DIC Builds New Globally Optimized Digital SCM Platform -The use of advanced digital technologies will help DIC realize sustainable, resilient supply chains-

- Management & IR

- News Release

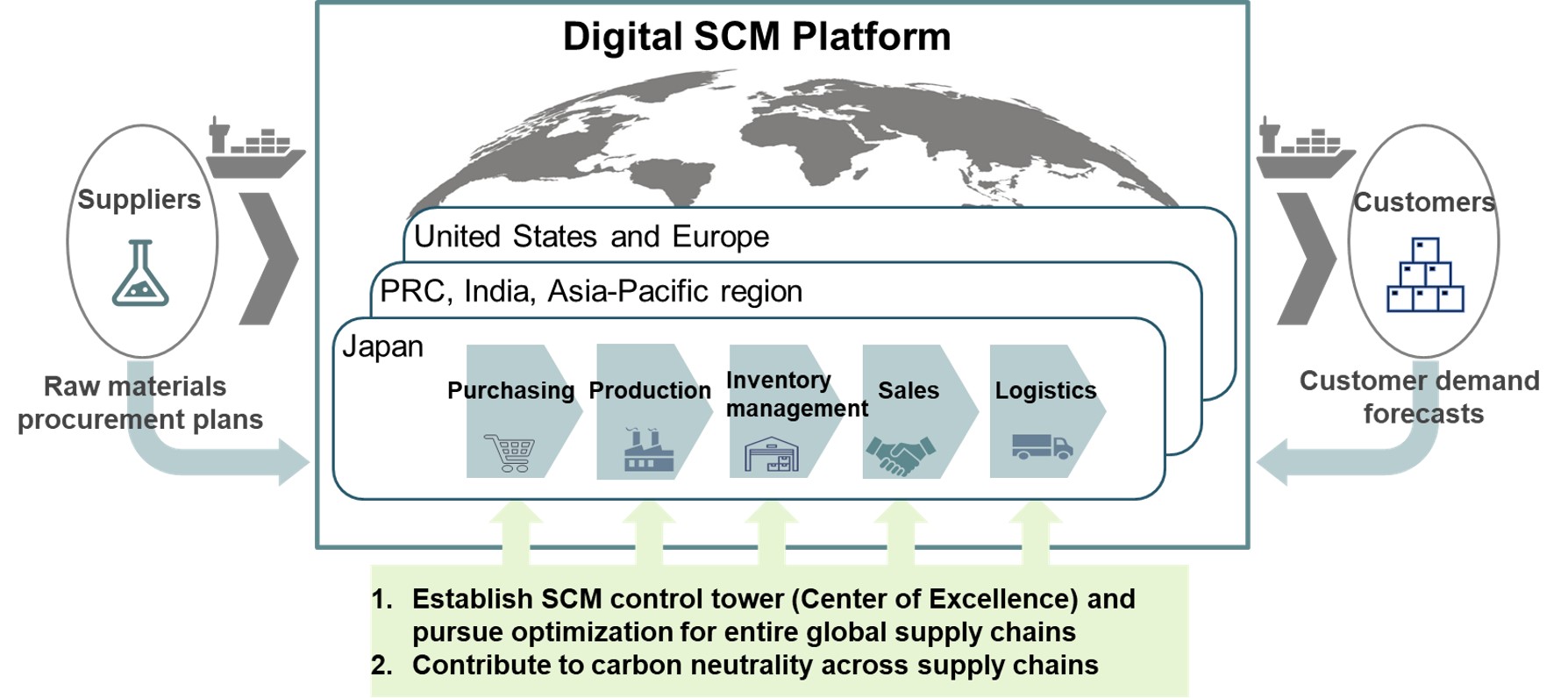

Tokyo, Japan—DIC Corporation announced today that it has built a new digital supply chain management (SCM) platform that leverages advanced digital technologies to optimize supply chains in its core businesses. The Company initially intends to introduce the new platform in certain markets and sectors of the color materials and performance materials businesses. Plans are to achieve full deployment worldwide by fiscal year 2025.

Owing to recent geopolitical tensions and rapid changes in the supply–demand balance driven by the COVID-19 pandemic, corporate management continues to be impacted by supply chain issues such as constraints on the raw materials procurement and the disruption of international logistics. Against this backdrop, SCM, which aims to optimize supply chains on a global basis, is taking on growing importance. With operations in more than 60 countries and territories around the world, DIC recognizes that optimizing and enhancing the visibility of its supply chains across multiple regions, businesses and organizations is an urgent challenge. Accordingly, one of the specific measures set forth for establishing a more robust global management, a key strategy of “DIC Vision 2030” long-term management plan, is to build a global SCM standard model.

To date, planning and other supply chain–related tasks, including the collection of customer demand data, production scheduling for local plants, management of site inventories (products and raw materials) and procurement planning, have been handled independently on a regional and business-specific basis. Complex coordination with a lot of stakeholders inside and outside the company, such as frequent adjustments to delivery dates and quantities, and the management or modification of inventories, have been conducted manually at individual sites using Excel spreadsheets or through direct communication by email. This has made it difficult to ensure the accuracy and efficiency of such procedures, while also maintaining speed.

To address such matters, DIC embarked on building a global SCM standards model by its SCM development project that involved more than 80 participants from both inside and outside the Company. Guided by the slogan “Total Optimization,” this project led to the successful realization of the Company’s new digital SCM platform. The Company selected RapidResponse®*¹ from top supply chain planning solutions provider Kinaxis® Inc.*² as its digital tool.

1. Establishes globally standardized, consistent business processes

In the past, business processes were optimized by country, region and sites. The new platform establishes globally standardized, consistent business processes with digital technologies to achieve total optimization and reduce dependence on individuals. This will facilitate the centralized management of global supply and demand, thereby helping to transform and improve the efficiency of operations, as well as to improve customer service levels.

2. Sets globally standardized KPIs

New globally standardized key performance indicators (KPIs) for SCM have been set and implemented to visualize, share, and monitor the progress in cash flows, customer service levels and operations efficiency on a global basis. Benefits will include optimized inventories, better on-time delivery rates and a decreased need for additional adjustments and negotiations due to shortages, etc.

3. Introduces globally standardized SCM planning tools

The new platform deploys the software-as-a-service (SaaS) RapidResponse as a globally standardized SCM planning tool for managing the flow of items through supply chains, making it possible to integrate individual sales plans, inventory plans, production capacity management and other information crucial to effective SCM, prepared by each site, into a single digital platform to bolster overall supply chain visibility. This will increase the efficiency of data collection, calculation and validation, as well by the use of statistical demand forecast reinforce the supply chain planning accuracy.

Given the difficulty of managing supply chains in a highly uncertain business environment, DIC is looking to advance system linkage both within the DIC Group and with the external stakeholders, such as raw materials suppliers, subcontracted producers, logistics companies, and our customers.

DIC is confident that the digitization of supply chain information will play a key role in new initiatives vital to the achievement of carbon neutrality across entire supply chains, including those aimed at calculating and improving the visibility of greenhouse gas emissions.

Looking forward, the Company also plans to actively promote the practical application of Internet of Things (IoT), artificial intelligence (AI), blockchain and other advanced technologies in its SCM.

Executive Officer Takao Iribe, Head of the SCM Unit.said following

“Our newly built digital SCM platform will enable us to eliminate organizational and regional silos in supply chains and secure the organizational capabilities necessary to grow our businesses on a global scale. In addition, by analyzing potential demand fluctuations from multiple perspectives, we will elevate services for customers, as well as our ability to respond to emerging needs, thereby driving the further improvement of customer value.”

*¹ Kinaxis and RapidResponse are registered trademarks of Kinaxis Inc and its affiliates.

*² Kinaxis Inc has been recognized as a Leader in the 2022 Gartner® Magic Quadrant™ for Supply Chain Planning Solutions for the eighth consecutive time.

– Ends –

DIC Corporation is one of the world’s leading fine chemicals companies and the core of the DIC Group, a multinational organization comprising over 190 companies, including Sun Chemical Corporation, in more than 60 countries and territories. The DIC Group is recognized as a global leader in the markets for a variety of products essential to modern lifestyles, notably packaging materials, display materials such as those used in television and computer displays, and high-performance materials for smartphones and other digital devices, as well as for automobiles. Through such products, the Group endeavors to deliver safety and peace of mind, and color and comfort, to people everywhere. The DIC Group also seeks to contribute to a sustainable society by developing innovative products that respond to social change and which help address social imperatives. With annual consolidated net sales exceeding ¥1 trillion and 22,000-plus employees worldwide, the Group pledges to continue working in close cooperation with our customers wherever they are.

Website: https://www.dic-global.com/