Special Feature Placing top priority on safety, the environment and health while maximizing benefits from chemical products

Social Imperative Striving for an Ideal Society and a Favorable Role for Chemical Products

Chemical products are used in various industrial fields and play a vital role in supporting our society, but the use of such products carries with it the possibility of adverse effects on human beings’health as well as on the surrounding environment. That is why we carefully manage and regulate usage, amounts and emission volumes of chemicals substances according to factors such as chemical type and properties. Furthermore, businesses involved with these chemical products implement various measures to ensure safety for end users, employees, local residents and others.

In an effort to achieve an ideal society and favorable role for chemical products therein, the action goal of minimizing environmental and health risk from chemical substances by 2020 was agreed upon in 2002 at the World Summit on Sustainable Development (WSSD) held in Johannesburg, and following the International Conference on Chemicals Management (ICCM) held in 2006, members in the industry began taking independent measures to achieve this target. Numerous businesses involved in everything from base materials to manufacturing of final products have brought together information on chemical substances involved in order to create a scientific basis for risk management and reduce risk from such substances.

DIC Initiatives Promoting Thoroughgoing Management of Chemical Substances and Reduction of Substances that Impact the Environment

The DIC Group integrated Responsible Care (RC) activities into the management system in 1995, and we are also implementing thoroughgoing management and taking measures to improve management of and increase activities related to safety, the environment, health and chemical substances while anticipating changes to legislation in each country and local region.

These efforts are carried out with a central focus on our proprietary Chemical substance Information Comprehensive management System (CIRIUS). While undertaking comprehensive management that covers even minute quantities of chemical substances found in raw materials and products, we apply automated checks for domestic legal regulations, and as a primary processing company we also provide accurate information to customers that we deliver our products to.

Furthermore, we regularly monitor quantities of chemical pollutants released into the environment (air, water and soil) at each DIC plant while continually undertaking measures to reduce the amount of environmentally harmful substances, minimizing impact on the surrounding environment.

VOICE

Proactive cooperation in programs to develop chemical product risk management

We are proceeding with international programs (global product strategy) to improve chemical product usage and safety management throughout the entire supply chain in the global chemicals industry and reduce risk to society as a whole from chemical products. The first step in this process is providing highly reliable information on chemical substances and products and scientifically evaluating risk.

We are involved in this type of program in Japan, through which the government and chemical industry work together to provide the necessary information and assess risk. As a chemical company, DIC strives to actively supply relevant information and promote “risk communication,” and we also aim to contribute to the improvement of precision in risk assessment.

Through such efforts, we hope to make proper use of chemical substances more widespread, provide stakeholders with easy-to-understand information, and decrease risk throughout all of society.

Masato Akama Department M anager in Charge of Regulatory AffairsResponsible Care Department

Social Imperative Increased interest in food product packaging material in Europe and the United States

Recently, consumers have increasingly expressed concern regarding the quality and purity of food products, including factors such as production region and environmental influences which might contribute to this. Attention has also been focused in many cases on components of the products’ packaging which are seen as another possible contributing factor.

In 2005, Italian authorities discovered the photoinitiator isopropyl thioxanthone in milk-based drinks—a problem that gained widespread public attention. This substance was shown to have no adverse effect on the human body, but because contaminants present in food products may not always be detectable by the sensory organs, we realized that more sophisticated methods of analysis for levels of such substances were needed.

Regulations and Guidelines for European Food Product Packaging

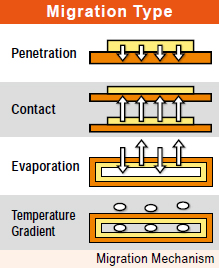

In Europe, there are three types of regulations and guidelines set by regulatory institutions/organizations regarding inks, coatings and other materials used in food product packaging which must be followed: (1) activities of the EU and legislative bodies of member states, (2) industry associations, and (3) self-imposed controls of brand owners, converters, etc. Some brand owners have already taken action to ensure that their packaging is produced to low migration standards, requiring strict control of the raw materials used and proof of low the migration capability of all packaging components.

Sun Chemical Group Initiatives

Sun Chemical Group Low-Migration Products

The Sun Chemical Group has many years of experience in supplying inks, coatings and other materials for printing food packaging. In order to meet demand for materials with low migration characteristics the Group has followed two formulation routes. The first employs energy curing (ultraviolet and electron beam curing) and focuses on significantly eliminating the probability of migration through careful raw material selection. This achieves the lowest possible levels of migration so minimizing the risk to the consumer.

The second applies to oil-based, conventional inks where the ingredients used are permitted food additives and migration characteristics are within the permissible daily intake levels for those materials. Sun Chemical has an analytical department that makes use of advanced technology and specialist knowledge on migration

Providing Comprehensive Solutions for Food Product Packaging

For many years, Sun Chemical has been aware of the strong market demand for guidance on migration characteristics and the correct specification of food packaging materials. Printing companies, converters, brand owners and other members of the industry must not only make the correct selection of inks and coatings and combination of packaging materials, but they must also take factors such as production processes and environmental measures into consideration, in order to manufacture a product which fully meets all specifications. This approach is necessary to ensure consistent use of low-migration products suited to specific purposes. The latest edition of such information, titled “Designing Packaging with Certainty: A Best Practice Guide” has been published and is highly regarded as a source document throughout the market.

In addition to these activities, Sun Branding Solutions also provides general guidance for brand owners on the design of food product packaging for specific applications.

VOICE

Providing Comprehensive Solutions for Food Product Packaging

For many years, Sun Chemical has been aware of the strong market demand for guidance on migration characteristics and the correct specification of food packaging materials. Printing companies, converters, brand owners and other members of the industry must not only make the correct selection of inks and coatings and combination of packaging materials, but they must also take factors such as production processes and environmental measures into consideration, in order to manufacture a product which fully meets all specifications.. This approach is necessary to ensure consistent use of low-migration products suited to specific purposes. The latest edition of such information, titled “Designing Packaging with Certainty: A Best Practice Guide” has been published and is highly regarded as a source document throughout the market.

In addition to these activities, Sun Branding Solutions also provides general guidance for brand owners on the design of food product packaging for specific applications.

Sun Chemical Corporation St. Mary Cray Technical Centre Dr. Nick Ivory Technical Director

Special Topics before 2012

The DIC Group: Striving for a Sustainable Society Utilizing the Power of Chemistry to Solve Problems and Create New Value

Shipping, information, housing, food products—there are number of problems that need solving in the industrial fields that support our daily lifestyles. Through creative development of new products, the DIC Group is contributing to solutions for such problems while generating new value.

Placing top priority on safety, the environment and health while maximizing benefits from chemical products

While supporting customer lifestyles through our wide variety of chemical products, the DIC Group makes efforts to ensure safety, protect the environment and ensure health in every phase of the product life-cycle.

Our Efforts in Environmental Responsiveness with Printing Ink Products

Ink products not using hazardous substances (soy-oil ink and vegetable ink) of which decrease the use of petroleum-derived solvents have been developed.

Urethane Resin for Artificial Leather

In order to respond to the requirement for the decreasing of VOC inside the vehicle, we are also putting our efforts into the development of environmentally friendly products, such as toluene-free and water-based materials.

Halogen-free PPS Resin

DIC has successfully decreased the chlorine content of the PPS resin to a level lower than the requirement level, 900 ppm. Thus, DIC has completed the lineup of low-halogen PPS compounds.

Environment-conscious Adhesives Used for Food Packaging

DIC has developed various types of adhesives to prevent the release of VOC such as a high-solid type in which the amount of organic solvent is reduced, a water-based type for which tap water can be used.