DIC Develops Sheet-Form Passive Heat Storage Material to Effectively Harness Solar Heat —Successful development of sheet-format material will facilitate easy use in housing construction and and expand the scope of applications—

- Business & Product

- News Release

Tokyo, Japan–DIC Corporation announced that it has developed a sheet-form passive heat storage material* for use in construction that helps maintain comfortable room temperatures. Created by dispersing a phase change material (PCMs)† in resin, this new material can be cut, fastened with screws or processed in other ways at construction sites, which is not possible with conventional offerings. DIC’s new product thus represents a revolutionary advance in PCMs for building because it can be used easily at construction sites.

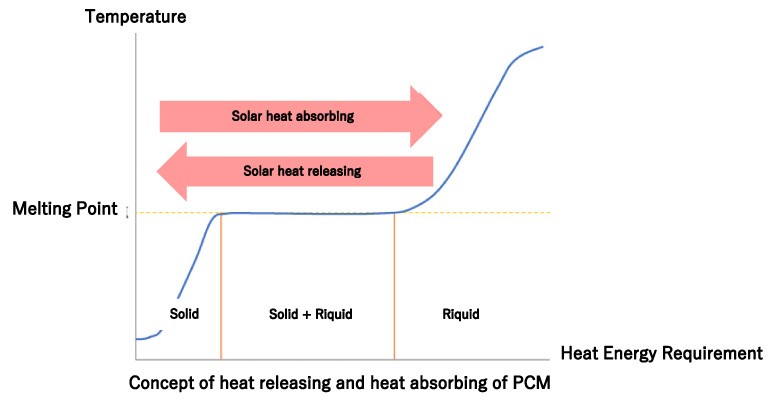

PCMs, which utilize the thermal properties of phase change-the process of changing from liquid to solid and vice-versa-liquefy at a certain temperature above melting point. PCMs laminated together with other materials have long been used in construction, but difficulties in altering size and poor workability have prompted housing builders and general contractors to call for the development of new materials.

Leveraging its proprietary coating and formulation technologies, DIC succeeded in developing a sheet-form PCM by establishing a technology for uniformly dispersing heat storage materials into resin with no degradation of the material’s properties to create a thick film, thereby preventing the heat storage material from oozing and leaking during phase change. In addition to a performance comparable to that of latent heat storage material in laminated packages, the new material can be cut, bent and fastened into place with screws on-site and is thus expected to deliver significantly greater workability. DIC’s new material can also be laminated together in advance with a variety of building materials such as plasterboard and flooring, significantly expanding options for imparting PCM properties to houses and other buildings. The material can also be used in walls and ceilings, which is difficult with conventional PCMs.

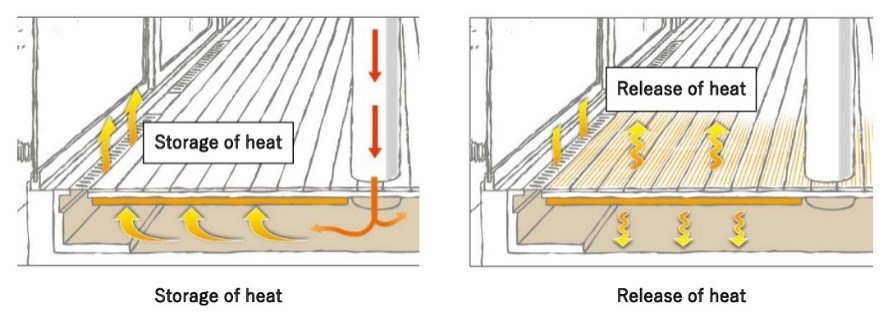

DIC verified the effectiveness of the new material through participation in the Technology Development of Solar Thermal Energy Utilization Houses project, organized by the New Energy and Industrial Technology Development Organization (NEDO). The first company to adopt the new material for commercial use is OM Solar, Inc., which collaborated with DIC to conduct verification trials. The new material will be launched in July 2017 by DIC Decor, Inc., the DIC Group company responsible for the manufacture and sale of building materials. OM Solar provides heating systems that utilize solar heat. Incorporated into the OM’s heating systems, DIC’s new material absorbs solar heat during the day and releases it at night when the ambient temperature has dropped, thus helping to mitigate nighttime declines in room temperatures and reduce energy required for heating.

The laboratory of Associate Professor Masayuki Mae of the University of Tokyo conducted simulations to forecast the impact of DIC’s new sheet-form heat storage material on annual energy use at NEDO verification facilities in Tokyo and Saitama. Simulations at the Tokyo facility projected an annual reduction of 19.1%, while those at the Saitama facility indicted a potential annual reduction of 14.7%.

DIC’s new sheet-form heat storage material can also be used in summer as a cold storage material, absorbing cooler outside air through the night and releasing it during the day to mitigate daytime increases in temperature.

In the housing market, needs are increasing in a variety of areas, including energy conservation, comfort and health. Such needs are driving a diverse range of proposed structures, building methods and materials. DIC has been a participant in Japan’s Heat Storage Building Materials Consortium, which was established to promote the use and development of heat storage building materials, a new genre of building materials, since its inception. The Consortium’s tasks include standardization via the creation of Japan Industrial Standards (JIS) and Japan Testing Center for Construction Materials (JTCCM) standard of testing methods, which will determine methods for measuring the performance of heat-storage materials, as well as reviewing simulations conducted to forecast the effectiveness of these materials in housing applications. These efforts are aimed at creating conditions that make it easier for housing builders and contractors to adopt heat storage materials for use.

While DIC’s new material has been launched as a heat-storage building material, the Company also intends to confirm its effectiveness for use in the constant-temperature transportation of pharmaceuticals, among others, as well as for horticultural, agricultural and other applications.

* Passive heat storage materials use renewable energy for heat absorption and radiation.

† PCMs: PCMs use heat released or absorbed during phase change, that is, the process of changing from solid to liquid/liquid to gas or vice-versa, with no change in material temperature. Heat storage materials use heat released during phase change from liquid to solid, while cold storage materials use heat absorbed during phase change from solid to liquid.

-Ends-

PDF download

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.