Special Feature Adhesive with Oxygen Barrier Properties (PASLIM)

Adhesive for packaging film that prevents oxygen permeation and keeps foods fresh longer

Social Imperative Reduce food loss and conserve packaging resources by realizing more functional packaging materials

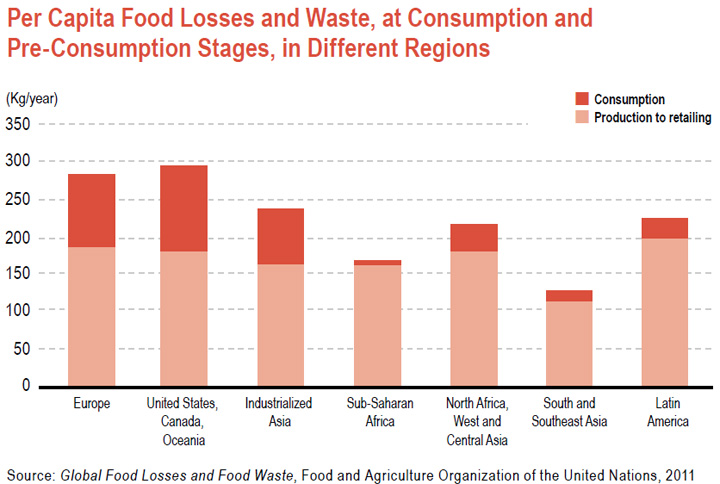

Millions of people the world over suffer from malnutrition, yet one-third—approximately 1.3 billion metric tons—of the food produced globally for human consumption is wasted annually, accordingly to an estimate made by the Food and Agriculture Organization of the United Nations in its 2011 report. Efforts are being made in many areas to help resolve this paradox, including through the use of high-performance packaging materials to prolong shelf life, thereby minimizing food loss in distribution, retailing and consumption. Particularly notable among these is flexible plastic film with oxygen barrier properties, which, as its name indicates, keeps oxygen—a key cause of bacterial growth—away from food. By preventing oxidization, these materials help extend expiration dates.

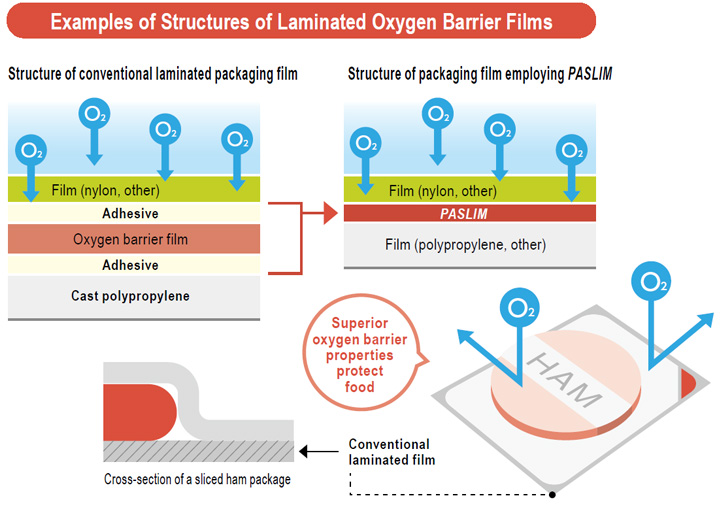

A key issue with oxygen barrier packaging films is that they are generally made from multiple layers of film that must be laminated together, which makes manufacturing difficult and discourages market acceptance in many places. Simplifying the laminated structure of such films would thus help reduce both food waste and resource consumption.

DIC’s Response An adhesive that prevents oxygen permeation, facilitating the reduction of packaging film weight

DIC has developed an adhesive that can be used instead of oxygen barrier film to minimize food loss

A supplier of diverse, highly functional products, including printing inks, films, adhesives and coatings, in packaging markets around the world, DIC is working to improve the oxygen barrier properties of food packaging materials with two aims—to prolong the shelf life of food, thereby reducing food loss, and to promote the efficient use of the resources from which such materials are manufactured.

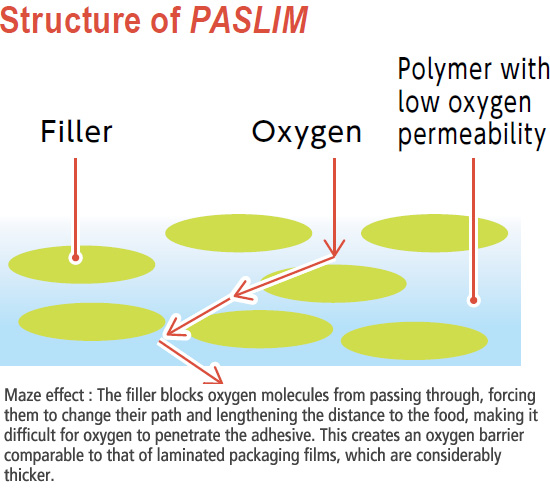

In summer 2013, these efforts led to the development of PASLIM, an adhesive with oxygen barrier properties. DIC realized this innovative, multifunctional material by combining a polymer with low oxygen permeability and an inorganic compound filler, thereby lengthening the distance to the food (the “maze effect”). PASLIM thus imparts an oxygen barrier performance equivalent to that of conventional laminated packaging films, which are several times thicker.

Because it eliminates the need for a conventional oxygen barrier film layer, PASLIM facilitates the manufacture of dramatically thinner and lighter laminated packaging films. As well as preventing food deterioration, PASLIM reduces the volume and the cost of film used, emissions of CO₂ during product transport and the amount of packaging film disposed of post-consumption. DIC estimates overall CO₂ emissions attributable to the production, use and disposal of PASLIM are around 30% lower than for conventional oxygen barrier films.

The first customer to adopt PASLIM was a livestock farming and processing company in the PRC, which chose the product for use in packaging for hams and sausages. The product has also been well received at numerous international packaging exhibitions. DIC continues to receive inquiries from interested food and packaging companies worldwide.

KEY PERSON of DIC

We are establishing a business model in the PRC and expanding its application worldwide.

In addition to our usual packaging materials customers, we have proposed a PASLIM-based food packaging solution directly to a Chinese food manufacturer. This is a successful example of a solution realized thanks to the provision of technical assistance to a local company, which encouraged the company to adopt PASLIM for use in its food packaging. Looking ahead, we plan to apply this business model worldwide by leveraging DIC’s technologies and networks to propose solutions tailored to market conditions and requirements across various countries and regions.

Manager in Charge, Adhesives Project Gen Suehiro

Our goal is to achieve harmony between basic research and applied technology.

In addition to synthesis technologies, which facilitated the creation of a resin with oxygen barrier properties, and dispersion technologies, used to separate out selected substances from a myriad of fillers, PASLIM harnesses a compounding technology that impar ts superior adhesiveness. Collaboration between the Corporate R&D Division and the Technical Administrative Division was instrumental in commercializing this well-balanced high-performance adhesive.

Head Researcher, Adhesive Technical Group 1, Adhesives Technical Division Mutsuhiro Shimoguchi

We are contributing to social sustainability through the enhancement of barrier properties.

SAVE FOOD is a global initiative aimed at promoting sustainability by reducing global food loss and waste that spearheads efforts involving members from various sectors, primarily in Europe and North America. Imparting oxygen barrier properties to packaging film is attracting considerable attention as one solution to the problem of food waste. We are working to help address this issue by developing products that capitalize on our polymer synthesis and other elemental technologies and by leveraging our connections with converting companies around the world. By further expanding our lineup of oxygen barrier adhesives and other solutions, we will continue working to contribute to global sustainability.

Manager in Charge, Packaging & Graphics Marketing Department Susumu Nishimura

Special Topics 2015

Adhesive with Oxygen Barrier Properties (PASLIM)

Adhesive for packaging film that prevents oxygen permeation and keeps foods fresh longer

Epoxy Resin and Curing Agent for Infrastructure Renovation (EPICLON with LUCKAMIDE)

Superior adhesiveness, even on damp surfaces, shortens repair times and improves workability

TOPICS

Groundbreaking Sun Chemical Solution Enhancesthe Recyclability of Shrink Sleeve-Labeled PET Bottles