Preventing Global Warming(2019)

Principal Initiatives in Fiscal Year 2019

01Energy Consumption and CO₂ Emissions by the Global DIC Group

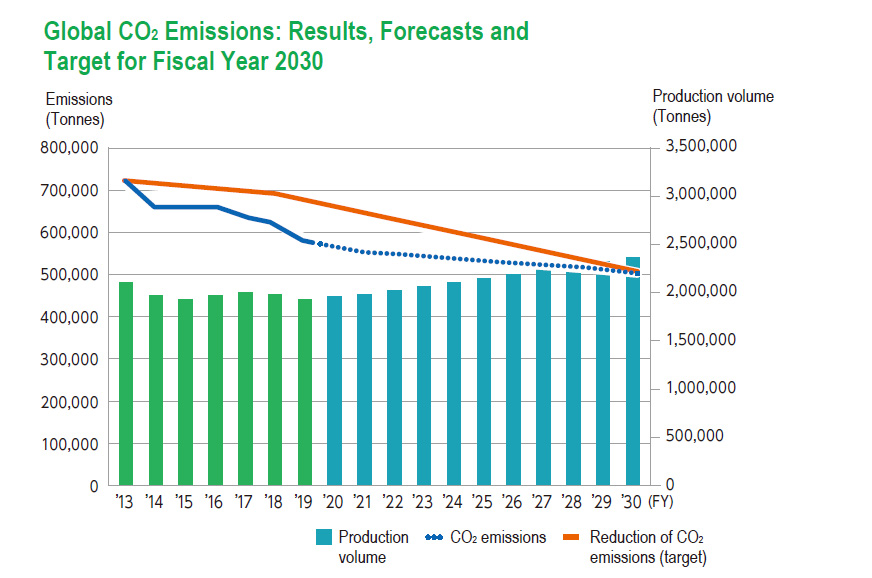

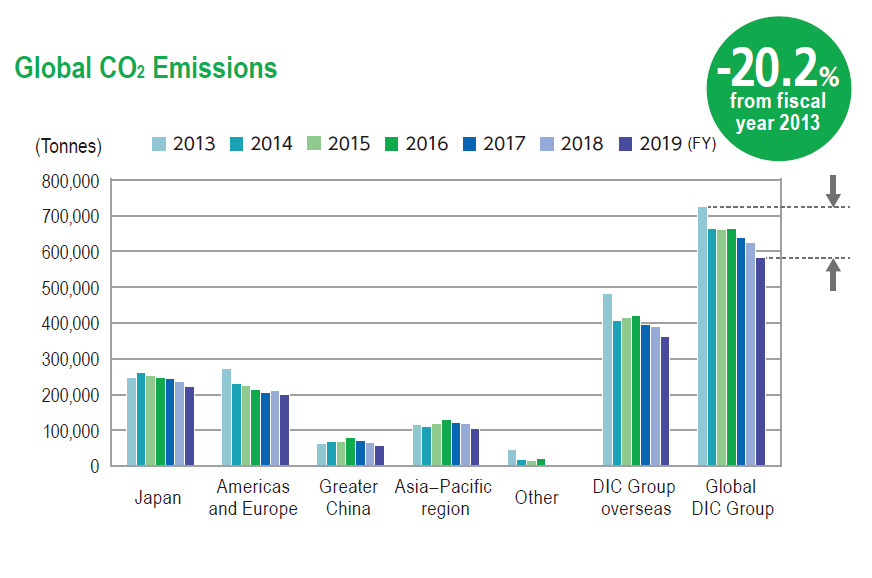

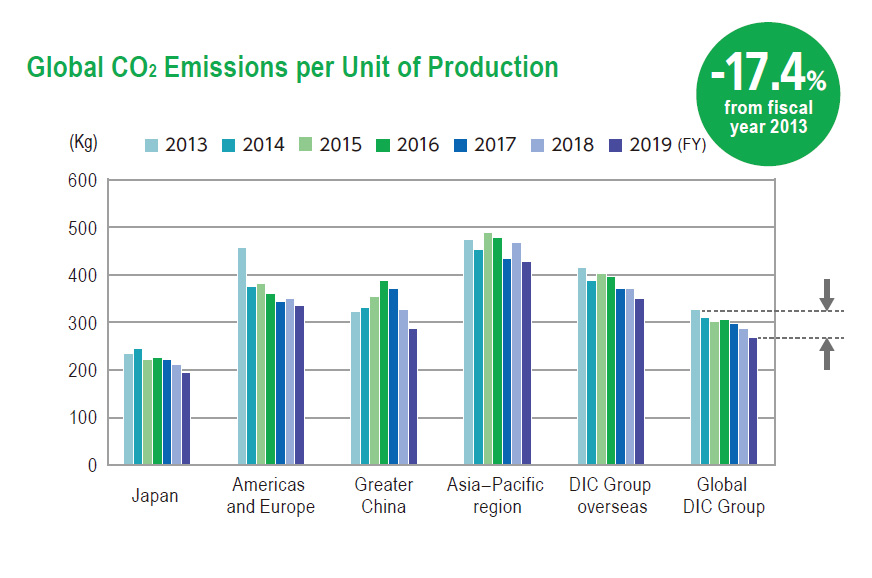

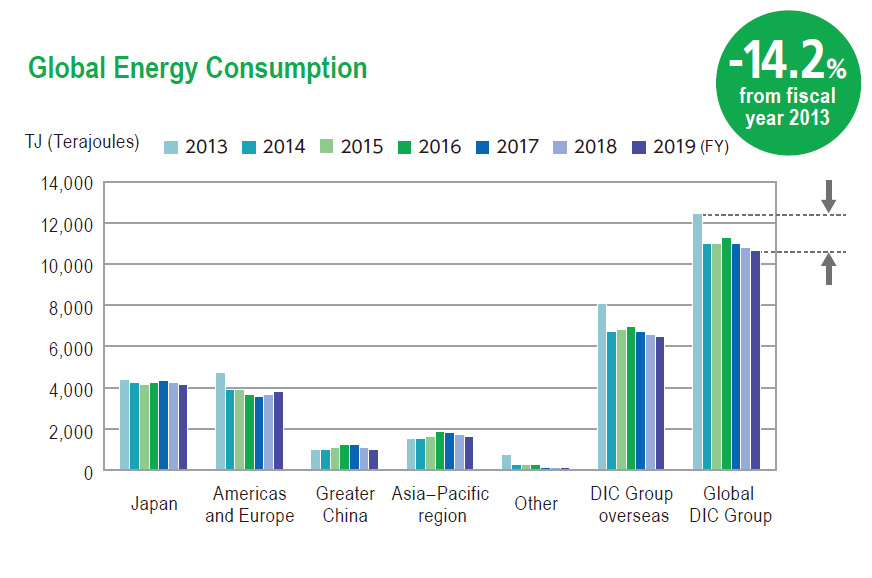

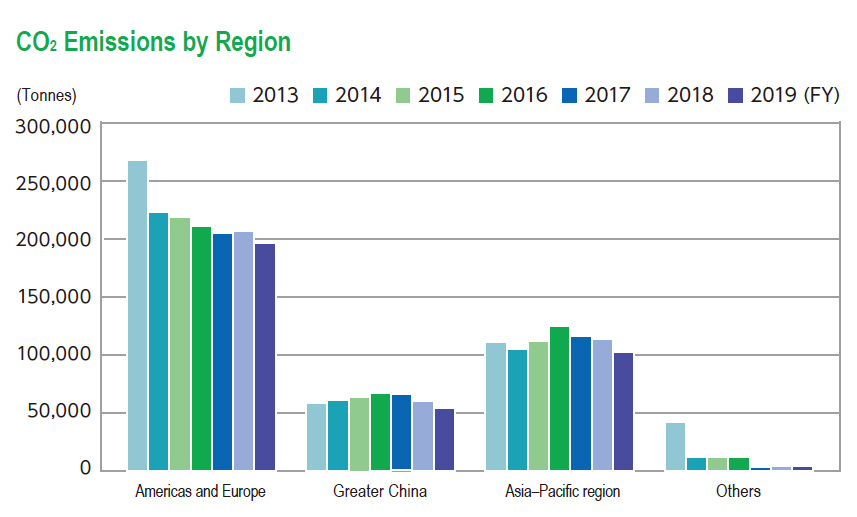

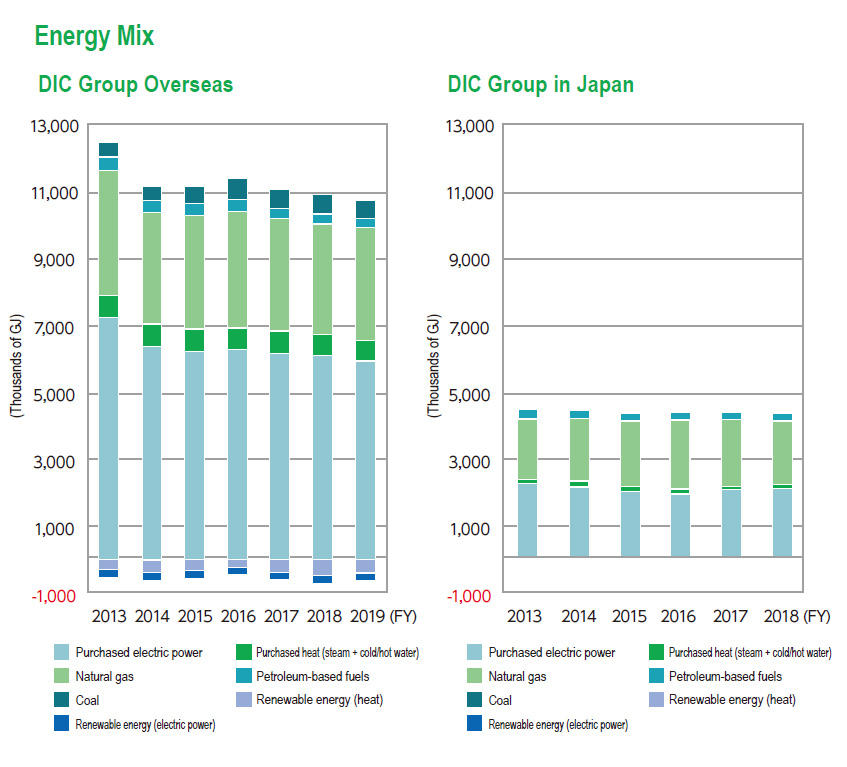

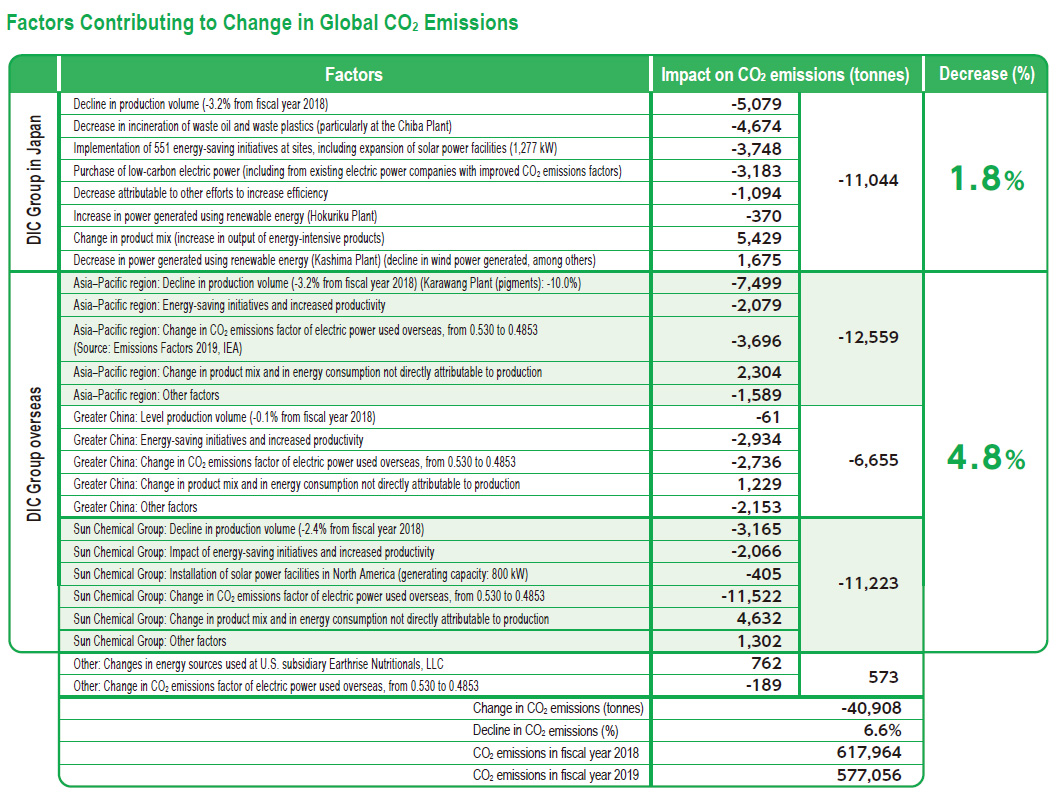

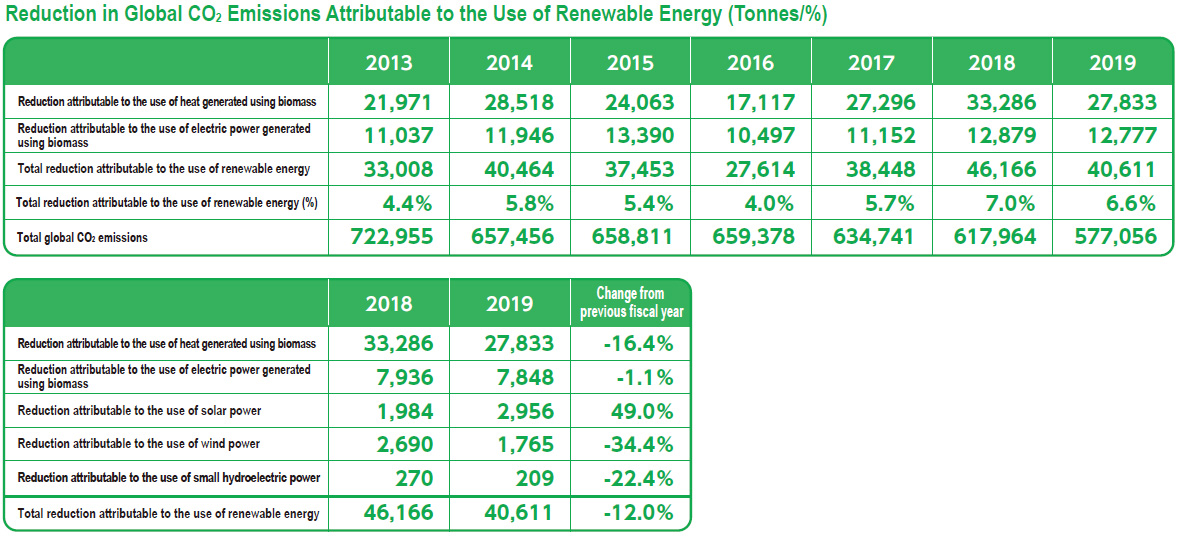

Energy consumption by the global DIC Group in fiscal year 2019 edged down 1.7% from fiscal year 2018 and 14.2% from the fiscal year 2013 base year. CO₂ emissions by the global DIC Group amounted to 577,056 tonnes, down 6.6% from fiscal year 2018 and 20.2% from fiscal year 2013. Global CO₂ emissions per unit of production—expressed in terms of kilograms per tonne—were 270 kilograms, down 7.4% from fiscal year 2018 and 17.4% from the base year.

The DIC Group’s diverse product portfolio includes printing inks, polymers, pigments, LCs, engineering plastics and compounds. Recent years have seen an uptrend in the output of energy-intensive fine chemicals and a downtrend in the output of general-purpose items, the production of which is comparatively energy efficient. Against this backdrop, the Group’s success in achieving a reduction in the volume of CO₂ it emits worldwide in excess of its target for the year included efforts by companies worldwide to break down the target—an annual average decrease of 2.1% from fiscal year 2018, set forth in the DIC111 medium-term management plan to ensure achievement of its long-term target of a 30% reduction from the fiscal year 2013 level by fiscal year 2030—and to promote energy-saving and decarbonization initiatives beyond what had been necessary to achieve its previous annual reduction target of 1.0%. Some of these initiatives are outlined below.

Going forward, the Group will continue to implement a variety of energy-saving measures, including introducing highly efficient facilities, promoting process improvements and improving capacity utilization rates, while at the same time further advancing its use of renewable energy by shifting to biomass and other clean fuels and installing solar power facilities.

02Energy Consumption and CO₂ Emissions by the DIC Group in Japan

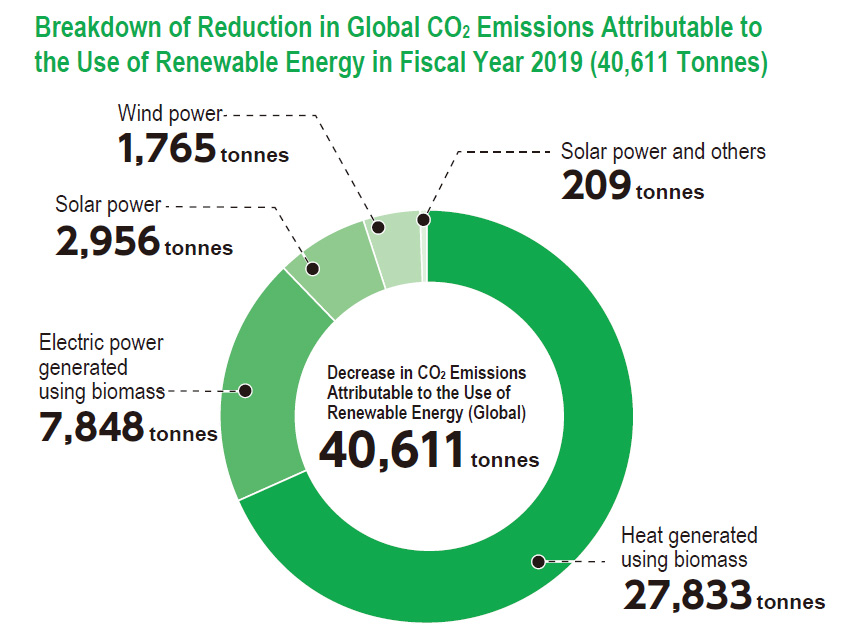

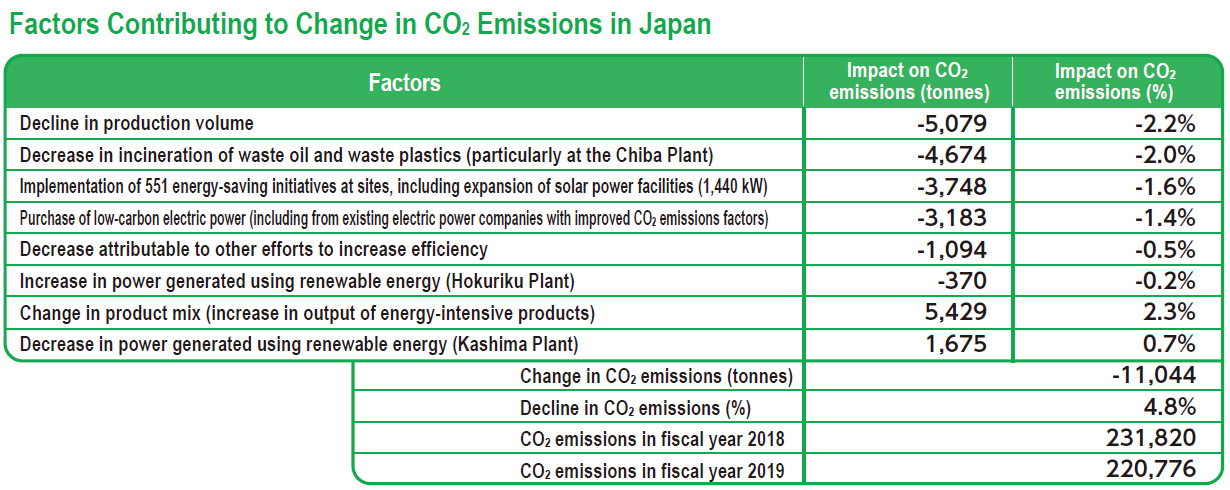

Energy consumption by the DIC Group in Japan—the 52 sites in Japan operated by DIC and domestic Group companies—in fiscal year 2019 edged down 1.7% from fiscal year 2018 and 4.9% from the fiscal year 2013 base year. Energy consumption per unit of production totaled 3.706 GJ/tonne, down 5.1% from fiscal year 2018 and 11.1% from the base year. In contrast, CO₂ emissions by the Group in Japan amounted to 220,776 tonnes, down 4.8% from fiscal year 2018 and 9.7% from fiscal year 2013, while CO₂ emissions per unit of production amounted to 195.6 kilograms, down 8.1% from fiscal year 2018 and 15.6% from the base year.

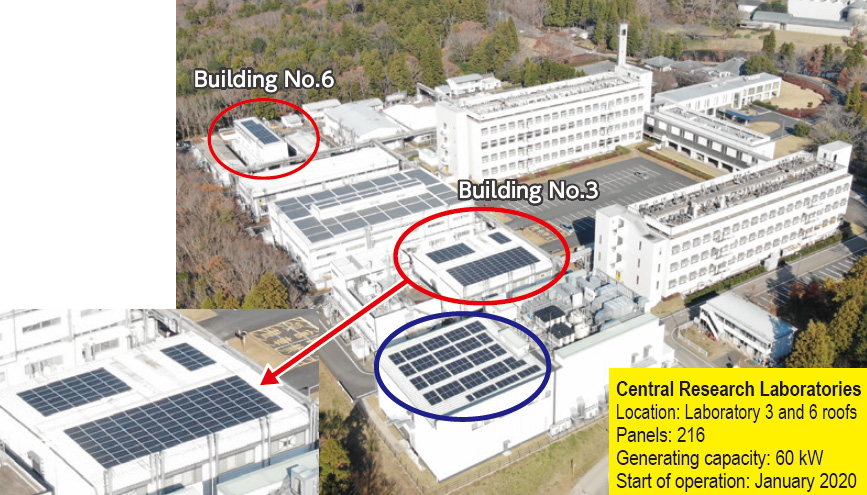

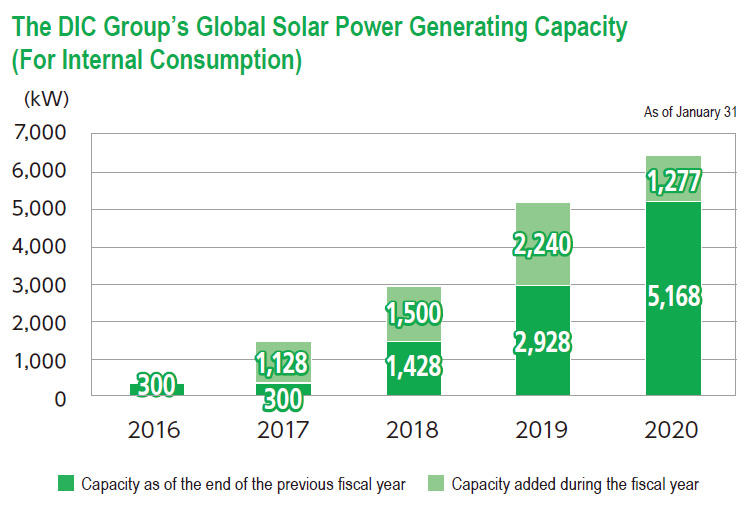

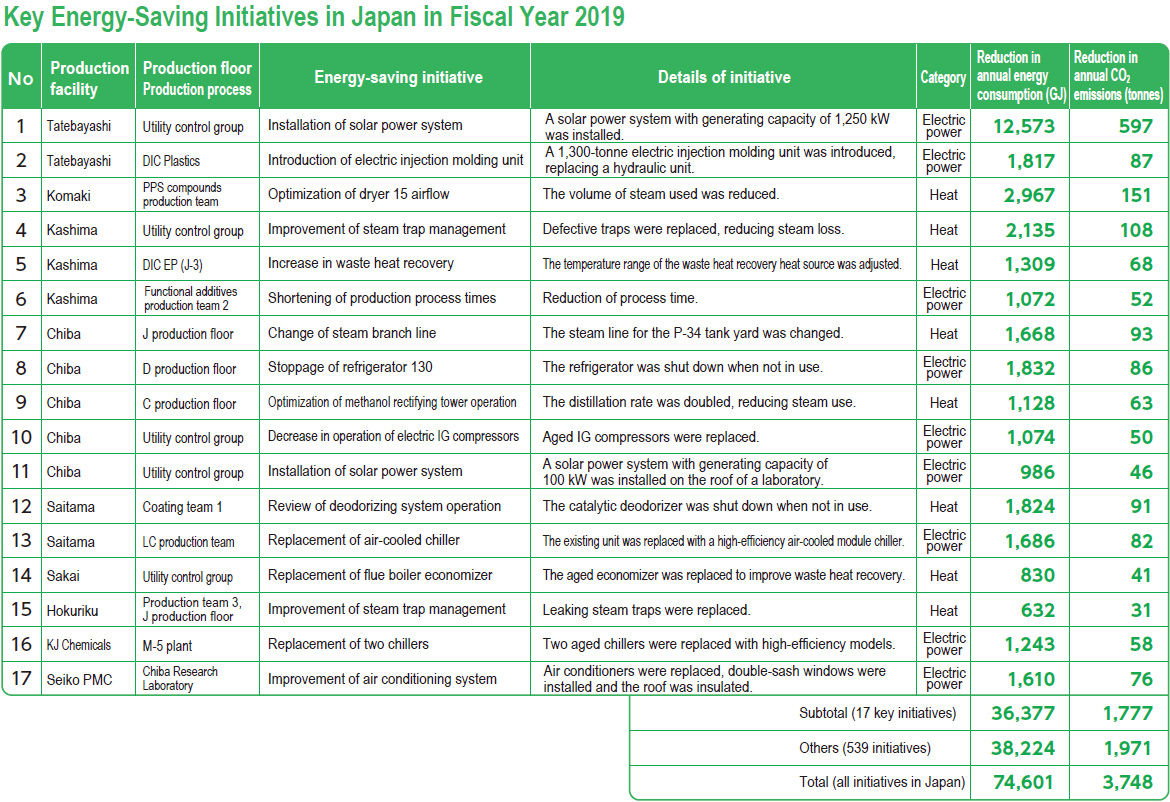

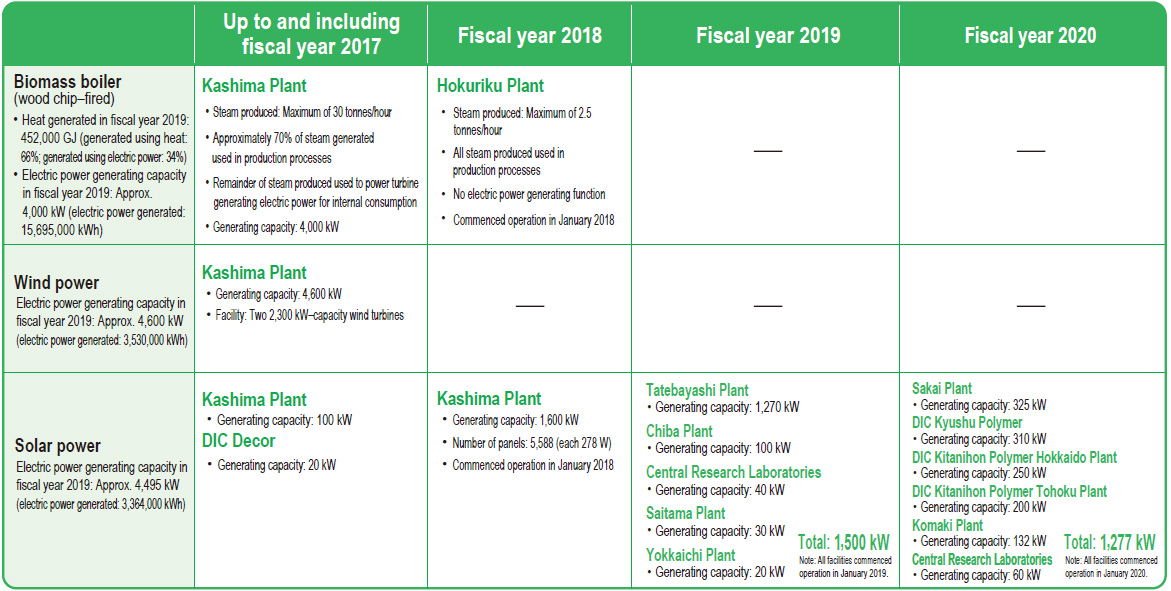

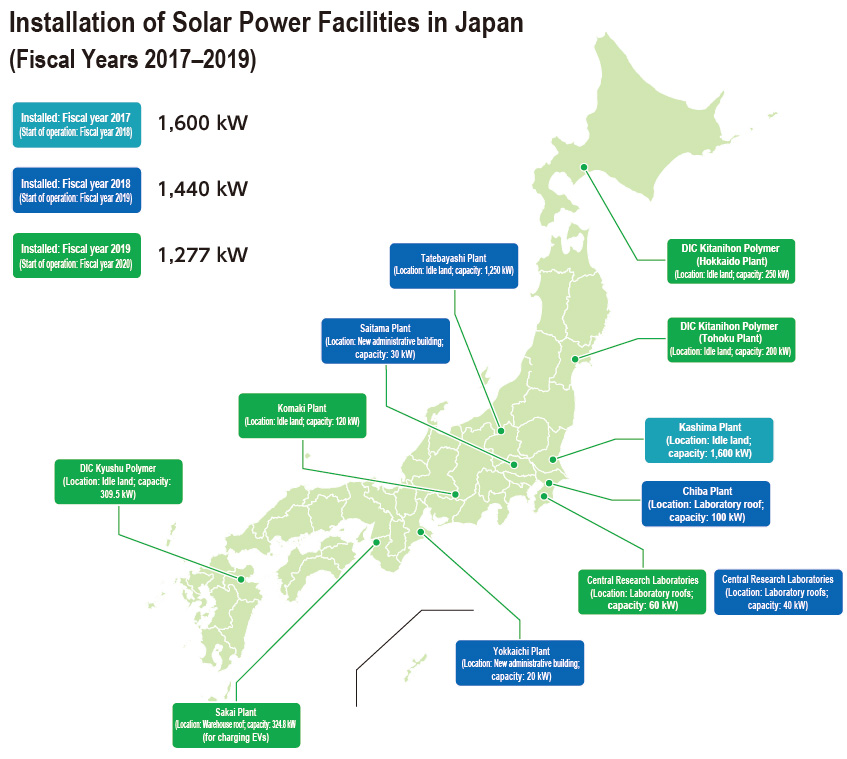

Principal factors behind the decline in CO₂ emissions by the Group in Japan included the implementation of 551 energy-saving initiatives at sites, as well as the start of operations of solar power facilities at five sites, including the Tatebayashi Plant, with a combined annual generating capacity of 1,440 kW. As of December 31, 2019, the total generating capacity of solar power facilities at DIC Group sites in Japan was 3,040 kW (all for internal consumption).

Other contributing factors included the fact that the change in CO₂ emissions attributable to a decrease in production volume was essentially level, despite a 3.4% decline in production volume, owing to an increase in the production of comparatively energy-intensive products. In addition, at the Chiba Plant, a decrease in the incineration of waste oil and waste plastics using a rotary kiln resulted in a decline in emissions attributable to the incineration of waste equivalent to 2.0% of the Group’s fiscal year 2018 production volume.

The DIC Group in Japan purchases a total of 201 million kWh of electric power from domestic electric power companies annually (contract volume: 50,000 kWh) and when renewing annual electric power supply contracts selects suppliers based not only on costs but also low CO₂ emissions factor. In fiscal year 2019, the Group was able to purchase a greater amount of low-carbon electric power than in the previous period, which accounted for a 1.4% decrease in domestic CO₂ emissions. Looking ahead, the Group will continue working to expand its purchases of low-carbon electric power.

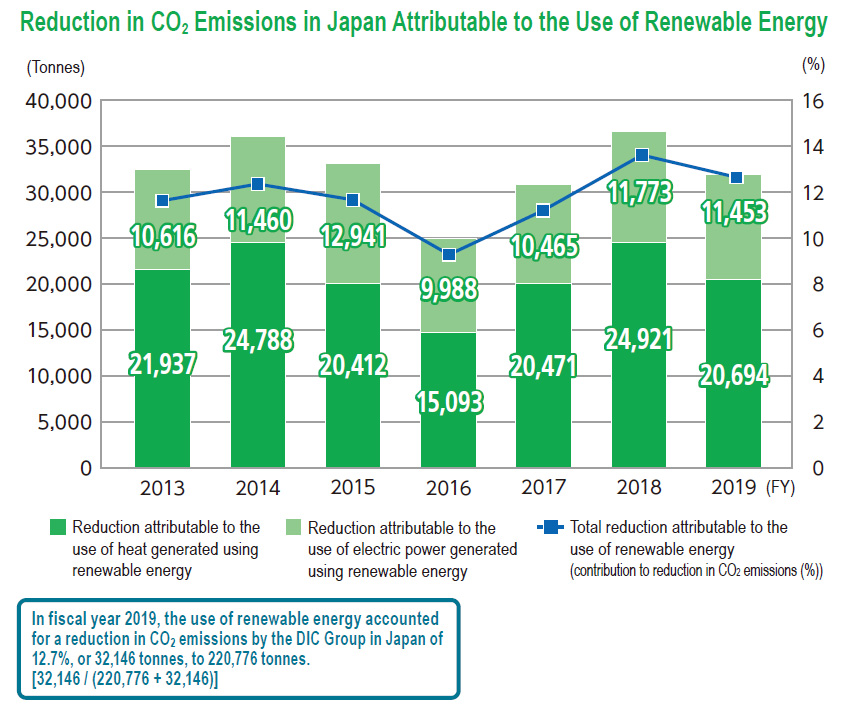

03Efforts to Promote the Use of Renewable Energy in Japan Renewable Energy as a Percentage of Total Energy Used in Japan: 11.0%

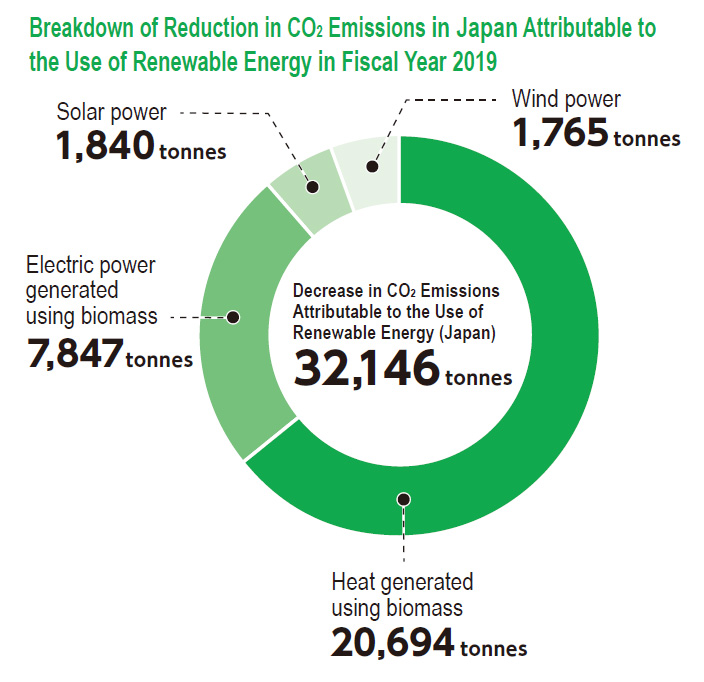

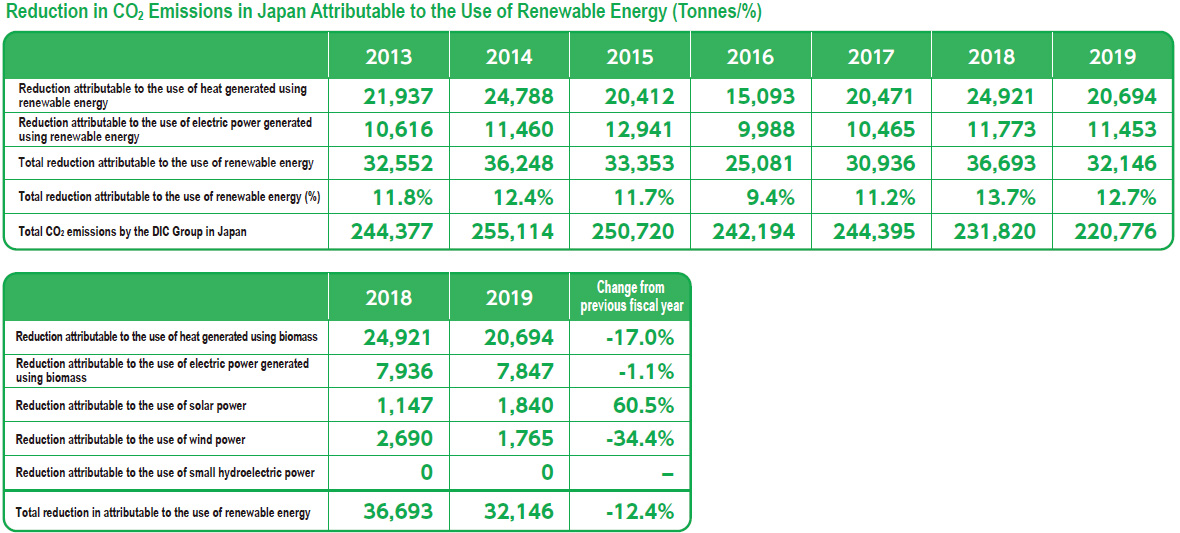

The bulk of renewable energy used by DIC Group companies in Japan is natural energy generated by a biomass boiler and wind and solar power facilities at the Kashima Plant. In fiscal year 2019, DIC Group companies in Japan used 519,000 GJ of renewable energy (equivalent to 13,391 kl of crude oil), down 11.5% from fiscal year 2018 and representing 11.0% of total energy (heat and electric power) consumed by these companies. The decrease in renewable energy use was attributable to a variety of factors, including a sharp drop in the amount of electric power generated by the Kashima Plant’s wind power system (two 2,300 kW–capacity wind turbines) as a result of repairs, which required close to three months to complete, and a decline in the positive impact of biomass boiler performance.

In fiscal year 2019, DIC completed the installation of solar power systems at five sites in Japan (the Tatebayashi, Chiba, Saitama and Yokkaichi plants and the Central Research Laboratories) with a combined annual generating capacity of 1,440 kW. As a consequence, the total generating capacity of solar power facilities at DIC Group sites in Japan as of December 31, 2019, was 3,040 kW. Solar power generated by the DIC Group in Japan in fiscal year 2019 soared 71.0%, to 3,364,000 kWh, from 1,968,000 kWh in fiscal year 2018.

The use of renewable energy by DIC Group companies in Japan in fiscal year 2019 accounted for a reduction in CO₂ emissions of 32,146 tonnes, or 12.7%, from the previous fiscal year.

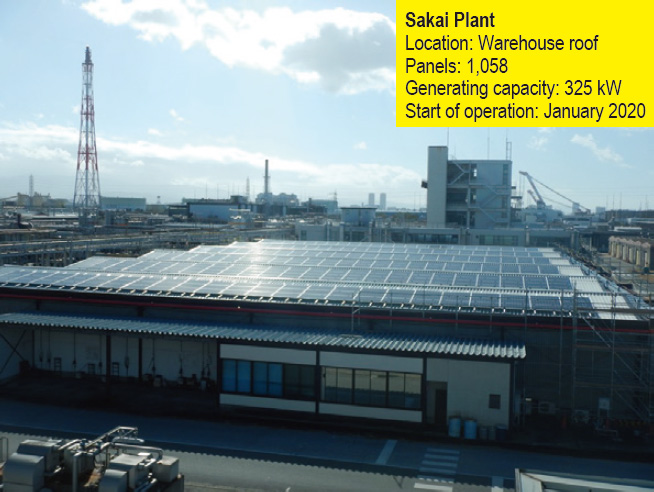

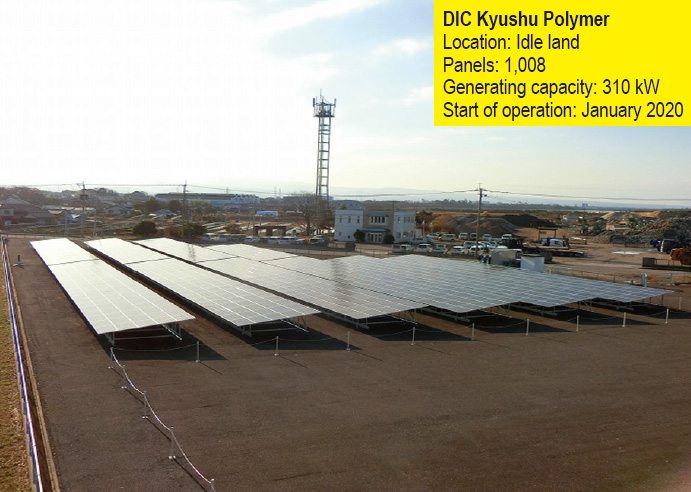

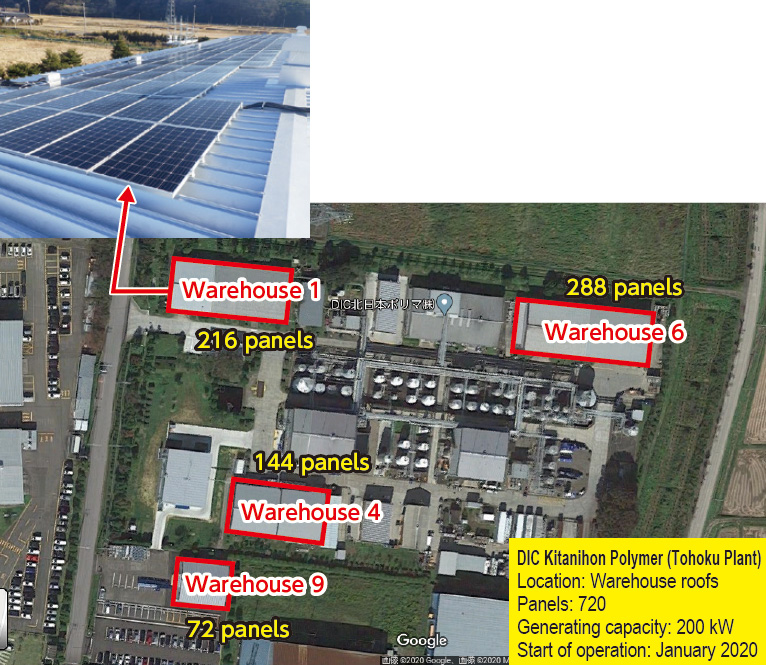

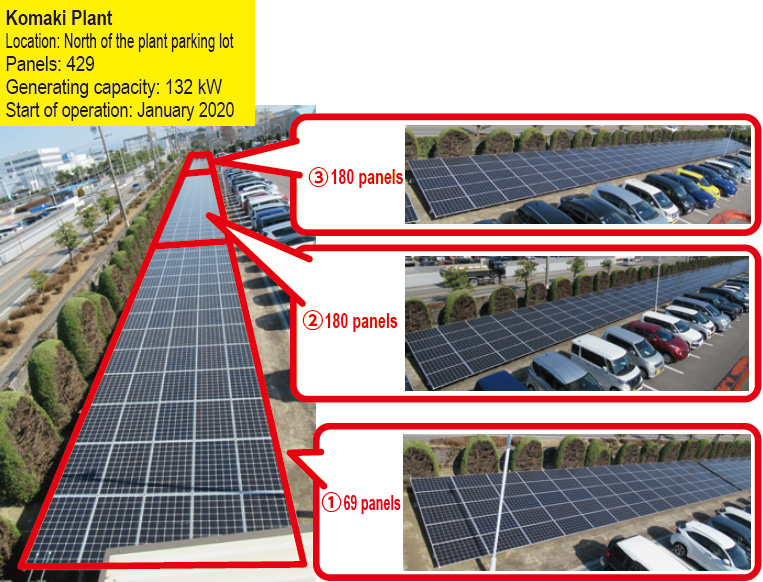

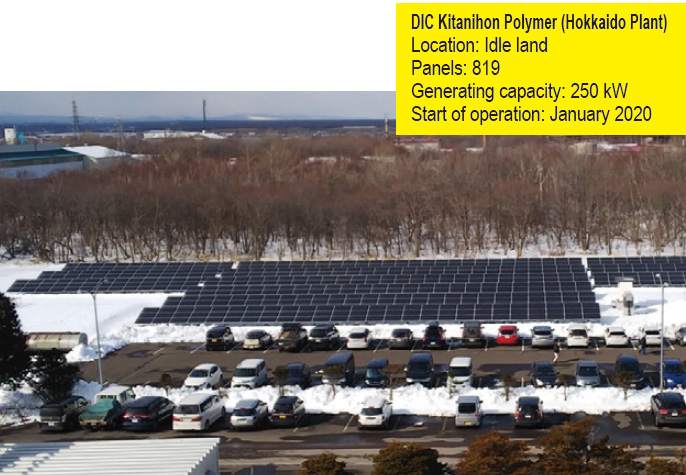

In fiscal year 2020, DIC will install solar power facilities at an additional six sites in Japan (the Sakai and Komaki plants, the Central Research Laboratories and Group companies DIC Kyushu Polymer Co., Ltd., and DIC Kitanihon Polymer Co., Ltd. (the Hokkaido and Tohoku plants)), which will add 1,277 kW (all for internal consumption) to the Group’s domestic solar power generating capacity, began operating in January 2020. Going forward, DIC will continue to take decisive steps to advance its use of renewable energy with the aim of achieving its long-term target for reducing emissions of CO₂ from DIC Group sites by 30% from the fiscal year 2013 level by fiscal year 2030.

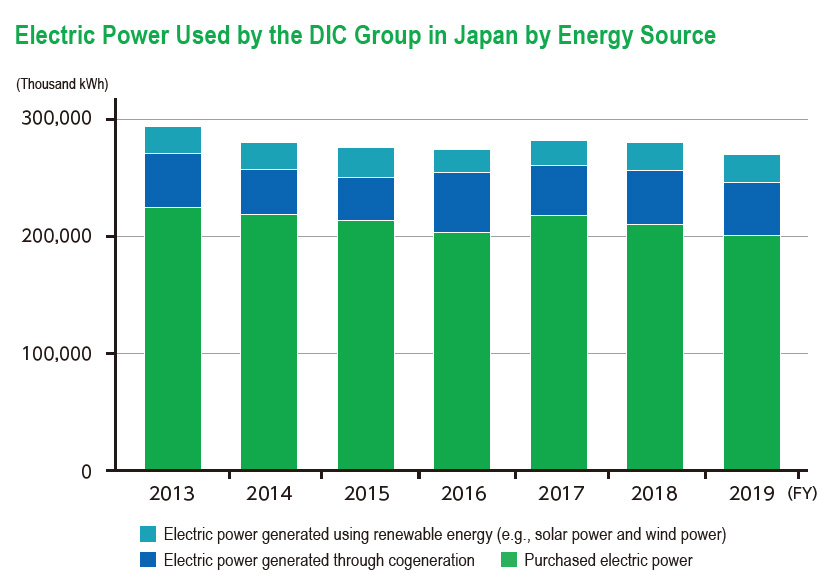

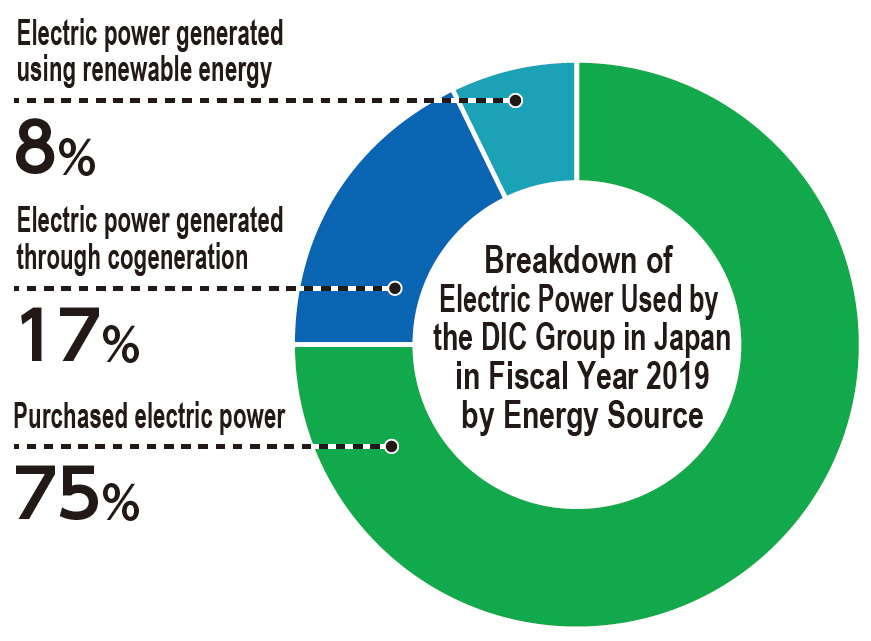

04Independent Electric Power Generation in Japan

In fiscal year 2019, electric power consumption by the DIC Group in Japan declined 2.9% from the previous fiscal year, to 270,970,000 kWh, approximately 25.1% of which was generated independently, with electric power generated using renewable energy accounting for 8.3% and that generated using cogeneration systems representing 16.8%. While independently generated solar power was up from fiscal year 2018, wind power edged down 0.9%.

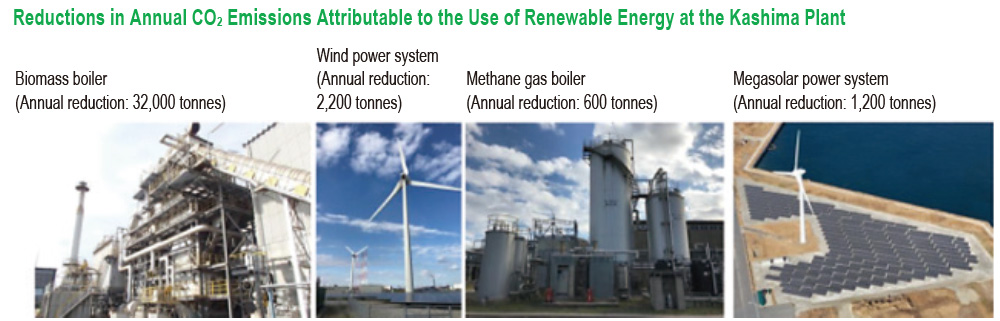

DIC Wins New Energy Foundation Chairman’s Award in the Adoption and Application Category of the 2018 New Energy Awards

In December 2018, DIC won a New Energy Foundation Chairman’s Award in the Adoption and Application Category of the 2018 New Energy Awards in recognition of the expanded use of renewable energy at the Kashima Plant. The awards program, which was presented by the New Energy Foundation, was established with the aim of encouraging the introduction of new energy and promoting awareness by commending particularly excellent initiatives.

The Kashima Plant has installed multiple renewable energy–powered generating facilities, including biomass and methane gas boilers, as well as wind power and solar power systems. As a consequence, 50% of electric power and 80% of heat consumed annually by the site is generated by using renewable energy. These facilities also contributed to a reduction in annual CO₂ emissions in fiscal year 2018 of more than 36,000 tonnes. Looking ahead, the department responsible for the plant’s energy supply will continue working to enhance the combustion efficiency of generating facilities, including biomass and methane gas boilers, by upgrading maintenance and management technologies and accumulating know-how.

The Chairman’s Award recognizes the positive results of these steadfast efforts. DIC will deploy know-how accumulated by the Kashima Plant at sites both in Japan and overseas with the aim of increasing its use of renewable energy and reducing its emissions of greenhouse gases around the world.

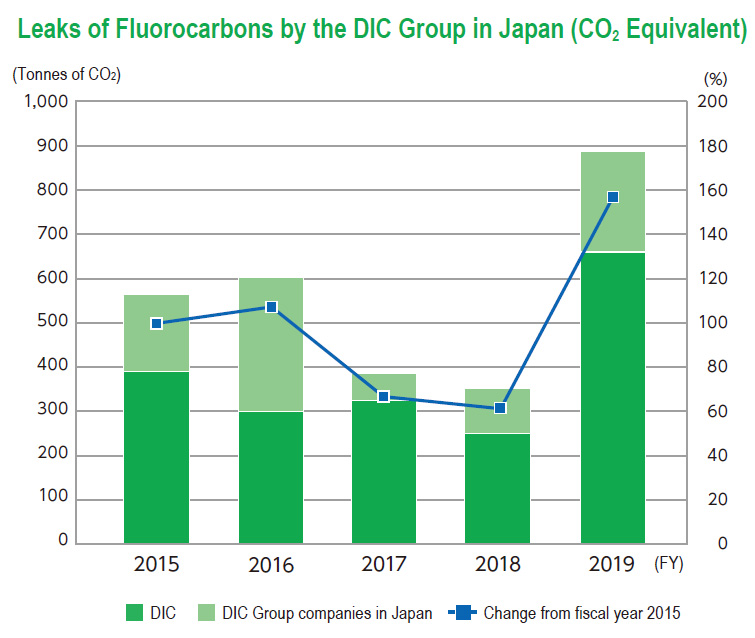

05Protecting the Ozone Layer

Hydrofluorocarbons (HFCs) are used widely as refrigerants in equipment and facilities. While not an ozone-depleting substance (ODS), HFCs have a warming potential 100–10,000 times that of CO₂ and their use is expected to account for a 0.5°C increase in the global average temperature by the end of the 21st century. At the 28th Meeting of the Parties in Kigali, Rwanda, held in October 2016, the Parties to the Montreal Protocol on Substances that Deplete the Ozone Layer reached an agreement to phase out the production and use of HFCs (the Kigali Amendment). Japan subsequently amended its Act on the Protection of the Ozone Layer Through the Control of Specified Substances and Other Measures in line with the amendment, which as of January 10, 2019, had been ratified by 65 Parties. Having surpassed the condition of ratification by at least 20 Parties, the Kigali Amendment entered into force on January 1, 2019.

In April 2015, Japan also revised its Fluorocarbons Recovery and Destruction Law. The same month, the Act on Rational Use and Proper Management of Fluorocarbons entered into force, compelling stakeholders to ascertain and report leaks of fluorocarbons from commercial equipment and facilities.

In fiscal year 2019, leaked fluorocarbons from DIC sites amounted to 886 tonnes of CO₂. (Leaks in excess of 1,000 tonnes per site or per company must be reported to the Japanese authorities.) The Company has worked to effectively manage fluorocarbons since the Act on Rational Use and Proper Management of Fluorocarbons entered into force in 2015 and has managed to keep leaks below the level requiring reporting. Leaked fluorocarbons in fiscal year 2019 were higher than in an average year as a consequence of the replacement of a substantial number of chillers. (Leaked fluorocarbons are calculated as the difference between amount filled into new equipment and amount recovered when equipment is dismantled.) The DIC Group will continue to select air conditioning and other equipment using nonfluorocarbon and other refrigerants that do not negatively impact the environment with the aim of reducing the amount of leaked fluorocarbons for which it is responsible.

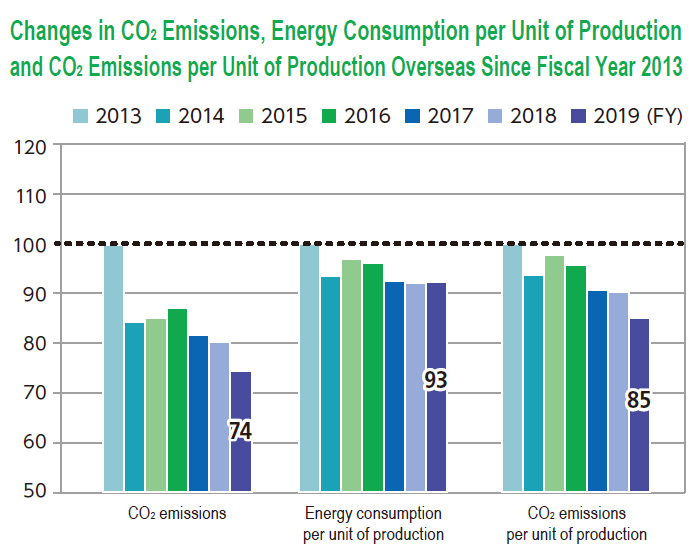

06Energy Consumption and CO₂ Emissions by the DIC Group Overseas

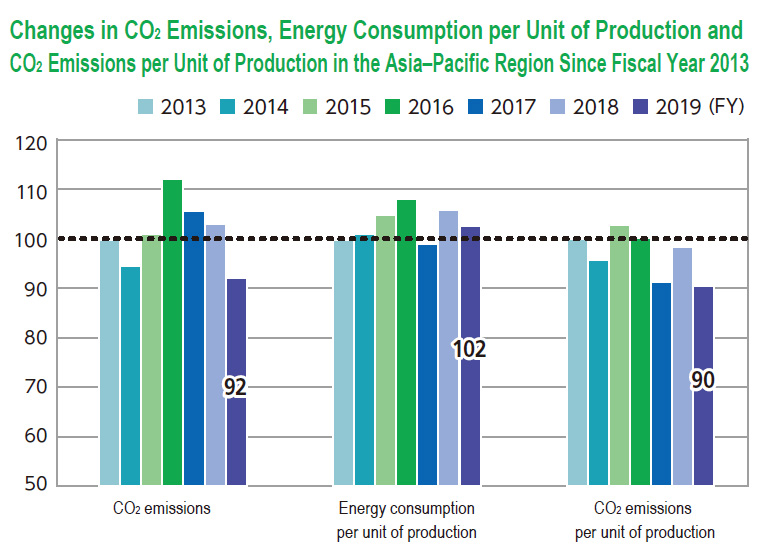

With production volume by the DIC Group overseas in fiscal year 2019 down 2.1% from fiscal year 2018, CO₂ emissions declined 7.7%, or 25.6% from the fiscal year 2013 base year, and CO₂ emissions per unit of production declined 5.7%, or 14.7% from fiscal year 2013. Energy consumption edged down 1.7%, or 19.2% from the base year.

Factors contributing to the decrease in CO₂ emissions included efforts by individual DIC Group companies to break down the Group’s emissions reduction targets and promote decarbonization initiatives, the installation of solar power facilities with an annual generating capacity of approximately 800 kW by Sun Chemical in the United States, and the improvement of the CO₂ emissions factors of electric power consumed by overseas Group companies in line with the factors published by the International Energy Agency (IEA).

Laws and regulations, as well as infrastructure, differ between countries and regions. The DIC Group strives to promote energy savings and efficient operations wherever it is active and in so doing sets precedents for the global chemicals industry.

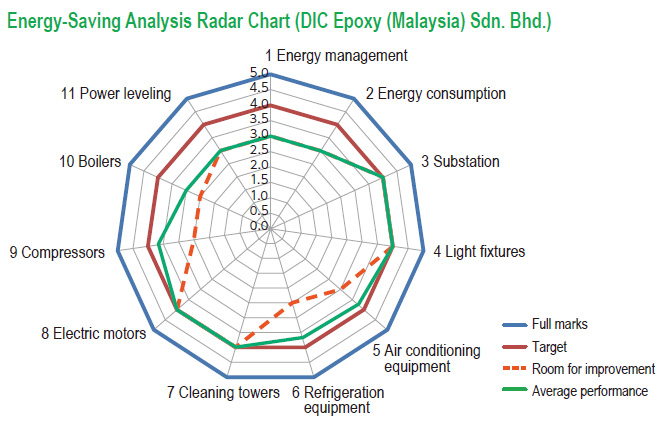

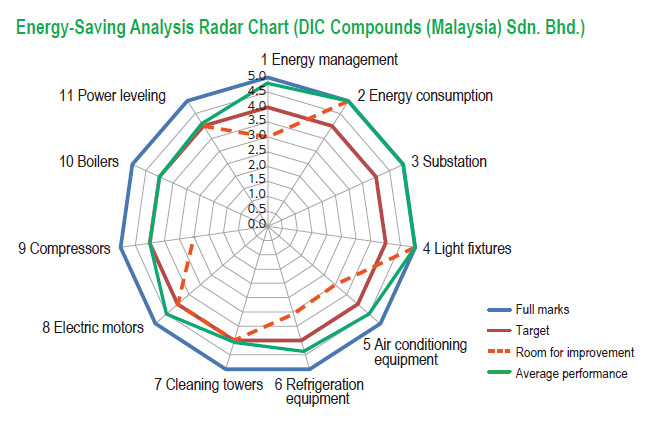

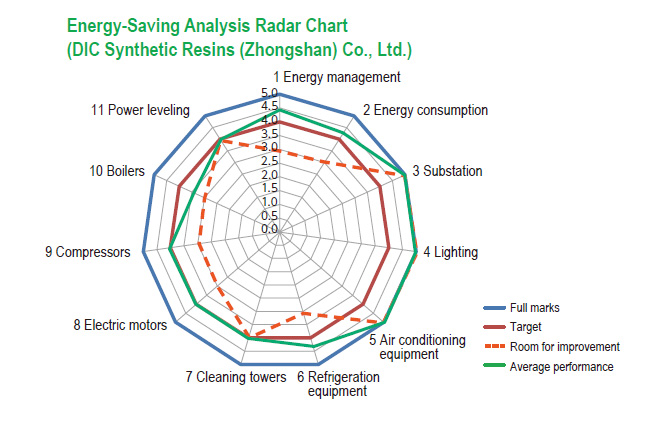

DIC Group companies overseas continue to implement a broad range of energy-saving initiatives, including improving production efficiency, reducing base load energy consumption, choosing high-efficiency models when replacing equipment and switching to LED lighting. The Group is also promoting the increased use of renewable energy. In fiscal year 2019, Sun Chemical, based in the United States, installed solar power facilities with an annual generating capacity of approximately 800 kW. In addition, corporate headquarters continued stepping up collaboration with overseas Group companies through energy-saving analyses and support for individual projects. During the period, energy-saving analyses were conducted at two sites in the Asia–Pacific region (DIC Compounds (Malaysia) and DIC Epoxy (Malaysia) Sdn. Bhd.) and one site in Greater China (DIC Synthetic Resins (Zhongshan)). At the same time, a project was promoted whereby effective initiatives are awarded “Good Job” accreditation and deployed horizontally at Group companies in Japan. This initiative also involves using the process of introducing best practices at production facilities as an opportunity to foster young employees.

Asia–Pacific Region

The 22 DIC Group sites in the Asia–Pacific region account for roughly 18% of the Group’s total global CO₂ emissions. Production volume in fiscal year 2019 was down 3.2% from fiscal year 2018, although it was up 1.9% from the fiscal year 2013 base year. Energy consumption by Group companies across the region decreased 6.6% from the previous fiscal year, but was 4.5% higher than in the base year, while CO₂ emissions declined 10.9% from fiscal year 2018, or 7.8% from fiscal year 2013. Indonesia is home to the Group’s mother plant for pigments, production of which is comparatively energy intensive. The pigments business accounts for more than 50% of energy consumption and CO₂ emissions in the Asia–Pacific region, underscoring its influence on results for the region as a whole. Accordingly, the Group continues to promote a variety of initiatives to reduce the business’ CO₂ emissions by reducing energy consumption, including by replacing a portion of the coal used to fire boilers with palm kernel shells (PKS), a biomass fuel, an effort that began in fiscal year 2016 and earning certification under ISO 50001, the International Organization for Standardization’s benchmark for energy management systems.

Since fiscal year 2014, the DIC Group has conducted energy-saving analyses overseas as well as in Japan. In fiscal year 2019, energy-saving analyses were conducted at two companies in the Asia–Pacific region: DIC Epoxy (Malaysia) and DIC Compounds (Malaysia). As part of its effort to ensure achievement of the CO₂ emissions target set for the global DIC Group, corporate headquarters assists regional Group companies by formulating and implementing energy-saving plans; promoting ongoing energy-saving analyses to support the identification of energy-saving themes and the implementation of remedial measures; deploying a practical energy management manual and best practice case study materials to establish management practices and promote horizontal deployment; and launching and providing support for energy-saving and carbon-reduction projects at suitable sites.

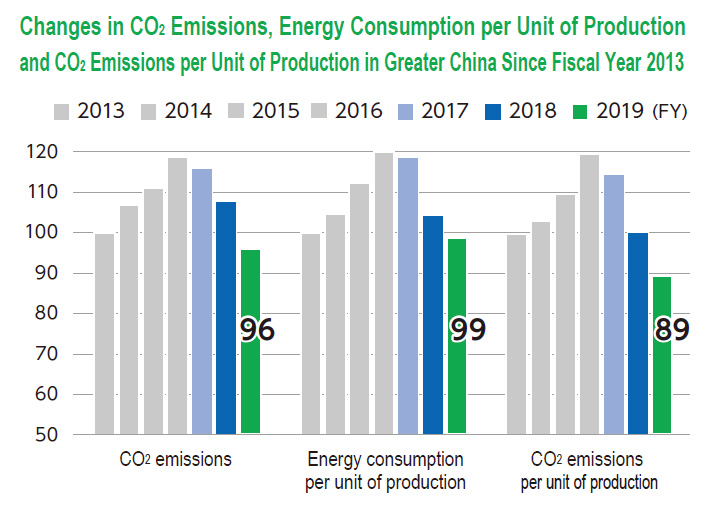

Greater China

The DIC Group’s 18 sites in Greater China account for approximately 9% of the Group’s total global CO₂ emissions. Production volume in fiscal year 2019 was essentially level with fiscal year 2018, but up 7.5% from the fiscal year 2013 base year. Nonetheless, energy consumption by Group companies across the region was down 5.5% from the previous fiscal year, although it was 6.0% higher than in the base year, while CO₂ emissions declined 10.8% from fiscal year 2018, or 3.8% from fiscal year 2013. The fact that energy consumption declined 5.5% despite a higher production volume was attributable primarily to significant improvements in energy consumption per unit of production at manufacturers Nantong DIC Color (pigments and inks) and Changzhou Huari New Material (synthetic resins), both of which operate large-scale production facilities in the region, underpinned by the implementation of energy-saving measures.

Qingdao Liquid Crystal, which manufactures LC materials, installed solar power facilities with an annual generating capacity of 400 kW in April 2017 and has implemented energy-saving measures in the years since—namely, the systematic replacement of existing air conditioning equipment and light fixtures—that have contributed to a sharp improvement in energy consumption per unit of production. As a consequence, the company’s CO₂ emissions in fiscal year 2019 were down 10.8% from fiscal year 2018.

As in the Asia–Pacific region, the DIC Group has conducted energy-saving analyses in Greater China since fiscal year 2014. In fiscal year 2019, an energy-saving analysis was conducted at DIC Synthetic Resins (Zhongshan), located in the southern part of the PRC.

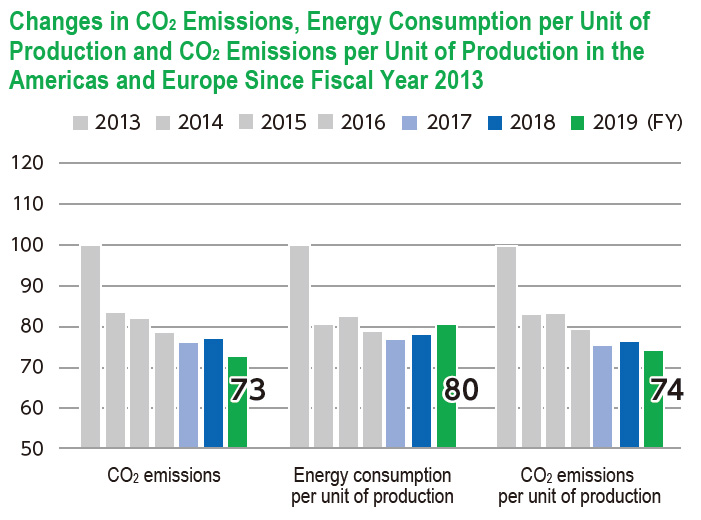

Americas and Europe

The DIC Group has 122 sites in the Americas and Europe (this category also includes sites in Africa), which account for roughly 34% of the Group’s CO₂ emissions. In fiscal year 2019, production volume was down 2.4% from the previous fiscal year and 1.7% from the fiscal year 2013 base year. Energy consumption by DIC Group companies across the region rose 1.3% from the previous period, but was down 21.0% from fiscal year 2013, while CO₂ emissions declined 5.4% from fiscal year 2018 and 27.3% from the base year.

DIC Group companies in the Americas and Europe promote a variety of measures with the aim of lowering CO₂ emissions. These include making use of biomass energy (landfill biogas), solar and small hydroelectric power; employing outsourcing to contract energy-efficiency consultants, among others, to advance the reduction of energy consumption; and integrating and enhancing the efficiency of regional production facilities. These initiatives have yielded consistently positive results since fiscal year 2014.

In fiscal year 2019, the Group’s regional headquarters, Sun Chemical, installed solar power facilities with an annual generating capacity of approximately 800 kW with the goal of expanding its use of renewable energy. Going forward, companies in the Americas and Europe will continue to implement ambitious initiatives that contribute to the reduction of its global CO₂ emissions.

Sun Chemical’s Approach to Sustainability

Sun Chemical promotes innovation with the aim of improving the sustainability of its manufacturing processes and products, maintaining a constant awareness of environmental impact. The company strives to use manufacturing processes that demonstrate environmental excellence through reduced waste generation, lower energy and water use, and a strong safety performance as measured using key metrics such as greenhouse gas emissions, energy and water consumption, carbon footprint and safety record. Sun Chemical is also committed to meeting local regulatory requirements in the countries and territories in which it operates and to working proactively with government, industry organizations and business partners in its value chain to better define, measure and promote sustainability.

Product stewardship and risk management are important components of Sun Chemical’s sustainability policy. The company continues to take a responsible, analytically based approach to fulfilling its role as a steadfast leader in this area. Through such ongoing efforts, the company increases environmental efficiency by helping its customers enhance the sustainability of their manufacturing processes and products. Sun Chemical’s longstanding reputation for quality, service and innovation and its dedication to improving sustainability influences both its daily operations and its global strategic direction.

Along with DIC, Sun Chemical has committed to a long-term strategic target for CO₂ emissions, which is to achieve a reduction of at least 30% by fiscal year 2030, with fiscal year 2013 as the base year, following the Paris Agreement, which succeeded the Kyoto Protocol (1990–2012) as the global framework for addressing the challenge of dealing with greenhouse gas emissions. This level, if implemented across all industries, would limit the increase in global average temperature due to climate change to below 2.0°C above pre-industrial levels. To achieve this target, Sun Chemical will focus on investments in sustainable energy, as well as on measures to improve the efficiency of its manufacturing processes.

Sun Chemical Steps Up Investment in Renewable Energy by Introducing Solar Panels

Sun Chemical has concluded a solar power purchase agreement (PPA) with Onyx Renewable Partners and installed solar panels on the roof of the parking structure at its R&D site in Carlstadt, in the U.S. state of New Jersey. The use of clean energy thus generated was expected to reduce the facility’s carbon footprint. Installation of the panels began in fall 2017 and was completed in January 2018. The system came on line in March 2018.

Sun Chemical has since completed a year-round solar panel operating configuration at the site that makes it possible to generate enough solar power on sunny days to satisfy 90% of the site’s needs. Between May 14, 2018 and May 13, 2019, the system generated a total of 871 MWh of power, reducing CO₂ emissions by an estimated 1,358,092 pounds (616 tonnes) over the same period.

Adoption of Renewable Energy by DIC Group Companies Overseas

Against a global trend toward decarbonization, including by popularizing the use of renewable energy, DIC Group companies in the Asia– Pacific region, Greater China, and the Americas and Europe are making use of government subsidies and support to, for example, install biomass boilers and solar power facilities. In fiscal year 2019, new solar power facilities with a combined annual generating capacity of 2,320 kW (1,440 kW in Japan and 800 kW in the United States) commenced operation. In January 2020, additional new facilities with an annual generating capacity of 1,277 kW came on line. Accordingly, as of January 2020 the Group’s global solar power generating capacity (for internal consumption) was 6,445 kW, comprising 4,341 kW in Japan and 2,104 kW overseas. The Group will continue to promote efforts to expand its solar power generating facilities worldwide.

In contrast, owing to the suspension of operations of the Kashima Plant’s wind power system (two 2,300 kW–capacity wind turbines) for approximately three months for repairs, wind power generated in fiscal year 2019 fell 34.0%, to 3,530,000 kWh, from 5,379,000 kWh in the previous fiscal year. In addition, renewable energy generated by the Kashima Plant’s biomass boiler (maximum steam produced: 30 tonnes/ hour; annual generating capacity: 4,000 kW) declined 12%, to 451,751 GJ, from 514,466 GJ in fiscal year 2018.

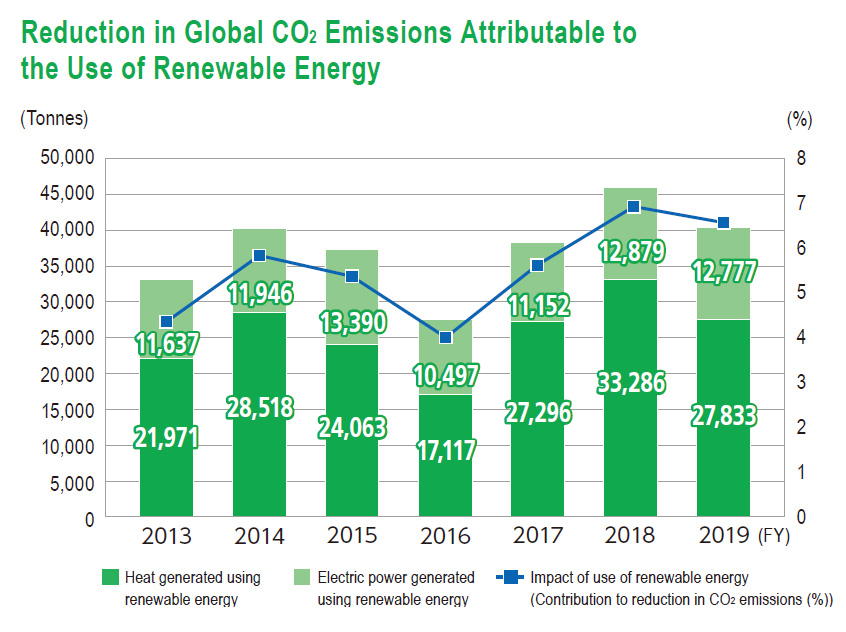

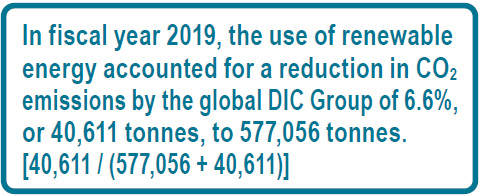

In fiscal year 2019, the DIC Group’s use of PKS, a biomass fuel, at its pigments production facility in Indonesia declined 16%, to 48,738 tonnes, from 58,308 tonnes in fiscal year 2018. This was commensurate with a decrease in the amount of mainstay fuel coal used (because the percentage of coal in the fuel mix is fixed). As a consequence, the global DIC Group used a total of 650,996 GJ of renewable energy in fiscal year 2019, down 10.6% from 728,183 GJ in fiscal year 2018. The use of renewable energy accounted for a reduction in the Group’s global CO₂ emissions of 40,611 tonnes.

Initiatives in Areas Other than Production (Offices and Research Facilities)

In fiscal year 2019, energy consumed by the DIC Group’s 21 offices and research facilities in Japan (excluding the Central Research Laboratories) declined 6.0%. Of particular note, DIC’s headquarters, the most energy intensive of the 21 domestic sites, achieved a decrease of 3%. Energy consumption by the eight offices and research facilities of DIC Group company Seiko PMC Corporation declined 13%, owing primarily to the replacement of air conditioning equipment and light fixtures at its Chiba Research Laboratory with high-efficiency units. Principal energy-saving initiatives implemented include replacing aged light fixtures and air conditioning equipment with newer, highefficiency models that satisfy standards set by the Energy Conservation Center, Japan (ECCJ) for its Top Runner program, turning off lights when not needed and implementing mandatory 22°C winter and 28ºC summer air conditioning settings, working with facility management companies to implement diligent energy-saving measures and promoting efforts in line with Japan’s Cool Biz and Warm Biz campaigns.

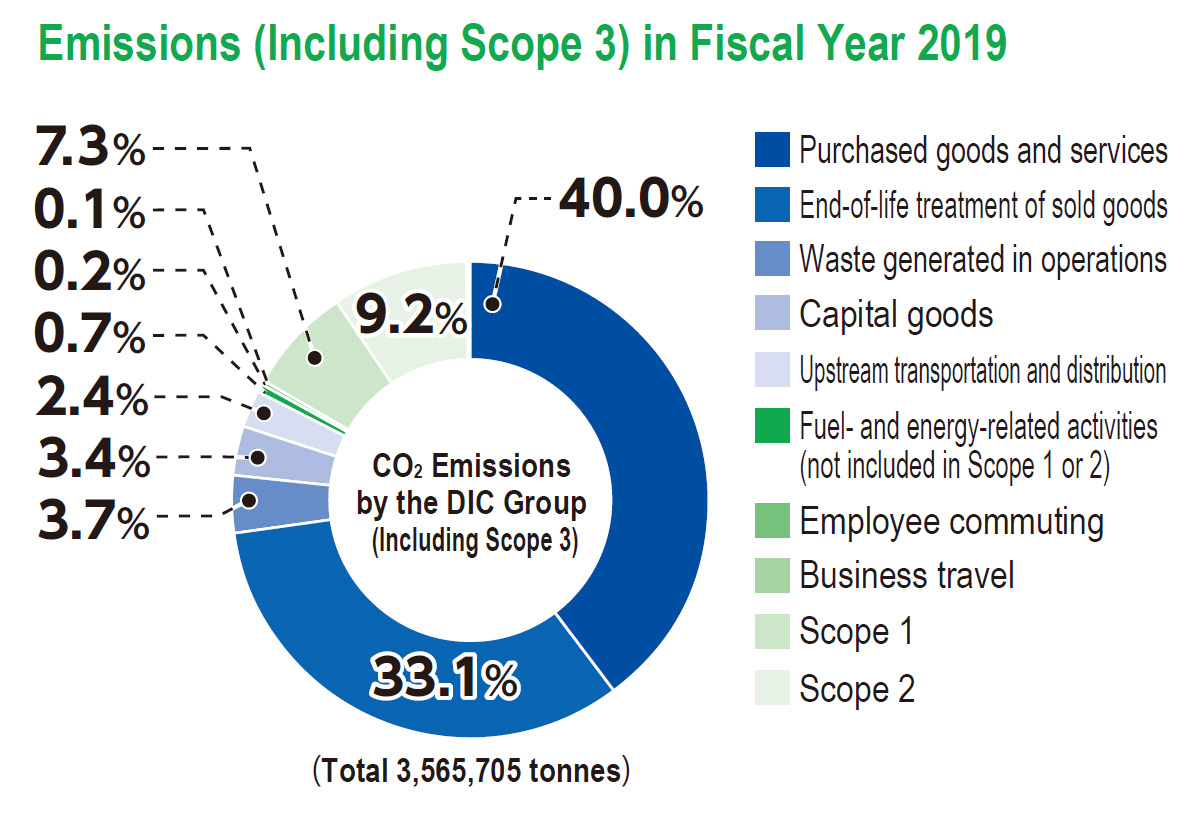

Grasping CO₂ Emissions Across the Supply Chain

Regarding CO₂ emissions across its supply chain (Scope 3* emissions), in fiscal year 2017 DIC participated in a lecture on the Science Based Targets (SBT) initiative organized by Japan’s Ministry of the Environment. As a consequence, DIC now reports global data for all categories of Scope 3. The Company also obtains third-party verification for its data for waste generated in operations.

- Scope 3 emissions are indirect emissions from production, transport, shipment, commuting and other activities in the supply chain.

Back number

- Principal Initiatives in Fiscal Year 2023

- Principal Initiatives in Fiscal Year 2022

- Principal Initiatives in Fiscal Year 2021

- Principal Initiatives in Fiscal Year 2020

- Principal Initiatives in Fiscal Year 2019

- Principal Initiatives in Fiscal Year 2018

- Principal Initiatives in Fiscal Year 2017

- Principal Initiatives in Fiscal Year 2016

- Principal Initiatives in Fiscal Year 2015

- Principal Initiatives in Fiscal Year 2014

- Principal Initiatives in Fiscal Year 2013