DIC Develops Hollow Fiber Membrane Decarbonation Module that Helps Extend the Useful Life of Ion-Exchange Resins Used in the Production of Pure and Ultrapure Water —New modules will be exhibited for the first time at AQUATECH AMSTERDAM 2017, the world’s largest trade show for water industries —

- Business & Product

- News Release

Tokyo, Japan–DIC Corporation has developed a hollow fiber membrane decarbonation module that extends the life of ion-exchange resins used in the production of pure and ultrapure water. The new membrane module removes approximately 1.7 times the amount of carbon gas than existing DIC membrane modules.

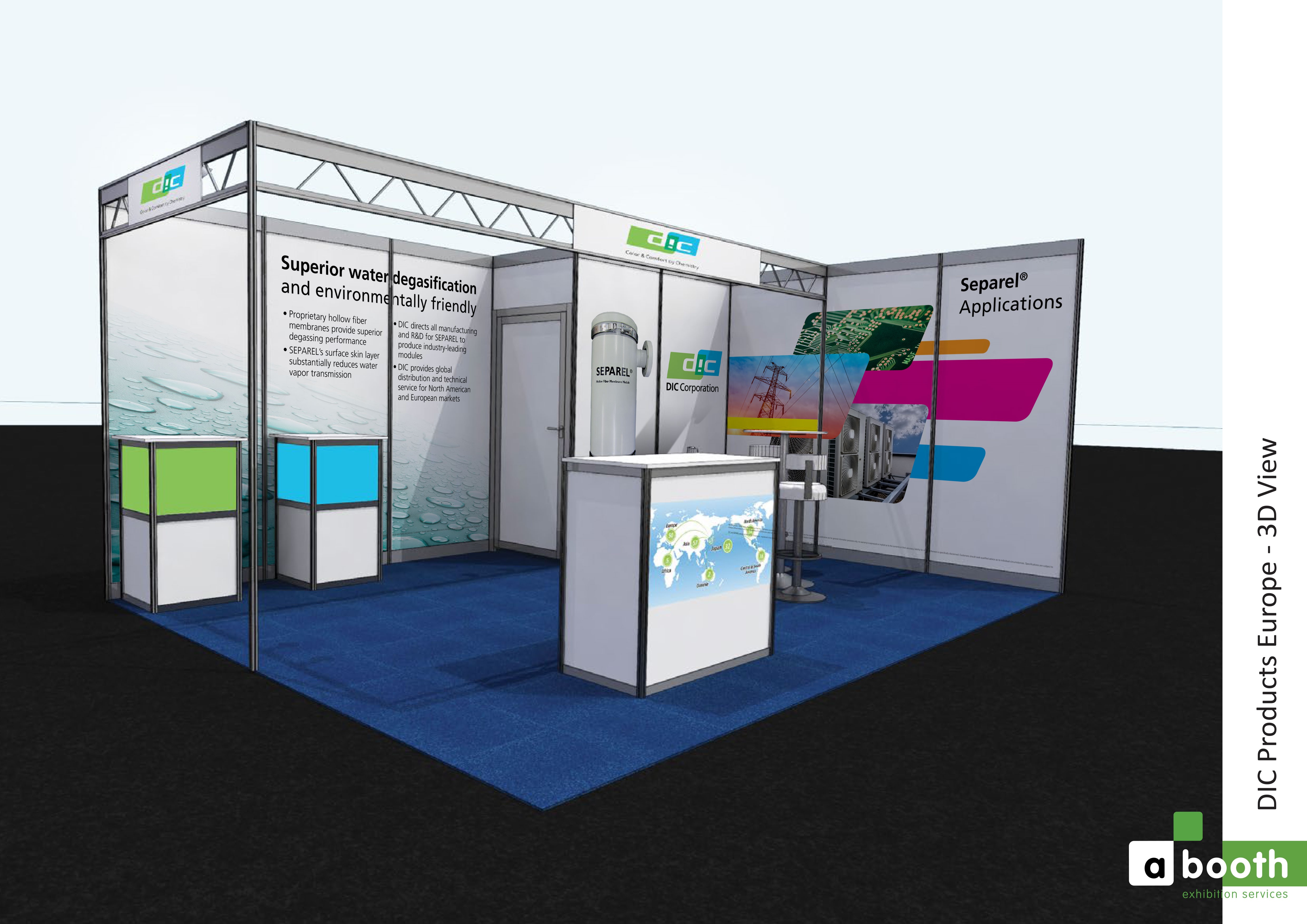

At stand 03.115, the new product will be shown as part of DIC’s SEPAREL® series of hollow fiber membrane modules at AQUATECH AMSTERDAM 2017, a trade show for water industries, which will take place on 31 October to 3 November in Amsterdam. Sales are expected to begin in November 2017.

Pure and ultrapure water are produced by removing salts, organic matter, dissolved gases and other impurities from ordinary water. Demand is expanding for pure and ultrapure water for use in precision cleaning in semiconductor fabrication, in boilers for production facilities, and to improve the quality and stability of pharmaceuticals and beverages. Additionally, due to limits on withdrawals of fresh water from rivers and groundwater, the recirculation of water through production equipment is growing in popularity. Therefore, the market for devices used in the production of pure and ultrapure water is expected to grow at approximately 5.0% annually for the foreseeable future.

Impurities in water are removed using modules with various separation capabilities, which are incorporated into production equipment. Ions are then removed using ion-exchange resins. Increasingly, however, manufacturers are installing decarbonation modules, which slow the degradation of these resins at the preceding stage. This is because a portion of the carbon gas in water exists in the form of carbon ions, which would otherwise be trapped by the ion-exchange resin and accelerate the resin’s degradation. Removing carbon ions at the previous stage minimizes running costs.

By leveraging its molding technologies to process the polymethylpentene (PMP) hollow fibers traditionally used in its hollow-fiber membranes, DIC succeeded in increasing their ability to remove carbon gas from water to a level comparable to that of products currently on the market. Degassing performance also depends on the contact area. Accordingly,DIC uses considerably finer hollow fibers than other companies, enabling it to produce decarbonation modules that are more compact than those of its competitors.

The launch of this new product will mark DIC’s entry into the market for decarbonation modules. By capitalizing on the extensive global network of the DIC Group, the company aims to achieve annual sales of decarbonation modules of JPN3.0 billion by fiscal year 2025.

-Ends-

| Dates/times | October 31–November 3, 2017 |

|---|---|

| Venue | RAI Amsterdam, Europaplein, 1078 GZ, Amsterdam, The Netherlands |

| Website | http://www.aquatechtrade.com/amsterdam/ |

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.