Major Applications of Surfactants/Surface Modifiers

This page introduces recommended product numbers from typical MEGAFACE application examples.

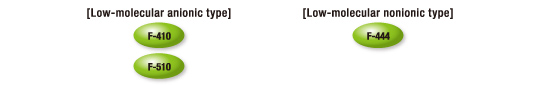

• Leveling agents

• Surface modifiers

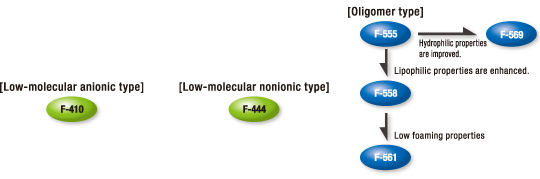

• Chemical additives

• PTFE particle dispersants

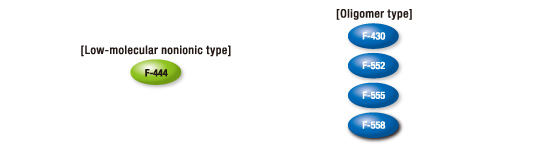

• Pigment dispersion stabilizers

• Non-diffusion additives

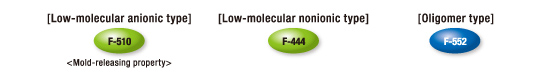

• Molding processing agents

• Fiber processing agents

• PC flame retardants, others

MEGAFACE exhibits substantial leveling properties and facilities thin-film coating and precision coating.

■ Smooth surface - Highly uniformed film-thickness.

■ Eradication of coating defects (unevenness, cratering, pin holes).

0.05 to 0.5 wt% (in solid content)

Coating for film

Water repellency, Oil repellency, Stain guard properties, Fingerprint removability, Demoldability, Lubricating properties, Abrasion resistance, Low friction, Water resistance

0.1 to 5 wt% (in solid content)

■ Coatings for home electric appliances, office automation equipment and mobile devices

■ Coatings for display surfaces (UV hard coating)

■ Surface modification of polyurethane foam, rubber, urethane elastomer and plastics

■ Metalic surface preparation

■ Water repellence and stain guard agents for car wax

Surface tension reduction, Improved wettability, Permeability, Improved detergency

0.005 to 0.3 wt% (in solution)

■ Detergent for metal and glass parts

■ Dry cleaning detergent

■ Liquid developer, rinse agents

■ Electrolyte for batteries

■ Remover for floor polishing

Dispersion of PTFE particles and other fluororesins and stabilization of dispersion

0.5 to 5 wt% (to fluororesin particles)

■ Solid lubricant coatings, Automotive window frame rubber, Automotive parts (sliding parts), Home electronics (movable parts), Movable part coatings for optical equipment/precision equipment

■ Fluorinated heat-resistant additives

■ Engine oil additives

Stabilization of pigment dispersion

0.01 to 0.1 wt% (in pigmented coating), 0.5 to 1 wt% (in ballpoint pen ink)

■ Agents for stabilizing pigment dispersions in general pigmented coatings and ballpoint pen ink

Anti-diffusion properties, Anti-oozing agents

0.5 to 5 wt% (in grease, ink and paste)

■ Grease

■ Printing ink and substrates (paper, plastic films)

■ Conductive paste

Demolding properties, Fluidity, Nonadhesiveness

0.1 to 5 wt% (in resin)

■ Molding of thermoplastic resins (demolding agent, die-build up prevention agent)

■ Molding of UV-curable resins (mold relasing agent)

Wettability, Penetrability, Demolding

0.01 to 0.3 wt% (in processing agent liquid)

■ Fiber processing (dyeing, post-processing)

■ Carbon fiber separating agent

■ Glass fiber processing

Improving flame-retardancy of polycarbonates

0.01 to 0.5 wt% (in polycarbonate resin)

Emulsifiers, foam stabilizers, foaming agents, lubricants, coating agents for toner carrier (electrification regulating agents)

Inquiry About This Product

-

Inquiry on website

-