Preventing Environmental Pollution

Goals and Achievements of Major Initiatives

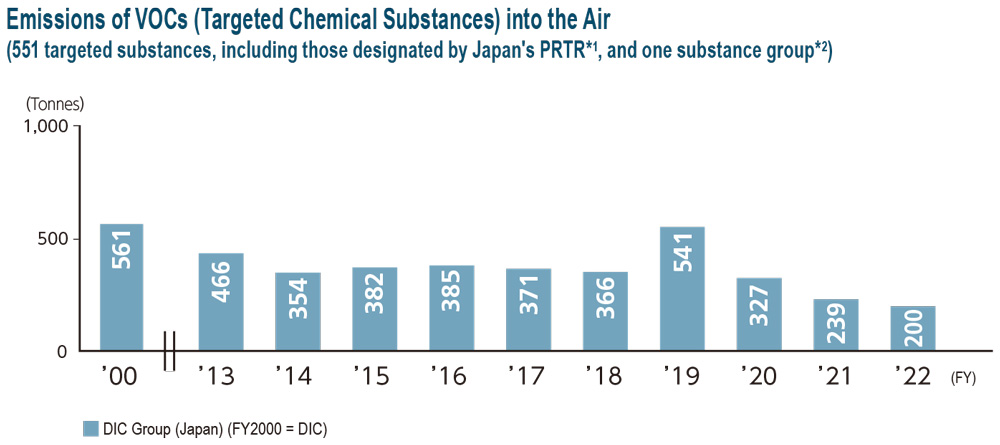

Reduce emissions of VOCs into the air.

| Scope of target | Japan |

|---|---|

| Goal for fiscal year 2022 | DIC Group (Japan): 325 tonnes (maintain at essentially level with fiscal year 2021; down 30% from fiscal year 2000) |

| Achievement in fiscal year 2022 | DIC Group (Japan): 200 tonnes |

| Evaluation | ★★★ |

| Goal for fiscal year 2023 | DIC Group (Japan): 280 tonnes (maintain at a level down 50% from fiscal year 2000) |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Policies and Organization

Basic Approach

The DIC Group works to grasp the environmental impact of its operating activities and promotes systematic measures to reduce its environmental footprint. The Group also advances efforts aimed at preventing environmental pollution.

Since chemicals companies handle a considerably greater volume and more diverse range of chemical substances than companies in other industries, they must be extremely vigilant to prevent discharges of substances into the environment. Against this backdrop, the DIC Group works to grasp the environmental impact of its operating activities and promotes systematic efforts to reduce its environmental footprint. The Group also advances efforts aimed at preventing environmental pollution. In Japan, the Group has worked since fiscal year 2005 to reduce emissions into the air, water and soil of substances designated in pertinent laws and regulations—including the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements in the Management Thereof, the Soil Contamination Countermeasures Act, the PRTR Law, the Ozone Layer Protection Law, the Act on Rational Use and Proper Management of Fluorocarbons and the Law Concerning Special Measures for Promotion of Proper Treatment of PCB Wastes—and of substances targeted for management under a voluntary scheme created by the JCIA.*

- The JCIA is a general incorporated association. As one of Japan’s major industry organizations, the JCIA is a member of the ICCA and pursues the healthy development of the chemicals industry together with other chemical–industrial organizations around the world.

Principal Initiatives in Fiscal Year 2022

01Reducing Emissions of VOCs

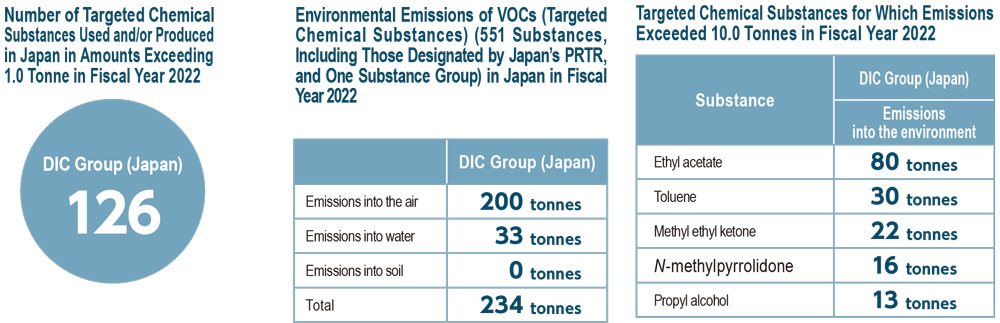

The DIC Group in Japan succeeded in achieving its voluntary target for reducing emissions of VOCs into the air for fiscal year 2010—30% from the fiscal year 2000 level—in fiscal year 2007. The Group has since raised this target to a 50% reduction from the fiscal year 2000 level. In fiscal year 2022, Group companies in Japan reported total emissions of VOCs of 200 tonnes, a decline of 16% from fiscal year 2021. The principal reason behind this was a decrease in products that are responsible for significant emissions of VOCs from the product mix. DIC Group companies in Greater China and the Asia–Pacific region continued to carefully monitor their emissions. In the PRC, in particular, the Group is updating equipment and stepping up emissions management practices in response to the tightening of pertinent local regulations.

- A PRTR is a scheme for assessing, aggregating and disseminating data on the source of hazardous chemicals, amounts released into the environment and amounts transferred off-site from industrial establishments via waste products.

- The “551 substances and one substance group” comprises 462 class1 chemical substances designated by Japan’s PRTR and 89 PRTR-designated substances (other than class 1) and one substance group (chain hydrocarbons with up to 4–8 carbon atoms) targeted for study by the JCIA.

In fiscal year 2022, the DIC Group in Japan monitored 462 class 1 chemical substances designated by the PRTR and 89 PRTRdesignated substances (other than class 1) and one substance group (chain hydrocarbons with up to 4–8 carbon atoms). During the period, Group companies in Japan used and/or produced a combined total of 126 of these substances in amounts exceeding 1.0 tonne.

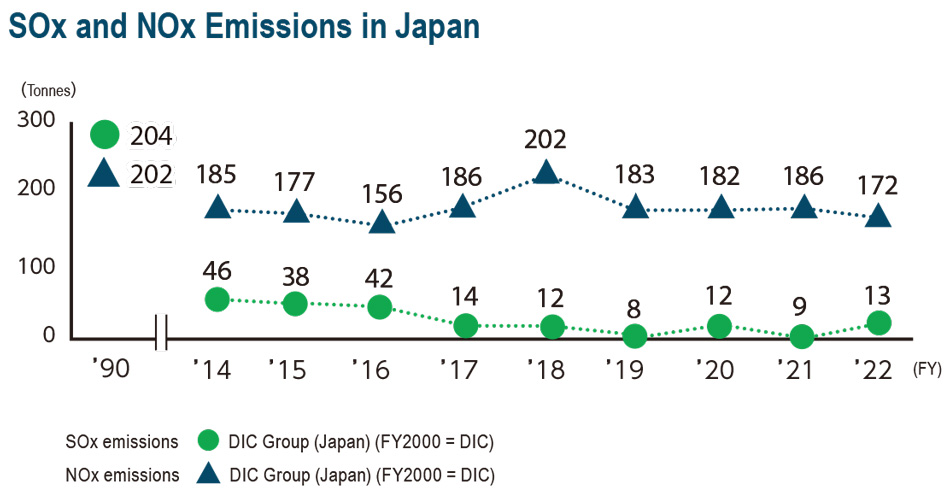

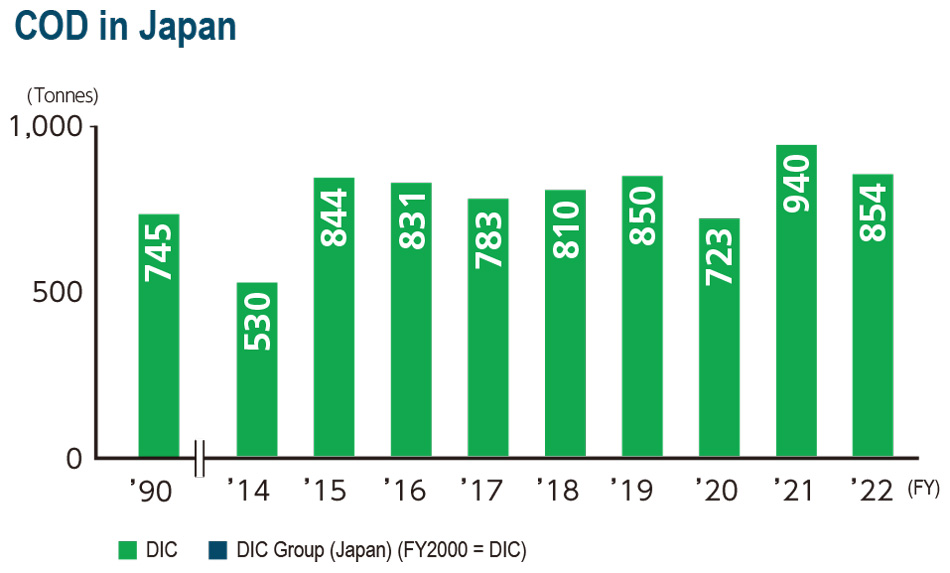

02Reducing SOx, NOx and COD

Taking fiscal year 1990 as the base year, the DIC Group in Japan has taken steps to reduce SOx and NOx emissions from boilers. The Group has also worked to reduce COD, an indicator of environmental impact, in wastewater, particularly by installing biomass boilers and modifying production processes. In fiscal year 2022, emissions of SOx by the Group in Japan amounted to 13 tonnes, a decline of more than 10% from the fiscal year 1990 level, while emissions of NOx were 172 tonnes, down 15% from fiscal year 1990. In contrast, the domestic DIC Group’s COD was 854 tonnes, lower than in the previous fiscal year, but still high and up 15% from fiscal year 1990. Principal contributing factors behind this result included an increase in production volume and changes in the product mix. The Group will continue working to reduce COD by promoting the effective management of water quality.

DIC Group companies in other countries and territories are also switching from diesel to natural gas, and from diesel- and heavy oil– fired boilers to biomass boilers. To reduce COD, these companies are promoting the reuse of water and the installment of environmentfriendly closed-loop recycling and wastewater treatment systems that purify wastewater to a level that exceeds that mandated by local laws.

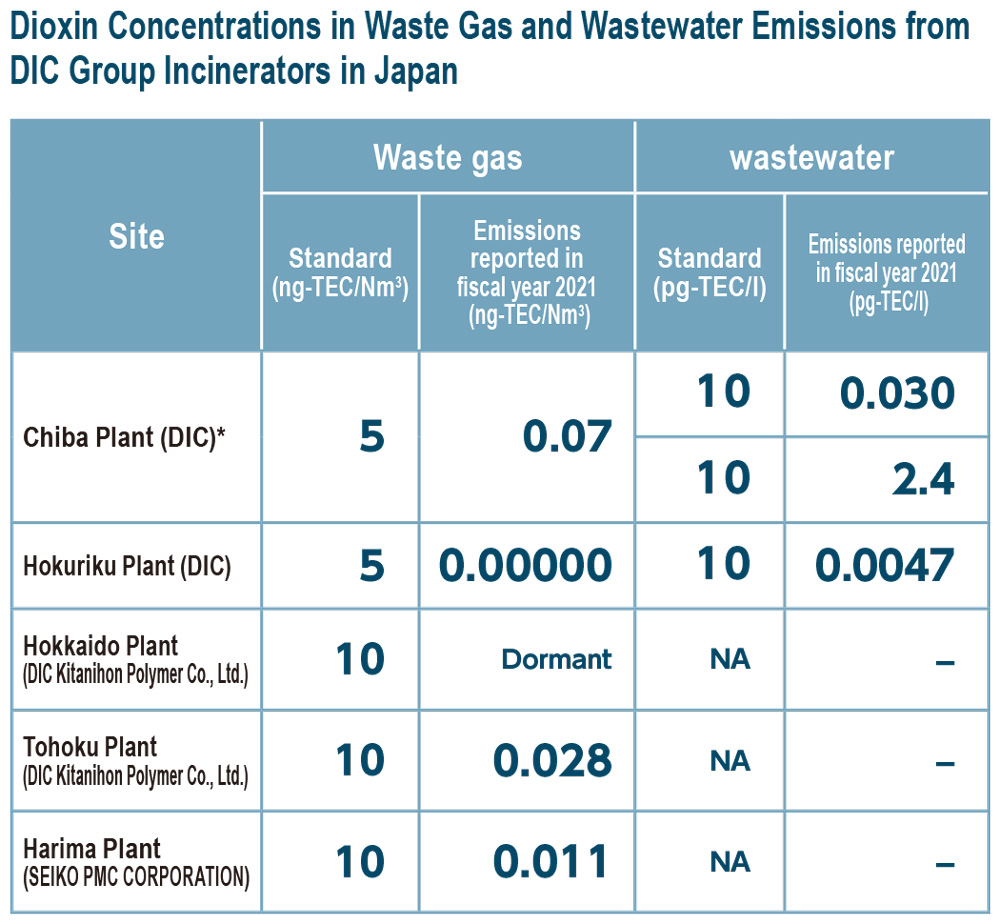

03Complying with Regulations Governing Emissions of Dioxins

In Japan, the DIC Group monitors emissions of dioxins from facilities that produce these byproducts, in accordance with the Act on Special Measures Against Dioxins. At present, the Group has five such facilities* in Japan, each of which has achieved reductions that surpass the standards set forth in the Act.

- In fiscal year 2022, DIC Interior Co., Ltd., shuttered operations, as a result of which the number of dioxinemitting DIC Group facilities in Japan declined from six to five.

04Ensuring the Appropriate Collection and Storage of PCBs

DIC Group companies in Japan work to ensure the appropriate collection, storage and management of equipment containing polychlorinated biphenyls (PCBs), including older-model transformers and capacitors, in accordance with the Law Concerning Special Measures for Promotion of Proper Treatment of PCB Wastes. These companies also ensure that equipment containing PCBs is disposed of in accordance with the practices of the Japan Environmental Storage & Safety Corporation (JESCO). The DIC Group in Japan expects to complete disposal of waste with high concentrations of PCBs in the first half of fiscal year 2023. Efforts to manage and dispose of low-concentration PCB waste will proceed apace.

05Responding to Asbestos Risks

The DIC Group in Japan strives to respond to potential risks associated with asbestos during demolition or when retrofitting equipment, as outlined in the Ordinance on the Prevention of Health Impairment due to Asbestos and the revised Air Pollution Control Law.

06Soil and Groundwater Pollution

In addition to complying strictly with the Soil Contamination Countermeasures Act, the DIC Group in Japan implements soil and groundwater surveys and countermeasures as necessary to assess related risks. In fiscal year 2021, a voluntary survey conducted at a third site belonging to the Hokuriku Plant resulted in the site being designated as an “Area which Requires Measures.” Purification measures are currently being implemented in line with the Act, as well as with pertinent regulations.

Building a Circular Economy

In recent years, waste plastic and marine plastics, a result of the improper disposal of end-of-life plastic containers and other products, have become issues of major concern worldwide. In Japan, the DIC Group works to prevent pollution of the environment, particularly through measures to preclude leaks of raw materials from production facilities and the recycling of plastic waste generated in production processes. In fiscal year 2020, 46% of waste plastic generated by the Group was recycled. Approximately 92% of this was reused, including in the recovery of energy from fuel utilization.

The building of a circular economy is not something that can be achieved by any one company. Accordingly, key initiatives are being promoted by industrial and public–private partnerships around the world. In Japan, DIC is a member of the Japan Initiative for Marine Environment (JaIME), formed by five chemicals industry organizations, and the Japan Clean Ocean Material Alliance (CLOMA), a Ministry of Economy, Trade and Industry–led alliance of companies in the plastic products supply chain. Overseas, Sun Chemical participates in A Circular Economy for Flexible Packaging (CEFLEX), a consortium working to make flexible packaging in Europe circular, ensuring its ability to access and share the most up-to-date information across the DIC Group. The Company has also organized projects involving various departments concerned with the circular economy to promote the collection of plastics, as well as the shift to alternative and/or biodegradable materials.

TOPICS

PT DIC Astra Chemicals Wins Award Under DKI–Jakarta–Company Environment Performance Appraisal Program.

In fiscal year 2018, PT DIC Astra Chemicals won an award from the Special Capital Region of Jakarta (Daerah Khusus Ibokota Jakarta (DKI Jakarta) in Indonesian) under the DKI–Jakarta–Company Environment Performance Appraisal Program. High marks were given to the company’s efforts to comply with Indonesia’s environmental management laws and related regulations, as well as the excellence of its systems for managing treating industrial effluents and air pollution. These awards are conferred on companies demonstrating excellence in the area of environmental protection based on the results of environmental performance audits of all companies in the special capital region, which are conducted by the Jakarta government. PT DIC ASTRA Chemicals was one of only eight award winners chosen from among more than 1,000 Jakarta-based manufacturers.

DIC’s Kashima Plant installs anaerobic wastewater treatment system

DIC’s Kashima Plant is promoting efforts to increase its wastewater treatment capacity and conserve energy. With the aim of enlarging its wastewater treatment facilities, DIC’s Kashima Plant recently installed a BIOIMPACT® expanded granular sludge blanket (ESGB) anaerobic wastewater treatment system. This system is manufactured by Sumitomo Heavy Industries Environment Co., Ltd. Conventional chemical wastewater treatment systems are aerobic, i.e., require oxygen. In aerobic wastewater treatment systems, activated sludge* is used to break down organic matter in wastewater into CO₂ and water. In contrast, the BIOIMPACT® system uses ESGB, a newly commercialized anaerobic process whereby wastewater is flowed into a tank containing a dense blanket of sludge granules (aggregates of anaerobic microorganisms), which rapidly break down organic matter into methane and CO₂. This innovative system, which also facilitates the reuse of methane produced for plant operation, is attracting considerable attention for its various performance features, which include superb efficiency and minimal space and energy requirements. The Kashima Plant expects the new system to reduce its annual emissions of CO₂ by 720 tons, as well as to significantly lower its operating costs.

Advanced Initiatives in the PRC Earn DIC Green Enterprise Certification

The PRC is reinforcing regulations pertaining to chemical substances with the aim of balancing economic growth and environmental protection. It is against that backdrop that 20 DIC Group companies in the PRC have promoted improvements in their own practices for handling chemical substances based on the Group’s environmental management system to reduce chemical substance emissions, water intake and discharge, waste disposal and energy consumption and have submitted data annually to the relevant authorities.

Green Enterprise certificate

These highly transparent initiatives have garnered considerable praise. In June 2012, Nantong DIC Color Co., Ltd., which manufactures organic pigments and printing inks, was certified as a Green Enterprise by the Nantong City Environmental Protection Committee, a designation recognizing companies with environment-friendly business practices. As a consequence, Nantong DIC Color is now seen as a model chemicals plant.