DIC Develops GELRAMIC™ Endothermic Pad Material that Prevents Battery Fires from Spreading —Applications for this new material, which leverages proprietary endothermic and ceramic technologies to physically prevent the spread of LiB fires, include LiB collection and recycling—

- Business & Product

- News Release

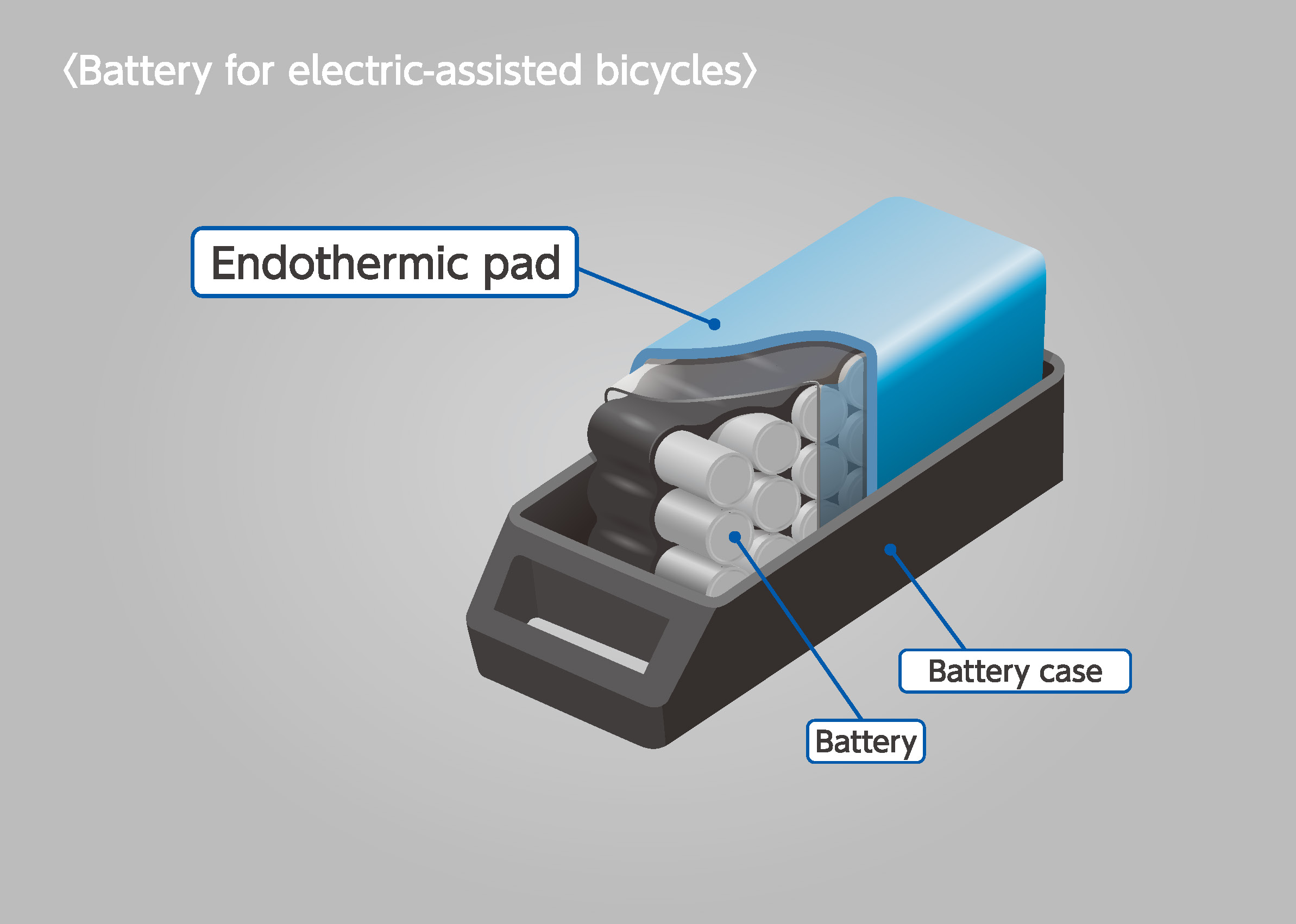

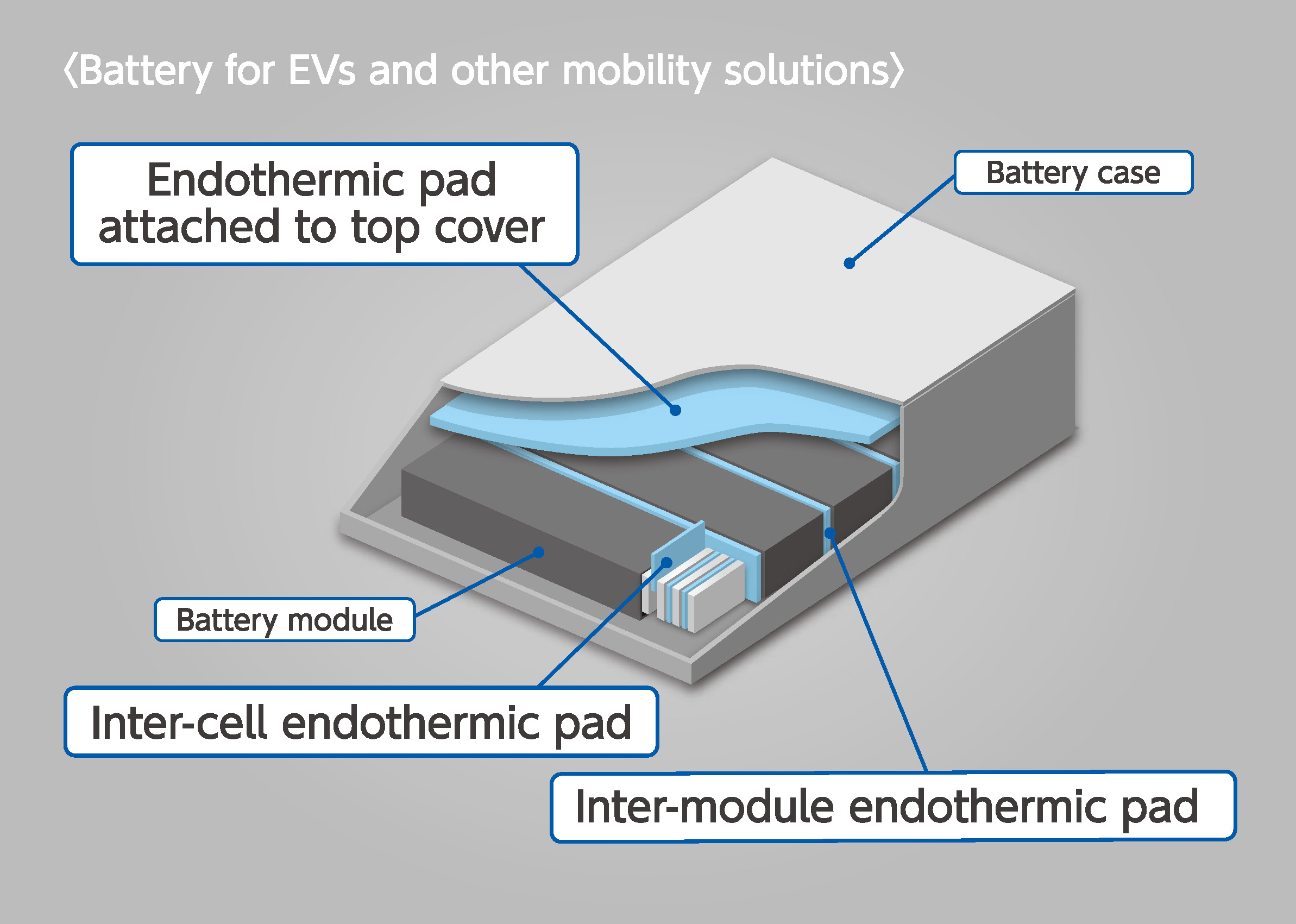

Tokyo, Japan—DIC Corporation has announced the development of GELRAMIC™, a fire-propagation prevention endothermic pad material for lithium-ion batteries (LiBs), designed to mitigate the risk of fire propagation caused by thermal runaway.* This pad material incorporates a proprietary gel with strong endothermic properties that absorbs heat during thermal runaway events, helping to suppress temperature increases and prevent fires from spreading beyond the battery. This material also transforms into a rigid ceramic sheet at elevated temperatures, providing thermal insulation and protection against flying debris, and physically preventing the transfer of fire and heat. DIC is currently evaluating this new material with multiple customers with the immediate goal of encouraging use in the area of LiB collection and recycling, particularly in used LiB collection containers. Over the medium to long term, the Company will look to expand its target market to include LiBs installed in vehicles, notably electric-assisted bicycles and EVs, aiming for sales of approximately ¥1.0 billion by 2030.

As the use of LiBs continues to grow, particularly in power banks and EVs, preventing batteries from overheating and catching fire has become an urgent social imperative. According to a report released by Japan’s Ministry of the Environment (MOE), LiB fires were responsible for approximately 8,500† conflagrations in fiscal year 2023 involving, among others, waste processing facilities and sanitation trucks, with the primary cause of these fires being improper disposal. A recent surge in fires involving LiBs in electric-assisted bicycles and EVs has also highlighted the need for measures to improve the safety of such vehicles.

Against this backdrop, MOE unveiled a policy in April 2025 calling for municipalities to collect used LiBs discarded by households. The Ministry of Economy, Trade and Industry (METI) also took the decision to make it mandatory for companies manufacturing or importing power banks, among others, to collect and recycle their used products, effective from April 2026.The installation of used LiB collection containers to encourage sorting and recycling is also increasing across Japan, accelerating the need for solutions that minimize the risk of fire spreading should a LiB ignite inside a collection container.

Seeking to help address these issues, DIC developed GELRAMIC™, a fire-propagation prevention endothermic pad material that leverages proprietary technologies to absorb excess heat generated by LiBs, significantly reducing the risk of fire spreading. It is flexible and easy to install under normal conditions, this pad material becomes a hard ceramic sheet in the event of thermal runaway, providing thermal insulation and protection against flying debris, as well as preventing the LiB from igniting or exploding and thereby damaging its surroundings.

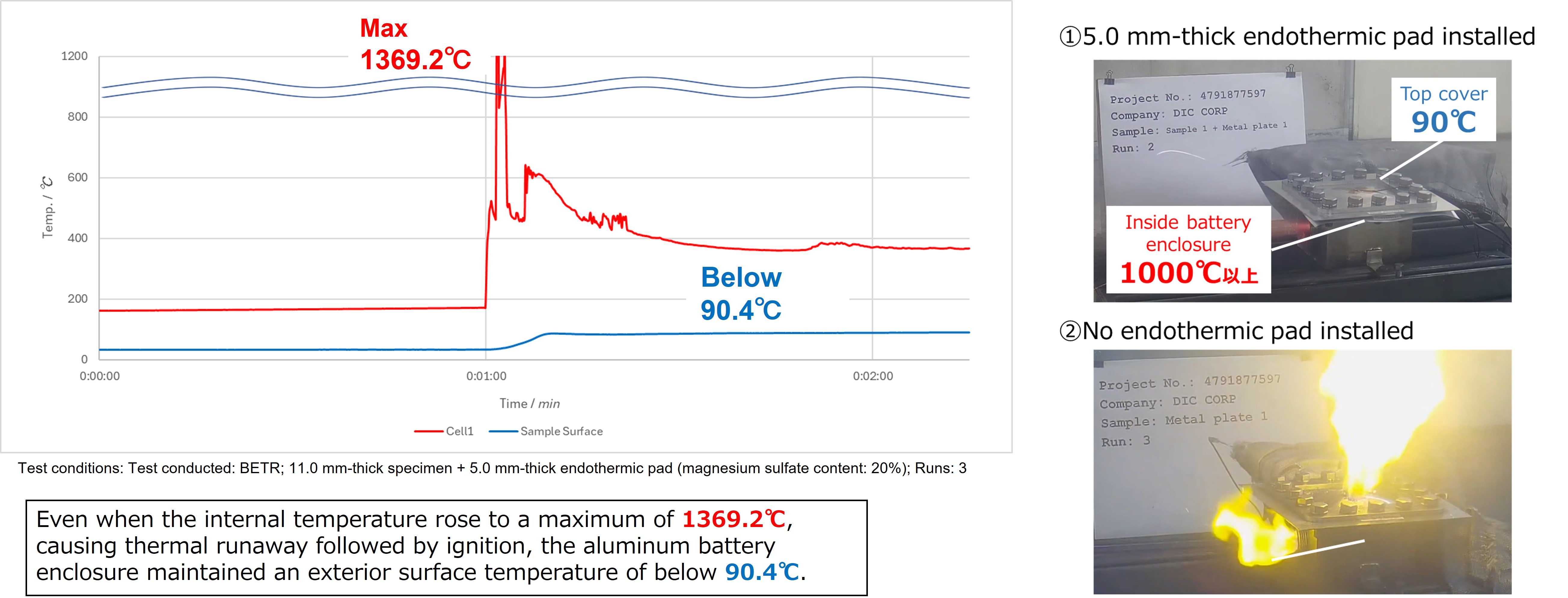

Testing conducted using the UL 2596‡ Battery Enclosure Thermal Runaway (BETR) Evaluation method on a battery enclosure containing multiple cells—with 5.0 mm-thick GELRAMIC™ pads installed as inter-cell material—confirmed that even when the LiB’s internal temperature rose to a maximum of 1,369.2 °C, causing thermal runaway followed by a flame jet, the aluminum battery enclosure maintained an exterior surface temperature below 90.4 °C.

In addition to offering both flexibility and cushioning, GELRAMIC™ can also be attached easily to curved surfaces, ensuring suitability for a wide range of applications. Potential uses include containers for used LiB collection, as well as batteries for electric-assisted bicycles and EVs.

GELRAMIC™ will make its debut at the Battery Japan International Rechargeable Battery Expo at Makuhari Messe in Chiba Prefecture (September 17–19, 2025; booth number: E2-12).

In its DIC Vision 2030 long-term management plan, DIC has set forth a basic strategy of creating new businesses in response to environment, safety and health (ESH)-related issues and social changes. In the area of sustainable energy, a pivotal focus is to commercialize functional materials for next-generation secondary batteries and fuel cells. Going forward, the DIC Group will continue contributing to sustainable prosperity for society through the development and provision of sustainable products that respond to social imperatives by helping to reduce energy consumption and environmental impact.

* Thermal runaway occurs when a LiB or other battery overheats or short circuits, causing its temperature to increase uncontrollably, eventually resulting in ignition or explosion.

† Source: Policies and measures for the proper disposal of LiBs and other items, published by the MOE (in Japanese only)

‡ UL 2596 is a testing method for evaluating the performance of EV battery enclosure materials.

– Ends –

Contacts:

Business Incubation Unit, New Business Development Headquarters

DIC Corporation

Email:gelramic@ma.dic.co.jp

- About DIC Corporation

DIC Corporation is one of the world’s leading fine chemicals companies and the core of the DIC Group, a multinational organization comprising over 170 companies, including Sun Chemical Corporation, in more than 60 countries and territories. The DIC Group is recognized as a global leader in the markets for a variety of products essential to modern lifestyles, notably packaging materials, display materials such as those used in television and computer displays, and high-performance materials for smartphones and other digital devices, as well as for automobiles. Through such products, the Group endeavors to deliver safety and peace of mind, and color and comfort, to people everywhere. The DIC Group also seeks to contribute to a sustainable society by developing innovative products that respond to social change and which help address social imperatives. With annual consolidated net sales exceeding ¥1 trillion and 21,000-plus employees worldwide, the Group pledges to continue working in close cooperation with its customers wherever they are. For more information, please visit the DIC global website.