DIC-Developed Product Wins Excellence Award at Semiconductor of the Year in the Electronic Materials for Semiconductors Category DIC Develops Resin for Resists Used in NIL, a Promising Next-Generation Semiconductor Fabrication Technology

- Business & Product

- News Release

Tokyo, Japan–DIC Corporation has received an Excellence Award at the 2017 Semiconductor of the Year Awards in Japan. The award, in the Electronic Materials for Semiconductors category, was for a resin developed by DIC for use in resists for nanoimprint lithography (NIL)—a next-generation semiconductor fabrication process. The Semiconductor of the Year Awards are organized by Electronic Device Industry News, an industry journal published in Tokyo by SangyoTimes Inc. On June 7, 2017, an awards ceremony and product presentations by award recipients took place at the Total Solution Exhibition for Electronic Equipment, held at Tokyo Big Sight.

This was the 23rd edition of the Semiconductor of the Year Awards program, which was established in 1994 to recognize excellence in semiconductor products and technology—both increasingly important to leading-edge IT equipment and related industries—with the aim of supporting the further evolution of the semiconductor industry and market. The 2017 awards covered new products and technologies announced between April 2016 and March 2017, as well as new products introduced in the Electronic Device Industry News during that period. Products and technologies voted on were nominated through, among others, recommendations by Electronic Device Industry News writers and a general call for entries. Grand Prix and Excellence awards were presented in three categories: Semiconductor Devices, Semiconductor Equipment and Electronic Materials for Semiconductors.

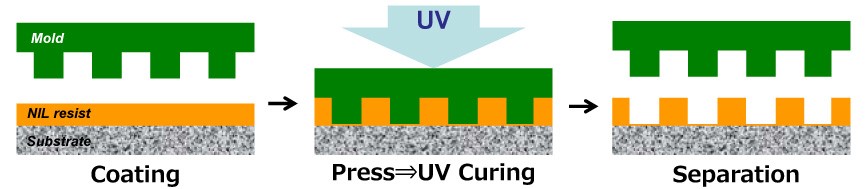

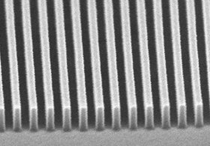

NIL is a next-generation microfabrication technology. A template containing a nanometer-scale embossed pattern is pressed against a substrate that has been pre-coated with a ultraviolet (UV)-curable imprint resist, to mold the pattern onto the imprint resist. The resist is then hardened using UV light, creating a finely patterned etching mask.

The resin developed by DIC that received the award has a base of UV-curable organic-inorganic composite resin, and enhances the dry-etching resistance (resistance to the reactive gases in plasma) necessary as a resist mask. In addition, it provides such properties as wettability onto the substrate, adhesion, and superior light curability, making it an optimal resin for the NIL process. On this occasion, these excellent performance properties and the resin’s novelty and future potential as a solution for the realization of NIL were appraised highly, leading to the product’s selection for the Excellence Award.

Looking ahead, DIC will continue working to support customers in the semiconductor industry, which is seeing rapid technological innovation, by providing pioneering high-performance materials suited to cutting-edge fabrication processes.

-Ends-

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.