DIC Develops DAILUBE™ KS-519, the World’s First Algae Oil–Based High-Performance Sulfurized EP Additive

—Achieves better performance than conventional vegetable oil–based products

while also reducing environmental impact—

- Business & Product

- News Release

Tokyo, Japan—DIC Corporation today announced the development of KS-519, the world’s first* algae oil–based offering in its 「DAILUBE™」 series of sulfurized extreme pressure (EP) additives. In addition to helping users curtail CO₂ emissions, thereby contributing to greater sustainability, the new product delivers a better performance than conventional vegetable oil–based alternatives, and is expected to be in particularly high demand in the electric vehicle (EV) industry. Going forward, the Company plans to expand its selection of algae oil–based EP additives with a view to bolstering sales to manufacturers of automobiles—particularly EVs—and of metalworking fluids and gear oils, among others, in Japan, the United States and Europe. DIC has set a goal for annual sales of these products of ¥8.0 billion by fiscal year 2030.

* World’s first sulfurized EP additive made with algae oil (as of December 2023, based on DIC research).

EP additives are lubricant compounds used to prevent wear and improve durability for mechanical parts, and are conventionally manufactured using vegetable oil or lard as a base material. Sulfurized triglycerides additives help lower friction, control wear and prevent unacceptable surface damage at high temperatures or under heavy loads. Compared with conventional alternatives, DIC’s newly developed algae oil–based KS-519 offers a superior lubricating performance, additional benefits such as a light color and low odor, and a reduced environmental impact thanks to, among others, decreased CO₂ emissions.

Lard-based sulfurized EP additives boast greater load-bearing properties than their vegetable oil–based counterparts. However, lard production has declined in recent years, making it difficult to secure stable raw material supplies, while environmental and religious considerations have made the use of lard-based products difficult in certain parts of the world. Given rising demand for a shift to new materials, particularly from overseas customers, algae oil–based KS-519 is expected to gain favor as an acceptable replacement for lard-based products as it relates to supply chain security.

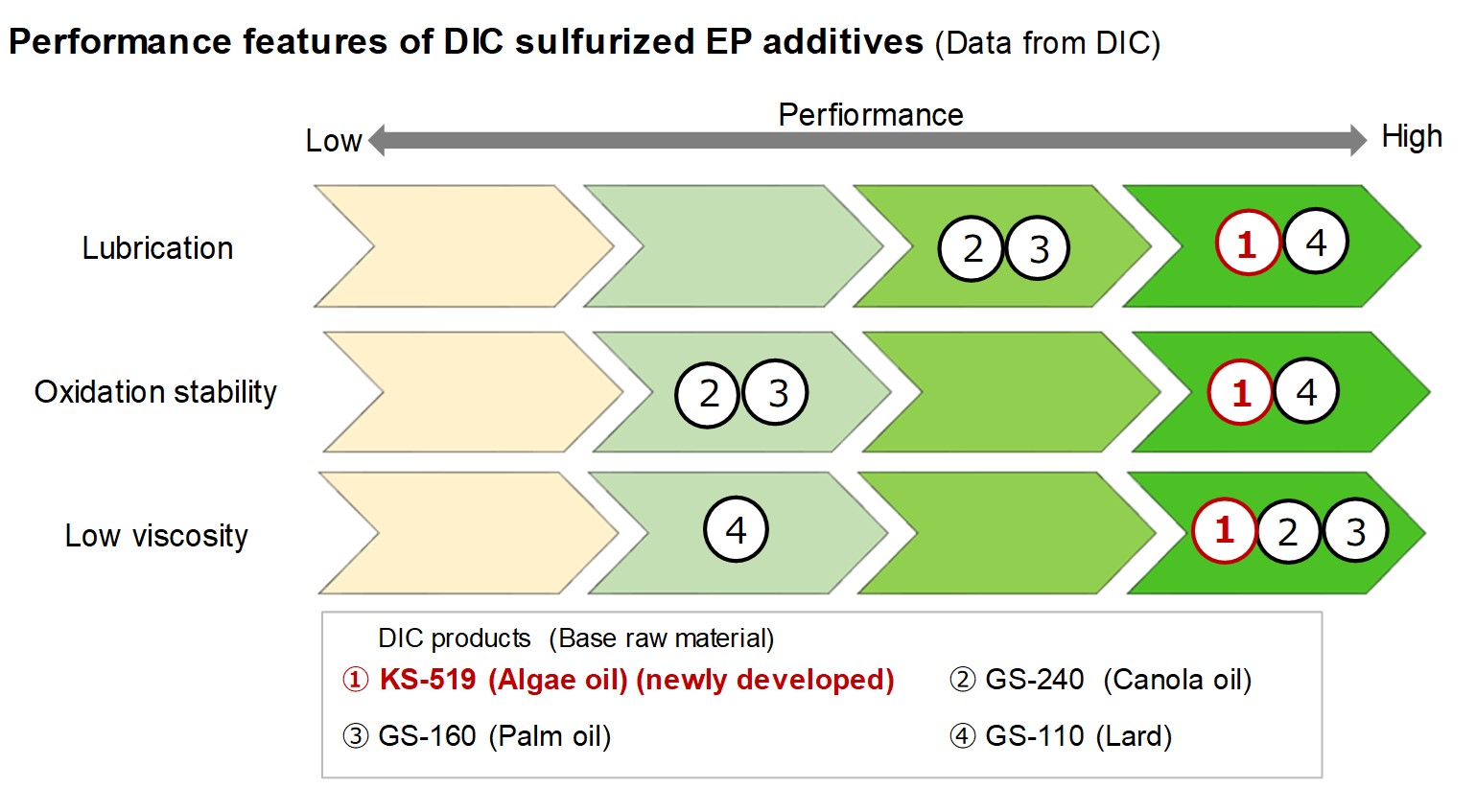

Main performance features

KS-519 builds on DIC’s existing DAILUBE™ products—which are prized for exceptional base oil solubility at a high flash point—and is particularly appropriate for use in lubricants for a wide range of metalworking applications requiring a specific viscosity level, sulfur content and active sulfur point. KS-519’s advantages over conventional sulfurized EP additives can be summarized as follows:

• A performance equivalent to that of lard-based products despite containing no lard;

• A pour point of –15°C, lower than that of conventional Sulfurized triglycerides additives; and

• High oxidation stability, ensuring suitability for long-term use.

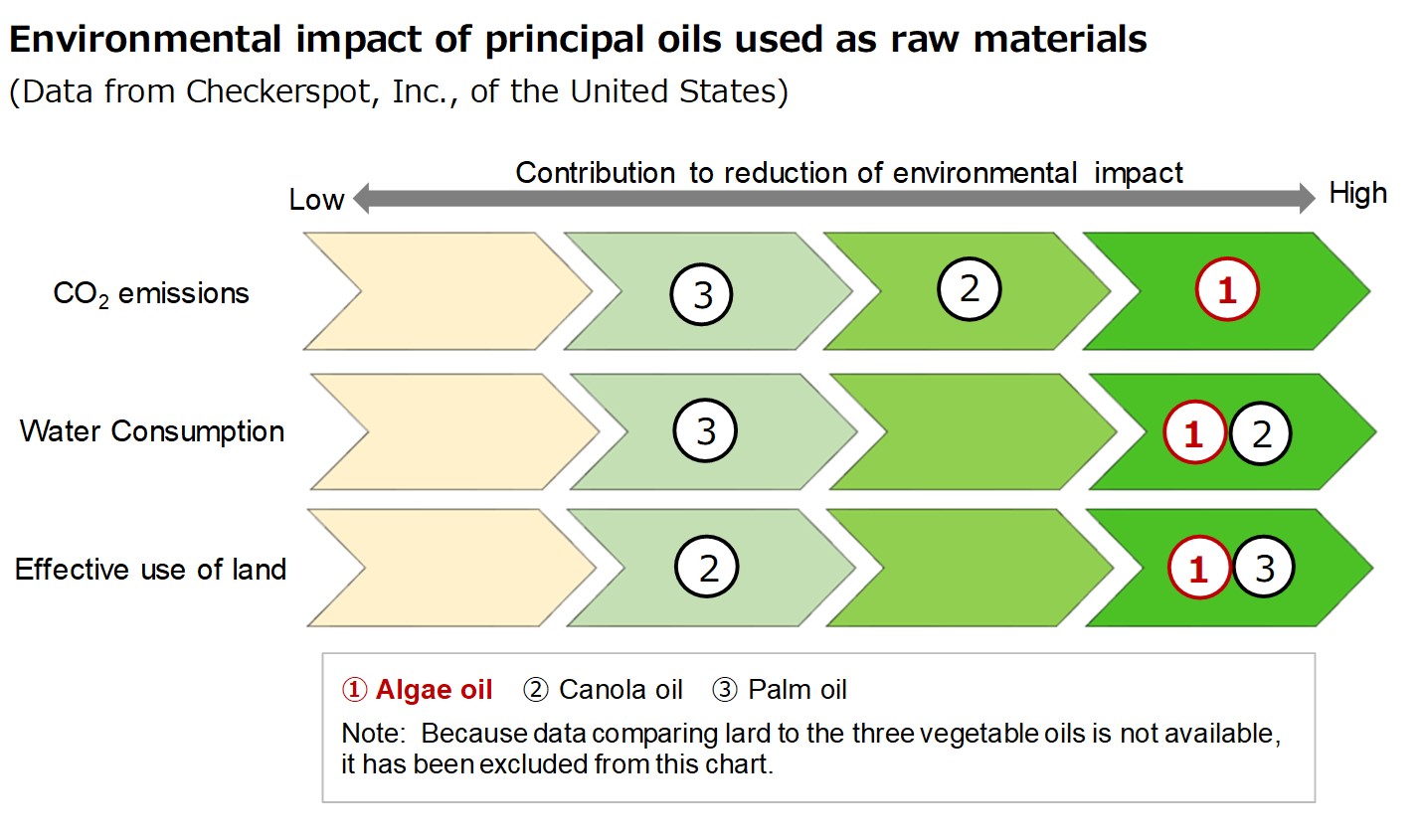

Contribution to a Reduced Environmental Impact

CO₂ emissions from the use of KS-519 are 5% less than those from the use of GS-240, a sustainable vegetable oil–based product in the DAILUBE™ series. Moreover, the algae oil used in KS-519 requires 85% less cultivated land than canola oil and 87% less water than palm oil per tonne harvested, and is thus expected to contribute to a significant reduction in environmental impact. (All carbon footprint calculations are in compliance with the International Organization for Standardization’s ISO 14040, ISO 14044 and ISO 14067 standards and are based on cradle-to-gate emissions data, Emissions factors were developed from primary and secondary data collected from, among others, supplier and industry organization databases, and the Inventory Database for Environmental Analysis (IDEA). Data for algae oil and other vegetable oils is from Checkerspot, Inc., of the United States, a manufacturer of algae oil raw materials and ingredients. Biogenic emissions are not taken into account.)

In its DIC Vision 2030 long-term management plan, DIC sets forth a basic strategy of expanding its Functional Products business with a focus on sustainable products. The DIC Group will continue to capitalize on its long history, as well as its wealth of expertise and technical capabilities, in the area of synthetic resins to accelerate the development and bolster sales of such products, thereby contributing to the resolution of key social imperatives.

– Ends –

About DIC Sulfurized EP Additive

URL: https://www.dic-global.com/en/products/sulfur/

About DIC Corporation

DIC Corporation is one of the world’s leading fine chemicals companies and the core of the DIC Group, a multinational organization comprising over 190 companies, including Sun Chemical Corporation, in more than 60 countries and territories. The DIC Group is recognized as a global leader in the markets for a variety of products essential to modern lifestyles, notably packaging materials, display materials such as those used in television and computer displays, and high-performance materials for smartphones and other digital devices, as well as for automobiles. Through such products, the Group endeavors to deliver safety and peace of mind, and color and comfort, to people everywhere. The DIC Group also seeks to contribute to a sustainable society by developing innovative products that respond to social change and which help address social imperatives. With annual consolidated net sales exceeding ¥1 trillion and 22,000-plus employees worldwide, the Group pledges to continue working in close cooperation with our customers wherever they are. For more information, please visit the DIC global website. https://www.dic-global.com/

Commercial Contact:

Performance Material Products Division’s Functional Additives Sales Group

E-mail: dailube_sustainable@ma.dic.co.jp