Special Feature Direct to Society: The Future of Color & Comfort

Transforming DIC into an organization that works together with society to identify imperatives and propose value

“Direct to Society” is a new business creation mechanism that seeks to realize new businesses by heightening our responsiveness to the needs of society and leveraging insights gained to develop and commercialize truly innovative products.

With the rapid evolution of communications and AI, chemicals companies—who play a key role in supporting social infrastructure—are also on the threshold of dramatic change. DIC has always excelled at developing products in response to customer demands, but a passive approach alone is insufficient for companies to gain an accurate grasp of the true needs of both consumers and customers. Having recognized this, the Company recently adopted a business creation mechanism it has dubbed “Direct to Society,” which emphasizes turning its attention directly to society, closing the gap between itself and consumers to envisage and realize solutions to future needs.

DIC has begun deployment of the Direct to Society mechanism in the area of smart living, which it has positioned as a key business area, and will accelerate related initiatives that exemplify the creativity of the DIC Group by taking on themes that transcend the traditional constraints of chemicals manufacturing.

Episode1 〜Direct to Society

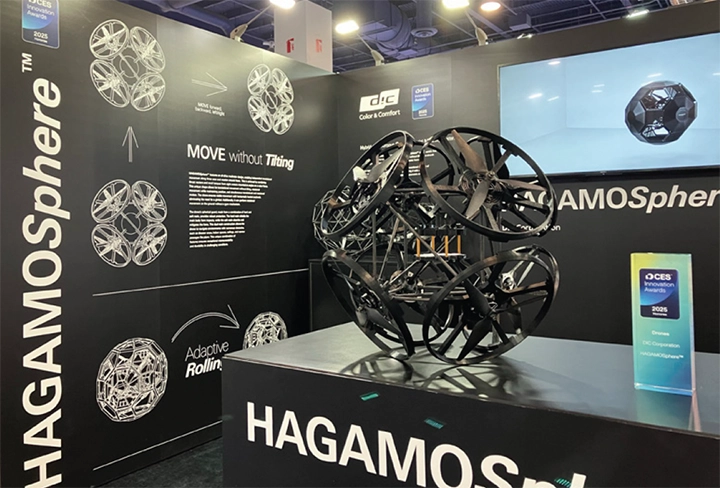

HAGAMOSphere® Omnidirectional Multicopter: Innovative Design and Engineering Features Create a Stir at CES

In January 2025, the DIC Group took part in CES 2025, one of the world’s leading technology trade shows for the consumer electronics industry, in the U.S. city of Las Vegas. At this event, the Group—a first-time participant— showcased a prototype of its new HAGAMOSphere® omnidirectional multicopter, a concept model that embodies the Direct to Society mechanism. Garnering praise from judges for its innovative design and engineering features, this prototype earned DIC designation as a CES Innovation Awards® 2025 Honoree in the Drones category.

Behind the Scenes (1)

A Flood of Ideas that Began with a Sketch

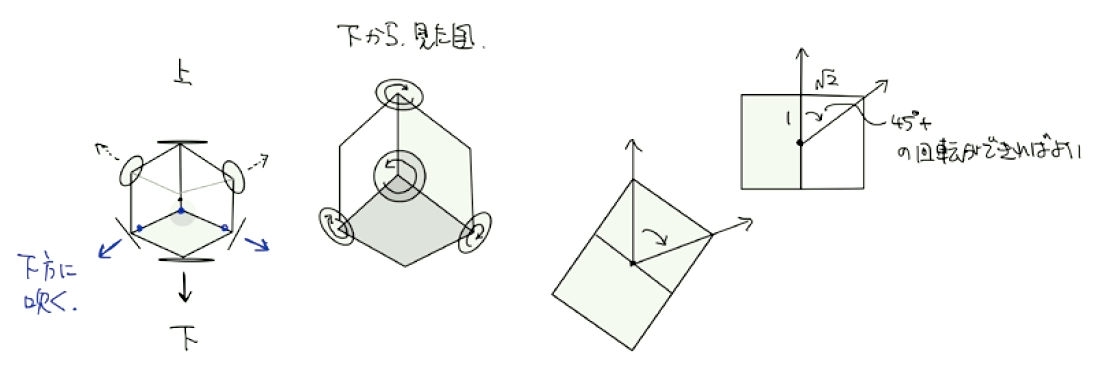

We began looking at different ways to make drones fly in 2023. It all came about thanks to a sketch by DIC’s president, who asked if the drone he’d conceived of could actually fly. We were initially taken aback by Mr. Ikeda’s daring idea, but by bringing together technologies and know-how in various areas from across the DIC Group and dispensing with any preconceived notions we had about drones, we succeeded in developing a unique algorithm to control the rotation of the eight propellers, enabling us to realize a configuration that allows the unit to fly horizontally without tilting. The spherical guard housing for HAGAMOSphere®, which consists of a combination of geometric shapes, was a major breakthrough in the development of this pioneering drone by enabling it to roll on the ground and move by itself, and to operate smoothly in small spaces and complex environments. This is expected to facilitate adoption for a wide range of applications, including inspections, surveillance and logistics. Participation in CES 2025 was a great morale booster for the entire HAGAMOSphere® team. We will continue working as one to improve the precision of this groundbreaking drone and bring it to market.

Part of the sketch that inspired development

AI Devices Group,

Business Incubation Unit,

New Business Development Headquarters

Behind the Scenes (2)

The Significance of DIC’s Entry into the Drones Business

DIC’s decision to expand into the manufacture of drones was because the peripheral materials and fluid analysis and molding processes required offer a tremendous opportunity for us to leverage our unique design technologies. Materials design technologies used—such as those for tough yet flexible epoxy resin–based carbon fiber– reinforced plastic, which offers superb elastic modulus, and PPS resins, which lower the weight of finished products—are not new for DIC, but rather leverage technologies DIC has cultivated over the years. CES 2025 was the first edition of this renowned event in which DIC has taken part, but the positive response of visitors was a clear sign of the market’s high expectations of HAGAMOSphere®. By addressing the needs of society through our new drone and robotic finger, as well as other device and module businesses, and delivering value and solutions that transcend the traditional constraints of chemicals manufacturing, we aim to create new businesses that overlap conventional industry and sector boundaries, such as by combining AI and devices.

Presentation by DIC president Takashi Ikeda and team members

Shinsuke Kotera

Leader,

Business Incubation Unit, New Business Development Headquarters

Episode2 〜Direct to Society

DIC’s New MoR® Grasps Objects as Easily as a Human Hand, Helping Customers Achieve “More”

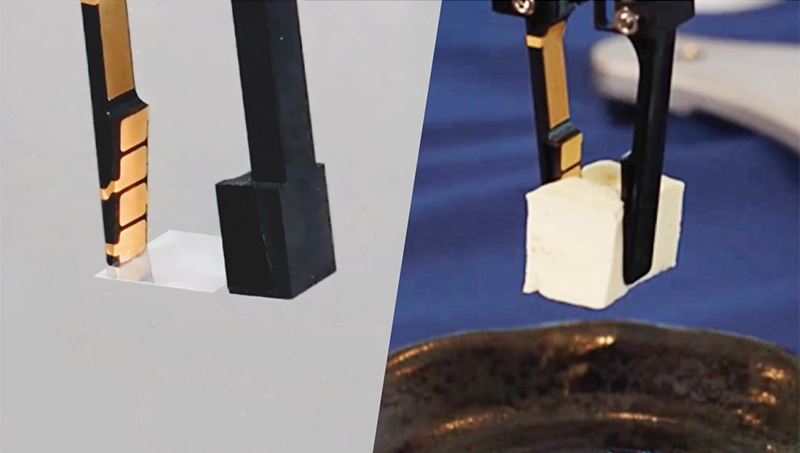

The technology behind MoR®, a new multifunctional robotic finger (MoR) developed by leveraging distinctively DIC materials and mechanical design capabilities, lets a robotic hand claw grasp objects with a delicacy comparable to that of a human hand. Conventional robotic hands use built-in cameras or sensors, to recognize and also pick up objects with the appropriate grip. With MoR®, no camera is necessary. Instead, circuit traces etched directly on the finger measure distortion and adjust strength, enabling a flexible and precise grip.

The flexibility with which the resin used in MoR® can be shaped and DIC’s proprietary compounding technologies make it possible to tailor finger shapes and circuit trace patterns to different applications to facilitate the most appropriate grip. As a result, MoR® is suited to use in everything from food to precision equipment. This innovative product is attracting interest across a wide range of industries as a solution that takes production automation to the next level.

MoR® picking up a microscope slide and a piece of soft tofu

Kotaro Mori

Manager, AI Devices Group, Business Incubation Unit, New Business Development Headquarters

Episode3 〜Direct to Society

A Groupwide Project Team Focused on Practical Implementation of the Direct to Society Mechanism and Securing Key Talent

In fiscal year 2024, DIC inaugurated the Smart Living Project, which in addition to employees in related departments opens participation to individuals from across the domestic DIC Group. The project has approximately 50 members. With our focus on smart living, that is, smart living environments and lifestyles, we endeavor to expand beyond conventional approaches to R&D, with each member taking a Direct to Society perspective, seeking to promote development and explore solutions that respond to future issues and anticipated values.

Thinking outside the box is challenging, and project members are working to broaden their horizons and remain flexible, finding the process fascinating while at the same time recognizing the difficulty of translating ideas into viable businesses. I believe strongly that fostering employees and a work environment that encourage a diverse team to create new value by rethinking approaches through projects such as this is crucial to DIC’s future evolution and growth and to the realization of its management vision.

Project team meeting

Mina Nishihara

Manager,

Smart Living Project,

Corporate Planning Department

Special topics 2025

Direct to Society: The Future of Color & Comfort

Transforming DIC into an organization that works together with society to identify imperatives and propose value