DIC Developed Artificial Intelligence System “Prism” Which Transfers Expert Knowledge to the Future Generation - This AI is applied to employees training and may transfer expert knowledges effectively and motivate frontline operators to improve their proficiency -

- Management & IR

- News Release

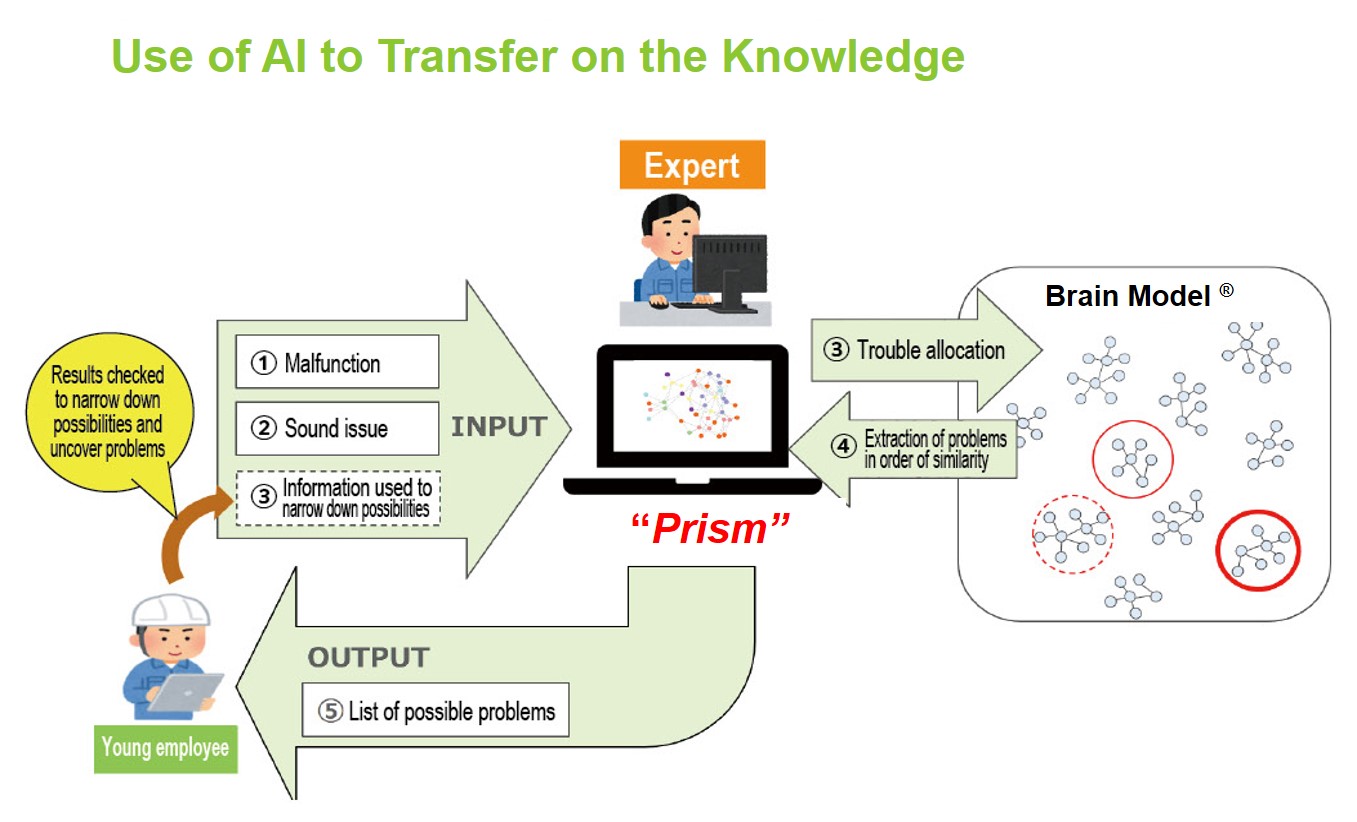

Tokyo, Japan— DIC Corporation announced today that it has collaborated with LIGHTz Inc. to develop and begin using Prism, an artificial-intelligence (AI) system for production sites that verbalizes the knowledge of experts cultivated through years of experience in resolving equipment issues, facilitating the creation of a database of case studies that frontline operators can quickly and easily access to help address new issues when they arise.

Given Japan’s declining labor force, a consequence of falling birthrates and an aging population, passing on the knowledge of experts to future generations is a challenge shared by production sites across the nation. DIC also recognizes that the effective transmission of such knowledge at its production sites is essential to its ability to ensure safe manufacturing and stable quality, as well as to appropriately resolve equipment issues. Accordingly, the Company has spent several years considering the use of digital transformation (DX) in its production departments.

In 2019, DIC launched a project to delve into the use of DX to pass on experts’ knowledge, the first step of which was to choose a site to serve as a model factory. This led to the selection of Kashima Plant, which had already created a database of equipment maintenance issues on its pigments production floor—giving it a foundation for the introduction of AI for this purpose—and to the decision to adopt AI to resolve these issues.

Given that its objective is knowledge transfer, rather than simply looking to derive answers from past data, DIC resolved to adopt ORGENIUS®,*1 a AI tool developed by LIGHTz that transforms the complex thinking of experts into easy-to-understand, accessible phrasing, giving form to the connections between words, and providing deep insights and inspiration. The Company subsequently developed Prism, a front-end system that links ORGENIUS® to the vast store of data contained in the Kashima Plant’s equipment maintenance management system database. DIC is confident that Prism will play a key role in resolving equipment maintenance issues at its production sites over the medium to long term because it:

• uses AI to transform experts’ thinking, represented in existing equipment maintenance data, into accessible phrasing, enabling the effective transmission of knowledge to future generations;

• accumulates and generalizes*2 knowledge to foster operators’ awareness of the importance of continuous learning; and,

• is a white box AI system, meaning that it does not simply generate conclusions, but it clearly shows how those conclusions are reached, thereby leading to new insights.

DIC began deploying Prism on the Kashima Plant’s pigments production floor in June 2021. Looking ahead, the Company will work to fully entrench the system, as well as to further explore ways in which it can be used. Once it has gathered sufficient data on the system’s use at the model factory, DIC plans to promote its horizontal deployment at other production facilities, as well as at business sites.

DX is a priority in the DIC Group’s DIC111 medium-term management plan. In production departments, the Group will continue to advance DX with the aim of realizing smart factories and will leverage AI across its diverse businesses to resolve a variety of issues at production sites and to enhance efficiency.

*1 ORGENIUS® is a natural language processing (NPL) AI middleware developed by LIGHTz Inc.

*2 In this context, “generalize” means to transform the exclusive, specialized knowledge of experts into a form that is easy for subsequent generations to understand.

– Ends –

LIGHTz provides an Artifitial Intelligence that support to transfering the expert knowledge and skill to the future generation. Combining data analytics and unique consulting appraoch, LIGHTz provides solutions for enhancin effectiveness and efficiency of operations, primaliry in the manufacturing industry, including designing, process engineering, fabrications, where the experts have important role in their activities.

DIC Corporation is one of the world’s leading fine chemicals companies and the core of the DIC Group, a multinational organization comprising over 170 companies around the globe, including Sun Chemical Corporation, in more than 60 countries and territories. The DIC Group is recognized as a global leader in the markets for a variety of products essential to modern lifestyles, including packaging materials, display materials such as those used in television and computer displays, and high-performance materials for smartphones and other digital devices, as well as for automobiles. Through such products, the Group endeavors to deliver safety and peace of mind, and color and comfort, to people everywhere. The DIC Group also seeks to contribute to a sustainable society by developing innovative products that respond to social change and which help address social imperatives. With annual consolidated net sales in excess of ¥700 billion and 22,000-plus employees worldwide, we pledge to continue working in close cooperation with our customers wherever they are. Please visit our website for more details.

PDF download

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.