Special Feature The DIC Group: Striving for a Sustainable Society Utilizing the Power of Chemistry to Solve Problems and Create New Value

CSR Activities in Research and Development

The Technical Administrative Division has reorganized thetechnical departments, which used to be located in each business division, into an organization based on the common elemental technologies in 2010. Since then, it has been producing effects in the development of high-performance integrated products by promoting the integration of all technological resources throughout DIC and internal collaboration. The Corporate R&D Department,

which is in charge of developing the next generation products/technologies, focuses on operating in various domains, including new materials/high-performance materials, displays/electronics, new energies, and life science. In addition, we are making a total commitment in solving social issues through mutual collaboration with domestic group companies, such as DIC Graphics, andoverseas companies, such as Sun Chemical Group research laboratories and the Qingdao DIC Finechemicals Co., Ltd., andutilization of global management resources.

Contributing to Solutions for Society’s Problems through Creative Product Development

Shipping, information, housing, food products—there are number of problems that need solving in the industrial fields that support our daily lifestyles. Through creative development of new products, the DIC Group is contributing to solutions for such problems while generating new value.

Social Imperative Improved Fuel Efficiency through Weight Reductions

In order to alleviate global warming caused by exhaust gas emissions, as well as depletion of fossil fuels and other such problems, improved fuel efficiency through vehicle weight reductions is needed. On the other hand, numbers of parts are being increased in order to enhance factors such as safety and comfort—this is where the substitutability of light plastic parts (engineering plastics) for heavier metal parts plays an important role.

However, automobiles are used in a wide variety of harsh environments ranging from deserts to freezing-cold regions, exposing engine-related parts to high temperatures resulting from combustion, incessant vibrations, and chemical products such as gasoline and oil. This means that the role of plastic products is limited due to demand for parts with extremely high heat resistance, chemical resistance, etc. If high-performance plastic products can be developed to overcome these problems, a shift toward plastic part usage in vehicles and increased fuel efficiency through vehicle weight reductions can be expected.

DIC Solution Using High-Performance PPS Plastic to Expand Substitutability for Metal Parts

Among available engineering plastics, PPS (polyphenylene sulfide) plastic is known as a “super engineering plastic,” as it has half the weight of aluminum, a melting point of 280°C (536°F) and superb chemical-resistant and flame-resistant properties. DIC started manufacturing the PPS compound in 1976 and the base polymer that serves as the raw ingredient for that compound in 1987. Today, this PPS compound accounts for the largest market share worldwide at approximately 27% as does the polymer at approximately 18%.

Automobiles PPS-compound parts meet demand for a wide range of characteristics including hardness, flexibility (shock resistance) and precise dimensional stability.

DIC utilizes integrated technology covering everything from polymer molecular design to mixing and compounds to respond to such needs, and we have expanded applications for plastic parts to not only engine-related parts but also to applications in brake systems, fuel, lighting, cooling, integration control systems and more, contributing to improved fuel efficiency through the replacement of metal parts with plastic ones.

VOICE

The Strength Needed for Integrated Supply of Everything from Base Plastics to Molding Compounds

We provide a range of PPS compounds in response to demands for a vast variety of material characteristics from automotive part manufacturers.

DIC’s strength lies in our ability to undertake integrated development and manufacturing in all areas ranging from polymer molecular design to mixing and compounds in order to respond with precise detail to the abovementioned needs.

In recent times, the Company has developed various innovative PPS compounds, including a compound that achieves the same machining characteristics and high levels of dimensional precision as metal parts, which was previously not possible, as well as the thermal shock property necessary to enable actual usage. DIC has also developed a long-glass-fiber compounding agent that replaces its short-glass-fiber counterpart for more than 4 times the shock resistance, 1.5 the long-term strength against high temperatures and 1,000 times stronger fatigue characteristics.

These new materials have been adapted in applications such as replacements for metal parts (previously not possible) and parts used in next-generation system for hybrid and electric vehicles, creating the potential for even greater fuel efficiency.

Masanori Uchigata Polymer Processing Technical Group 2 Polymer Processing Technical Department

Social Imperative Reduction of Resource Use in Newspaper Publication Efficient Use of Resources for Newspaper Publication

Newspaper companies in Japan are increasing the number of pages to include more information while newsprint paper becomes thinner and thinner from the view point of effective use of natural resources and reduction of delivery cost. In 1970s, 51.8 grammage of newspaper was very common, but paper weight became lighter and dropped to 43 grammage in the late 1980s. It led to the forest preservation and the reduction of energy consumption (or CO₂ emission) for paper-forming process, transportation, and everything.

In recent years, newspaper companies have made further strides in these areas while also working to reduce the amount of ink used in newspaper printing operations. However, the combination of thinner newsprint paper and reduced amounts of ink create the risk of lower newspaper quality, posing the difficult question of how to simultaneously achieve both resource conservation and quality.

In recent years, people become more environmentally aware. So newspaper companies are urged further efforts for environmental protection and trying to reduce the ink consumption. But there are many difficulties to balance resource conservation with printing quality by using thinner newsprint with lower ink film thikness.

DIC Solution Resource conservation Energy conservation

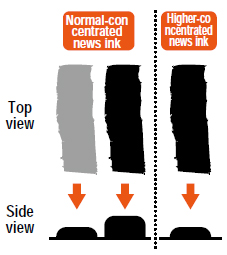

Achieving Both Resource Conservation and Newspaper Printing Quality through Thin-Coating with High-Concentration Ink Solution for the Balance between Resource Conservation and Printing Quality Applying thin layers of high-concentration ink containing large amounts of pigment to reproduce color pages is an effective method of achieving both reductions in ink usage and newspaper printing quality.

The important factors in carrying this process out are securing the color printing quality for newspaper, undert the advanced automated offset rotary printing press systems, and maintaining printing condition even thin-coating, to prevent instability while printing, or deteriorate of transfer. In order to achieve these, DIC makes full use of its unique know-how from select raw material, to compounding techniques, to develop optimized high-concentration inks. (brand name: “PROUD” co-mark recognized). “PROUD” has realized 23.1% ink usage for 3 colors (red, yellow, blue) in average.

Higher-concentrated news ink is one solution to achieve the printing on thinner paper with lighter ink film layer. But this type of ink sometimes caused unstable ink density, poor ink transfer and poor water fighting property under the high speed running condition before. Our DIC developed new resin by gathering all DIC technology, selected suitable materials, and optimized ink formulation. And finally we have launched new generation high-concentrated news color ink series “PROUD” that complies with ECO-mark requirements in Japan. PROUD would be expected around 20% reduction of ink usage for 3 colors (yellow, Magenta, and Cyan) in average.

Resource conservation Energy conservation

VOICE

Decreased Resource Use, Work Environment Improvements and Fewer Shipments

ffective Utilization of Limited Resources, Improvement of Work Environment, and Decrease in Number of Shipments Because printing on thin paper creates a high risk of “strike-through” where the ink soaks through to the other side, as well as accidental offset resulting from ink being transferred to the opposite page due to immediate folding over the page following printing, the needs for high-concentration ink to enable thin-coating is increased.

DIC responds to such needs by developing “PROUD” Furthermore, offset printing operates based on the repulsion of oil(ink) and water (fountain solution with chemical agents mixed in) and when high-concentration ink is used the amount of fountain solution can be reduced, leading to operational improvements through decreased amounts of mist dispersal during printing. This also means fewer ink deliveries to newspaper companies, resulting in reduced CO₂ emissions from delivery operations.

Although we began developing high-concentration newsprint inks later than other companies, our inks are highly rated for their excellent color-reproduction performance and stability, and we have seen growth in new orders as a result. Newspaper companies can decrease the thickness of ink layer by using high-concentrated news ink “PROUD”. And demands for this ink are increasing rapidly because it reduces the risk of “strike-through” that the ink penetrates into the paper and can be seen from the back side. PROUD contributes to prevent the set-off problem during the folding process due to the fast drying property. Furthermore, newspaper companies could get the following benefits from PROUD: decrease in the usage of dampening water, improvement of work environment by the lower misting of ink, and the reduction of CO₂ emissions from transportation.

New generation high-concentrated news color ink “PROUD” is getting a high reputation in Japanese marke and the sales of it is also increasing sharply.

Kazundo Suzuki Newspaper Ink Technical Group DIC Graphics Corporation

Social Imperative Enhancing the Environmental Performance of Mobile Phones, TVs and Office Automation Equipment

In contrast to the increasing multifunctionality and circuit integration encountered in our advanced, information-based society, there is demand for resource and energy conservation and high recyclability in consideration of the environment. We must make devices thinner, lighter and smaller in size; increase functionality while promoting efficient energy use; and overcome other problems that present opposing needs.

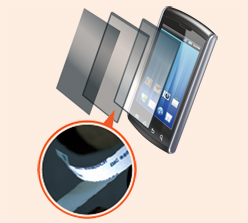

DIC Solution Promoting Advances in Mobile Phones via Tapes, Films and More

DIC plays an important role in advancing mobile phone technology. The use of thin adhesive tape in place of screws to fix parts in the device contributes to thinner mobile phone designs (resource conservation). In addition, we developed a water-resistant tape by combining a foam substrate that provides cushioning with a special adhesive, contributing toward achievement of the world’s first water-resistant mobile phone.

This highly-evaluated technology enables the handset to be submerged in 1 meter of water for 30 minutes without being damaged, and it has been adopted for use in mobile phones both inside and outside of Japan.

Furthermore, we have “anti-scattering film” prevents glass shards on the display from scattering when broken should the handset be dropped, ensuring a high level of safety.

DIC’s industrial-use adhesive tapes and films hold parts in place while contributing to improved environmental performance

DIC Solution Heat radiation from LED lights, and Easy Recycling of Office Automation Equipment

LCD TVs using an LED back light needs adhesion and radiating heat for tape. To address this, DIC developed thermally conductive double-sided adhesive tape with high thermal conductivity for a powerful heat-dissipation effect. This approach has been adopted by multiple consumer electronics manufacturing companies for its effectiveness in limiting temperature increases when compared with screw-mounting methods for attaching LEDs.

In office automation equipment, consumer electronic products and other such products, there is demand for double-sided tape used for attaching parts that will not come off during use and facilitates easy dismantling of end-of-life products collected from users.

DIC has responded by developing a high-strength, removable acrylic adhesive whose adhesive strength does not increase the longer it is attached as with most standard adhesives. Furthermore, a high-strength-type product with nonwoven fabric substrate material that resists tearing during removal was jointly developed to overcome problems.

This easy-to-recycle, high-strength, removable acrylic adhesive tape product has continued to be one of the Company’s top sellers since it was released on the market more than 20 years ago.

High-strength, removable acrylic adhesive tape that facilitates easy product dismantling

VOICE

Utilizing DIC’s Combined Power for High Added Value in Adhesive Materials

Industrial-use tapes, films and similar products play a pivotal role in enhancing the environmental performance of electric and electronic devices. There is a wide range of differing customer needs depending on factors such as product type and location of use, and many different types of pecial characteristics are needed including part attachment, product protection (shock resistance, scratch resistance, water resistance), transparency, heat dissipation and low VOC (volatile organic compound) levels.

DIC is able to provide products optimized to meet a wide range of needs thanks to its integrated, high-level knowledge covering everything from polymer design and synthesis, to resin design for coating films, additive formulation technology, and replacement of conventional parts with films and tapes.

In the field of mobile devices, where tablet-type products have made remarkable progress in recent years, the Company has supplied highly conductive transparent film for touch panel screens, tape that provides shielding against interference from electromagnetic waves which may cause device malfunctions, and other such products that contribute to fields outside of environmental performance.

-

Akira Yamakami

Manager, Coating & Applied Materials Group 1

Coating & Applied Materials Technical Department -

Hiroki Takano

Manager, Coating & Applied Materials Group 1

Coating & Applied Materials Technical Department

Social Imperative Creating Spaces Where Large Numbers of People Can Feel Comfortable and at Ease

People need spaces brimming with warmth and a sense of repose in public facilities used by numerous people, and also in facilities such as welfare facilities and hospitals used by the elderly, patients and others. However, utilization of the natural wood building materials needed to create this type of atmosphere is hindered by failure of such materials to meet fire prevention and flame resistance standards as defined in building standards, forest protection measures that make it difficult to obtain certain woods, and other such factors.

On the other hand, many patients with eye problems, those who see colors differently (sense of color) for genetic reasons, and others with differing visual capabilities (there is said to be more than 5 million in Japan) have difficulty distinguishing between different facility signs, which leads to problems in terms of universal design.

DIC Solution Harnessing the Power of Chemistry to Produce the Feel of Natural Wood, and the Power of Color Universal Design for Accessible Color Usage

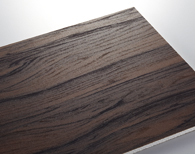

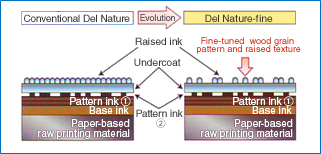

The DIC Group adapts its resin-treatment, printing and other technologies to supply decorative boards, decorative sheets, artificial marble and a wide range of other interior design materials for the housing and construction industry. One such product is the Company’s non-flammable “DIC Funen WO” decorative board (developed in 2010), which features natural wood color patterns made using a photomechanical process (“Del Nature-fine” DIC proprietary printing method) and a rough wooden texture faithfully recreated via resin treatment—the texture and warmth of this product resemble wood so closely it is hard to tell it apart from the real thing. Elderly care facilities, hospitals, educational institutions and other facilities that prefer the expressiveness of wood materials have praised the designs of DIC’s products highly and installed them in their own buildings.

Non-flammable “DIC Funen WO” decorative board expresses the texture and warmth of natural wood

“Del Nature-fine” for unique design expression

Additionally, in order to promote the spread of color universal design (CUD) and achieve color usage that is accessible to all, DIC collaborates with the Color Universal Design Organization (CUDO) in measures to improve public facility signage. Along with provision of display boards for those who see differently than the average person (such as timetable and route map displays in train stations and information panels for building facilities), collaborative efforts also include seminars for specialists involved with public facilities in an effort to promote widespread diffusion of CUD.

VOICE

Pursuing “Color & Comfort” through Accumulation of Unique Technologies and Knowledge

Non-flammable “DIC Funen WO” decorative board is the perfect product for welfare facilities for the elderly and other facilities where a sense of warmth and repose is desired. Because the cost of installing this product is more reasonable than that for scarce, high-class natural wood materials, and because it also contributes to forest protection, we expect further growth for DIC Funen WO in the future. In addition, our display boards and panels designed with consideration for color universal design make use of our knowledge on color science combined with know-how related to pigment, paint and coating technologies for truly original products. One might call these products the realization of DIC’s “Color & Comfort by Chemistry” approach.

Masaki Hayashi Senior Manager, DIC200 Promotion Department Architecture and Housing Material Sales Department

Development of Original Washstands for Elderly Care Facilities

DIC has a wide range of experience with products in the construction and housing field, including decorative panels and sheets, artificial marble made from polyester resin and more. Originally, the Company supplied products in this field in the form of materials; however, in 2011 we harnessed in-house technology and began developing an original washstand product, and in FY 2012 we plan to begin sales of this product to elderly care facilities. We have managed to recreate the warm feel of natural wood and stone without making use of scarce forest resources or building stone materials. Furthermore, we utilize the unique characteristics of DIC in our products, including incorporation of barrier-free design for wheelchair accessibility and color coordination with a focus on traditional Japanese colors.

Junya Tsuruta Senior Manager, DIC200 Promotion Department Architecture and Housing Material Sales Department

TOPICS

DIC Color Design initiatives Contributing to enhanced product appeal and brand strength through color design originating from uniquely Chinese elements

Japanese companies that want to pursue growth within in China’s maturing domestic market, and Chinese companies that want to increase their value amidst a staggering number of established global brands—DIC continues to provide effective proposals to meet these types of needs by utilizing our unique analytical capabilities and viewpoint.

A Unique Viewpoint, For Everything from Brand Strategy to Communication of Trends

In order to make one’s presence known in the Chinese market, one must appeal to consumers through color designs that leverages both uniquely Chinese characteristics and Chinese novelty, based on observations of global trends and the latest materials and expressive techniques. At DIC, we continually provide Chinese color trends based on many years of surveys and analytical experience, and propose our highly effective CMF (Color/Material/Finish) method of communicating as part of brand strategy. The importance of color-based marketing strategy continues to grow, expanding rapidly in various industries including automotive, home electronics, cosmetics, food products, fashion and others.

2013–2014 Chinese Color Trend Book

Eri Ohmae

Color Director (and editor-in-chief of the Chinese Color Trend Book)

Consulting Division DIC Color Design, Inc.

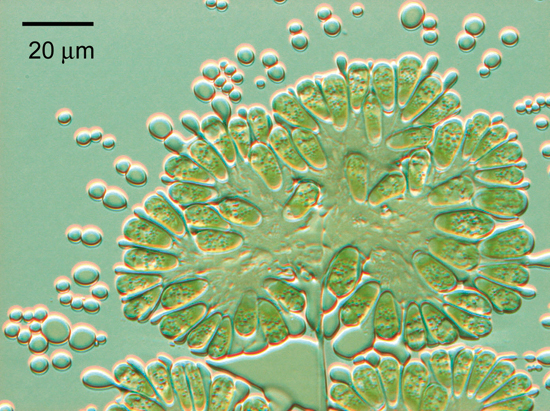

A Trial in Sustainable Resources and Energy Production through the Development of Spirulina Cultivation Technology

With fossil fuel resources running dry, global warming intensifying, the risks of nuclear energy becoming more apparent and other such factors, natural energy has become the focus of much attention. Plants and algae, whose photosynthetic processes make use of one of our most familiar energy sources (the Sun), provide examples of the ultimate sustainable resource and energy solution. In particular, algae exhibits photosynthetic efficiency as well as a highly effective CO₂ absorption effect (carbon offset) while under cultivation—a fact that has caught the interest of many.

The DIC Group sells the photosynthetic algae spirulina for various purposes, including use as a health food product and use as the food coloring “Lina Blue,” and DIC is the only company to use spirulina outdoor mass cultivation technology, which is based on more than 30 years of experience.

With the goal of fully utilizing this technology, the University of Tsukuba as well as the American company Sapphire Energy are simultaneously undertaking collaborative research related to outdoor mass cultivation for production of jet fuel, chemical product raw materials and other products. The DIC Group plans to utilize its outdoor mass cultivation know-how to support practical implementation of an algaebased biofuel, with the goal of freeing society from reliance on nuclear power, fossil fuels and other such energy sources and contributing toward the development of clean and sustainable energy and resource development.

Special Topics before 2012

The DIC Group: Striving for a Sustainable Society Utilizing the Power of Chemistry to Solve Problems and Create New Value

Shipping, information, housing, food products—there are number of problems that need solving in the industrial fields that support our daily lifestyles. Through creative development of new products, the DIC Group is contributing to solutions for such problems while generating new value.

Placing top priority on safety, the environment and health while maximizing benefits from chemical products

While supporting customer lifestyles through our wide variety of chemical products, the DIC Group makes efforts to ensure safety, protect the environment and ensure health in every phase of the product life-cycle.

Our Efforts in Environmental Responsiveness with Printing Ink Products

Ink products not using hazardous substances (soy-oil ink and vegetable ink) of which decrease the use of petroleum-derived solvents have been developed.

Urethane Resin for Artificial Leather

In order to respond to the requirement for the decreasing of VOC inside the vehicle, we are also putting our efforts into the development of environmentally friendly products, such as toluene-free and water-based materials.

Halogen-free PPS Resin

DIC has successfully decreased the chlorine content of the PPS resin to a level lower than the requirement level, 900 ppm. Thus, DIC has completed the lineup of low-halogen PPS compounds.

Environment-conscious Adhesives Used for Food Packaging

DIC has developed various types of adhesives to prevent the release of VOC such as a high-solid type in which the amount of organic solvent is reduced, a water-based type for which tap water can be used.