DIC Launches PASLIM VM Series of Dry Laminating Adhesives that Enhance the Oxygen Barrier Properties of Vacuum Deposition Films —Helps Reduce Food Loss and Light Weighting the Laminated Structure of Packaging Films—

- Business & Product

- News Release

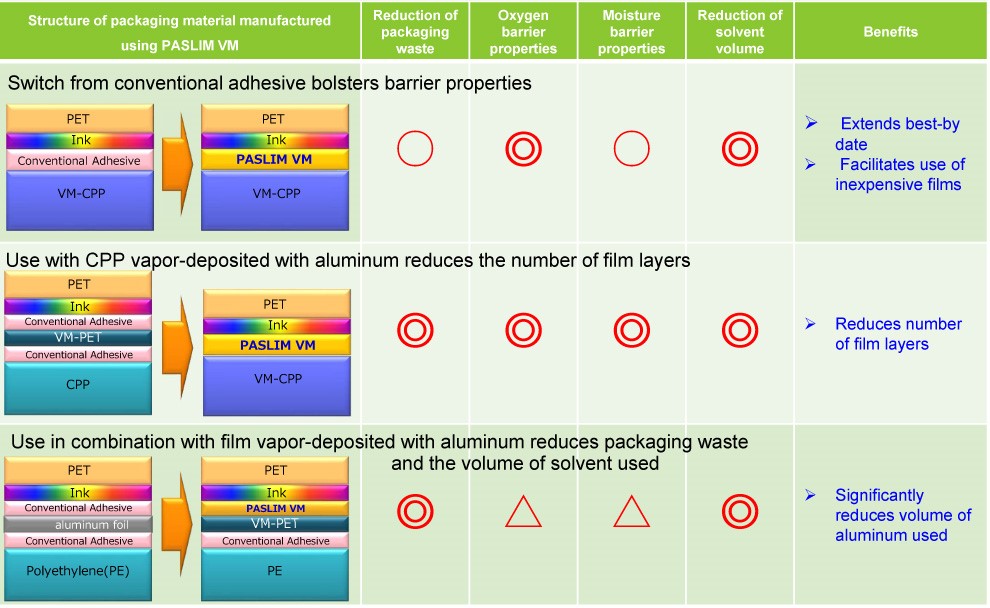

Tokyo, Japan–DIC Corporation announced that has developed a series of dry laminating adhesives that enhance the oxygen barrier properties of vapor deposition films, which have been launched under the name PASLIM VM. These new adhesives have being adopted for use by multiple overseas manufacturers and DIC continues working to reinforce its sales efforts worldwide. A groundbreaking achievement, PASLIM VM dry laminating adhesives improve the oxygen barrier properties of food packaging materials made with vapor deposition films, thereby helping reduce food loss and light weighting the laminated structure of such films.

Ensuring the efficient use of food resources an increasingly critical global issue. Accordingly, the need to reduce food loss in developed economies and post-harvest loss in emerging economies by extending use-by and best before dates for foodstuffs and food products is driving demand for high-performance packaging materials that shield food from oxygen and other gases, as well as from moisture.

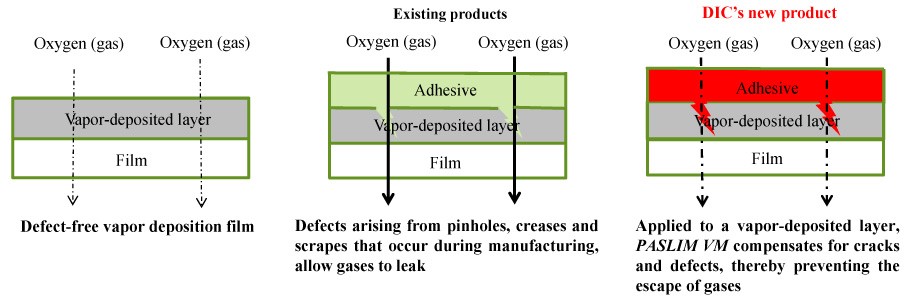

Until now, food packaging materials with oxygen barrier properties have centered on multilayer films, which comprise a layer of aluminum foil—a highly effective gas barrier material—bonded with multiple layers of biaxially oriented polyethylene terephthalate (PET), biaxially oriented polypropylene (OPP) and cast polypropylene (CPP) and/or other film using an adhesive. Production of these films uses a significant amount of energy, while separating and disposing of the aluminum foil and polymer layers is troublesome. For these reasons, and because of a desire to reduce packaging waste, recent years have seen an increase in the use of barrier films having aluminum or another inorganic material vapor-deposited onto one of the aforementioned polymer film layers. However, vapor-deposited film layers are susceptible to defects arising from pinholes, creases and scrapes that occur during manufacturing. These defects allow gases to escape and weaken barrier properties, prompting calls for effective countermeasures.

Leveraging its proprietary polymer design capabilities, DIC created a unique solvent-based dry laminating adhesive by revamping the structure of the polymer raw material used to realize a structure that inhibits oxygen permeation. The new adhesive reinforces the oxygen barrier properties of vapor-deposited film layers to which it is applied by compensating for cracks and defects, thereby enhancing such layers’ inherent barrier properties to achieve a performance level close to that of aluminum foil.

In addition, although DIC’s new dry laminating adhesive exhibits excellent handling properties equivalent to those of conventional products, the high solid design means that its emissions of volatile organic compounds (VOCs) are 50% lower than those of existing DIC adhesives.

As well as complying with codes and standards for packaging based on article 18 of Japan’s Food Sanitation Act (Ministry of Health, Labour and Welfare Ordinance No. 370), DIC’s new laminating adhesive has met the U.S. Food and Drug Administration’s 175.105 regulation for adhesives used in food packaging.

Under its current medium-term management plan, DIC108, the DIC Group aims to increase its annual sales of packaging materials including printing inks, films, adhesives to \320.0 billion by fiscal year 2018, up \50.0 billion from fiscal year 2015. To this end, the Group will continue actively to promote the development of distinctive products in its adhesives business, including next-generation barrier materials, with the goal of doubling the business’ sales from the fiscal year 2015 level by fiscal year 2020.

-Ends-

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.