Sustainable Technology and Product Development

Proposing Solutions that Leverage Core Technologies

Goals and Achievements of Major Initiatives

Enhance ability to develop products and technologies that facilitate contribution to a sustainable society.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 |

|

|

★★ |

| 2025 |

|

― | ― |

Accelerate efforts to develop products that contribute to sustainability.

| Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|

| 2024 | Accelerate efforts to develop products that contribute to sustainability. | Efforts in the area of synthetic resin–related products led to the development of a number of products for infrastructure repair that have obtained Japan’s Biomass Mark designation. | ★★ |

| 2025 | Accelerate efforts to develop products that contribute to sustainability. | ― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Achieving Sustainable Growth

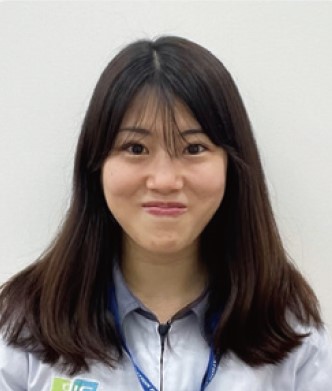

With the aim of realizing its vision statement, “We improve the human condition by safely delivering color and comfort for sustainable prosperity— Color & Comfort,” the DIC Group strives to add depth to its existing basic technologies in the areas of optics and color, organic materials design, polymer design and dispersion, and to foster new technologies in the areas of inorganic materials design and biomaterials design. The Group also actively promotes the use of AI and materials informatics (MI), as well as the training of AI specialists.

To build a portfolio of next-generation products and new technologies and drive sustainable growth, the DIC Group continues working to integrate Groupwide technological resources, as well as promotes open innovation by, among others, collaborating with industrial concerns, government bodies and academic institutions and making use of CVC.

Specific Initiatives

The DIC Group is advancing the development of a variety of materials and components that improve the environmental performance of the products in which they are used, making the use of DIC products a way customers can contribute to addressing global environmental issues. In Japan, the Group devotes approximately 51% of its technological resources to the development of such products. Specific key initiatives and achievements are introduced below.

Packaging & Graphic Segment

Newly developed printing inks included a next-generation ink for paper containers that combines oil-based ink and a UV-curable overprint varnish, which was unveiled at Tokyo International Packaging Exhibition 2024 (TOKYO PACK 2024). DIC also announced that a waterborne coating varnish approved as a food contact material and achieves outstanding water and oil resistance, while at the same time containing no PFASs, had been adopted for use in paper food cups manufactured without plastic film. In addition, the DIC Group introduced a subscription-based digital service that leverages color management technology to enable the accurate and prompt generation of desired color data using offset, gravure, flexo and inkjet printing.

In the area of packaging materials, DIC inaugurated a proprietary polystyrene dissolution and separation facility, a significant step toward achieving the packaging materials industry’s first-ever closed-loop recycling system for colored and/or patterned polystyrene foamed food trays that deploys material recycling.

Newly developed products overseas include a deinkable water-based printing ink that meets recyclability standards for shrink labels used on high-density polyethylene containers, as well as a biorenewable low-migration ink for hightemperature food labels.

Color & Display Segment

In addition to developing pigments for color filters used in displays, efforts emphasized the launch of effect pigments for cosmetics with unique colors and sustainability features. In pigments for inkjet inks, DIC launched water-based pigment dispersions compatible with nonabsorbent media such as food packaging, PVC wallpaper and labels.

Overseas, efforts included expanding the DIC Group’s lineup of high-performance, design-friendly solar heat–suppressing black pigments, as well as launching a new line of effect pigments for automotive coatings that deliver highly saturated color and shine.

Functional Products

Highlights in the area of synthetic resins include commencing mass production of lowdielectric resins for circuit boards for next-generation 5G/6G-enabled communications devices. DIC also proceeded with the development of an epoxy resin designed to facilitate easy disassembly, as well as a heat-resistant epoxy resin curing agent that can withstand temperatures up to over 200°C and is recyclable. Efforts to promote sustainable products included obtaining Japan’s Biomass Mark designation for products used in infrastructure repair, including an asphalt crack filler, a nonslip pavement binder and a top coat for drainage pavement. In surfactants, the Company developed and promoted the expansion of its lineup of PFAS-free antifoaming agents for lubricating oils for EVs that boast excellent antifoaming properties, thermal stability and durability.

Working with two plating manufacturers, DIC developed a new PPS compound that can be plated onto metals using existing plastic plating lines. In the area of automotive components, the move toward electrification is spurring the increased use of plastics for electronic device housings. This new PPS compound imparts electromagnetic shielding properties tailored to specific frequency bands. In industrial-use adhesive tapes, the Company expanded its lineup, as well as bolstered production, of toluene-free ultrathin tapes for smart devices.

A Global R&D Configuration that Underpins Product Development

The DIC Group’s R&D organization in Japan comprises the Technical Management Unit, which is responsible for product development and modification connected directly to businesses; DIC Graphics’ Technical Division; the R&D Management Unit, which is responsible for adding depth and potency to existing basic technologies; and the New Business Development Headquarters, which is charged with creating strategic new businesses and commercializing business units’ next-generation products. Overseas, the Group’s R&D is conducted by the Sun Chemical Group’s research centers in the United States, the United Kingdom and Germany; Qingdao DIC Finechemicals Co., Ltd., in the PRC; printing inks technical centers in the PRC and the Asia–Pacific region; the Polymer Technical Center—China; the Solid Compound Technical Center–Asia Pacific; the Pigment Technical Center–Asia Pacific; the DIC/Earthrise Algae Research Center in the United States; the Tape Technical Center–China; and the 3D Printing Materials Laboratory– Korea. These facilities are working as one to promote the global development of products and technologies.

Product Stewardship

The DIC Group views product stewardship as a key aspect of its operations. The Group has established a global product stewardship team for printing inks, adhesives and other products used in food packaging, which it supplies to customers around the world. The team shares information on regulations and relevant topics from various markets, as well as advances awareness thereof and provides training. Knowledge thus gained is incorporated into product design and is used to produce compliance certificates across the supply chain, which are sought by customers worldwide.

The DIC Group also strives to maintain a solid grasp of laws and regulations in different countries and territories, and of trends in environmental initiatives, to ensure its ability to design products that comply with diverse controls on the use of chemical substances. In addition, the Group conducts environmental assessments on a continuous basis.

Intellectual Property

Basic Approach

To achieve the goals of DIC Vision 2030, the DIC Group is promoting a variety of key initiatives, focusing on pursuing structural reforms and greater efficiency and launching new businesses in priority business areas, in line with its global intellectual property business strategy.

In preparing for the launch of new businesses in the smart living area, one of five priority business areas, the DIC Group is advancing strategies for building a competitive intellectual property portfolio by further leveraging its technology intelligence (TI) tools and enhancing its intellectual property risk management system to create a framework for the effective use of its intangible assets that is worthy of stakeholder trust.

Leverage TI in Business Strategy Planning

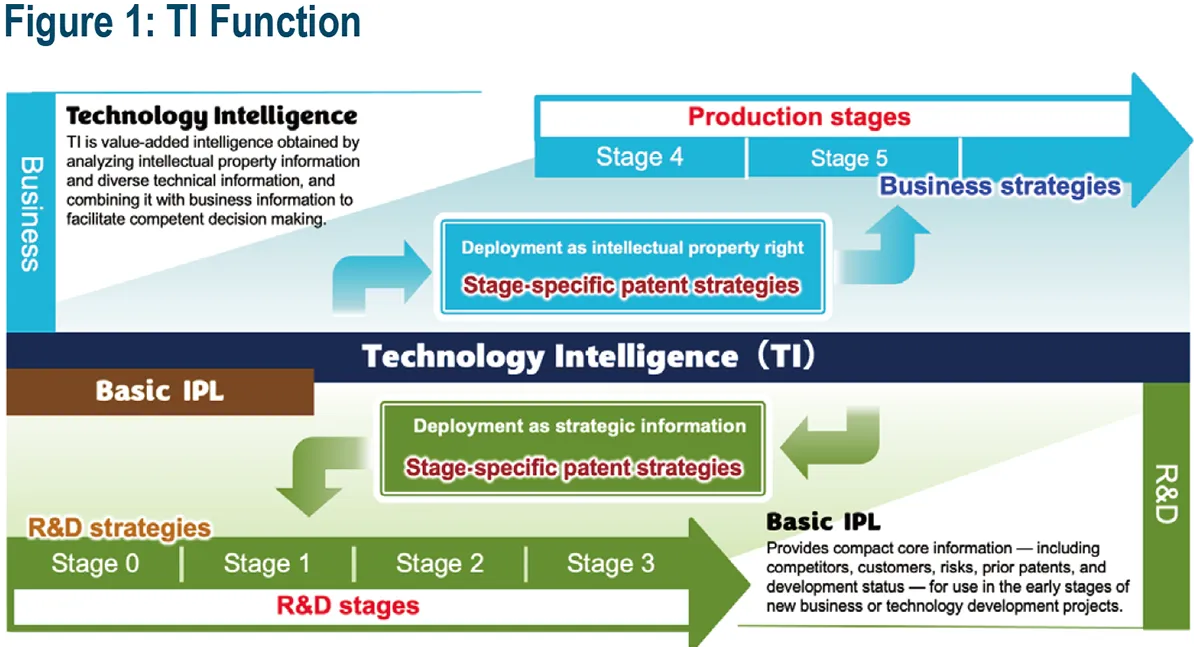

TI is value-added intelligence obtained by analyzing intellectual property information and diverse technical information, and combining it with business information as necessary, to facilitate the most competent decision making. By creating a business promotion– related TI function within its Intellectual Property Center, the DIC Group makes it possible to narrow down measures implemented to those with a high probability of success and to help prioritize the balanced allocation of management resources. In particular, in the early stages of promoting a new business or technological development theme, this means providing core information, including a basic intellectual property landscape (IPL) detailing competitors, customers and risks, among others, in a concise format, thereby facilitating the selection of themes that are most likely to be successful. The Company has also established a process for confirming whether efforts to realize new businesses based on these themes proceed appropriately using intelligence derived at the technology development, commercialization and mass production stages. This framework is key to the Group’s new Direct to Society business creation mechanism.

Strategies for Building a Competitive Intellectual Property Portfolio

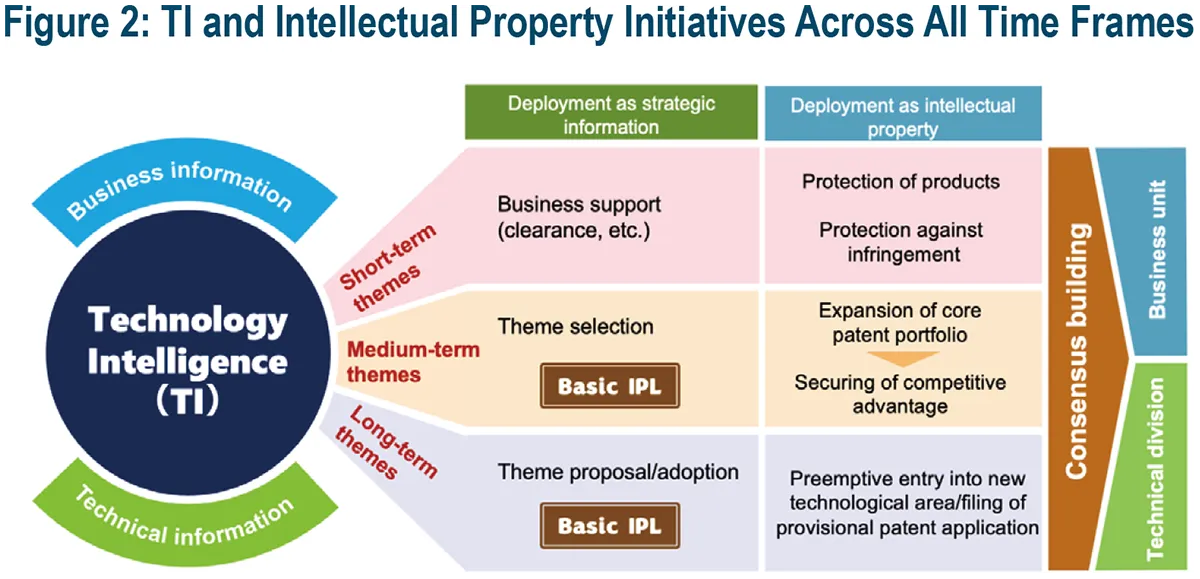

To facilitate the swift launch of new businesses, the business units, technical divisions and Intellectual Property Center work together to promote intellectual property–related initiatives across all time frames. As shown in figure 2, TI is used not only in the analysis of intellectual property but also as strategic information for the selection, as well as the proposal and adoption, of themes for developing new businesses, helping to facilitate consensus building by the aforementioned three parties.

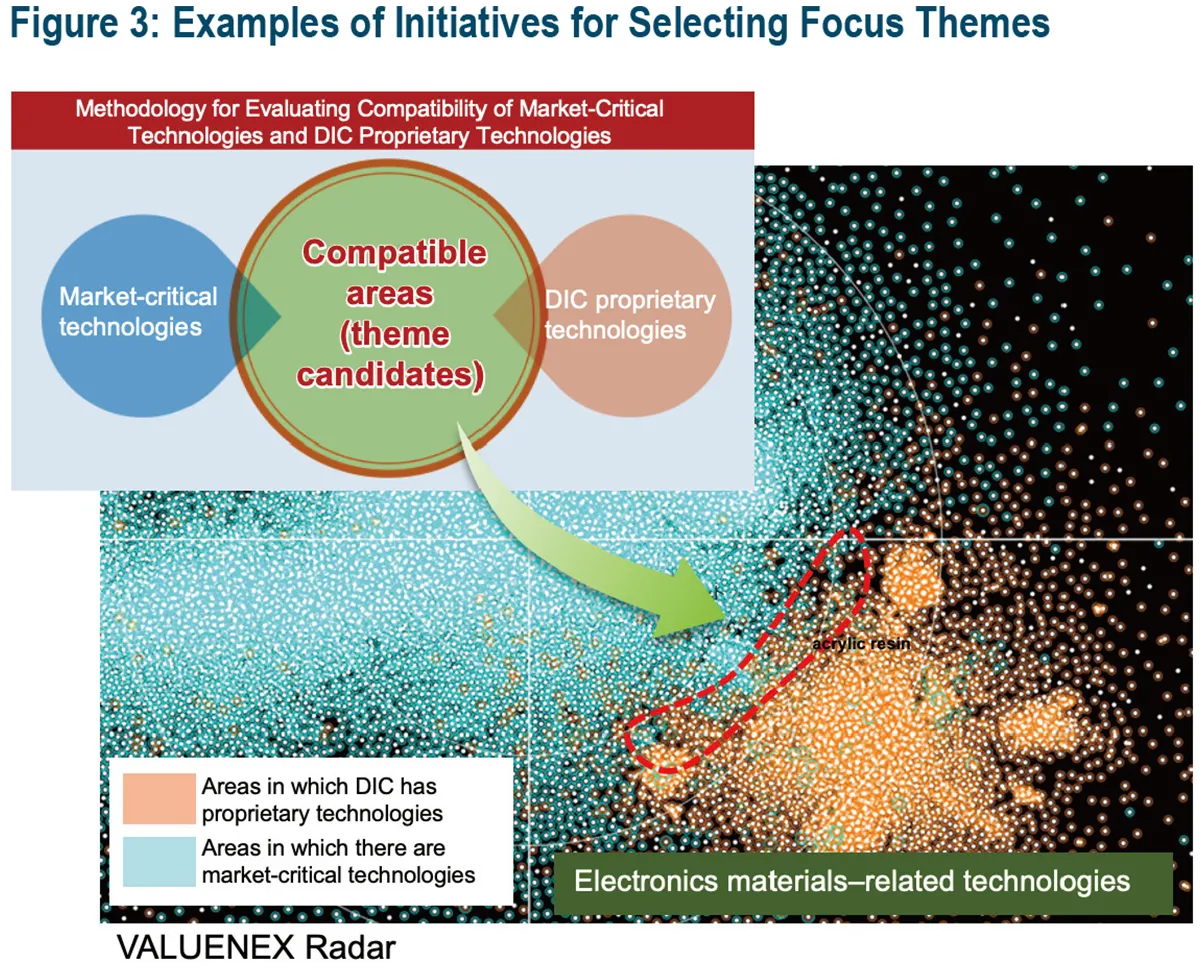

One initiative the DIC Group is promoting to select key technological development themes, shown in figure 3, is the development of a methodology for comparing and analyzing key aspects of the external environment, such as market-critical technologies, and of the internal environment, notably the Group’s own proprietary technologies, based in intellectual property, and evaluating compatibility thereof. This methodology enables the Group to select themes in unique technological areas in which there are no competitors and promote the building of a patent portfolio designed to secure a competitive advantage from the early stages of development. This and other efforts will help the Group swiftly build an effective intellectual patent portfolio focused on its priority business areas, including chemitronics, that gives it a global competitive advantage in those areas.

The DIC Group’s patent strategy is highly evaluated by external observers, underscored by its position in the ranking of companies in the chemicals industry in Japan in terms of patent assets owned conducted by Patent Result Co., Ltd., and the global ranking of patent value growth conducted by LexisNexis.

Intellectual Property Risk Management System

In line with its basic policy on compliance, the DIC Group conducts exhaustive patent clearance searches in new markets and for new technologies, promoting contract management, meticulously managing confidential information and advancing initiatives to prevent counterfeiting, patent infringement and the use of similar trademarks. The Group also established the Risk Management Working Group, a subordinate entity of the Sustainability Committee, as part of its effort to strengthen its comprehensive framework for global risk management, which also includes minimizing intellectual property risks. Practical measures to eliminate risks are spearheaded by the staff of the Intellectual Property Center. Active use is also being made of new AI-based tools, including for patent classification, to ensure that patent research is both efficient and comprehensive.

The IP Portfolio Committee, which seeks to ensure the DIC Group’s intellectual property portfolio aligns with its businesses, and the Patent Reward Council, which deliberates on patent compensation as an incentive for technological development, are the Group’s principal bodies for the management of intellectual property. This, combined with effective management supervision that facilitates the promotion of intellectual property–related initiatives that respond to changes in the operating environment and appropriate disclosure regarding investments in intangible assets and other matters, has enabled the Group to realize a configuration for leveraging its intangible assets that has earned the trust of stakeholders.

VOICE

We developed a sustainable methacrylic resin that helps extend the useful life of key infrastructure.

In line with the efforts to promote carbon neutrality, in recent years the development of material and process technologies in the areas of civil engineering and infrastructure has progressed rapidly. Functional Materials Technical Group 4 pioneered the development of three products for infrastructure repair and paving that are made with biomass materials. These products maintain the same high level of durability as conventional offerings while also contributing to the reduction of greenhouse gas emissions. We also succeeded in obtaining Biomass Mark designation for all three of these products, reinforcing their appeal as sustainable alternatives, and anticipate that this will further expand DIC’s share of this market.

Functional Materials Technical Group 4, Functional Materials Technical Division, DIC Corporation Mizuki Arase