Special Feature Inks/adhesives for food packaging

We want to use them with security because we need them in our lives.

Social Imperative Achieving both safety and printing quality in food packaging

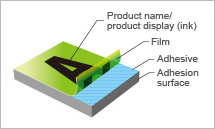

For food packaging, securing safety is imperative nowadays, both in view of the use of the packages and in the process of package production. “Laminate processing,” in which we bond plastic film/aluminum foil/paper, etc., not only protects food from shock/humidity/oxygen/light/pollution etc. to keep it safe and healthy but also enables long-term storage, making it easier to transport and handle. In order to enhance the functionality, films are made in multi layers depending on the characteristics, such as snacks, beverages, or retort pouch food representing curry, soup and so on. In addition, inks that display various information representing the expiration date, production location etc., have the function of not only communicating those necessary information but also playing the role to enhance product values with beautiful images.

On the other hand, the method to dilute inks and adhesives with solvent is the main method in the processing step. Further reduction of the used solvent amount and solvent-less process are being promoted, while it should be strictly conformed with laws and regulations* which have been formulated in various countries/regions. Furthermore, reduction of volatile organic compounds (VOC), which are created in the diluting/drying processes, has also become an issue to improve the operation environment.

It needs to be added that the solvent residue is highly recommended not to exceed a certain concentration level as finished product.

- Food Sanitation Act/voluntary standards in the industry (Japan), regulations in Europe(Swiss Ordinance), Food and Drug Administration (FDA) regulations, and China national standards GB9685, etc.

Laminate processing

DIC’s Response Development of next generation inks/adhesives with less solvent residue, and contribution to reduce VOC and CO₂

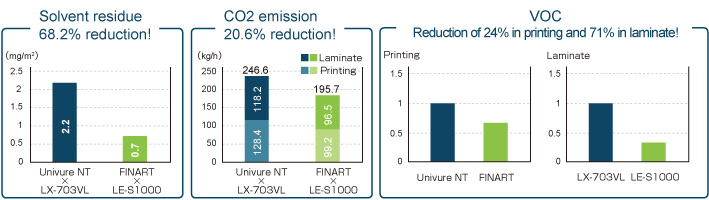

DIC focuses on the development of next generation inks/adhesives in preparation for achieving reduction of solvent residue/VOC and printing quality that enhances product values. The newly developed gravure ink “FINART,” which is toluene-free and methyl ethylketone (MEK) * -free type ink, especially responds to the food packaging regulations in Europe (Swiss Ordinance). Furthermore, it also secures high printing quality with small amount of solvent due to the fact that it has low viscosity and high concentration, enabling VOC and CO₂ reduction in the printing process.

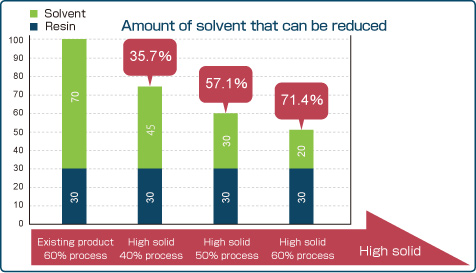

DIC also focuses on the development of “super high solid type,” adhesives with which solvent is reduced by 70% by increasing the solid content in laminating process, and “solvent-free type” adhesives. Those activities enable DIC to promote the promising products with the best balance of performance and cost.

We assure that DIC Group has established internal development systems in all aspects of pigments, and synthetic resins (including adhesives). Therefore, we are in a position to fully respond to various market needs, such as environment friendly and high performance, etc., to offer value creation in the packaging area in various regions, including Japan, Asia, Europe, and the U.S.

- Organic solvents that may cause symptoms of poisoning when inhaled over a long period or a large amount.

VOICE

Global standard of gravure inks

Laws and regulations worldwide for food packaging and inks has become strict more and more in recent years, shifting from “negative list regulations that only specify prohibited substances”(NL) to “positive list regulations that only specify approved substances”(PL). DIC quickly responded to such movements, reviewed product designing from raw material source, and took on the challenge of developing toluene-free and methyl ethylketone-free products. “FINART,” is a product that provide the beautiful package and high ink performance with safety.

Dispersion Technical Group 1 Dispersion Technical Department 1 Manager Yoshihisa Shirasaki

Proposing highly performance laminate adhesives

Laminate adhesives are roughly categorized into 3 types which are; organic solvent type (conventional type/high solid type), solvent-free type, and water-based type. DIC focuses on super high solid type and solvent-free type of adhesives as we prioritize the reduction of solvent, VOC and waste liquid, in addition to the basic performance of adhesives. On the other hand, we also take initiatives of simplifying package composition which contribute to the cost reduction by replacing the films with adhesives having gas barrier function, etc. We will be eagerly working on the development of highly composite products, based on our elemental technologies on a global scale, so that we can contribute to the sustainable growth in the market.

Dispersion Technical Group 2 Dispersion Technical Department 1 Manager Shigekazu Takahashi

Special Topics 2013

Inks/adhesives for food packaging

We want to use them with security because we need them in our lives.

FRP sheet pile for construction

Faster and safer sewer construction that supports our living environment

Epoxy resins/curing agents for electronic substrate

Even convenient tools that support the information society must be considerate to the environment.

TOPICS

Supporting the Development of a New Technology to Facilitate Precise Brand Color Reproduction and Management Worldwide

Drawing on its exclusive technologies and network capabilities, DIC Group company Sun Chemical Corporation has played a crucial role in a project aimed at ensuring a consistent global image for one of Heinz’s main brands.

Downloaded worldwide for the convenience of digital guide (As of May 31, 2013)

DIC digitalized the COLOR GUIDE in October, 2010, and started releasing it as a free application for smartphones (iPhone by Apple). Since then, we have been expanding the users while enhancing compatible OS and contents.