Special Feature Firefighting Foam (MEGAFOAM)

Foam extinguishing agent quickly extinguishes fires involving hazardous substances, thereby minimizing damage

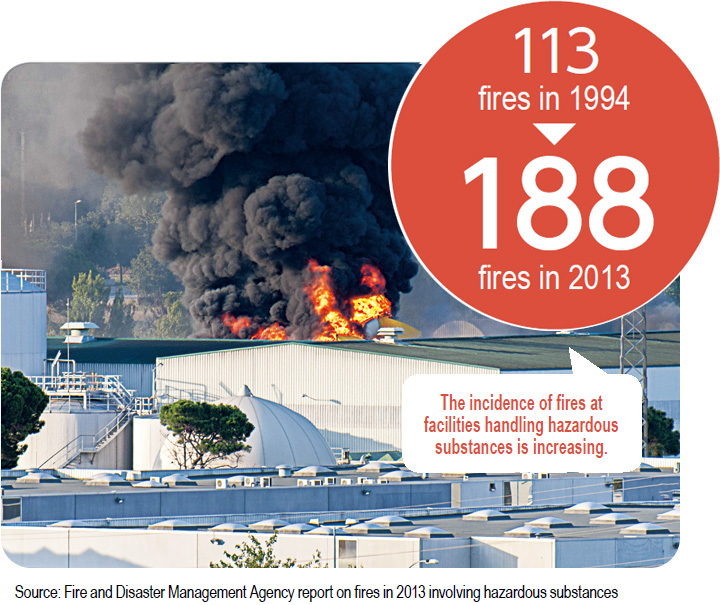

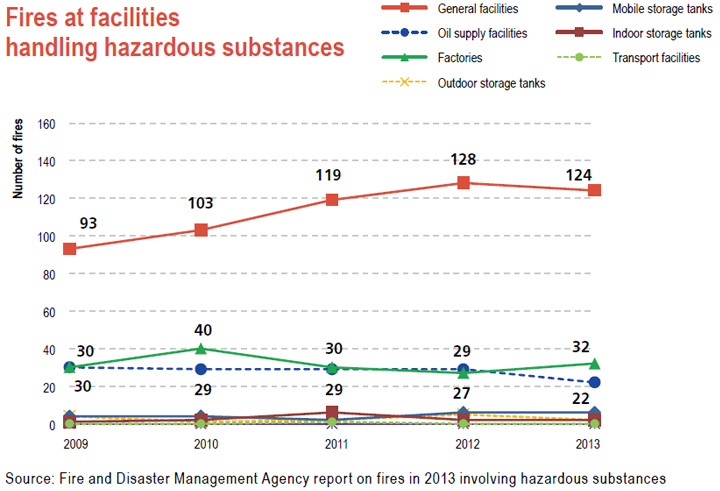

Social Imperative Effectively extinguish dangerous fires at facilities handling hazrdous substances

Fires at petrochemical complexes, chemical plants and other facilities handling hazardous substances designated under Japan’s Fire Service Act have the potential to cause massive damage. In addition to human casualties, such fires can result in the loss of machinery and equipment, and of raw materials and products, the release of environmentally damaging substances and the suspension of production and resulting disruption of supply chains. Accordingly, it is vital to extinguish such fires as quickly as possible.

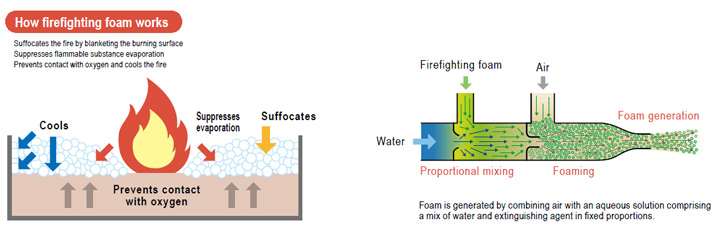

Unlike regular structural fires, chemical fires—notably those involving water-insoluble flammable liquid materials such as gasoline and water-soluble flammable liquid materials such as alcohol—cannot be extinguished by water alone. For such fires, it is imperative to blanket burning surfaces with a firefighting foam containing a fire extinguishing agent diluted with fresh water or seawater, which prevents contact with oxygen while cooling the fire. The foam must coat the burning surface quickly without being broken down by the heat and be able to suppress fires involving a variety of chemicals.

DIC’s Response A firefighting foam with a superior extinguishing performance that has earned it the top share of the Japanese market

DIC has developed a firefighting foam with a wide range of applications

Developed in 1982, MEGAFOAM is Japan’s first aqueous film-forming firefighting foam, an innovative product that leverages DIC’s molecular design and mixing technologies in the area of fluorochemical surfactants. Surfactants form a thin aqueous film at the interface between two materials with hydrophilic and lipophilic properties, thereby transforming the material surfaces. Common surfactants include soap and shampoo. Aqueous film-forming surfactants lower surface tension, making it easier to form films and preventing the foam generated from breaking down. Firefighting foams harnesses this capability.

Since its launch, MEGAFOAM has earned an outstanding reputation for its fire extinguishing capabilities. In addition to being adopted by the Japan Self- Defense Forces and fire departments, MEGAFOAM is currently in use at numerous airports, facilities handling hazardous substances, tunnels, underground parking lots and other facilities. Owing to the revision of pertinent legislation, corporate sites and areas with floating roof storage tanks the diameter of which exceed 34 meters are obliged to install large-capacity foam monitor systems. As a consequence, the use of firefighting foam systems by industrial complexes and fire departments across the country has expanded rapidly. MEGAFOAM is currently the leading firefighting foam in Japan in terms of market share.

MEGAFOAM can be adapted to extinguish fires involving water-soluble flammable liquid materials

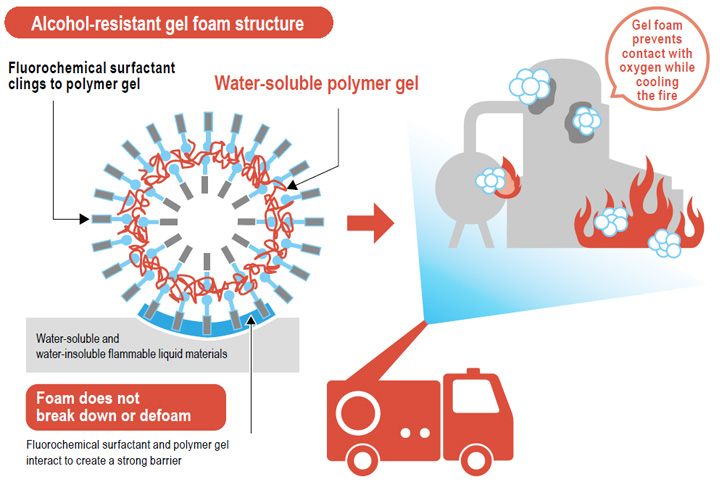

Unlike fires involving gasoline and other water-insoluble flammable liquid materials, fires involving water-soluble flammable liquid materials such as alcohol, ketones, esters and amines are extremely difficult to put out because firefighting foam reacts with water and dissolves. In the mid-1980s, DIC capitalized on its polymer gel formation technologies to develop a robust foam structure. This led to the commercialization of an alcohol-resistant version of MEGAFOAM. As it is also effective in extinguishing fires involving gasoline, oil and other waterinsoluble flammable liquid materials, this version of MEGAFOAM is particularly prized by fire departments, which often must deal with fires involving unspecified materials.

Applications range from fire trucks to fire extinguishing systems for industrial complexes

KEY PERSON of DIC

Easily diluted and resistant to breaking up, MEGAFOAM combines numerous DIC technologies

With firefighting foam, you can alter expansion and choose a foam shower, nozzle or other discharge format according to the nature of the fire to be extinguished. In addition to its superior fire extinguishing performance, MEGAFOAM has garnered praise for its manageability and suitability for diverse applications, both attributable to foam generating capabilities that reflect our high-precision polymer design and mixing technologies.

Head Researcher, Polymer Technical Group 10, Polymer Technical Division 2 Jiro Matsuo

DIC’s surfactant technologies are also attracting attention overseas.

A late entrant into the firefighting foam market, DIC took a different approach to market development than existing players. This included collaborating with fire extinguishing equipment manufacturers and focusing on ease of use at fire sites. MEGAFOAM’s performance has been proven in various fires and its use at industrial complexes, airports, tunnels and other facilities continues to expand. Our proprietary fluorochemical surfactant technologies are also attracting considerable attention from firefighting foam manufacturers overseas.

General Manager in Charge of Fluorochemical Sales Department, Advanced Polymer Sales Division Kouichi Jinba

Special Topics 2015

Adhesive with Oxygen Barrier Properties (PASLIM)

Adhesive for packaging film that prevents oxygen permeation and keeps foods fresh longer

Epoxy Resin and Curing Agent for Infrastructure Renovation (EPICLON with LUCKAMIDE)

Superior adhesiveness, even on damp surfaces, shortens repair times and improves workability

Firefighting Foam (MEGAFOAM)

Foam extinguishing agent quickly extinguishes fires involving hazardous substances, thereby minimizing damage

TOPICS

Groundbreaking Sun Chemical Solution Enhancesthe Recyclability of Shrink Sleeve-Labeled PET Bottles