PFAS-Free Surfactants

MEGAFACE

Functional Products

MEGAFACE

Functional Products

DIC set out to develop a new line of surfactants without PFAS*, combining proprietary technology with more environmentally friendly materials to successfully deliver a new series of surfactants, MEGAFACE EFS, capable of delivering the same wettability as conventional fluorinated surfactants.

Until now, no other formulations have delivered nearly the same performance level demonstrated by fluorinated surfactants. Here, DIC has preserved, delivering a product with high surface tension-reducing properties that will perform at levels equal to or greater than PFAS products today for excellent uniformity in coating/leveling.

DIC has developed a line of high-performance surfactants formulated without per- and poly-fluoroalkyl substances (PFAS). DIC’s new line of PFAS-free surfactants delivers the same performance levels you have come to expect from surfactants containing PFAS while reducing environmental impact.

DIC surfactants now offer formulators a new, more environmentally friendly alternative for a wide range of applications previously dominated by conventional surfactants containing PFAS.

*The MEGAFACE EFS series PFAS-Free standard is less than 50 ppm of fluorine atoms derived from PFAS.

The DIC PFAS-Free logo appears on digital media, including sales collateral and technical documents, for DIC products that meet DIC’s PFAS-Free standard. DIC established a PFAS-Free standard to support the increasing number of customers who require more environmentally conscious options that meet the technical requirements for superior product performance.

The DIC PFAS-Free logo serves as a signal to everyone working with these products, throughout the supply chain, that DIC prioritizes environmental concerns and the well-being of those who regularly handle these materials, from product developers to plant workers and end-users.

Surfactants are chemical compounds that decrease the surface or interfacial tension between two different liquids, a liquid and a gas, or a liquid and a solid. Among these, surfactants that act between liquids and gases have hydrophobic groups. The hydrophobic group typically consists of a hydrocarbon chain, a siloxane chain, or a fluorocarbon chain.

Hydrocarbon surfactants have a hydrocarbon chain, and Fluorosurfactants have fluorocarbon chains. Siloxane surfactants have siloxane chains. Fluorosurfactants are highly effective at lowering the surface tension of water and solvents when compared to hydrocarbon or siloxane surfactants.

Fluorosurfactants, such as those in perfluorinated alkylated substances (PFAS), contain fluorocarbon chains, raising health and environmental concerns. Many PFAS (forever chemicals), including Perfluorooctane sulfonic acid (PFOS) or Perfluorooctanoic acid (PFOA), are known as persistent organic pollutants or 'forever chemicals' because they do not break down via natural processes. This lack of biodegradability poses a serious threat to our environment and health.

DIC has replaced fluorosurfactants—the highest-performing surfactants on the market—with DIC MEGAFACE EFS, PFAS-free surfactants capable of delivering performance equal to or higher than Fluorosurfactants.

The growing concerns about the environmental impact of PFAS (also known as forever chemicals) have created an urgent need for alternatives to fluorosurfactants. Regardless of your position in the global supply chain, the time to act is now. Replacing fluorosurfactants with more eco-friendly PFAS-free surfactants is not merely a choice but a significant business imperative.

As an industry leader, DIC is not just reacting to the rising concerns about PFAS but taking a proactive, pro-safety, and pro-environment approach. DIC is committed to helping our customers navigate this uncertain and fast-changing landscape.

Here, DIC has developed several PFAS-free surfactants for precision coating applications, providing our customers with reliable, more eco-friendly fluorosurfactant alternatives. These PFAS-free surfactants are a demonstration of DIC’s unwavering commitment to a more environmentally friendly future.

Chemitronics Technical Group Manager Hideya Suzuki and Assistant Manager Junpei Ueno lead the DIC EFS Series Product Development Team. This team of experienced researchers and chemical engineers is developing new, more environmentally friendly surfactants (EFS) for various applications, notably as leveling agents (flow modifiers).

Responding to mounting public concerns regarding the potential long-term health implications of fluorine-based substances present in numerous fluorosurfactants, local regulatory bodies worldwide are enacting new measures that may impose constraints or limitations on the utilization of these compounds.

Group Manager Hideya Suzuki says, "Given growing concerns over the persistence of per- and poly-fluoroalkyl substances (PFAS) in the environment due to the use of PFAS in fluorosurfactants, our team is committed to replacing them with new, more environmentally friendly surfactants (EFS) that are free of per- and poly-fluoroalkyl substances (PFAS), that we’re calling PFAS-free surfactants. The new DIC EFS Series has already demonstrated the potential to deliver leveling performances equal to or better than those of fluorosurfactants.”

Assistant Manager Ueno further explains, “For example, when used as a leveling agent for precision coating, the addition of per- and poly-fluoroalkyl substances (PFAS) can cause coating liquids to foam more easily.” Beyond visual defects and loss of clarity, excessive foaming can cause defects in the final coating, including reduced protective function when foaming reduces the coating's ability to protect surfaces, making coatings more permeable. Here, DIC EFS Series surfactants deliver substantially reduced foaming, eliminating the need to add a defoamer to a system that could cause other issues.” Assistant Manager Ueno adds, “Moreover, when applying multiple coats, PFAS in the base coat can easily cause poor wettability. However, the new DIC EFS Series can offer improved results in applications requiring multiple coats."

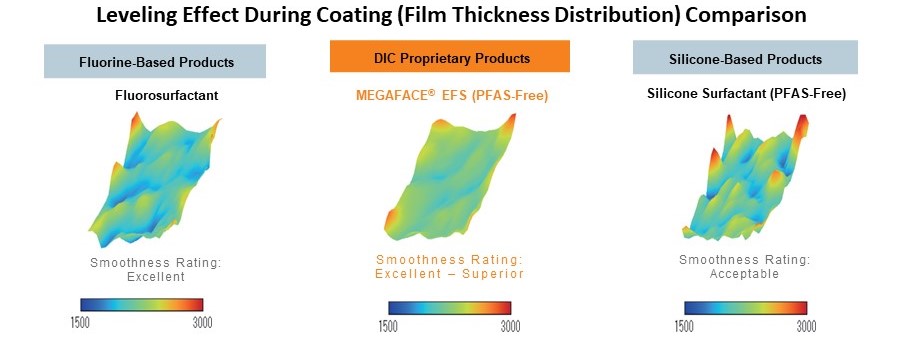

Experimental Conditions:

• Prepare a resist composition using PGMEA (Propylene Glycol Methyl Ether Acetate) solution.

• After spin-coating a liquid coating material at 400 rpm onto a 10 cm x 0 cm Cr substrate, pre-bake the substrate at 80°C for 3 minutes to form a thin film coating.

• Evaluate the surface smoothness of the coating using a thickness monitor.

Leveling agents, also known as flow modifiers, are added to paints, varnishes, and other coatings to enhance their application properties. Leveling agents work by reducing the surface tension of coating liquids, which helps:

• Eliminate surface defects like fisheyes, craters, and orange peel

• Ensure even coating thickness

• Promote smoother application

• Enhance aesthetics of coated surfaces

• Enhance coating longevity/durability

Some common types of leveling agents include silicone-based agents (Polydimethylsiloxane modified), Hydrocarbon-based agents (e.g., polyacrylates), and Fluorocarbon-based agents (Modified Fluorocarbons).

DIC is not merely a surfactant producer/supplier. As a manufacturer of various resins, DIC is highly knowledgeable in resins and solvents, as well as formulating highly customized solutions for customers using specific surfaces (e.g., glass, plastic, and metal surfaces with resins, urethane, acrylic, epoxy, phenolic, etc. in combinate with coating techniques, including spin-coating, slit die-coating, spray-coating, etc.

DIC surfactant products have a history spanning approximately 40 years, dating back to 1983. DIC surfactant products are used as leveling agents for precision coatings, such as those for semiconductors and LCDs, and plastic paints for automobiles and mobile phones, primarily in Japan and East Asia. DIC's strengths in customization, evaluation technology, and quality have enabled DIC to produce high product ratings.

• Surfaces: glass, plastic, or metal

• Materials: resins, solvents, water, and other agents

• Coating Methods: spin coating, bar coating, slit coating, gravure, etc., including slow and high-speed coating

Wetting agents are surfactants that reduce the surface tension of liquids, allowing them to spread and penetrate surfaces more easily. Leveling agents are surfactants that reduce the surface tension of coating agents, promote even spreading on the substrate, and form a flat, smooth coating film that delivers the target performance of the coating agent.

Wetting agents are surfactants that reduce the surface tension of liquids, enabling them to spread quickly and wet surfaces more effectively. Substrates characterized by low surface tension, such as plastic parts or substrates contaminated with contaminants like oil residues or mold release agents, can hinder adequate wetting.

Aqueous coating systems exhibit inherently higher surface tension compared to solvent-borne coatings. This can increase wetting issues. Leveling additives reduce a coating’s surface tension and increase substrate wetting.

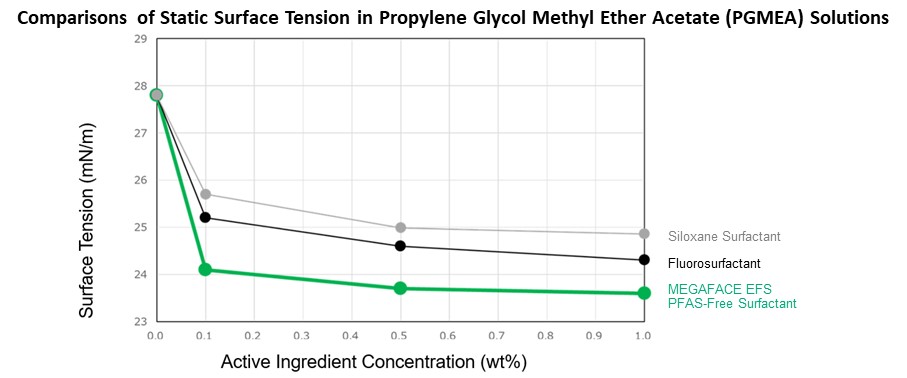

DIC’s new innovative PFAS-free Wetting and Leveling Agents offer equal performance to their predecessors, which used fluorosurfactants but with lower dosages of active ingredients.

Substrate wetting primarily depends on the surface tension of the liquid coating material and the substrate's critical surface tension for coating. To achieve good wetting, the coating's surface tension should generally be lower than or equal to the surface tension of the substrate.

Poor wetting, i.e., a crawling or beading of the coating, will occur if the coating surface tension is higher than the substrate surface energy. Substrates with generally lower surface tension (e.g., plastic parts) or contaminated surfaces (oil residue, release agent) are typically difficult to wet.

Due to their high water content, aqueous coating systems have a higher surface tension than solvent-borne coatings and exhibit more significant wetting issues.

DIC PFAS-free surfactants adopt a surface tension-reducing unit that replaces fluorine for improved substrate wetting and leveling with low surface tension. MEGAFACE EFS PFAS-free surfactants replicate the high-leveling and high-wettability performance previously only achievable with PFAS.

Experimental Conditions

• 0.1%, 0.5%, and 1.0% PGMEA solutions of surfactants were prepared, and the surface tension was measured using the Wilhelmy plate method*.

Note: The Wilhelmy plate method involves dipping a thin plate into a liquid and directly measuring the force on the plate normal to the interface.

The technique called spin coating is used to create uniform thin films on flat substrates. A small amount of the liquid coating material is dispensed onto the center of the wafer, which is then spun at high speed (e.g., 3000 rpm). As centrifugal force spreads the liquid outwards, it thins out, resulting in a uniform film coating.

A leveling agent with high dynamic surface tension reducing performance must be selected for high-speed application processes to cover the newly created surface as quickly as possible, thereby maintaining a constant surface tension. Constant dynamic surface tension means maintaining constant surface tension while spreading the coating area at high speed, such as in high-speed spin coating.

After a spin coating at 3000 rpm, the surface of a silicon wafer (with a film thickness of approximately 2 microns) was observed under a microscope.

Slit-die coating (also called slot-die coating) is a versatile coating technique. In slit-die coating, a solution is delivered onto a substrate through a narrow slit for the rapid creation of a thin, uniform film with very minimal waste.

Surfactants exist near the surface and control the solvent's evaporation rate. This is effective when a large amount of solvent remains after application, such as in slit-die coating. This effect is noticeable with oligomeric surfactants, and by balancing molecular weight, compatibility with matrix resin, amount added, etc., excellent leveling properties can be achieved.

Please use the Contact Form to request more information.

Improved Substrate Wetting

Enhanced Wetting on Challenging Substrates

Improved Pigment Wetting

Enhanced Color Acceptance

Improved Leveling

Superior performance across a wide range of coatings

Anti-Blocking

Enhanced Anti-Blocking in Water-Based Systems

Reduced Foaming

| MEGAFACE | EFS-131 | EFS-132 | EFS-241 | EFS-321 | EFS-322 | EFS-323-S |

|---|---|---|---|---|---|---|

| Active ingredients / wt% | 20 | 50 | 50 | 20 | 40 | 100 |

| Solvent | Butyl acetate | Butyl acetate | PGMEA | PGMEA | PGMEA | - |

| Ionicity | Non-ionic | Non-ionic | Non-ionic | Non-ionic | Non-ionic | Non-ionic |

| Alternative to | F-568 | F-571 | F-477 | F-551-A | F-559 | F-251 |

| MEGAFACE | EFS-331 | EFS-341 | EFS-521 | EFS-701 | EFS-801 | EFS-821-S |

|---|---|---|---|---|---|---|

| Active ingredients / wt% | 50 | 50 | 20 | 100 | 100 | 100 |

| Solvent | Butyl acetate | PGMEA | PGMEA | - | - | - |

| Ionicity | Non-ionic | Non-ionic | Non-ionic | Non-ionic | Non-ionic | Non-ionic |

| Alternative to | - | F-556 | F-551-A | F-554 | F-554 | - |