Safety in Logistics

Goals and Achievements of Major Initiatives

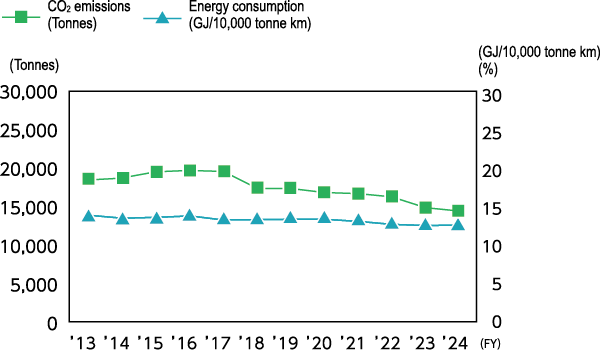

Reduce CO2 emissions attributable to logistics.

| Scope of target | Fiscal year | Goals | Achievements | Evaluation |

|---|---|---|---|---|

| Japan | 2024 | Reduce CO2 emissions attributable to logistics by 1.23% from fiscal year 2023. |

|

★★ |

|

★★★ | |||

| 2025 | Reduce CO2 emissions attributable to logistics by 1.23% from fiscal year 2024. | ― | ― |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Basic Approach

The DIC Group works with logistics partners to minimize risks, including by supplying information needed for the safe shipping and transport of chemicals.

Policies and Organization

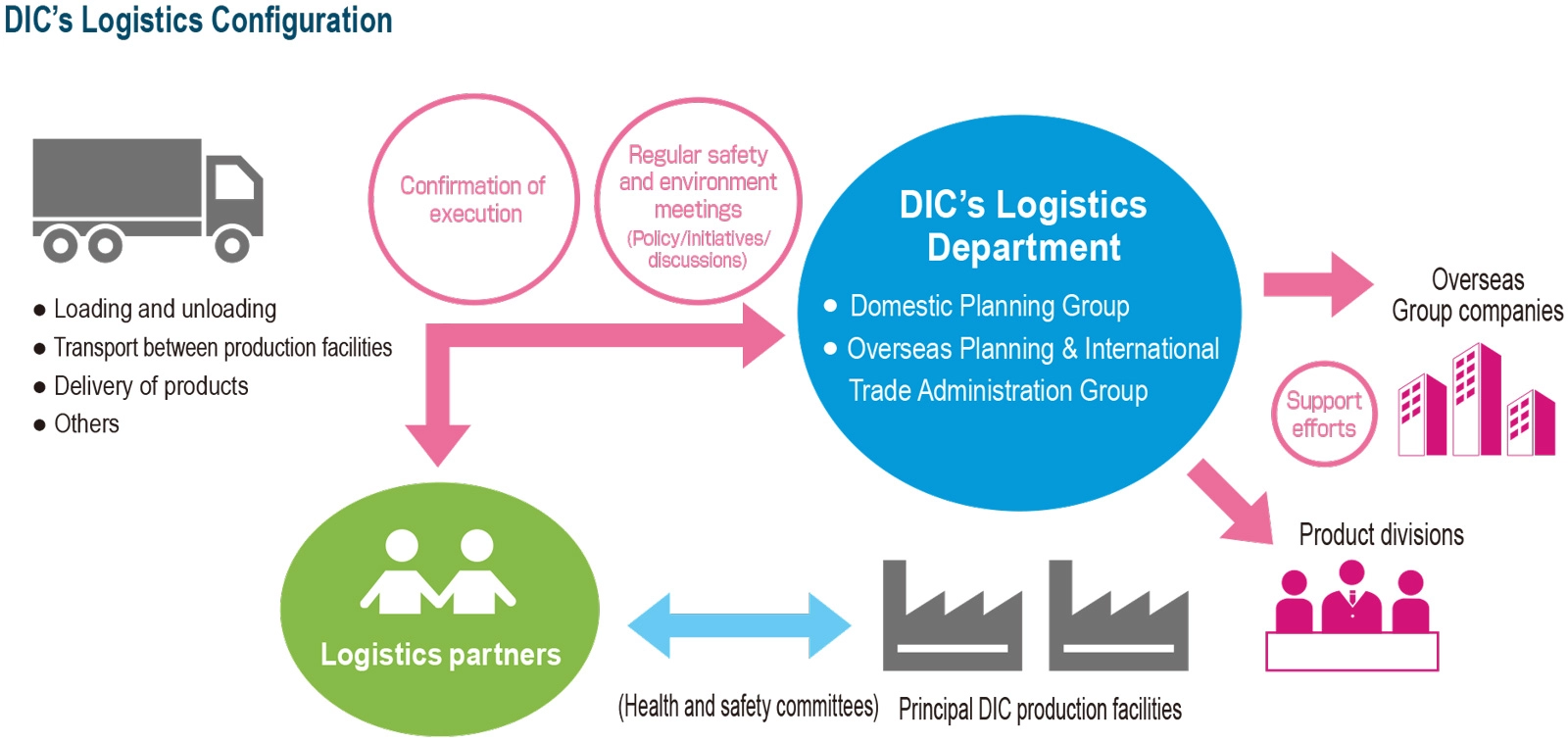

Having positioned the reduction of CO2 emissions attributable to the transport of its products as a key aspect of its commitment to promoting Responsible Care, the DIC Group sets annual targets and promotes relative initiatives on an ongoing basis. In 2011, responsibility for the logistics configuration—components of which include transport between production facilities, the transport of products to customers, and international logistics—was transferred to a logistics partner, that is, a third-party logistics (3PL) firm,*1 in a bid to improve safety and curb CO2 emissions. In January 2016, the logistics management functions of DIC’s various departments were combined to create a single Logistics Department with the goal of responding better to social imperatives associated with the transport of chemicals over the medium to long term.

The Logistics Department advances initiatives to enhance the safety and reduce the environmental impact of the DIC Group’s logistics. The department consists of the Domestic Planning Group, which devises strategies to optimize logistics in Japan and across Asia, and the Overseas Planning & International Trade Administration Group, which is charged with capitalizing on export controls and free trade agreements (FTAs)*2 in line with the Foreign Exchange Law and implements measures to reduce import–export costs.

- 3PL firms provide partial or complete outsourced logistics services.

- FTAs are agreements between countries/territories or groups thereof to eliminate import taxes, import quotas and other trade barriers for a set period of time, thereby encouraging trade.

Reducing Environmental Impact and Addressing the 2024 Issue

Japan’s logistics industry continues to contend with a shortage of drivers, owing to the growing popularity of e-commerce and restrictions on drivers’ working hours resulting from a legal amendment dubbed the “2024 issue.” Lowering greenhouse gas emissions is another urgent challenge. Against this backdrop, DIC continues to promote modal shift*1 in the transport of its products in Japan with the aim of curtailing drivers’ working hours and reducing environmental impact. DIC is also proceeding with the implementation of initiatives in line with the logistics policy package*2 established by the Ministry of Economy, Trade and Industry and the Ministry of Agriculture, Forestry and Fisheries.

DIC Group companies overseas continue taking steps to reduce the environmental impact of their logistics activities, including reviewing logistics bases to shorten transport distances and curb CO2 emissions.

- Modal shift is a shift in the mode of cargo transport from trucks and other vehicles to rail and ships, which have a smaller environmental impact.

- This logistics policy package, formulated by the Japanese government and announced in June 2023, sets forth concrete measures for reviewing commercial practices and improving logistics efficiency, as well as for modifying the conduct of shippers and consumers.

Safety in Logistics

Safety Management Initiatives

The firms to which the DIC Group outsources logistics use containers that comply with the Fire Service Act and other transportation laws, as well as with related United Nations(UN) standards. The Group supplies information needed to display labels complying with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) as well as provides safety data sheets (SDSs) and other documentation to ensure safe shipping whether in Japan or overseas. The Group also shares information on the transport of products requiring UN numbers (i.e., hazardous substances) by sea and air to facilitate the sharing of information, including alerts.

In Japan, the Logistics Department cooperates with logistics partners, meeting regularly to discuss measures for improving the safety of both loading and transport work. In particular, logistics quality issues that inconvenience customers such as leaks, undelivered cargo and delivery errors are designated as incidents for priority attention and decisive steps are taken to improve performance, notably by confirming targets, incident number, causes and preventative measures. Other ongoing efforts include initiatives aimed at preventing the recurrence of past accidents and regular logistics safety campaigns. Members of DIC Group site health and safety committees also participate in each other’s meetings, as well as meetings of logistics partners’ site general managers, with the objective of ensuring safe site operations. The Logistics Department also inspects the offices of logistics partners located on-site at its main domestic production facilities. In fiscal year 2023, issues were pointed out at three of these offices, after which improvements were confirmed. In addition, to ensure effective responses to emergencies during transport, DIC requires transport personnel to carry Yellow Cards,* making it possible to prevent the spread of damage in the event of an accident.

- Yellow Cards are part of activities recommended by the Japan Chemical Industry Association(JCIA). These cards contain information about the correct actions to take if an accident occurs. They provide contact details to ensure proper responses by transportation companies, firefighters and police officers if an accident occurs during the transport of chemical substances. Transport personnel must carry these cards at all times.

Regular meeting with a logistics partner

Yellow Cards carried by transport personnel

TOPIC

Switching to Easy-To-Understand Labeling

Work styles for individuals employed in the logistics industry are becoming increasingly diverse, with the number of part-timers also on the rise. Because the labels it currently uses in Japan to indicate correct upright position of cardboard boxes for transport feature industry technical jargon, the DIC Group is promoting a shift to easy-to-understand labels that clearly say “This way up” so that all logistics workers can readily grasp the meaning and act accordingly.

VOICE

We will continue evolving to achieve sustainable logistics.

As a comprehensive chemicals manufacturer, our mission is to ensure a stable supply of high-quality products worldwide. Logistics plays a critical role in this, but the industry has faced numerous challenges in recent years, including rising geopolitical risks, supply chain complexities, labor shortages and the need to reduce environmental impact. In particular, lowering CO2 emissions and improving working conditions in the logistics industry are key themes for achieving sustainable logistics.

To address these challenges, we are reinforcing cooperation with 3PL firms and leveraging digital technologies to enhance efficiency. Additionally, we are optimizing transport methods and promoting modal shift. In terms of safety, we are committed to rigorous management of risks in the transport of chemicals, as well as to strict compliance with relevant laws and regulations and working with logistics partners to improve transport quality.

Going forward, we will continue to embrace the challenge of building a sustainable logistics framework while also fulfilling our responsibilities to society as a corporate citizen. Our goal is to further evolve to achieve safer, more efficient and more environment-friendly global logistics.

Masahiro Kawasaki

(Right)General Manager, Logistics Department, Sun Chemical Corporation

Glenn Sokoloski