Spectrasense™ Black L 0082 novel black pigment significantly enhances near-infrared (NIR) signal detection for autonomous driving.

One of the world’s leading pigment companies, DIC Corporation (DIC), and wholly owned subsidiary, Sun Chemical Inc., combine business and technical resources to further develop, manufacture, and market Spectrasense™ Black L 0082, the innovative carbon black pigment alternative boasting outstanding solar heat management and excellent LiDAR signal detection needed to deliver tomorrow’s autonomous vehicles today.

Key Takeaways

- LiDAR sensors face a significant challenge when detecting objects, including other vehicles, that are coated with colors containing conventional carbon black.

- Replacing carbon black with the NIR-transparent Spectrasense™ Black L 0082 allows automakers and automotive paint formulators to formulate automotive coating systems with enhanced NIR signal reflection and improved LiDAR detectability.

- By replacing carbon black with the functional Spectrasense™ Black L 0082, coating manufacturers can deliver automotive coatings with the broadest gamut of colors, including neutral gray and rich dark tones, while providing near-infrared (NIR) reflectivity and detectability.

- Spectrasense™ Black L 0082 novel black pigment could be a game-changer for the automotive industry, significantly enhancing the detection of near-infrared (NIR) signals—a key component in the operation of LiDAR systems used in autonomous vehicles.

Significantly enhancing near-infrared signal detection, Spectrasense™ Black pigments also improve solar heat management in cars and buildings.

How Are New Functional Black Pigments Changing the Pigments Industry

Analyzing the global pigments market, DIC Color & Display Business Planning Department Manager Mineo Yoda believes the outlook is bright for the future of functional pigments:

“Our new functional black pigments, a significant milestone in the pigment industry, hold immense potential. Traditionally sold for solar heat management applications, these pigments now represent pioneering sensing applications, opening new horizons for DIC and Sun Chemical.”

“Moving forward, we are focused on expanding sales of functional color materials through our global sales channels and diversifying our product portfolio. We aim to leverage DIC's R&D capabilities with Sun Chemical’s to develop more sustainable products, enhancing our overall value proposition.”

Mineo Yoda

DIC Color & Display Business

Planning Department Manager

Why Is Managing Near-Infrared Radiation Vital for LiDAR-Based Systems

The management of near-infrared (NIR) radiation is now widely recognized as being crucial for various applications, such as managing heat build-up or observing objects using LiDAR (Light Detection and Ranging) based systems.

LiDAR systems, often used in conjunction with other mapping systems (visible, RADAR, vehicle-to-vehicle interactivity, etc.), are a key component in enabling vehicles to operate autonomously in real-world environments. In autonomous vehicles (AVs), LiDAR sensors utilize reflected NIR signals to scan the surroundings, guiding the vehicle along a safe path.

LiDAR (light detection and ranging) sensors produce 3D maps of the surroundings, aka point clouds, for higher autonomous performance.

Why Do Objects Coated in Conventional Carbon Black Pigments Impede LiDAR Sensors

LiDAR sensors face a significant challenge when it comes to detecting objects, including other vehicles, that are coated with colors containing conventional carbon black (P.Bk.7) pigments. These pigments, which are widely used in most colors, particularly neutral grays or dark low-chroma colors, have high NIR absorption, leading to a decrease in LiDAR detectability. Spectrasense™ Black L 0082 is here to change that.

The replacement of carbon black with the NIR-transparent Spectrasense™ Black L 0082 allows for the formulation of automotive coating systems with enhanced NIR signal reflection and improved LiDAR detectability. It offers superior coloristic performance and enables the formulation of neutral grey and rich dark shades near masstone.

How Does Spectrasense™ Black L 0082 Eliminate Trade-Offs Posed by Carbon Black Pigments

Previously, automakers and consumers faced a trade-off between luxurious color design and superior LiDAR signal response. The 'go-to’ standard black pigment, carbon black, supports the formulation of dark shades in automotive coatings, from deep blacks to reds, blues, and greens, as well as neutral colors, such as metallic grays; carbon black also enhances secondary properties such as coating opacity—playing a vital role in automotive body color design—a key factor in the discerning consumer’s decision to purchase a new vehicle.

With the introduction of Spectrasense™ Black L 0082, this trade-off is no longer necessary, as it offers both superior color design and LiDAR signal response.

By replacing carbon black with the functional Spectrasense™ Black L 0082, coating manufacturers can deliver automotive coatings with the broadest gamut of colors, including neutral gray and rich dark tones, while providing near-infrared (NIR) reflectivity and detectability. This enables improved autonomous vehicle driving performance without compromising the visual design.

Automotive coatings containing Spectrasense™ Black L 0082 reflect LiDAR signal NIR wavelengths, enhancing detectability.

What Is Near-Infrared Light

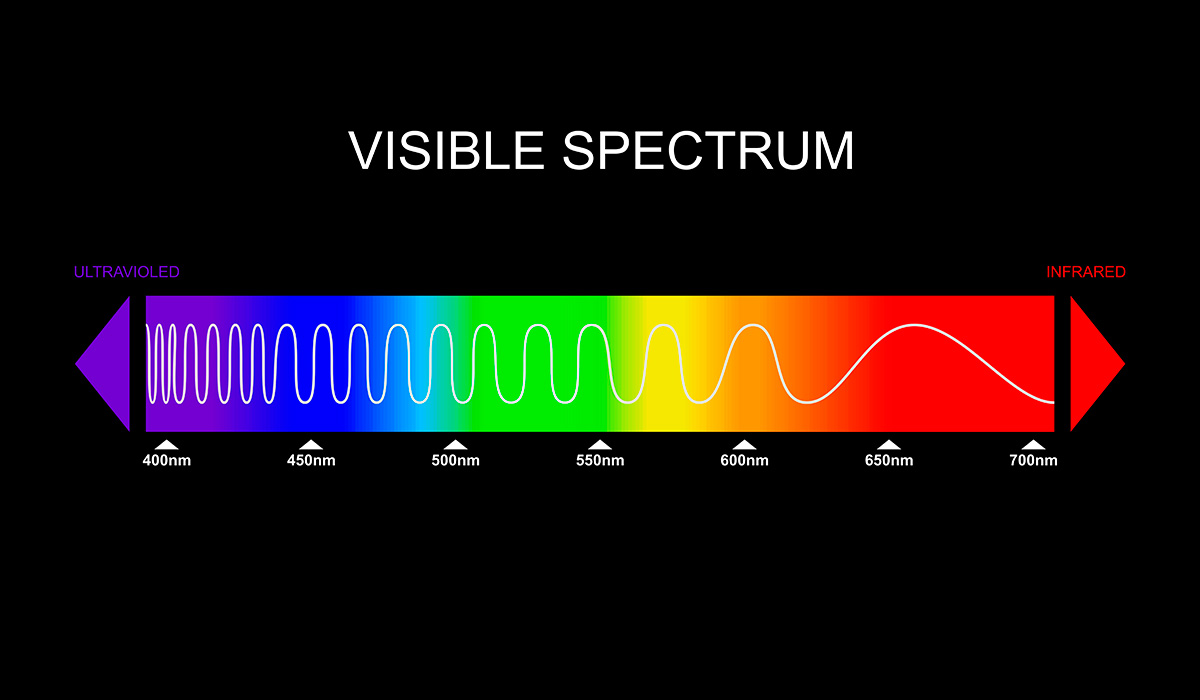

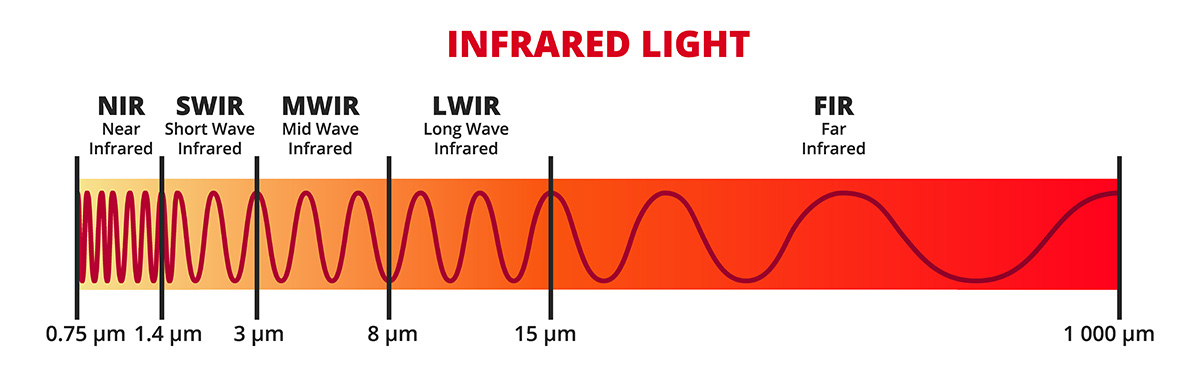

Infrared radiation (IR)—also called infrared light—is the electromagnetic radiation range (EMR) occupying the spectrum between microwaves and visible light.

The electromagnetic radiation range (EMR) spectrum between microwaves and visible light

The infrared spectrum can be further divided into near-, mid-, and far-infrared light. Near-infrared light (NIR) is the section of electromagnetic radiation (EMR) wavelengths nearest to, but just beyond, what human beings can see.

The infrared spectrum is divided into near-, mid-, and far-infrared light.

What is LiDAR

Light Detection And Ranging (LiDAR) systems are three-dimensional detection systems for the entire physical environment surrounding a LiDAR sensor array. LiDAR works like the more familiar RAdio Detection And Ranging (RADAR) systems.

Where RADAR systems use longer wavelength radio waves to determine the distance and velocity of targets, LiDAR systems use shorter wavelength light emitted from NIR lasers for improved spatial accuracy.

It is important to note that LiDAR systems use lasers at wavelengths that are safe for human beings and animals to interpret the immediate surroundings. They render all detected objects visible in three dimensions for highly accurate 3D representations of the surveyed environment.

Multiple LiDAR sensors work by sending pulsed NIR light waves into the surrounding environment. Each NIR light pulse bounces off objects located within range of each sensor, and each sensor automatically measures the time it takes for each return pulse to reach it, facilitating the calculation of the distances to objects.

By repeating this relatively simple process millions of times per second, LiDAR sensors create precise, real-time 3D maps of surrounding environments—also called point clouds. In autonomous vehicles, onboard computers use LiDAR point clouds to identify where objects are located and thereby navigate a safe path around them.

Automotive coatings containing carbon black absorb LiDAR signal NIR wavelengths, hindering detection.

How Do LiDAR Sensors Work on Autonomous Vehicles

Global automakers are now developing the necessary next-generation mobility technologies to further facilitate autonomous vehicle driving. Light detection and ranging (LiDAR) sensors can identify the shape, distance, and velocity of surrounding objects by irradiating them with NIR lasers and measuring the reflected light received from them.

This highly accurate spatial information is necessary for the autonomous vehicle to navigate accurately and for vital collision avoidance. However, LiDAR sensor cognitive impairment remains a significant factor in autonomous automobile accidents, and color pigmentation can be a significant contributor.

What Are the Drawbacks of Carbon Black Pigment-Based Automotive Coatings

Automotive manufacturers increasingly recognize the value of NIR reflective coatings for all color offerings to facilitate LiDAR NIR light detection. Carbon black pigments used in automotive coating systems and plastic components contain fine carbon particles that absorb radiation at wavelengths across the whole visible and NIR electromagnetic spectrum.

The absorbance of NIR wavelengths is not only problematic for LiDAR-based driving systems but also results in heat absorption. Increased solar radiation absorption raises the temperature of vehicle structures, which, apart from time-to-comfort-related issues, can affect the performance of onboard electronics.

It is important to note that exposing automotive electronic components to high temperatures often increases thermal stress, degrading their performance and reliability over time.

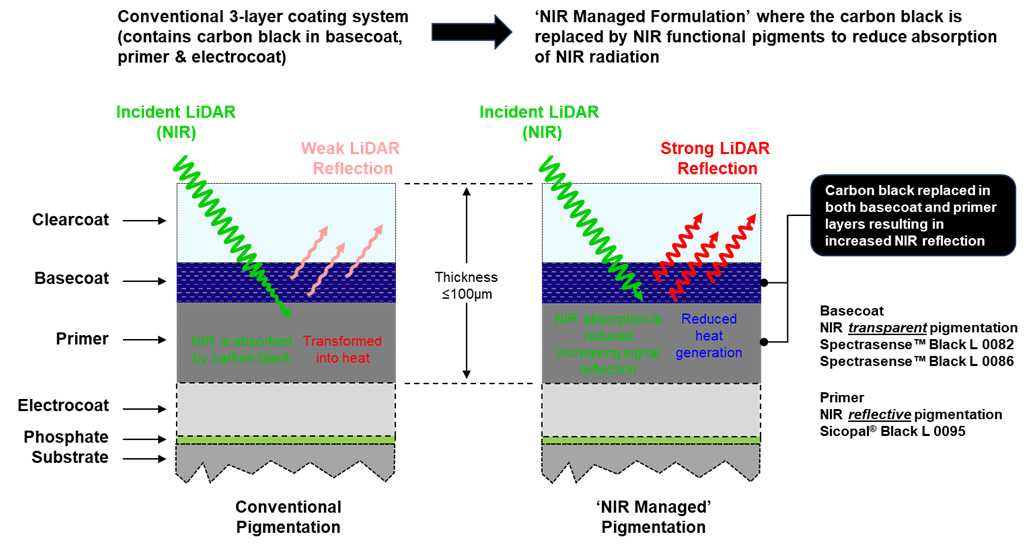

Through the development of NIR functional black pigments, the DIC Group pigments business unit developed NIR management components for conventional multi-layer coating systems. Using an NIR transparent-colored topcoat layer combined with an NIR reflective primer/substrate, an automotive coating can be formulated with strongly enhanced NIR reflection and detection.

Spectrasense™ Black L 0082 eliminates the traditional trade-offs between luxurious color design and superior LiDAR signal response.

How Do New Automotive Paint Color Formulations Support Superior LiDAR Detection

With the development of the Spectrasense™ brand, it is possible to formulate clean, deep, and dark colors without using carbon black pigments.

Traditional Three-Layer Automotive Coatings System

- Layer One: A primer layer to remove surface irregularities and protect the electrocoat.

- Layer Two: A base coat layer providing the required color.

- Layer Three: A clear coat layer to seal the coating, providing gloss and protection from the elements.

Replacing carbon black with Spectrasense™ Black L 0082 in the basecoat and

primer layers of a traditional three-layer automotive coatings system increases NIR reflection.

Traditionally used carbon black pigments in the primer and basecoat layers can be replaced with NIR-transparent or NIR-reflective functional black pigments, delivering high-performance color properties as well as the desired NIR reflectivity for LiDAR detection and low heat absorbance.

Automotive coating manufacturers can also use a similar pigmentation approach if the paint system in question omits conventional primers and instead uses a system comprising two modified base coat layers to fulfill the combined roles of the primer and base coat.

As NIR-transparent/NIR-reflective coatings employing functional black pigments may also be applied to a wide range of industrial products that employ LiDAR sensors or require heat management capability, the sky is the limit on potential applications and use case scenarios.

Revolutionary Perylene Black pigment improves jetness and enhances neutral colors

Revolutionary Perylene Black Pigment with High Jetness and Neutral Coloristics for Ease of Color Formulation

Global Innovation Manager–HP Organic Pigments, Color Materials, Sun Chemical, Switzerland, Dr. Paul Brown notes, “We successfully developed pigments for reducing NIR wavelength absorption for improved heat-shielding in building materials and improved this pigment technology for automotive coatings.”

Global automakers and automotive coating and plastics suppliers have long-needed pigments with NIR management capabilities, initially for heat management and later for LiDAR detection applications. The latest perylene black developments have achieved NIR management for heat management and LiDAR detection applications, along with improved coloristic performance for the near-masstone dark shades and color neutrality in metallic greys.

“We needed to develop a new functional black pigment to replace carbon black that was readily usable in color formulations and also easy to incorporate into coating systems for better LiDAR reflection and heat management.”

Dr. Paul Brown

Global Innovation Manager– Organic Pigments,

Color Materials, Sun Chemical, Switzerland

Optimal NIR Performance in All Color Compositions

By using this new neutral-colored black pigment in combination with other NIR reflective or non-absorbing pigments, DIC has created formulation capabilities for the primer and basecoat layers that deliver excellent LiDAR reflectivity in a wide range of desirable colors.

Initially introduced in April 2021, the improved NIR-transparent Spectrasense™ Black L 0082 has already drawn praise from global automotive coating manufacturers and automakers alike for its potential to eliminate the automotive industry’s dependence on conventional carbon black pigments and facilitate NIR functional coating performance.

As the new Spectrasense™ Black L 0082 produces both neutral tones and higher jetness than previously achievable for a NIR functional black pigment, global automotive coating manufacturers can now produce neutral grays and blacks in a similar way to carbon black pigments without having to compensate for the unwanted color shift of the previously available pigments.