DIC announces that it is developing an innovative near infrared-based food contaminant detection system with Mitsui Kinzoku Instrumentations Technology —Innovative technology responds to food safety-related needs—

- Business & Product

- News Release

Tokyo, Japan–DIC Corporation announced that it is developing a near infrared-based food contaminant detection system in collaboration with Mitsui Kinzoku Instrumentations Technology Corporation, based in Aichi Prefecture.

Contaminants in food products may result in serious incidents that endanger the safety of food for consumers. The occurrence of such an incident can threaten the existence of a food product manufacturer. Accordingly, such companies implement various measures at the production stage to prevent contaminants from getting into their products. They also take steps to ensure that should contamination occur, affected products do not reach the market.

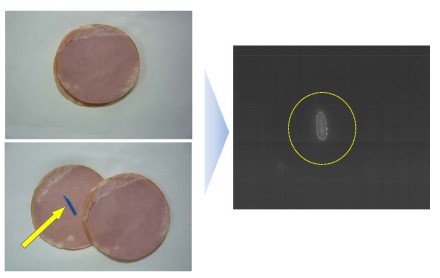

Magnetic and X-ray-based detection devices enjoy widespread popularity. While such devices are excellent at discovering metals, stones and other high-density contaminants, they are less effective in screening for plastics, rubber and other materials with a low relative density. Accordingly, demand has long existed for technologies that would facilitate the detection of low-density contaminants.

The system currently under development by DIC and Mitsui Kinzoku Instrumentations Technology combines dyes that emit near infrared and a device that detects near infrared and is thus expected to be able to identify plastics and other contaminants the detection of which has traditionally been considered difficult. Thanks to its safety—it has little damage on human health and food products—and the ease with which it penetrates matter, near infrared is already used in near infrared spectroscopy (NIRS) inspection systems for finished food products, which detect transmitted light in the near infrared region. As a consequence, the potential for application in the detection of contaminants in food products is seen as being high. With the new system, light-emitting dyes are previously mixed into plastic components for food processing line equipment. As a consequence, even if such a component were to accidentally fall into a food item during processing the light emitted by the plastic would be visible to the device, ensuring highly sensitive contaminant detection.

As a partner in this joint R&D project, DIC is currently developing near infrared dyes for the new system that deliver higher emission intensity than conventional dyes and can stand up to melt-kneading into plastic. DIC is also leveraging proprietary compounding technologies to commercialize masterbatches and compounds comprising dyes kneaded into plastics. Mitsui Kinzoku Instrumentations Technology will use the materials developed by DIC to design a highly sensitive near infrared detection device, capitalizing on its expertise in NIRS inspection systems for vegetables, fruits and other products, as well as on the distinctive characteristics of near infrared. Mitsui Kinzoku Instrumentations Technology will also promote the development of an inspection system that enables the device to be integrated into existing processing lines.

Used in combination with existing metal detection and X-ray-based detection devices, the new system will significantly reduce the risk of contamination for manufacturers, thereby contributing to greater food safety and peace of mind for consumers.

—Ends—

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.