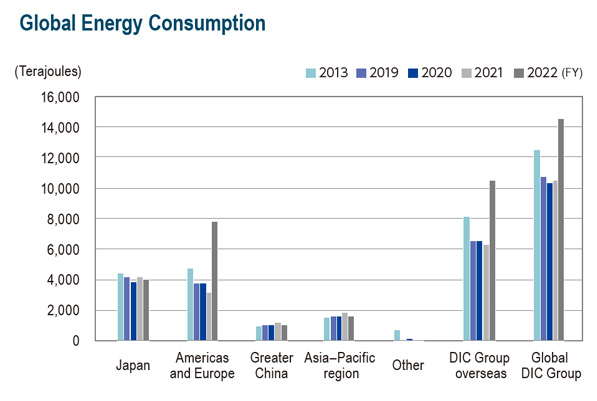

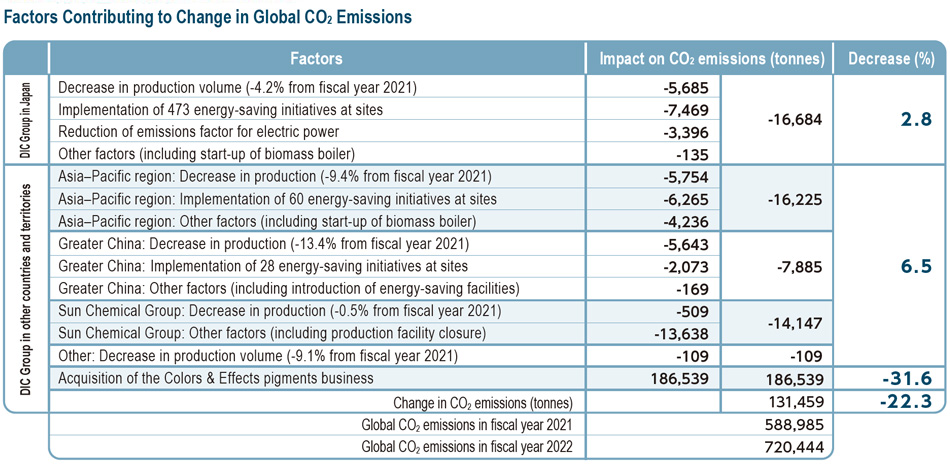

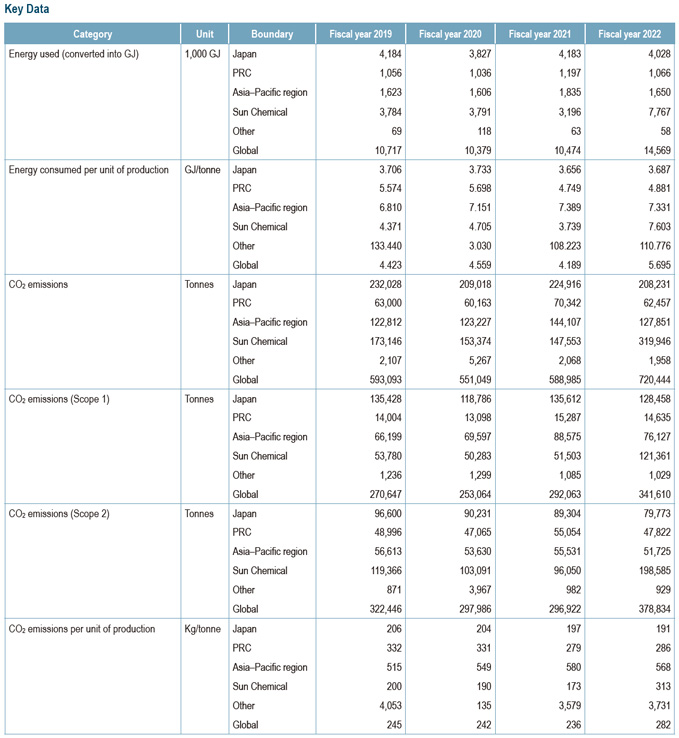

Energy consumption by the global DIC Group in fiscal year 2022

amounted to 14,569,201 GJ, while CO₂ emissions totaled 720,444

tonnes. CO₂ emissions per unit of production were 281.6 kg/tonne.

Both energy consumption and CO₂ emissions were up sharply from

fiscal year 2021, owing to the acquisition of the Colors & Effects

pigments business. The Group intends to obtain third-party verification

of its energy consumption and CO₂ emissions (Scope 1 and 2) data,

including the impact of this change.

The DIC Group achieved its goals for reducing its CO₂ emissions and

CO₂ emissions per unit of production worldwide as a result of efforts

by Group companies to break down the target set forth in the threeyear

management plan that concluded in fiscal year 2021—a 50%

decrease from the fiscal year 2013 level by fiscal year 2030—into an

annual average decrease of 3.5% from the fiscal year 2018 level—and

the promotion of more ambitious energy-saving and decarbonization

initiatives, including the adoption of internal carbon pricing. Some of

these initiatives are outlined below.

Going forward, the DIC Group will continue to implement a variety of

energy-saving measures, including introducing highly efficient facilities,

promoting process improvements and boosting capacity utilization

rates, while at the same time further advancing its use of renewable

energy by shifting to biomass and other clean fuels and installing solar

power facilities.

In addition, the Sustainability Committee has made the decision to

adopt CO₂-free electric power at all DIC Group sites in Japan. The DIC

Building (DIC’s corporate headquarters) and the No. 2 DIC Building in

Tokyo switched fully to CO₂-free purchased electric power. Remaining

sites will begin gradually changing over in fiscal year 2023.

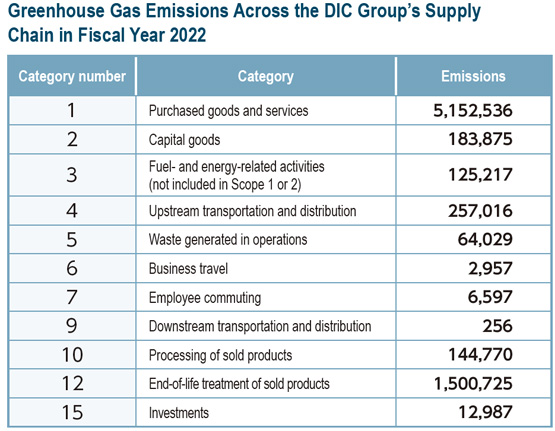

02Grasping CO₂ Emissions Across the DIC Group’s Supply

Chains (Scope 3)

The DIC Group recognizes the importance of reducing emissions of greenhouse gases across its supply chains and works to ensure a grasp of emissions in all categories of Scope 3. The Group has also revised its calculation for emissions in category 1 (Purchased goods and services) with the aim of refining data reported in this category.

Initiatives in Areas Other than Production(Offices and Research Facilities)

In fiscal year 2022, energy consumed by the DIC Group’s 21 offices and research sites in Japan (excluding the Central Research Laboratories) rose 17.6%, with contributing factors being an increase in the number of sites and the inclusion in the calculation, for the first time, of fuel used by Company cars. Principal energy-saving initiatives implemented include replacing aged light fixtures and air conditioning equipment with newer, high-efficiency models that satisfy standards set by the Energy Conservation Center, Japan (ECCJ) for its Top Runner program, turning off lights when not needed and implementing mandatory 22°C winter and 28ºC summer air conditioning settings, working

with facility management companies to implement diligent energy-saving

measures and instituting a year-round no-jacket/no-tie dress code under

the WSR 2020 project.

In fiscal year 2022, Group company DIC Kyushu Polymer Co., Ltd., completed

construction of a new office building that incorporates net zero-energy building

(ZEB)*1 construction, which aims to achieve virtually zero energy consumption.

The new office building was designed with a variety of energy-saving equipment

and fixtures, including solar power generation facilities, heat insulation

materials and LED lighting fixtures, allowing it to achieve a reduction in primary

energy consumption (energy saving + energy creation) of 111% and earning

it certification as a top-level ZEB*2 building. DIC Kyushu Polymer participated

in the 2021 ZEB demonstration project conducted by the Ministry of Economy,

Trade and Industry’s Agency for Natural Resources and Energy, earning that

company certification as a ZEB Leading Owner.*3 DIC Kyushu Polymer is the

first Group company to pursue such an initiative. The DIC Group will continue

working actively on building ZEB-compliant offices.

- A ZEB is a building with considerably reduced annual energy consumption by saving as much energy as possible via better heat insulation, solar shading, natural energy and high-efficiency equipment as well as creating energy (e.g., with photovoltaic power generation), while maintaining comfortable environments.

- The ZEB series consists of four ranks based on net reduction in primary energy consumption achieved: ZEB (net energy saving of 100% or more), Nearly ZEB (buildings that achieve net energy saving of 75% or more), ZEB Ready (buildings that achieve net energy saving of 50% or more) and ZEB-oriented (buildings with a floor space in excess of 10,000 m2 that achieve net energy saving of 40% or more).

- A ZEB Leading Owner is an owner of a ZEB building that publicly discloses its targets for promoting awareness of ZEB, introduction plans and implementation results, as well as the results of related efforts.

Procurement Initiatives

Based on the DIC Group Sustainable Procurement Guidelines, DIC formulated the DIC Group Sustainable Procurement Guidebook, version 3 of which was published in February 2020, which it uses to survey suppliers and encourage them to reduce their emissions of greenhouse gases. With the objective of better understanding and lowering the carbon footprint of DIC products, the Group is also making provisional calculations of the carbon footprint of the raw materials it uses, as well as seeking to expand its used of bioderived and recycled raw materials. The Group is also working to reduce greenhouse gas emissions by using common tools such as EcoVadis to expand dialogue with suppliers.

Logistics Initiatives

In Japan, DIC Group companies are using fewer, larger trucks and taking decisive steps to improve loading efficiency, as well as promoting the use of modal shift and the efficient combination of truck, rail and marine transport. Group companies in other countries and territories are advancing initiatives tailored to local circumstances. Over the long term, the Group expects that the expanded use of next-generation vehicles and LNG carriers will further help reduce greenhouse gas emissions attributable to logistics.

Internal Carbon Pricing System

In fiscal year 2021, the DIC Group introduced an internal carbon pricing system. Instituting its own internal price places a monetary value on greenhouse gas emissions (Scope 1 and 2) that the Company can then factor in cost–benefit assessments. This will allow more accurate capital investment decisions by making it possible to quantify the impact of emissions reductions while also raising awareness of the relationship between capital investments and CO₂ emissions. With the goal of expanding applications for its internal carbon pricing system, DIC will also look at using internal carbon pricing to factor the cost of emissions into calculations for energy procurement and rationalization efforts.

DIC Sustainability Index

The DIC Sustainability Index was established as a yardstick for measuring the social value of DIC Group products. The index’s vertical axis quantifies each product’s contribution to the reduction of environmental impact, which the Group is working continuously to reduce. In particular, the Group is focused on reducing greenhouse gas emissions (Scope 1 and 2) and ensuring steady progress toward achievement of the targets it has set for fiscal years 2030 and 2050.

Calculating Products’ Carbon Footprint

To lower CO₂ emissions across its supply chain, the DIC Group calculates and works to minimize emissions associated with its products from the sourcing of raw materials through to provision to the customer. The Group is currently developing a scheme to calculate each product’s carbon footprint, which it believes will assist its efforts to foster dialogue with suppliers and respond to customer expectations and social imperatives. In response to requests from global customers, the Group is also creating guidelines for calculating products’ carbon footprint that are consistent with those employed by Sun Chemical, as well as to create an information-sharing mechanism. For customers in Japan, the Group set up a system for responding to inquiries related to products’ carbon footprint that is spearheaded by the Sustainability Department and held related presentations for technical and sales teams.

Avoided Emissions

The term “avoided emissions” refers to CO₂ emissions that can be avoided through the use of a product. Examples include products that contribute to improving fuel efficiency by reducing vehicle body weight and products that help reduce energy used for heating and cooling by improving insulation. The DIC Group is working to appropriately calculate avoided emissions’ contribution to emissions across the supply chain, as well as to quantify their importance to the value its products deliver.

Innovation

By capitalizing on open innovation to promote the chemical recycling of its products, as well as the recycling and conversion of recovered CO₂ into new raw materials, the DIC Group is working to realize manufacturing that does not rely on fossil fuels, thereby helping contribute to sustainability for the global environment and for society, as set forth in DIC Vision 2030.

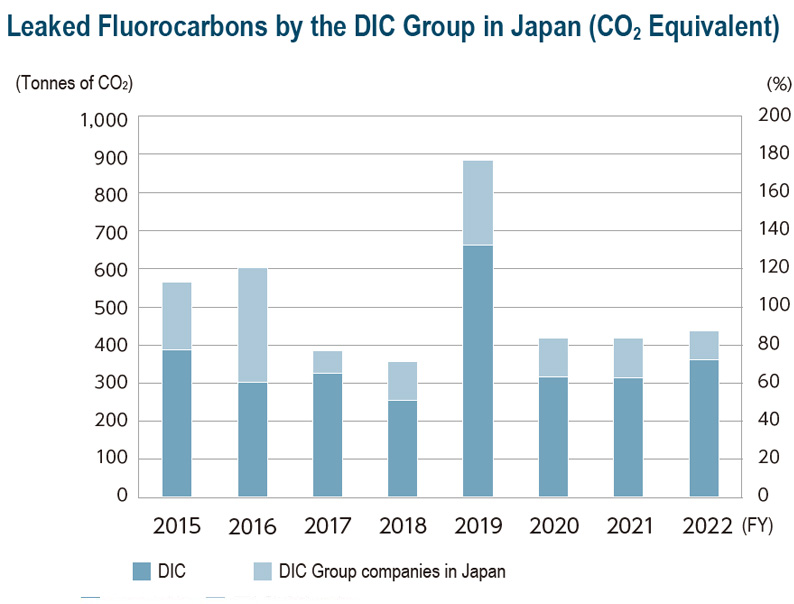

Protecting the Ozone Layer

Hydrofluorocarbons (HFCs) are used widely as refrigerants in

equipment and facilities. While not an ozone-depleting substance

(ODS), HFCs have a warming potential 100–10,000 times that of

CO₂ and their use is expected to account for a 0.5°C increase in the

global average temperature by the end of the 21st century. At the 28th

Meeting of the Parties in Kigali, Rwanda, held in October 2016, the

Parties to the Montreal Protocol on Substances that Deplete the Ozone

Layer reached an agreement to phase out the production and use of

HFCs (the Kigali Amendment). Japan subsequently amended its Act

on the Protection of the Ozone Layer Through the Control of Specified

Substances and Other Measures in line with the amendment, which

as of September 26, 2022, had been ratified by 138 Parties. (Having

surpassed the condition of ratification by at least 20 Parties, the Kigali

Amendment entered into force on January 1, 2019.)

In April 2015, Japan also revised its Fluorocarbons Recovery and

Destruction Law. The same month, the Act on Rational Use and

Proper Management of Fluorocarbons entered into force, compelling

stakeholders to ascertain and report leaks of fluorocarbons from

commercial equipment and facilities.

In fiscal year 2022, leaked fluorocarbons from DIC Group sites were

equivalent to 439 tonnes of CO₂. (Leaks in excess of 1,000 tonnes per

site or per company must be reported to the Japanese authorities.) The

Company has worked to effectively manage fluorocarbons since fiscal

year 2015, when the Act on Rational Use and Proper Management

of Fluorocarbons entered into force, and has managed to keep leaks

below the level requiring reporting. In fiscal year 2022, the Group’s efforts to comply with laws governing leaked fluorocarbons were

recognized in the Japan Refrigerant and Environmental Organization’s

second JRECO Fluorocarbon Rating, which selected it as one of 49

A-rank performers from among 1,840 companies surveyed. Going

forward, the Group will continue working to ensure compliance

with pertinent laws and regulations, as well as to reduce leaked

fluorocarbons from its sites by, among others, choosing air conditioning

equipment with low environmental impact refrigerants, including those

containing no fluorocarbons.

Back number

- Principal Initiatives in Fiscal Year 2023

- Principal Initiatives in Fiscal Year 2022

- Principal Initiatives in Fiscal Year 2021

- Principal Initiatives in Fiscal Year 2020

- Principal Initiatives in Fiscal Year 2019

- Principal Initiatives in Fiscal Year 2018

- Principal Initiatives in Fiscal Year 2017

- Principal Initiatives in Fiscal Year 2016

- Principal Initiatives in Fiscal Year 2015

- Principal Initiatives in Fiscal Year 2014

- Principal Initiatives in Fiscal Year 2013