Kazuo Kawaguchi, Group Manager, Utility Control Group 2, Kashima Plant, DIC Corporation

Climate change is today widely perceived as a critical global issue that needs to be urgently addressed. Against this backdrop, attention is being increasingly focused on what companies are doing to combat global warming. The DIC Group has set a target for reducing annual CO₂ emissions by 50% from the fiscal year 2013 level by fiscal year 2030, with its long-term goal of achieving carbon neutrality—net zero CO₂ emissions—by fiscal year 2050.

Group Manager Kazuo Kawaguchi of the Kashima Plant’s Utility Control Group 2 has spearheaded the domestic DIC Group energy management program. We spoke to him about the plant’s initiatives to save energy and to use energy from renewable sources, as well as the Group’s road map for realizing its fiscal year 2050 carbon neutrality goal.

Shifting to renewable energy for 45% of the energy used by the Kashima Plant has reduced annual CO₂ emissions by 35,000 tonnes

The Kashima Plant, located near the Pacific coast of southeastern Ibaraki Prefecture, is one of DIC’s core production facilities, with a vast site area of 602,000 km²—approximately 13 times the size of Tokyo Dome. The plant’s principal products include organic pigments, base inks and metal carboxylates, as well as polyphenylene sulfide (PPS) resins, which play an indispensable role in reducing vehicle body weight, crucial to improving fuel efficiency. The production of these materials uses a significant amount of energy, making the plant the most energy-intensive of DIC’s domestic sites (comprising all production facilities and the Central Research Laboratories). Accordingly, the plant has long focused on global environmental protection efforts, notably the promotion of energy-saving initiatives and the installation of renewable energy systems.

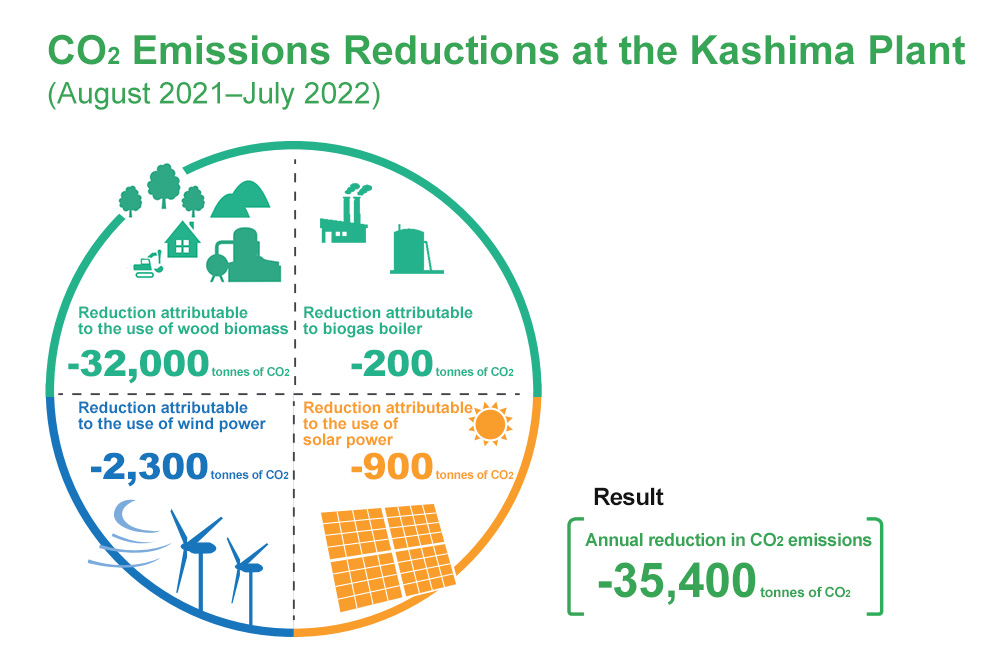

The Kashima Plant’s biomass boiler, inaugurated in 1985, is fired by wood chips made from construction waste. In 2008, the boiler was replaced with a cogeneration system.1 In 2009, the plant began operating two wind turbines with a rotor diameter of 71 meters, while in 2011 it installed a boiler that converts biogas (methane) generated in the process of wastewater treatment into steam. In 2016, the plant introduced a gas turbine cogeneration system that generates electric power and steam, which was followed in 2018 by the installation of a solar power system with a 1.5-megawatt annual generating capacity.

As a consequence, renewable energy now accounts for 45% of the total energy consumed by the plant, achieving a decline in annual CO₂ emissions of approximately 35,000 tonnes.

In December 2018, DIC won a New Energy Foundation Chairman’s Award in the Adoption and Application Category of the 2018 New Energy Awards in recognition of the expanded use of renewable energy at the Kashima Plant.

Utility control groups are responsible for managing supplies of materials essential to production

Management of the thermal and electrical energy used by the Kashima Plant is overseen by the facility’s Utility Control Group 2. The group’s remit includes the operation and management of supply systems for steam, electric power, water and compressed air, for the entire site, and of wastewater treatment facilities, as well as the planning and implementation of energy saving, equipment maintenance and efficiency improvement measures. For example, operation of the plant’s biomass boiler begins with the receipt of 14 large truckloads—approximately 140 tonnes—of wood chips from construction waste. Labor-intensive operational and maintenance processes, including the loading of wood chips into the boiler, adjustment of settings to ensure optimal combustion and removal of ash is carried out around the clock.

Group Manager Kazuo Kawaguchi

Utility Control Group 2 Group Manager Kawaguchi described his team’s responsibilities to us. “Our principal duties are ensuring supplies of water, electric power and fuel—which are essential to production activities—energy management and the treatment of wastewater,” he explains. “Our work involves transforming purchased fuel into steam, and electric power into cryogenic energy and compressed air, which drive turbines, which generate electric power and steam for production purposes. We therefore focus primarily on guaranteeing not only stable supplies, but also efficient supply processes. Of course, there are always potential issues that could hinder efficiency. We do not ignore such issues, but instead work to eliminate “muri, muda, mura”2 from all processes. We also strive constantly to identify the most effective ways to combine renewable energy systems within the plant, taking into consideration the operating status of such equipment, in a manner that allows us to provide an optimally efficient supply.

Achieving significant reductions in electricity costs through collaboration across utility control groups

In 2015, Kawaguchi launched the Utility Control Liaison Working Group to share information on the activities of utility control groups at DIC sites across Japan. This group holds quarterly conferences that are also attended by members of operations and planning committees, along with members of electrical technology, energy-saving, wastewater technology, facility maintenance and other working groups. Participants propose key themes and work together to address common issues. “I think the biggest achievement so far has been the reduction of overall costs for the purchase of electrical power. In the past, sites have had to negotiate with power companies on an individual basis,” explains Kawaguchi. “By undertaking comprehensive negotiations involving multiple sites, we were able to significantly lower outlays for electric power. This has provided further momentum for Utility Control Group 2’s activities.”

The horizontal deployment of various measures has progressed in the years since. For example, following the lead of the Kashima Plant, the Hokuriku Plant, among others, have also installed biomass boilers. A number of facilities, including the Kashima Plant, have installed systems that enhance the visibility of energy performance by presenting power consumption data in graph form. Department- and division-specific consumption data, trends by fiscal period, year-on-year comparisons and more can be easily accessed by divisional staff, as well as individuals on the front lines of production and in business groups, from their desktop computers. This data is also used by the energy-saving promotion working groups, which meet regularly at each plant, with departments reporting notable improvements invited to report on efforts and share know-how.

Upgrading biomass boiler with the aim of restructuring the Kashima Plant’s energy mix

DIC’s utility control groups have continued to play a leading role in DIC’s energy conservation and creation efforts, essential to achieving previously set Group CO₂ emissions reduction targets, namely, 7% from the fiscal year 2013 level by fiscal year 2020 and 30% from the fiscal year 2013 level by fiscal year 2030. Since the Paris Agreement,3 efforts to counteract global warming, notably those promoting decarbonization, have become increasingly rigorous. In May 2019, the DIC Group declared its support for the Task Force on Climate-related Financial Disclosures (TCFD),4 pledging to disclose climate-related information in line with TCFD recommendations and to conduct cross-departmental discussions, led by the Sustainability Committee, with the aim of setting a new CO₂ reduction target. In June 2021, DIC therefore announced a new target that calls for the achievement of carbon neutrality by fiscal year 2050 and reducing CO₂ emissions by 50% from the fiscal year level 2013 by fiscal year 2030.

As a result of extensive in-house discussions in the year-plus since the announcement of the new targets, Kazuo Kawaguchi is convinced that their achievement is not as impossible as it might seem. We asked him to elaborate on his plans for the Kashima Plant.

“Thanks to the installation of a biomass boiler, as well as wind power, solar power and other renewable energy systems, the Kashima Plant has contributed to the achievement of CO₂ emissions reduction targets to date,” Kawaguchi explains. “However, for us to help ensure the new targets set in fiscal year 2021 are met, we will need to restructure our energy mix to further improve efficiency, taking advantage of the biomass boiler update scheduled for fiscal year 2023, and expanding our installation of renewable energy systems.”

The Kashima Plant currently emits approximately 40,000 tonnes of CO₂ annually, making it the biggest emitter among DIC’s domestic sites. This is after achieving the 45% reduction through the introduction of energy-saving equipment and the cogeneration system. Factoring in projected growth in our annual production volume, currently approximately 40,000 tonnes, a 50% reduction in CO₂ emissions from the fiscal year 2013 level (28,000 tonnes) equates to a reduction of approximately 30,000 tonnes. So even if we were to switch to green power for 100% of the electric power we purchase, we would still have to achieve a further reduction of 18,000 tonnes.

“To meet the target we have set, it is vital that we restructure our energy mix after updating our biomass boiler next year,” Kawaguchi says. “Specific measures will include maximizing our use of steam from biomass; reviewing the operations of our cogeneration system; installing 4-megawatt-class solar panels on idle land; replacing existing wind power facilities (scheduled for fiscal year 2026); reducing energy consumption used by superfluous equipment through collaboration with production floors; and promoting untiring efforts aimed at increasing energy savings by 1% annually. If we can implement these measures between now and fiscal year 2030, the only thing left to ensure carbon neutrality by fiscal year 2050 will be to eliminate CO₂ emissions from the fuel (city gas) used in heat medium boilers and other equipment. Shifting to the use of hydrogen after fiscal year 2030 will thus be essential.”

(To be continued in Part 2)

1 A cogeneration system uses heat from biomass boilers to drive turbines, which generate electricity and provide steam for production purposes.

2 Muri, muda, mura is an expression describing three issues that hamper efficiency, the first word meaning wastefulness, that is, work that does not add value; the second indicating the overburdening of equipment and operators; and the third denoting irregularities in operations.

3 The Paris Agreement was adopted by nearly 200 nations (parties) at the 2015 United Nations Climate Change Conference, the 21st annual session of the Conference of the Parties to the United Nations Framework Convention on Climate Change (COP21), with parties setting a goal to limit global warming to well below 2°C compared with pre-industrial levels, preferably to 1.5°C.

4 The TCFD was established by the Financial Stability Board (FSB) in response to a request from the G20 to examine climate-related information disclosure and corresponding actions that should be taken by financial institutions. The task force has recommended that companies and other organizations disclose information concerning their governance, risk management, strategies, and metrics and targets where relevant to climate change–related risks and opportunities.