Sustainable

The film substrate can be recycled

by removing the ink layer from the packaging material.

DIC Original

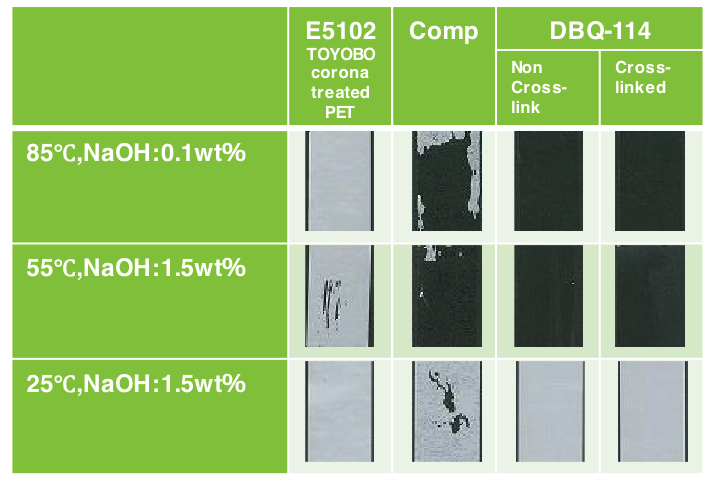

A)Excellent deinking even when used in combination with crosslinking agents.

This can also be applied to olefin-based substrates.

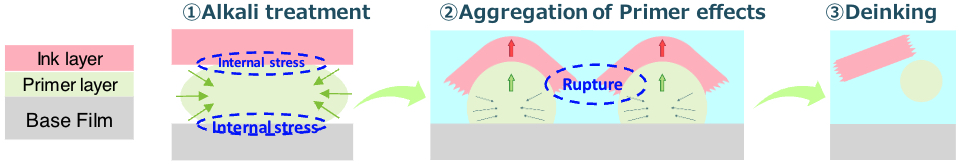

B) Deinking occurs only in alkaline solutions at high temperatures.

It has excellent alkaline resistance at room temperature.

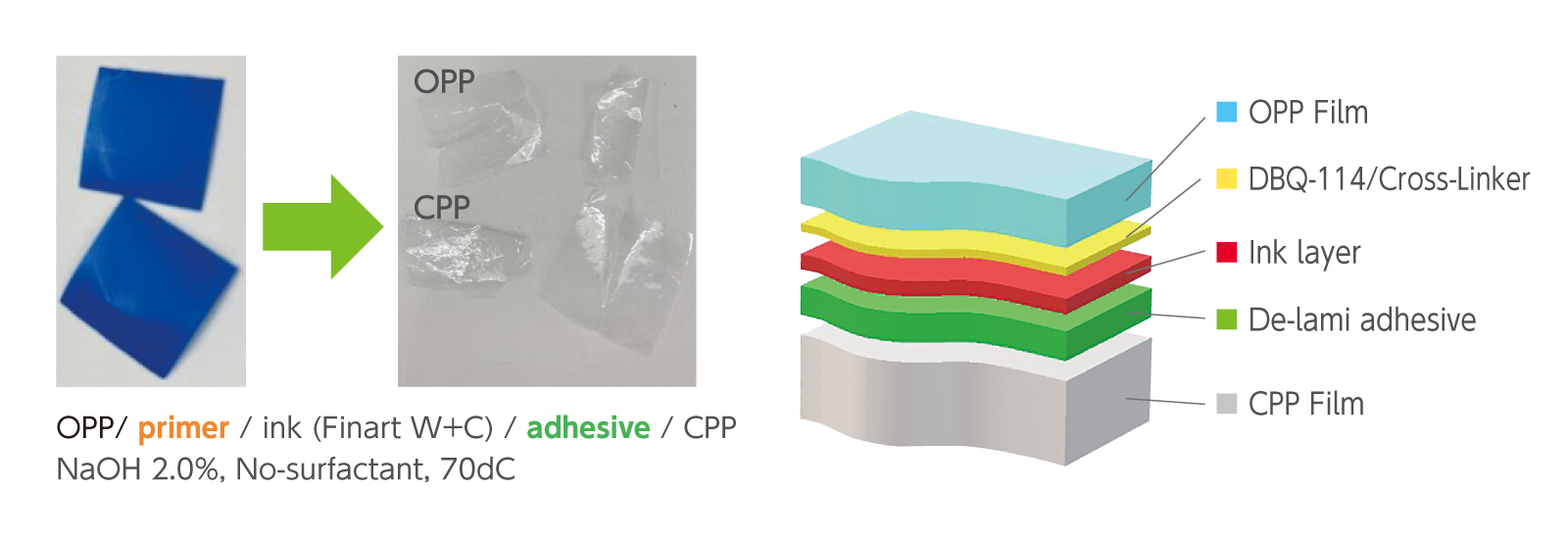

C)Packaging recycling by delamination is also possible

by using this deinking primer and delamination adhesive.

Are you troubled that packaging film base material of cannot be recycled because of ink?

We can solve this problem by simply applying HYDRAN™ DBQ-114

to the film base material and removing ink.

3 reasons to choose HYDRAN™ DBQ-114

You can remove the ink by simply applying a primer.

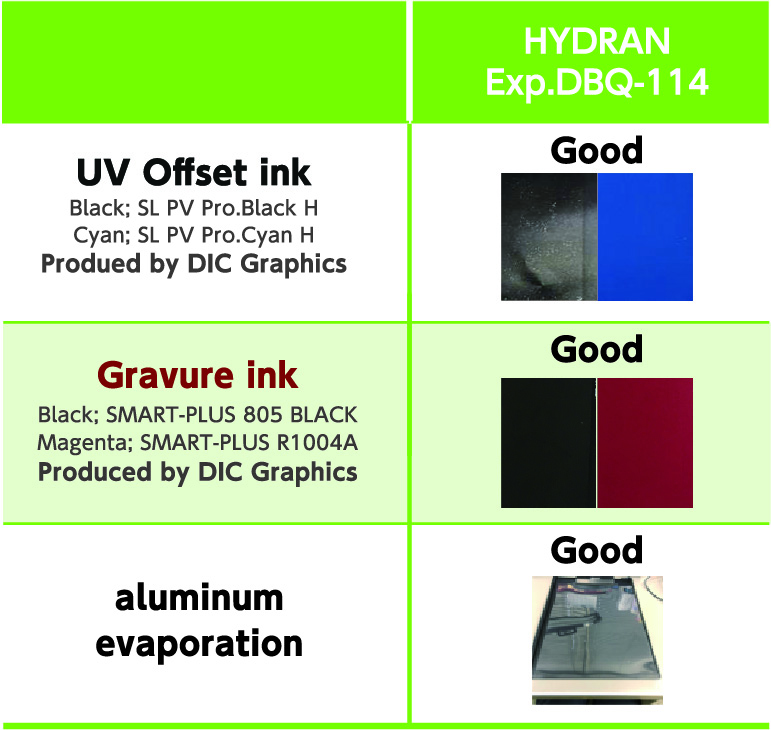

DBQ-114 has the same properties (printability and vapor deposition) as conventional water-based urethanes.

By simply applying DBQ-114 to the film base material, it is possible to remove the ink from the conventional ink.

Excellent alkaline resistance.

Possibility of adaptation to film base material by combined use of crosslinking agent.

DBQ-114 enables deinking by heating in alkaline solution.

At a high temperature of 85°C, it can be deinked at a very low concentration, and shows excellent alkaline resistance under normal use at 25°C.

Excellent deinking is possible even with the use of cross-linking agents.

It can be applied to various film substrates.

Possibility of recycling proposals other than de-inking

Packaging recycling by delamination is also possible

by using this deinking primer and delamination adhesive.