DIC Develops Wireless Sensor which realizes Soft Electronics New sensor, which facilitates convenient installation and removal, as well as boasts outstanding safety and decorative properties, can be used to detect temperature, humidity and light intensity in commercial complexes, office buildings and other facilities

- Business & Product

- News Release

Tokyo, Japan– DIC Corporation announced that it has developed a sensor for detecting internal temperature, humidity and light intensity in commercial complexes, office buildings and other facilities and in and in the fall of 2018 began verification testing of the sensor in collaboration with several other companies. Using multiple DIC Group materials enabled DIC to realize a groundbreaking wireless sensor that is flexible, easy to install and remove, and boasts outstanding safety and decorative properties.

Monitoring the indoor climate is crucial to maintaining comfortable environments in commercial complexes and office buildings. Moreover, given the increased importance of reducing environmental impact, indoor climate data is essential to the effective implementation of measures to lower the energy consumption of air conditioning systems. Wired sensors have dominated to date, but issues have persisted, notably difficulties with installation in existing facilities and the inability to reposition appropriately to accommodate new tenants and floor layouts. Wireless sensors also exist, but because many conventional offerings feature molded plastic casings there is a danger of them coming loose and falling if convenient double-sided adhesive tapes are used for installation. The thickness of wireless sensor casings and the lack of color choices has also prompted increased calls for improvements to enhance compatibility with facility designs.

Key features of the newly developed sensor

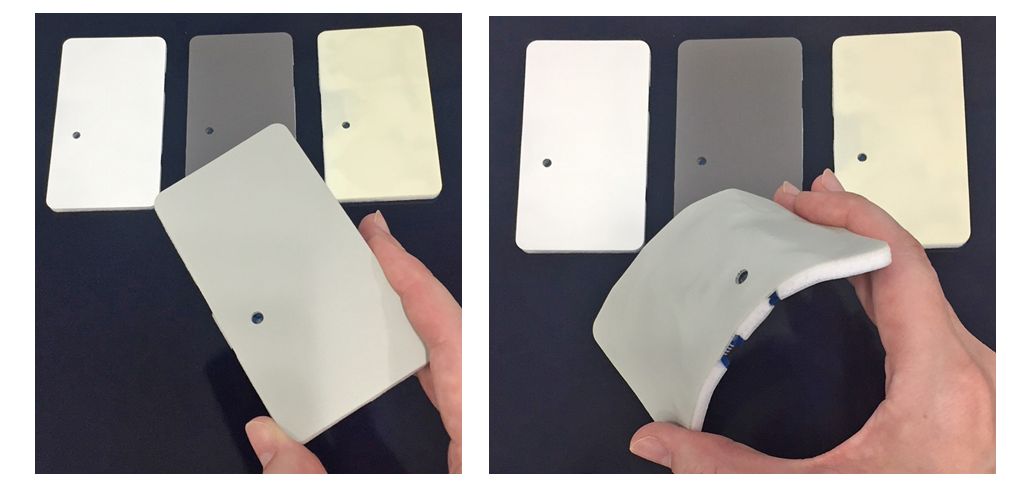

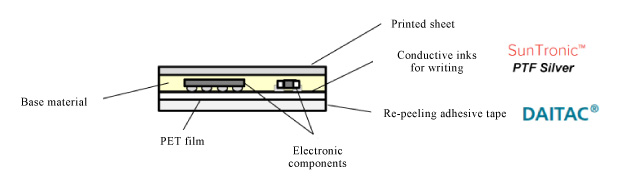

1.SunTronic™ conductive inks, a DIC Group product, were used to print circuits on substrates, enabling DIC to achieve a soft, flexible casing that is also thin (aprx.5mm) and light (aprx.20g). The use of DIC’s DAITAC® re-peeling adhesive tapes to mount the sensors facilitates easy installation and datachable.

2.Substrates are made from flexible, flame-retardant materials and clad with printed sheets, thereby delivering both safety and decorative properties.

3.The use of LoRa (Long Range)—a low power wide area (LPWA) network technology that enables long-range communication with low power consumption—and a simple star network topology*, facilitates battery-powered operation and easy equipment management, thereby reducing system costs.

DIC will press ahead with verification testing and envisions commercialization of the new sensor within one to two years.

The DIC Group has positioned the creation of business models that address social imperatives as a key medium- to long-term theme that will guide its efforts to realize the image it aspires to in fiscal year 2025. Accordingly, it will continue working diligently to develop products and technologies that contribute to sustainability for its customers and society.

* “Network topology” is a generic term for the topological structure of a network. A star network features a central hub to which all devices are connected. This is a much simpler structure than that of a mesh network, in which all devices are also connected to one another.

-Ends-

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.