Special Feature FRP sheet pile for construction

Faster and safer sewer construction that supports our living environment

Social Imperative Reduction of construction period and improvement of safety for city tunnels

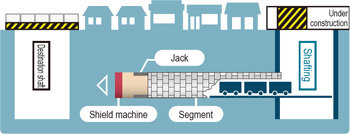

Sewers are an important infrastructure that supports our comfortable living environment. However, in cities where buildings are built closely together with a lot of traffic, it is difficult to construct tunnels (sewer pipes and public utility conduit) by opening and cutting street pile. Therefore, the “shield construction method”, with which they use excavators called “shield machines” starting with shafting and excavate underground to create tunnels, is rapidly starting to become popular in recent years.

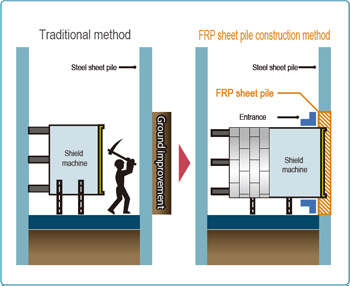

However, shafting requires (1) Pressure insertion of sheet pile (steel) around the tunnel to prevent soil from collapsing and groundwater seeping through, (2) Improvement of the ground by injecting cement milk in order to stabilize the surrounding ground, and (3) “Ground breaking process”, with which they cut the steel sheet pile with a burner to run the shield machine. Such a construction method takes time and efforts, and the ground breaking process also involves safety-related risks.

Concept image of the shield construction method

DIC's initiative Reduction of ground improvement and ground breaking work with the newly developed “carbon FRP sheet pile”

DIC has been providing FRP (Fiber Reinforced Plastics) bathtubs and artificial marble kitchen counters, which utilize sophisticated resin processing technologies, to housing equipment manufacturers. We also have manufacturing experience with construction materials, such as FRP for temporary construction, etc. Based on this knowledge, we launched the development project of new sheet pile that improve the workability of the shield construction method in cooperation with the Zenitaka Corporation. In 2012, DIC succeeded in developing “carbon FRP sheet pile” with the same level of strength as steel sheet pile by layering strong and light carbon fibers and glass fibers and impregnating/curing resin.

By incorporating these sheet pile into shafting, we no longer need the improvement of the ground by injecting cement milk or the process to manually cut sheet pile. Shield machines can excavate tunnels by directly cutting through FRP sheet pile. This not only improves work safety but also enables significant reduction of the construction period and resource conservation.

DIC plans to proactively propose the shield construction method utilizing the “carbon FRP sheet pile” for sewer construction, etc. in urban areas based on the evaluation of workability, etc. through demonstration experiments in the field by the Zenitaka Corporation.

Newly developed “carbon FRP sheet pile”

VOICE

Unique molding method was established after trial and error

DIC used to manufacture FRP “Light Sheet Pile” (6mm thickness x 30cm width) for shallow ground constructions, but the sheet pile that support the shafting in the shield construction method require a whole different size (23mm thickness x 45cm width)/shape and level of the strength/durability. After trial and error in experiments, we were finally able to develop a molded product (molded product patent) that satisfies the performance requirements by layering fabric-like carbon fibers and glass fibers within an mold using Resin Transfer Method (RTM). You connect this with steel sheet pile and joints to insert into soil with a hydraulic machine.

I think that the development of “carbon FRP sheet pile” with completely different characteristics than the existing sheet pile is the result of full utilization of DIC’s comprehensive knowledge and technologies from designing to raw material procurement and resin processing/manufacturing. We hope that this will be widely utilized not only in city tunnel constructions for sewers, etc. in Japan but also in the emerging country market in Asia in the future.

Polymer Processing Technical Group 6 Polymer Processing Technical Department Manager Michinari Kanemoto

Special Topics 2013

Inks/adhesives for food packaging

We want to use them with security because we need them in our lives.

FRP sheet pile for construction

Faster and safer sewer construction that supports our living environment

Epoxy resins/curing agents for electronic substrate

Even convenient tools that support the information society must be considerate to the environment.

TOPICS

Supporting the Development of a New Technology to Facilitate Precise Brand Color Reproduction and Management Worldwide

Drawing on its exclusive technologies and network capabilities, DIC Group company Sun Chemical Corporation has played a crucial role in a project aimed at ensuring a consistent global image for one of Heinz’s main brands.

Downloaded worldwide for the convenience of digital guide (As of May 31, 2013)

DIC digitalized the COLOR GUIDE in October, 2010, and started releasing it as a free application for smartphones (iPhone by Apple). Since then, we have been expanding the users while enhancing compatible OS and contents.