Managing Industrial Waste

Goals and Achievements of Major Initiatives

Reduce industrial waste disposed of as landfill (achieve “zero emissions”).

Reduce industrial waste generated by production facilities.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Japan | 2024 |

|

|

★★★ |

| 2025 |

|

― | ― |

Promote recycling.

| Scope of target | fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Japan | 2024 | Resource recycling rate* DIC Group (Japan): 80% | Resource recycling rate: 84% | ★★★ |

| 2025 | Resource recycling rate DIC Group (Japan): 80% | ― | ― |

Reduce industrial waste disposed of as landfill (achieve “zero emissions”).

Reduce industrial waste generated by production facilities.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Sun Chemical | 2024 | Total industrial waste generated per unit of production: 10% reduction from the fiscal year 2019 level by fiscal year 2030 | Total industrial waste generated per unit of production: 0.0629 tonne (up 12% from fiscal year 2019) | ★ |

| 2025 | Total industrial waste generated per unit of production: 10% reduction from the fiscal year 2019 level by fiscal year 2030 | ― | ― |

- Resource recycling rate: (Volume of industrial waste recycled + Waste heat recovered) / Volume of industrial waste generated

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Policies and Organization

Basic Approach

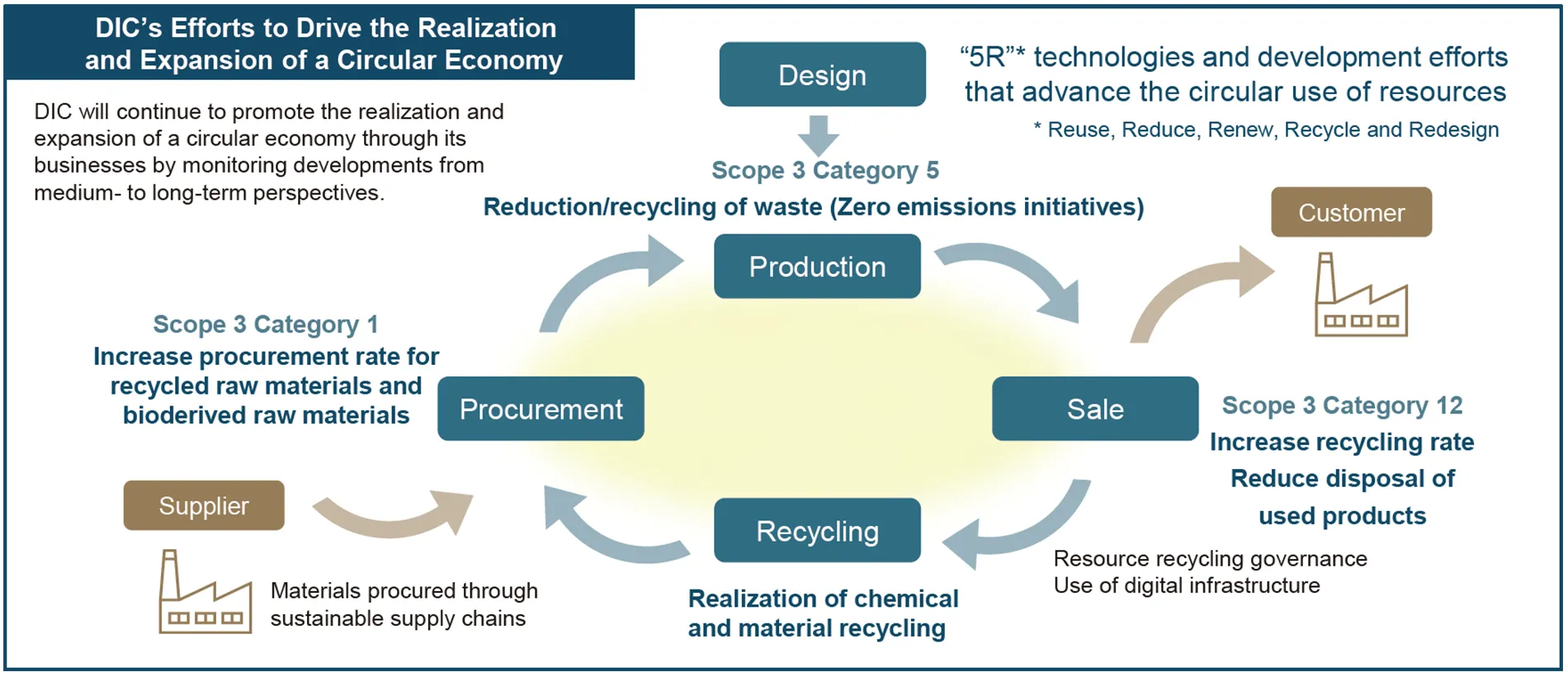

To promote the realization of a circular economy, the DIC Group strives to use resources effectively, as well as to reduce the impact of its disposal of industrial waste.

Illegal dumping of industrial waste may directly lead to serious environmental pollution. It is thus important to ensure the proper handling of waste from discharge through to final disposal. The DIC Group works to effectively manage and dispose of industrial waste as appropriate, depending on degree of risk, in compliance with the laws of the countries and territories where its production facilities are located.

In seeking to promote the realization of a circular economy, the DIC Group is stepping up efforts to encourage the “3Rs” of waste management (reuse, reduce and recycle). Of particular note, the Group is striving to minimize production losses by increasing throughput yields. The Group also works to fully grasp and effectively manage industrial waste at its production facilities from generation and discharge on-site through to intermediate treatment and final disposal as landfill, as well as to reduce the volume of industrial waste it disposes of as landfill and to boost its resource recycling rate by increasing recycling (material and chemical) and recovering waste heat from incineration.

Principal Initiatives in Fiscal Year 2024

01Global DIC Group

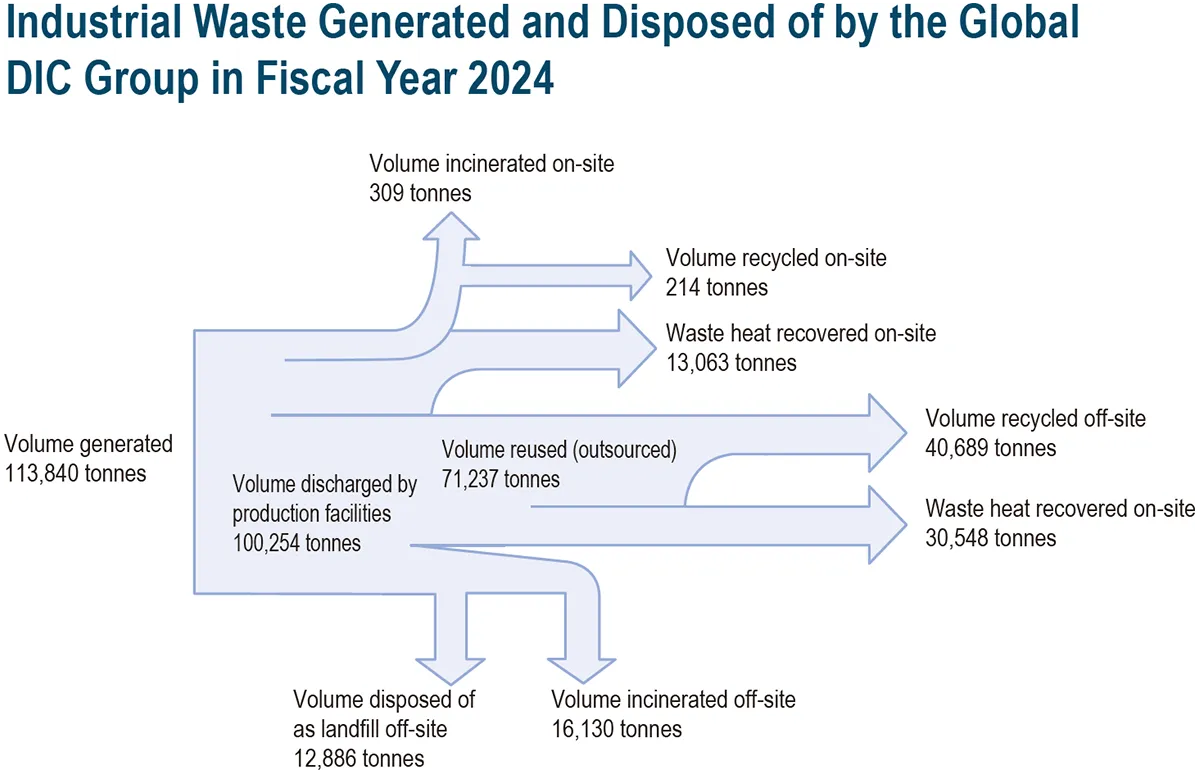

The DIC Group works to fully grasp and effectively manage industrial waste at its production facilities around the world from generation and discharge on-site through to intermediate treatment and final disposal as landfill. The chart below illustrates the management of industrial waste by the global DIC Group in fiscal year 2024. As this shows, the Group breaks down and calculates amounts at all stages of this process.

02DIC Group in Japan

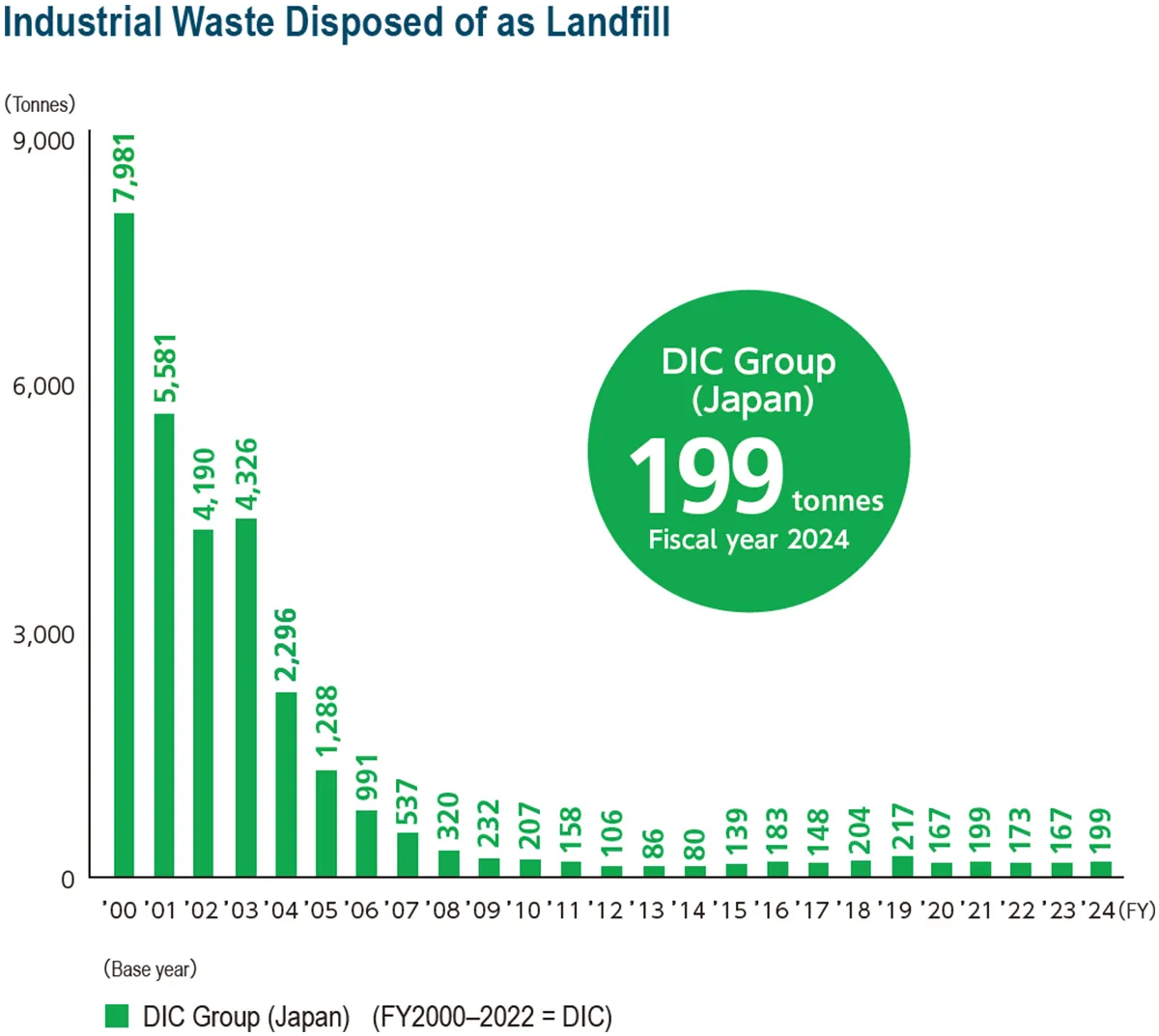

The DIC Group in Japan has long promoted zero emissions initiatives with the aim of reducing the total volume of industrial waste disposed of offsite as landfill by 95% from the fiscal year 2000 level, a target it actually achieved in fiscal year 2010. The Group is currently working to maintain the annual industrial waste it disposes of as landfill at this level (200 tonnes). With efforts to shift toward a circular economy intensifying in recent years, the Group is now also working to reduce industrial waste generated by production facilities, as well as to curb waste disposed of as landfill, and has set a target of 45,000 tonnes for the former.

In fiscal year 2024, the DIC Group in Japan met its target for industrial waste generated by Group production facilities in Japan. It amounted to 34,101 tonnes, a decrease of 14% from fiscal year 2023, thanks to robust initiatives at individual facilities. Industrial waste disposed of as landfill by Group companies in Japan totaled 199 tonnes, up 19% from the previous period but still below its 200-tonne target. While the decrease in overall industrial waste generated actually resulted in a smaller volume of waste requiring disposal as landfill, a change in the method of calculation resulted in an increase. Had the previous method been used, industrial waste disposed of as landfill would have decreased.

DIC Group companies also pressed ahead with efforts to ensure the appropriate disposal of equipment industrial waste containing polychlorinated biphenyls (PCBs). The disposal of industrial waste containing PCBs was completed.

Breakdown of Waste Generated by Production Facilities in Japan in Fiscal Year 2024

| Type of waste | Volume generated (tonnes) |

|---|---|

| Cinders | 937 |

| Sludge | 8,016 |

| Waste oil | 6,826 |

| Waste acid | 387 |

| Waste alkali | 2,252 |

| Waste plastics | 1,912 |

| Waste plastics (subject to the Act on the Promotion of Resource Circulation for Plastics) |

2,973 |

| Scrap rubber | 0 |

| Scrap metal | 1,915 |

| Waste glass, concrete and ceramic | 47 |

| Slag | 0 |

| Debris | 0 |

| Dust | 26 |

| Waste paper | 714 |

| Wood chips | 611 |

| Fiber waste | 0 |

| Animal and plant residues | 19 |

| Unwanted animal solid matter | 0 |

| Livestock excreta | 0 |

| Animal carcasses | 0 |

| Industrial waste from products containing mercury | 1 |

| Total for nontoxic waste (ordinary industrial waste, etc.) | 7,465 |

| Toxic waste (specially controlled industrial waste) | 34,101 |

VOICE

The origins of our passion for environmental education is DIC’s collaboration with the city of Yokkaichi.

DIC signed a comprehensive partnership agreement with the city of Yokkaichi in fiscal year 2023 with the aim of promoting efforts to balance the realization of a carbon-neutral society and sustainable industrial development. As part of this agreement, we conduct a comprehensive environmental education program for Yokkaichi elementary schools. My day job is plant operator, but I also served on the organizing committee for the Yokkaichi Children’s Science Seminar in August 2024, an educational event for elementary schools held in collaboration with 13 neighboring companies.

The seminar included making plastic shrink art with the students who took part, which allowed each child to express their own vibrant individuality. We also had an environmental quiz, during which we actually had children shouting out the answers while the questions were still being asked. This highilights how aware they already are of environmental issues. I look forward to the children sharing with their families what they learned about recycling. I can say for sure that the experience has changed my own recycling habits. The seminar also addressed the importance of providing items for recycling in an appropriate state.

Looking ahead, we will continue working to deepen understanding of environmental issues, as well as to promote educational activities for the next generation of individuals who will have to continue addressing these issues.

Polystyrene Production Department, Yokkaichi Plant, DIC Corporation Nanami Azusa

03Initiatives in Japan Related to Plastic Waste

The Act on Promotion of Resource Circulation for Plastics, which came into force in April 2022, obliges companies to make efforts to recycle plastic resources throughout a product’s life cycle, from design through to final disposal. Companies responsible for generating plastic waste specified under the Act are taking steps to reduce the volume they generate and to expand recycling into new plastic resources. DIC has disclosed plastic waste generated and plastic resources recycling data for the DIC Group in Japan since fiscal year 2023 in compliance with pertinent laws and regulations.

Plastic Recycling Rate and Resource Recycling Rate (Waste Recycled into Materials with Value + Waste)

| Domestic DIC Group company |

Waste | Materials with value + waste | ||||

|---|---|---|---|---|---|---|

| Volume discharged (tonnes) |

Recycling rate | Resource recycling rate |

Volume discharged (tonnes) |

Recycling rate | Resource recycling rate |

|

| DIC Corporation | 3,206 | 31% | 92.4% | 4,219 | 47.6% | 94.2% |

| DIC Graphics Corporation | 243 | 59.9% | 86.9% | 246 | 60.4% | 87.1% |

| DIC EP Corp. | 31 | 16% | 96.9% | 31 | 16% | 96.9% |

| DIC Color Coatings, Inc. | 28 | 5% | 100% | 28 | 5% | 100% |

| DIC Kitanihon Polymer Co., Ltd. | 33 | 29% | 58.6% | 33 | 29% | 58.6% |

| DIC Kyushu Polymer Co., Ltd. | 14 | 100% | 100% | 14 | 100% | 100% |

| DIC Decor, Inc. | 158 | 38.1% | 49.1% | 232 | 55.4% | 62.9% |

| DIC Plastics, Inc. | 27 | 59.6% | 93.8% | 100 | 89% | 98.3% |

DIC Corporation Recycling rate of 48.2% (fiscal year 2025)

DIC Graphics Corporation Recycling rate of 63.0% (fiscal year 2025)

04Deployment of the E-Manifest System in Japan

Japan’s e-Manifest system helps manage the movement of industrial waste by facilitating the electronic transmission of manifest information and tracking the flow of waste from generation through transport, intermediate treatment and disposal. In fiscal year 2016, the DIC Group in Japan introduced GENESYS ECO, a comprehensive industrial waste management system, for use with the e-Manifest system. Deployment of this system was completed at all domestic Group production sites in fiscal year 2019, an achievement that has helped to both save labor and ensure legal compliance.

05DIC Group in Other Countries

In addition to ensuring that disposal of industrial waste complies with national and regional legal and regulatory requirements, the DIC Group’s production facilities outside Japan work to minimize waste through the voluntary recycling and reuse of materials. At production facilities in the Americas and Europe, Greater China and the Asia–Pacific region, the Group is introducing new waste treatment systems and promoting the horizontal deployment of best practices, including those aimed at improving production processes. In fiscal year 2024, waste generated by DIC production sites in other countries and territories totaled 79,739 tonnes, up 15% from fiscal year 2023. Industrial waste disposed of as landfill at these sites rose 10%, to 12,687 tonnes. Both increases are attributable to an increase in production volume. Going forward, the Group’s regional headquarters outside Japan will focus on reinforcing compliance with local laws and regulations, as well as reducing the generation of industrial waste and the disposal thereof as landfill.