Sustainable

It can be used for paper applications that

reduce consumption of petroleum resources and reduce environmental impact.

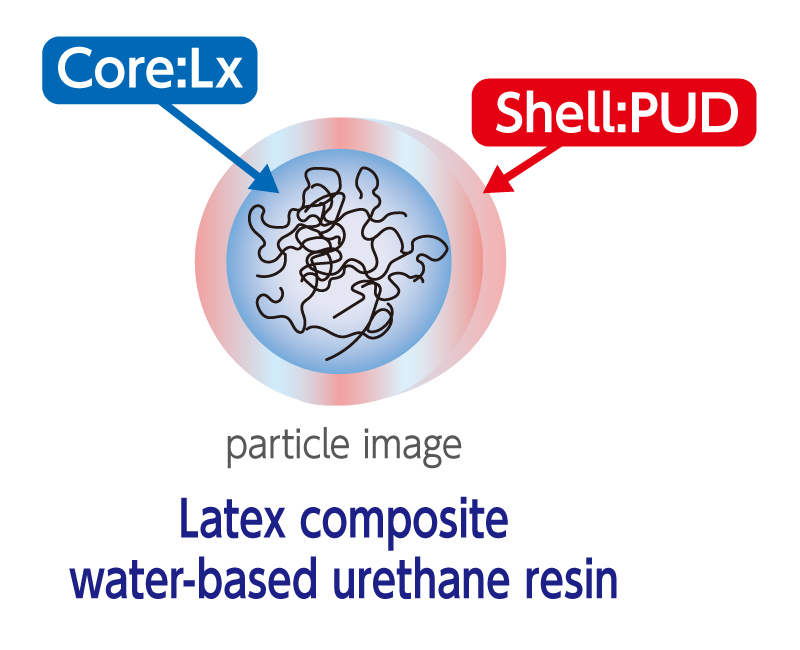

DIC Original

A composite of DIC's synthetic rubber latex resin and water-based polyurethane resin.

By combining them, it is possible to express functions different from those of blend systems.

In addition, bleeding of low-molecular-weight components can be

suppressed as this resin is emulsifier-free.

You want to reduce your use of plastic,

but are concerned that replacing plastic with paper might make it more susceptible to water and oil?

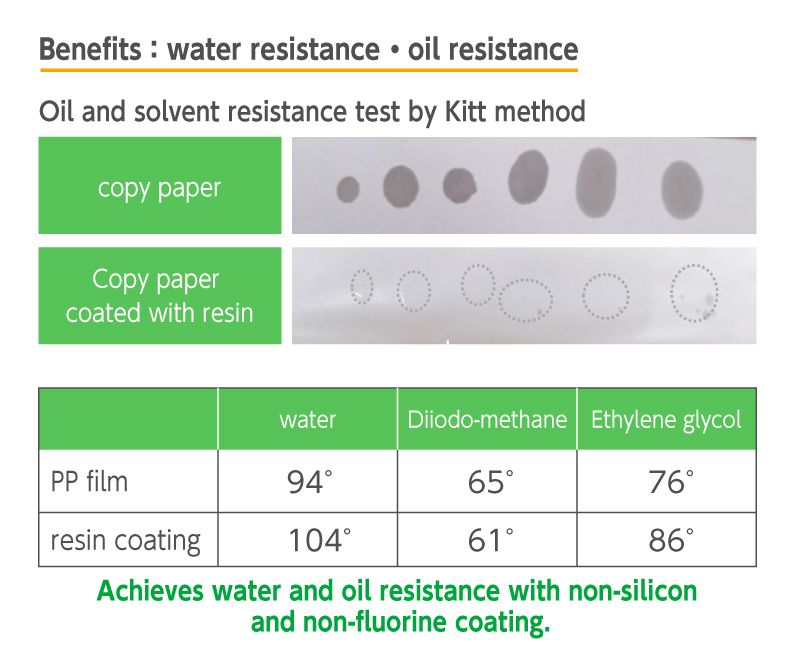

HYDRAN™ UX series solves this problem by providing water and oil resistance simply

by being applied to the paper.

3 reasons to choose HYDRAN™ UX series

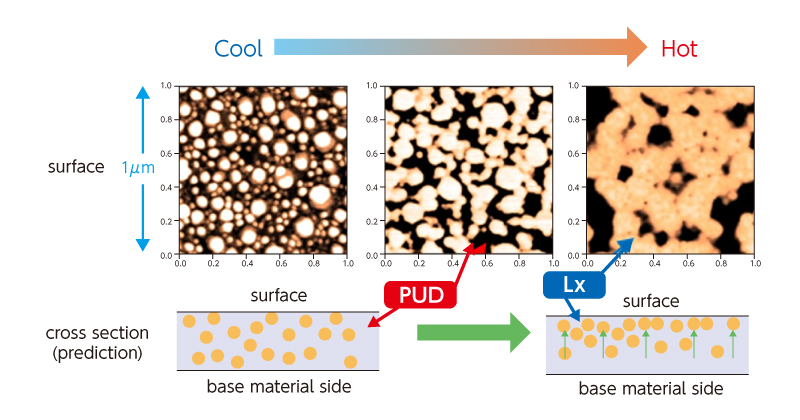

Creates a sloped structure by simply applying it to paper.

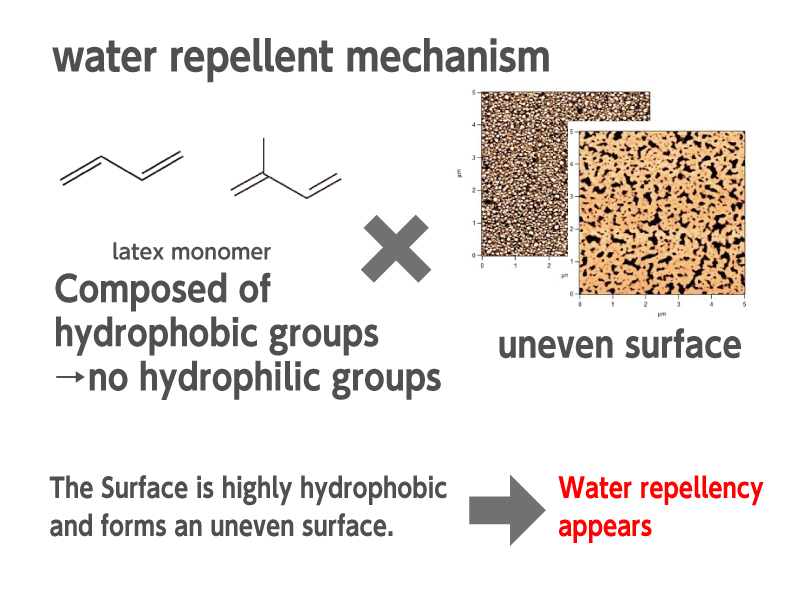

Two different components are combined into the same particle: urethane resin (PUD),

which has excellent adhesion and penetration into paper, and latex resin (Lx),

which has no hydrophilic groups and has excellent water and oil resistance.

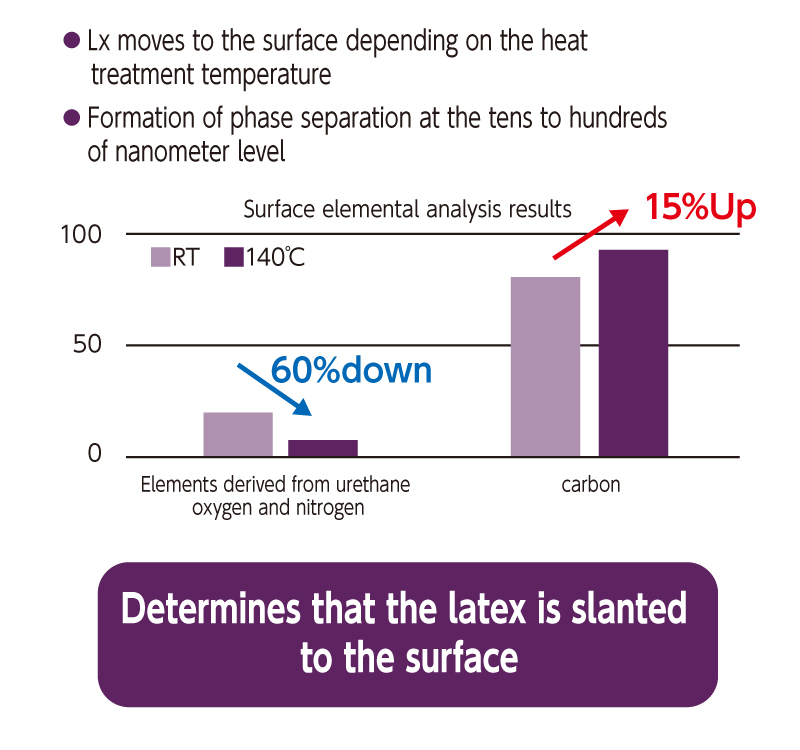

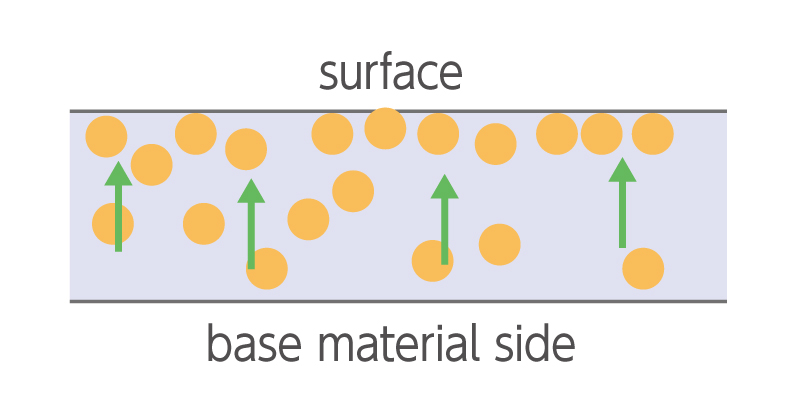

When coated on a paper base material, the low polarity Lx migrates to the surface (air layer)

and the high polarity PUD migrates to the base material surface, creating a slopedfunction.

It becomes water and oil repellent simply by applying it to the paper.

When coated on a paper base material, the low polarity Lx migrates to the surface (air layer)

and the high polarity PUD migrates to the base material surface, creating a sloped function.

This creates a highly concentrated Lx layer on the surface that repels water and oil.

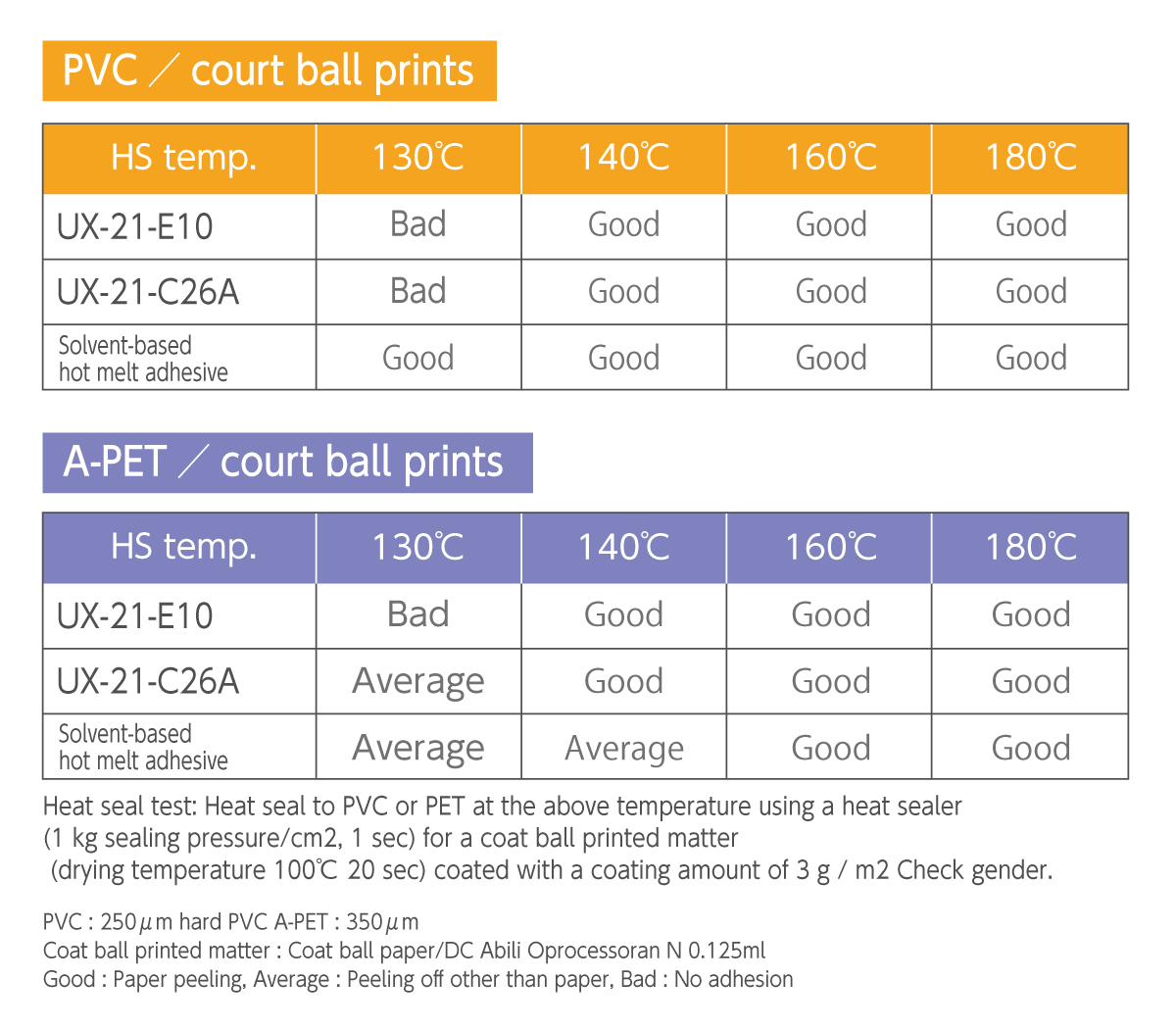

Heat-sealing properties are achieved on a wide range of substrates simply by applying it to paper.

When heat is applied, the PUD melts and develops sealing properties. Normally, a sealant must be selected based on the base material to be used, but by utilizing the properties of both PUD and Lx, a wide range of base materials can be adhered with a single sealant.