Occupational Safety and Health/Disaster Prevention

Goals and Achievements of Major Initiatives

Ensure occupational safety and health.

| Scope of target | Global |

|---|---|

| Goals for fiscal year 2022 | Reduce TRIR. Targets: DIC Group in Japan: 2.40 PRC: 1.00 Asia–Pacific region: 1.10 Americas and Europe: 8.00 (Global DIC Group: 4.36) |

| Achievements in fiscal year 2022 | DIC Group in Japan: 2.23 PRC: 0.79 Asia–Pacific region: 1.21 Americas and Europe: 6.33 (Global DIC Group: 4.00) |

| Evaluation | ★★★ |

| Goals for fiscal year 2023 | Reduce TRIR. Targets: DIC Group in Japan: 2.10 PRC: 1.00 Asia–Pacific region: 1.00 Americas and Europe: 8.00 (Global DIC Group: 4.65) |

Prevent disasters.

| Scope of target | Global |

|---|---|

| Goals for fiscal year 2022 |

|

| Achievements in fiscal year 2022 |

|

| Evaluation | ★★★ |

| Goals for fiscal year 2023 |

|

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Policies

Basic Approach

Viewing the prioritization of operational safety as a core management tenet, the DIC Group works tirelessly to prevent occupational accidents and disasters, as well as to bolster occupational health and safety levels.

The DIC Group recognizes operational safety both as fundamental to its businesses and the core component of Responsible Care. The Group thus promotes active occupational safety and health, security and disaster prevention measures to foster a “Safety First” philosophy Groupwide and on the part of every employee. Because its operations span diverse fields, the Group has numerous processes that use hazardous and toxic materials, as well as rotating devices, not all of which involve chemical reactions. Any accident using such materials or devices has the potential to significantly impact society in general and damage the health of Group and/or partner company employees and local residents. With the aim of preventing such accidents, the Group encourages Group companies to earn the International Organization for Standardization’s Occupational Safety and Health Management System (OSHMS) certification and, based on the results of stringent risk assessments, prioritizes reducing risks in the workplace by promoting adherence to Principles of Safe Conduct and training highly perceptive safety personnel. The Group also strives to enhance safety through efforts to reinforce its safety infrastructure and create a safety-oriented corporate culture.

Framework for Promotion

Under the supervision of the Sustainability Committee chair (DIC’s president and CEO), the Safety and Environment groups of DIC Group companies, plants and R&D facilities, and the Responsible Care Department collaborate to promote a variety of initiatives. In Japan, the Responsible Care Department meets regularly with site ESH officers to confirm the status of priority issues and the achievement of targets, as well as to manage the progress of related efforts. Elsewhere, the Responsible Care Department and individual regional headquarters work together to set regional targets, while site ESH officers conduct site risk assessments, analyze accidents and promote remedial measures to ensure the continuous improvement of occupational safety and health overseas.

TOPICS

Management Spearheads the Promotion of Safety Initiatives

Believing that it is important for management to take the lead in promoting the idea of “Safety First,” managing executive officer Naoyoshi Furuta, General Manager of the Production Management Unit, prepares a monthly memo for distribution to all sites, including those of Group companies, as part of a campaign dubbed “Learning from the Past and Implementing Practical Solutions.” Each memo presents a recent actual occupational accident or introduces occupational accidents that are likely to occur at specific times—e.g., heatstroke in summer or static electricity–related accidents in winter—with an analysis of causes and suggestions for countermeasures. This memo is also read out once a month at a morning assembly at each site to promote awareness among employees and encourage a common understanding.

Principal Initiatives in Fiscal Year 2022

1. Global DIC Group

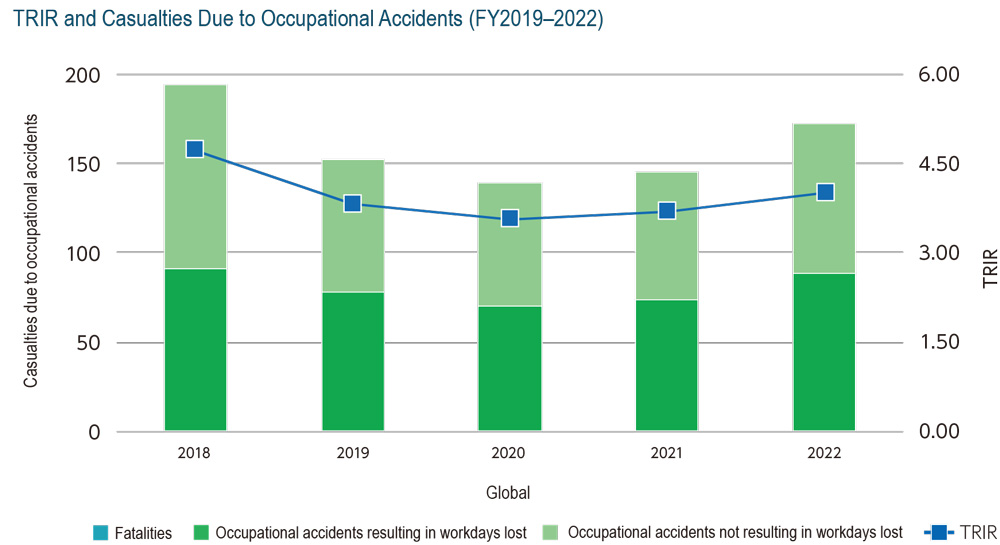

The DIC Group promotes a variety of initiatives around the world with the aim of eliminating occupational accidents. Of particular note, the Group sets targets for total recordable incident rate (TRIR)—calculated as the number of casualties (i.e., fatalities and injuries) due to occupational accidents, both those resulting in workdays lost and those not resulting in workdays lost, per million work hours—for the DIC Group in Japan, the PRC, the Asia–Pacific region, and the Americas and Europe. In all regions, the number of employees used to calculate TRIR is the number of direct regular, temporary and part-time employees. Employees of on-site and outside contractors are not included.

In fiscal year 2022, the TRIR for the global DIC Group was 4.00, below its 4.36 target. None of the occupational accidents at global Group sites resulted in fatalities. A total of 89 injuries resulting in workdays lost were reported, while injuries not resulting in workdays lost numbered 83. Looking ahead, the Group will continue working to reduce occupational accidents by promoting the sharing of information on and analyzing the causes of accidents and disasters, conducting risk assessments, promoting adherence to Principles of Safe Conduct and providing occupational safety and health–related education and training. Some of these efforts are described in this report.

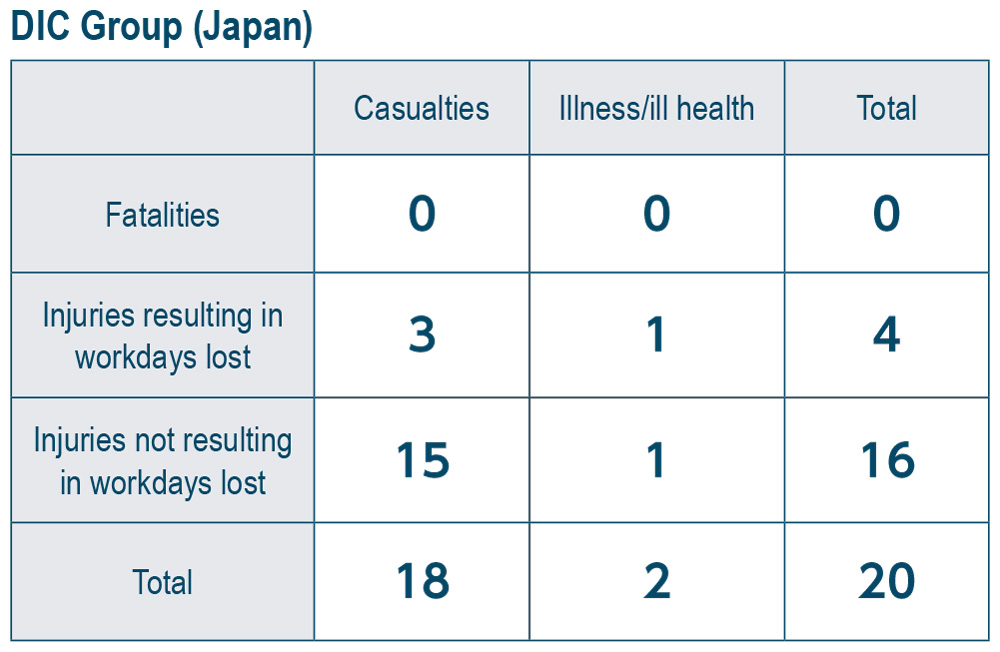

2. DIC Group in Japan

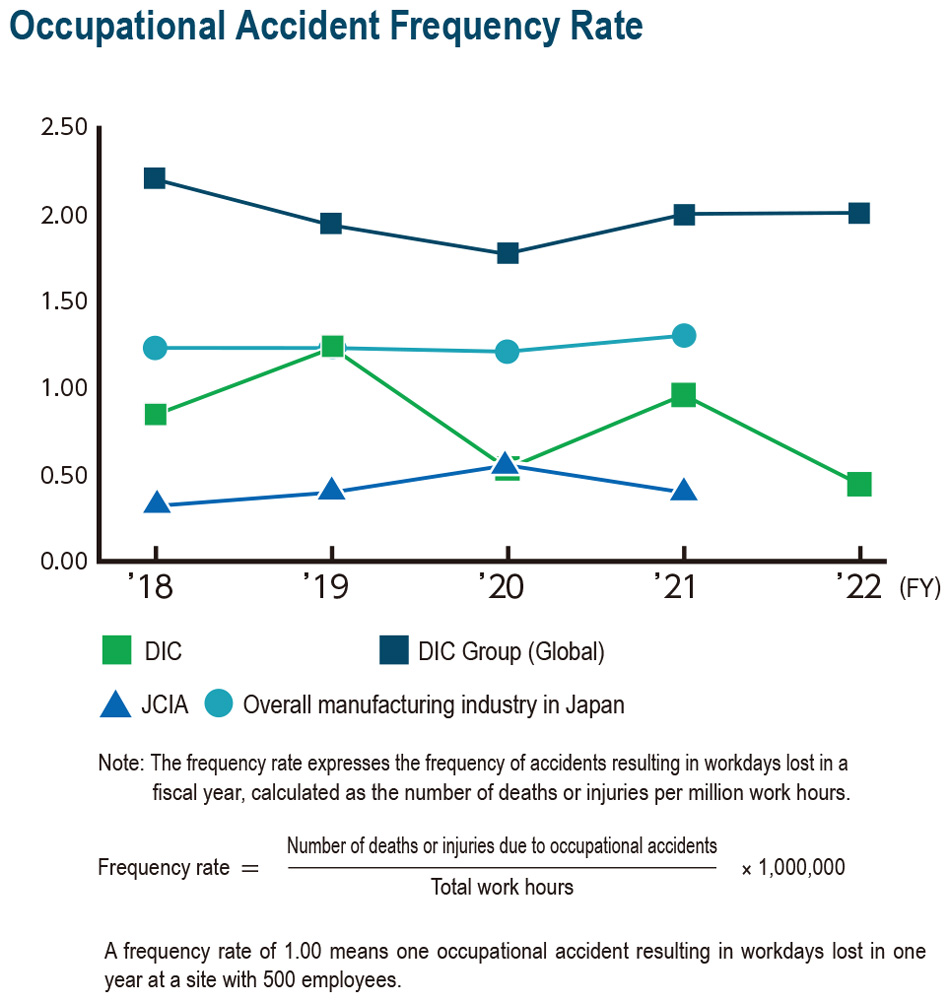

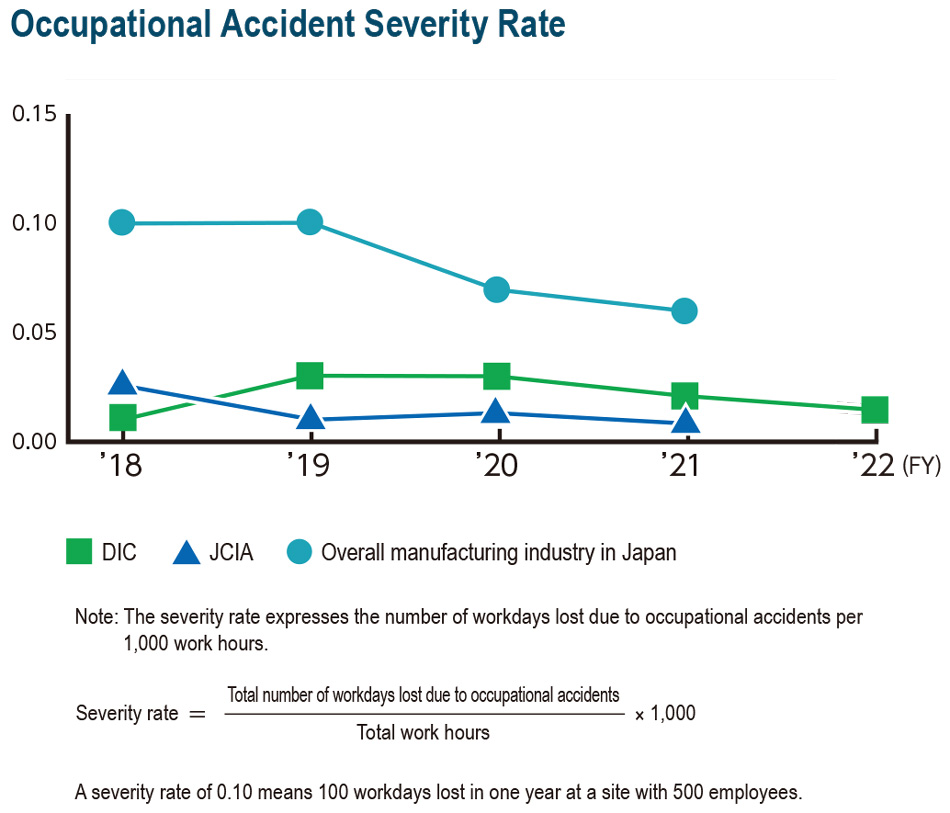

In fiscal year 2022, the DIC Group in Japan achieved a TRIR of 2.23, better than its target of 2.40 and a significant improvement from 3.60 in the previous fiscal year. No occupational accidents resulting in fatalities were reported. There were four occupational accidents resulting in workdays lost and 16 occupational accidents not resulting in workdays lost. These numbers are broken down in the table below. At 0.45, the frequency rate of occupational accidents was lower than the average for the manufacturing industry in Japan and for member companies of the Japan Chemical Industry Association (JCIA). The severity rate was 0.015, which is also lower than the average for manufacturers in Japan and in line with that of JCIA member companies.

3. DIC Group in Other Countries and Territories

The TRIR for the DIC Group in the PRC was 0.79, while that for the Americas and Europe (the Sun Chemical Group) was 6.33, both in line with regional targets. The DIC Group in the Asia–Pacific region reported a TRIR of 1.21, falling short of the regional target. No occupational accidents resulting in fatalities were reported. There were 81 injuries due to occupational accidents resulting in workdays lost and 65 injuries due to occupational accidents not resulting in workdays lost.

TOPICS

DIC Fine Chemicals’ Dahej Plant Achieves 4,500 Consecutive Days of Safe Operation

On March 24, 2022, DIC Fine Chemicals Private Limited’s plant in Dahej celebrated 4,500 consecutive days of safe operation, that is, with no injuries resulting in workdays lost. “Safety is the cornerstone of the DIC Group,” said the company’s safety and environmental officer regarding this accomplishment. “The Dahej Plant has established standards for the implementation of important safety procedures We see the well-being of our employees as our utmost priority. There are no words to express my appreciation to the team for their tireless efforts to keep everyone safe.” The Dahej Plant was opened in 2010 as a production facility for sheetfed inks.

Infrastructure for Preventing Occupational Accidents

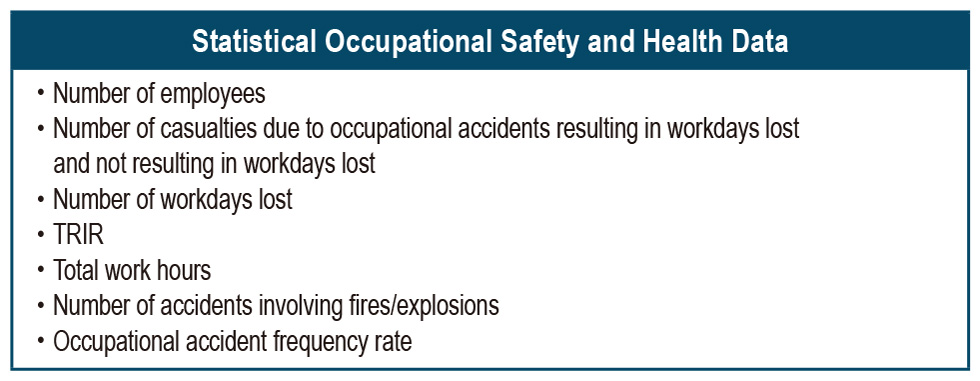

1. Monthly Occupational Safety and Health Data

The DIC Group conducts its diverse businesses in accordance with a wide range of national and regional legal systems, working conditions and practices. However, to raise the level of occupational safety and health of the entire Group, it is crucial to establish common standards and benchmarks and to align regional initiatives. The DIC Group promotes the sharing of information related to occupational safety and health across the global Group by aggregating regional statistical data on a monthly basis. Specifically, local data is gathered by DIC (China) for the PRC, DIC Asia Pacific for the Asia–Pacific region, and Sun Chemical for the Americas and Europe, which is then collated and analyzed by the Responsible Care Department. This makes it possible to objectively compare and evaluate the operational safety of individual Group companies, establish precise targets for individual countries and regions, and formulate programs to achieve improvements. In fiscal year 2019, the Group introduced the DIC ESH Data Collection System (DECS), a cloud-based system for recording data.

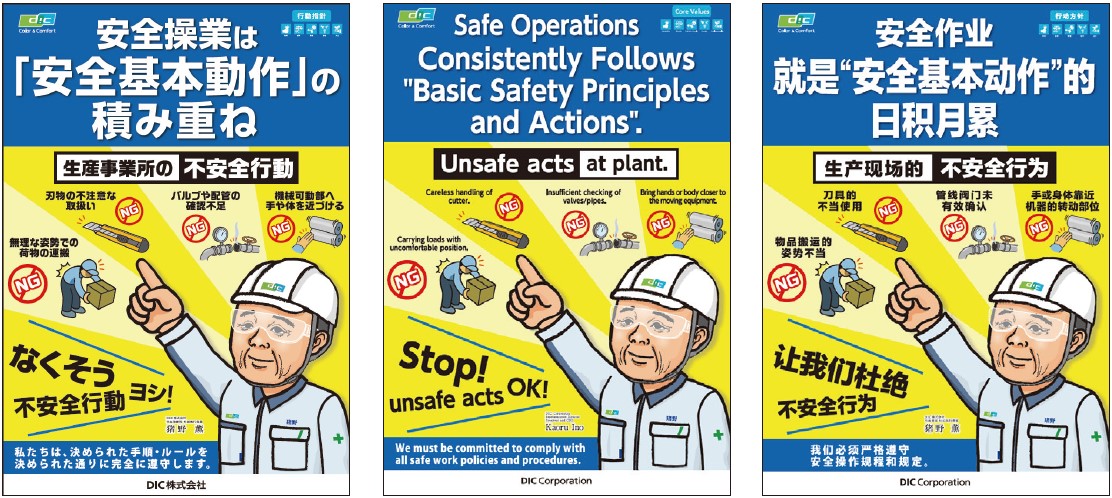

2. Principles of Safe Conduct

Using resources such as case studies of accidents and disasters in the past, DIC has created rules and codes of conduct to ensure operational safety, which it has compiled as a guidebook titled Principles of Safe Conduct, the fifth edition of which was published in fiscal year 2019. English- and Chinese-language versions have also been prepared for use by DIC Group companies in the Asia–Pacific region and Greater China.

3. Conducting Risk Assessments

By understanding potential risks in production processes, facilities and devices, and the hazards of chemical substances, the DIC Group systematically prepares initiatives to prevent accidents and occupational injuries. In Japan, the Group has formulated guidelines for conducting risk assessments when deploying new or modified equipment or changing production processes to identify and evaluate the impact on employees and the community from design through to operation. With the aim of reducing risks associated with chemical substances, since fiscal year 2015 the Group has promoted the creation of a framework to facilitate the methodical implementation of risk assessments in line with the policy set by the Ministry of Health, Labour and Welfare. Of particular note, in fiscal year 2016 the Group formulated proprietary assessment guidelines, including for assessment procedures, and is evaluating hazards associated with and the toxicity of chemicals set forth in Japan’s Poisonous and Deleterious Substances Control Act, as well as considering measures to lower related risks, including revising handling methods and upgrading facilities.

4. Analyzing Accidents and Disasters and Providing Information in a Timely Manner

In the event of an accident or disaster at a DIC Group site, the site in question and the corporate headquarters’ department in charge of safety work together to analyze the causes thereof and implement appropriate countermeasures. The department in charge of safety and site Safety and Environment groups hold regular meetings to dig deeper into the causes of accidents and debate the effectiveness of countermeasures. Findings are deployed horizontally to Group sites and companies with the aim of preventing recurrence, as well as shared with DIC Group companies worldwide. DIC has compiled such information to create Accident Case Studies and Occupational Accident Case Study databases, which are used in safety education for Group companies in Japan.

5. Promoting E-Learning–Based Safety and ESH Training at Production Facilities

To enhance its capabilities in the area of occupational safety and health, and in disaster prevention, the DIC Group recognizes the importance of ensuring that all of its employees gain a broad understanding of chemical substances, production processes, and pertinent laws and regulations. In fiscal year 2016, the Group introduced an e-learning program in Japan. Initially structured around laws and regulations pertinent to the operational safety of production facilities, including Japan’s Fire Service Act, Air Pollution Control Law and High Pressure Gas Safety Act, the e-learning program’s focus was later expanded to include static electricity as a non-regulatory component, with the appropriateness of the program’s training materials verified from the perspective of Responsible Care Department specialists, site ESH officers and production departments. Employees are able to take up to 16 classes. In fiscal year 2022, the Group introduced an online occupational safety and health education service from Tokyo-based LaKeel, Inc., that centers on the distribution of short films on the subject.

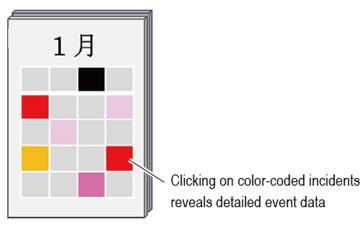

6. Accident and Disaster Calendar

In fiscal year 2022, the DIC Group compiled information on past accidents and disasters into case studies in the form of a monthly calendar that is visible to all employees on the first page of the DIC Group portal site. Information posted includes date of occurrence, site, type of event (i.e., heatstroke, chemical injury or other) and impact (i.e., resulted in workdays lost or did not result in workdays lost). This allowed users to identify incidents of concern to them and view detailed data summarizing conditions surrounding occurrence and the effectiveness of countermeasures. Displaying data for all accidents and disasters on a monthly basis also sheds light on trends. Employees looking at the calendar on any given day are able to learn about an accident or disaster that occurred on that day in the past, bolstering awareness of safety and disaster prevention across the Group.

TOPICS

DIC Graphics’ Gunma and Tokyo Plants Conduct Fall Prevention Training

DIC Graphics’ Gunma Plant, in collaboration with several affiliated and associated companies, launched the Fall Prevention Project, which held four sessions in fiscal year 2022. The first session, a fall prevention seminar, featured a physiotherapist who introduced exercises to relieve lower back pain that can be done while lying down or sitting. This was followed by a seminar focusing on risk assessment self-checks (physical fitness checks) and gauging awareness levels. Individuals displaying a significant gap between physical fitness and awareness were judged as being at particular risk of falls and were urged to exercise caution. Third was a presentation by a nutritionist on dietary changes that can help prevent locomotive syndrome, a condition involving decreased mobility due to disorders of the musculoskeletal system. For the fourth session, members of the Hitachi Transport System Track and Field Club were invited to give a seminar about functional training,* which centered on correct walking posture, how to maintain one’s center of gravity and awareness, and how to use one’s shoulder blades and hamstrings, among others, as well as the importance of all of these factors. Also on offer was a program developed by Hitachi Transport System, Ltd., directed at the prevention of falls caused by tripping and stumbling.

The Tokyo Plant also conducted fall prevention training. Here, too, instructors were members of the Hitachi Transport System Track and Field Club, a renowned corporate club that is active in competitions across Japan, including the New Year Ekiden, one of Japan’s preeminent longdistance running multistage relay races. The Club’s manager, Kenji Beppu, taught participants how to walk correctly, including how to improve their posture, position their shoulders and raise their legs. Demonstrations were given by Kenta Ueda, a current member of the Club, who earned praise for his excellent posture and lithe movements. Going forward, the DIC Group will continue to plan programs like this that help improve employee health.

Hands-On Safety Training

The DIC Group’s full-fledged hands-on safety training program began in 2012 with the introduction of a mobile initiative using equipment transported from site to site using a 10-tonne truck. Since fiscal year 2013, the Group has installed permanent training equipment at six sites in Japan, as well as expanded deployment globally, including in the PRC and the Asia–Pacific region. This program has helped to almost halve the occupational accident frequency rate at Group sites in Japan. By simulating common production floor accidents—including those involving entanglement in rotating devices, falls from high places and incised wounds caused by cutting equipment—based on actual previous examples, the Group’s hands-on safety training seeks to reduce employees’ willingness to take risks and foster their ability to recognize danger. In doing so, the Group seeks to transform the mindset of employees by encouraging them to think and act on their own to protect themselves and each other from latent risks.

In fiscal years 2020 and 2021, COVID-19 forced the DIC Group to cancel hands-on safety training. However, the Group used the period to review and revise equipment and procedures to facilitate implementation even during the pandemic. Ordinary in-person training resumed in fiscal year 2022.

1. DIC Group Companies in Japan

In fiscal year 2014, the DIC Group opened the Saitama Hands-On Safety Center, a training facility that fosters skilled safety personnel by incorporating hands-on safety training in the new employee and rank-specific training programs. In the same year, DIC and DIC Graphics began including hands-on safety training and Kiken Yochi Training (KYT) (“hazard prediction training”) in the training curricula for new employees. The Chiba, Sakai, Hokuriku, Tokyo, Kashima and other plants have also established their own hands-on safety training equipment to further ingrain a safety-conscious corporate culture. In fiscal year 2015, the Group downsized six types of hands-on training equipment for lending to individual sites as part of a mobile training initiative. The Responsible Care Department trains employees at individual sites to serve as hands-on training instructors and has established an instructor licensing system.

2. DIC Group Companies in Other Countries and Territories

DIC Group companies in other countries and territories are also deploying hands-on safety training. In Greater China, hands-on safety training equipment has been installed at Nantong DIC Color Co., Ltd., DIC Graphics (Guangzhou) Ltd. and Changzhou Huari New Materials Co., Ltd., in the PRC and DIC Graphics Chia Lung Corp. in Taiwan. In the Asia–Pacific region, equipment has been installed at DIC Compounds (Malaysia) Sdn. Bhd., PT DIC ASTRA Chemicals in Indonesia, Thailand’s Siam Chemical Industry Co., Ltd., and DIC India Limited’s Noida Plant. These companies provide hands-on safety training for employees across their respective regions, as well as training for instructors.

TOPIC

DIC Asia Pacific Holds Safety Day for Regional DIC Group Companies

The United Nations’ International Labour Organization (ILO)’s World Day for Safety and Health at Work, part of its campaign to promote occupational safety and health, is celebrated annually on April 28. In line with this initiative, DIC Asia Pacific held its first annual Safety Day on May 6, 2022. The theme of Safety Day in fiscal year 2022 was “CARE for Safety,” with the first word being an acronym drawn from three key ideas:

- Communication between colleagues and learning from each other

- Awareness of the environmental and safety issues

- Responsibility for actions and/or in actions

DIC Asia Pacific has set a target for its ESH program, encapsulated in the phrase “DIC ESH—Goal Zero,” which local Group employees are united in working to achieve. Safety Day 2022 activities at Group companies across the Asia–Pacific region centered on a Safety Day town hall meeting, which included video messages from the managing director who serves as general manager of the Production Management Unit and the managing director of DIC Asia Pacific, and Safety Day events and activities, which included games, quizzes, competitions, an awards ceremony and performances devised by the individual company.

VOICE

I participated in a program to foster employee hands-on training instructors.

Having previously taken part in hands-on training at the Kashima Plant, this year I participated in a program to foster employee hands-on training instructors that qualified me as a second-class instructor. The content of the program ranged from creating guidelines for assigned hands-on training exercises and practice in conducting training sessions. The latter in particular was a first for me.

I found the whole experience extremely valuable in that it further heightened my awareness of safety—the ultimate goal of hands-on training—and gave me an appreciation of the difficulty of the approach used in this training, which is to give participants hints that encourage them to take what they learn back to their workplaces to discuss with their colleagues and come up with answers themselves. I look forward to polishing my ability to conduct hands-on training in a manner that sharpens the ability of participants to grasp the specific objectives of individual exercises.

Safety and Environment Group, Kashima Plant, DIC Corporation Tetsuya Ishikawa

Efforts to Foster a Safety-Conscious Corporate Culture

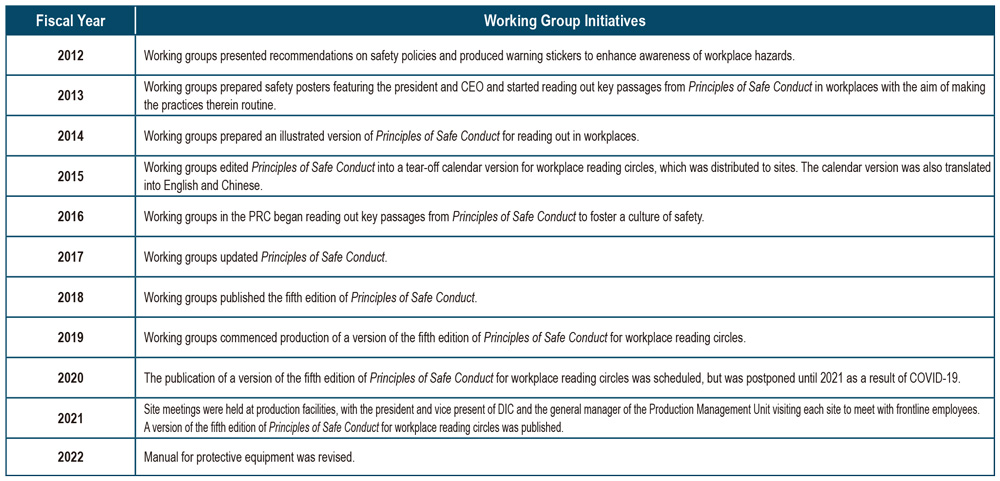

1. Safe Corporate Climate Cultivation Working Groups

In line with its “Safety First” philosophy, the DIC Group works to foster a safety-conscious corporate culture. In fiscal year 2011, personnel in charge of safety at plants belonging to DIC and DIC Graphics created Safe Corporate Climate Cultivation working groups, which regularly meet to discuss and exchange proposals regarding safety policies and measures.

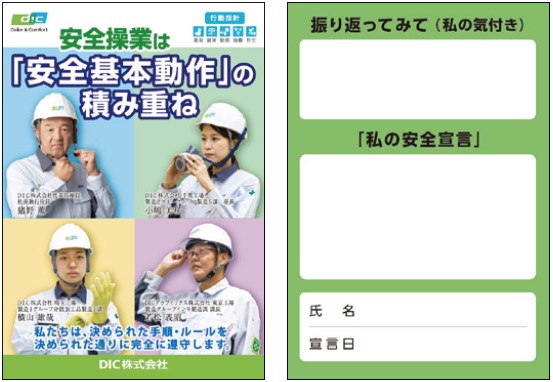

2. DIC Safety Pledge Day

DIC has declared September 6 “DIC Safety Pledge Day,” an annual occasion for all of the DIC Group employees to pledge their commitment to ensuring safe operations and not repeating past serious accidents and disasters. On this day, each employee makes their pledge by writing a personal declaration on a special card.

2022 safety declaration card

TOPICS

DIC Participates in National Industrial Safety and Health Convention

The general manager of DIC’s Responsible Care Department took the stage as a panelist at National Industrial Safety and Health Convention 2022, which took place in Fukuoka, Japan, in November. The event, which focused on legal and regulatory changes in the realm of occupational health and safety made in 2022, featured panelists from government, academia and industry, namely, the Ministry of Health, Labour and Welfare; the University of Occupational and Environmental Health, Japan; the Japan Industrial Safety & Health Association; and DIC, who discussed challenges faced by companies in responding to legal revisions. Attendance at the event was high, with many attracted by the fact that it shone a spotlight on diverse related corporate initiatives. Participants could also take part from satellite facilities in other parts of the country. As a manufacturer of fine chemicals that handles a broad range of chemical substances, DIC presented past efforts to effectively manage chemical substances and comply with amended laws.

DIC Graphics’ Kyushu Production Group Wins Special Prize in the JCIA Safety Awards

The Kyushu Production Group of DIC Graphics’ Tokyo Plant won a special prize for safety excellence in the 44th JCIA Safety Awards. The JCIA gave high marks to the Kyushu Production Group’s dedicated efforts to ensure occupational safety, as a result of which at the time of the award it had achieved 50 years and nine months of accident-free operations and expressed its hope that the unit would maintain this record going forward.

Accident-Free Operations

Start of operations: December 1958

Accident-free operations: Hours: 3,362,000 hours

Years: 50 years and nine months

Comment by Kyushu Production Group Representative

We are delighted to have received this award for safety excellence from the JCIA. This award is evidence of the

determined efforts of everyone who has worked in the Kyushu Production Group to ensure occupational safety.

In addition to expressing our gratitude to those who came before us for their dedication, which has made it

possible for us to achieve 50-plus years of accident-free operations, this award provides an opportunity for all of

us to reaffirm our understanding of the importance of occupational safety and our commitment to “Safety First”

in all we do to maintain accident-free operations going forward.

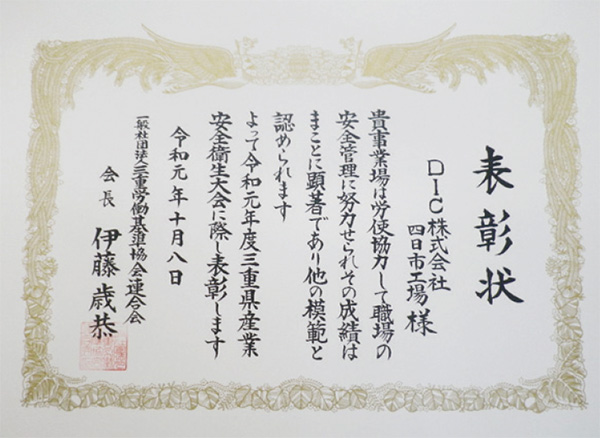

DIC’s Yokkaichi Plant Receives Award as Excellent Safety Site from the Mie Federation of Labor Standards Associations

In October 2019, DIC’s Yokkaichi Plant, located in Yokkaichi, Mie Prefecture, received an award as a site with an excellent occupational safety performance from the Mie Federation of Labor Standards Associations. High marks were given to the plant’s more than 15 consecutive years of accident- and disaster-free operations (5,562 days as of September 30, 2019) and its extensive record of occupational safety and health initiatives, which include conducting occupational safety and health patrols and implementing safety education and assessing risks associated with facilities and chemical substances based on an annual educational plan. Going forward, the Yokkaichi Plant will continue to promote purposeful occupational safety and health initiatives with the aim of serving as a model for the DIC Group, as well as the chemicals industry as a whole.

Disaster Prevention

Policies

Basic Approach

In addition to establishing a safety management system to prevent major accidents, the DIC Group implements prompt, effective countermeasures in the event an accident occurs.

Any fire, explosion or leak of a hazardous substance from a chemicals plant could have a tremendous impact on local residents and the rest of the community and damage the health of employees, including those of our partner companies. As well as operating and maintaining its facilities in line with pertinent laws and regulations, the DIC Group regularly conducts emergency drills and has earthquake and other response measures in place in the event a major accident occurs.

Framework for Promotion

Under the supervision of the Sustainability Committee chair (DIC’s president and CEO), the Safety and Environment groups of DIC Group companies, plants and R&D facilities collaborate with the Responsible Care Department to promote a variety of initiatives. The Responsible Care Department holds meetings regularly with site Safety and Environment groups to exchange information, as well as to confirm the status of priority issues and the achievement of targets, and to manage the progress of related efforts.

Principal Initiatives in Fiscal Year 2022

1. Process Safety Accide

The International Council of Chemical Associations (ICCA) formulated criteria for chemical process safety accidents that require reporting in fiscal year 2017. Since fiscal year 2018, the DIC Group has reported process safety accidents for the Group in Japan in line with these standards. In fiscal year 2022, the Group reported three process safety accidents. The process safety accident frequency rate—the number of such accidents per 200,000 work hours—was 0.055. Beginning in fiscal year 2023, the Group will set targets based on results for the immediately preceding three years and implement measures to ensure their achievement.

2. Risk Assessments at Chemicals Production Facilities

The DIC Group’s production facilities have an array of application-specific equipment, ranging from units where chemical reactions are conducted to machine presses and other processing equipment. In 2013, the Group formulated the DIC Process Risk Management (PRM) Guidelines, which it uses to conduct systematic risk assessments at individual sites. These guidelines outline timetables and implementation frameworks for assessing risks associated with chemical substances handled, production processes, production formulas, machinery and work practices with the aim of comprehensively identifying and steadily reducing risks associated with R&D processes. Since fiscal year 2020, the Group has also used hazard and operability (HAZOP) studies developed to assess the risk of accidents such as leaks, fires or explosions at chemicals production facilities. Specifically, the Group deploys HAZOP studies to assess risks at facilities that have chemical reaction equipment, including the Yokkaichi, Chiba, Kashima and Hokuriku plants.

3. Third-Party Assessments by the Safety Competency Enhancement Center

In 2013, DIC introduced an assessment system as a means of objectively evaluating and enhancing its safety competency.* This system was developed by the Japan Society for Safety Engineering (JSSE), together with chemicals industry engineers, as a common industry benchmark and is currently used by all companies in Japan that are members of the Safety Competency Enhancement Center. Assessments were conducted at all DIC Plants, beginning with the Kashima Plant in fiscal year 2014, which was followed by the Yokkaichi and the Saitama plants in fiscal year 2017, the Komaki Plant in fiscal year 2018, the Chiba and Tatebayashi plants in fiscal year 2019 and the Hokuriku Plant in fiscal year 2020. These facilities have used assessment results to promote further improvements. The Yokkaichi Plant, for example, subsequently launched a HAZOP study–based risk assessment.

In December 2019, the Safety Competency Enhancement Center provided DIC’s president and CEO with an overall report on the results of assessments conducted at six production facilities, facilitating the sharing of understanding regarding safety and disaster-related issues across the management team.

- The assessment system encompasses questions about safety infrastructure (technical considerations) and culture of safety (operation and management of organizational culture).

TOPICS

DIC Kitanihon Polymer’s Hokkaido Plant Receives Award from Tomakomai Fire Marshals’ Association

In November 2021, DIC Kitanihon Polymer Co., Ltd.’s Hokkaido Plant received an award as an excellent site from the Tomakomai Fire Marshals’ Association at the association’s annual meeting for 2021. Article 27 (Awards) of the bylaws of the Tomakomai Fire Marshals’ Association defines an “excellent site” as one with fire prevention practices that serve as a model for other business establishments that has worked toward the same target for more than five consecutive years under the guidance of a fire marshal* and achieved outstanding results. Awards are approved by the association’s Board of Directors. DIC Kitanihon Polymer’s Hokkaido Plant was judged to have fulfilled these criteria and selected to receive a fiscal year 2021 award.

- Representative: Keizo Yukishige, General Manager, Hokkaido Plant Fire marshal: Satoshi Tsuchida (took over from predecessor on February 22, 2016)

Encouraged by the award earned by DIC Kitanhihon Polymer’s Hokkaido Plant, DIC Group production facilities will step up collective efforts to further improve safety management.

DIC Graphics’ Gunma Plant Receives Award as Excellent Hazardous Materials–Related Site

In June 2016, DIC Graphics’ Gunma Plant received an award as an Excellent Hazardous Materials–Related Site from the Japan Association for Safety of Hazardous Materials. A total of 49 facilities across Japan were recognized, with DIC Graphics’ plant being the only one in Gunma Prefecture. The award is one of several given out at a national conference devoted to hazardous materials safety every June. To prevent the spread of COVID-19, however, the June 2020 conference was canceled. Instead, the award was presented by Chief Fukuchi of the Gunma Prefectural Tatebayashi Fire Department. This award underscores the solid evaluation given the safety protocols of the Gunma Plant, which handles a large volume of hazardous materials, encouraging employees to continue working as one to further enhance the site’s ability to handle hazardous materials safely.

Initiatives to Prevent Electrostatic Accidents

Recognizing that static electricity is a key cause of fires for chemical companies, the DIC Group has organized static electricity safety sessions guided by an expert in this field at sites in Japan since fiscal year 2017. In fiscal year 2019, the Group expanded this initiative to include the overseas DIC Group. In March 2019, sessions were held at multiple sites in Indonesia, led by the same instructor that has a solid track record of leading sessions in Japan. Overseas sessions in fiscal year 2019 were divided into three parts: An inspection of site electrostatic accident prevention measures, a lecture on static electricity and confirmation of areas identified during the inspection as requiring remedial measures. In addition to an academic component, these sessions included a demonstration of static electricity, which enabled participants to experience the relationship between the strength of an electric spark that can be felt by humans and the minimum energy required for ignition. The demonstration also included a targeted explanation about grounding and specific grounding procedures that are effective in preventing electrostatic accidents. The combination of academic study and on-site demonstration focused on measures to prevent electric sparks enabled participants to gain valuable knowledge about static electricity beyond what is possible with video-based training.

4. Emergency Response Drills

In addition to daily security patrols and periodic equipment checks, the DIC Group conducts regular emergency response drills based on business continuity plans (BCPs), at production sites in Japan and overseas.

TOPICS

DIC’s Sakai Plant Conducts Comprehensive Disaster Drill Using Nankai Trough Megathrust Earthquake Scenario

In September 2019, DIC’s Sakai Plant hosted a comprehensive disaster drill for the Sakai–Senboku coast*. Approximately 220 individuals participated, including employees of companies belonging to the Sakai–Senboku Coast Special Disaster Protection Area Council and the Osaka prefectural government. The scenario developed for the drill was that a Nankai Trough megathrust earthquake with a seismic intensity of close to 5 has occurred, triggering a massive tsunami and damaging plant tanks, causing solvents to leak from tanks, penetrate the oil barrier and catch fire. Drill exercises were diverse and included measures to be taken immediately after a major tsunami advisory, confirming the safety of and suspending operations of equipment, guiding employees to safety, reporting circumstances to the fire department, rescuing injured individuals and extinguishing fires. This allowed participants to demonstrate skills acquired through everyday practice.

- The drill was organized by the Sakai–Senboku Coast Special Disaster Protection Area Council in line with the Act on the Prevention of Disaster in Petroleum Industrial Complexes and Other Petroleum Facilities.

Environmental Protection

Policies

Basic Approach

The DIC Group seeks to contribute to protection of the global environment by improving its own environmental performance, as well as by complying with pertinent laws and regulations.

Environmental protection is among the most important of corporate sustainability activities. The DIC Group’s efforts focus on a number of areas, including addressing climate change, preventing environmental pollution, managing industrial waste (responding to a circular economy), managing water resources and biodiversity. As a manufacturer of fine chemicals with operations around the world, the Group promotes environmental protection with a global perspective.

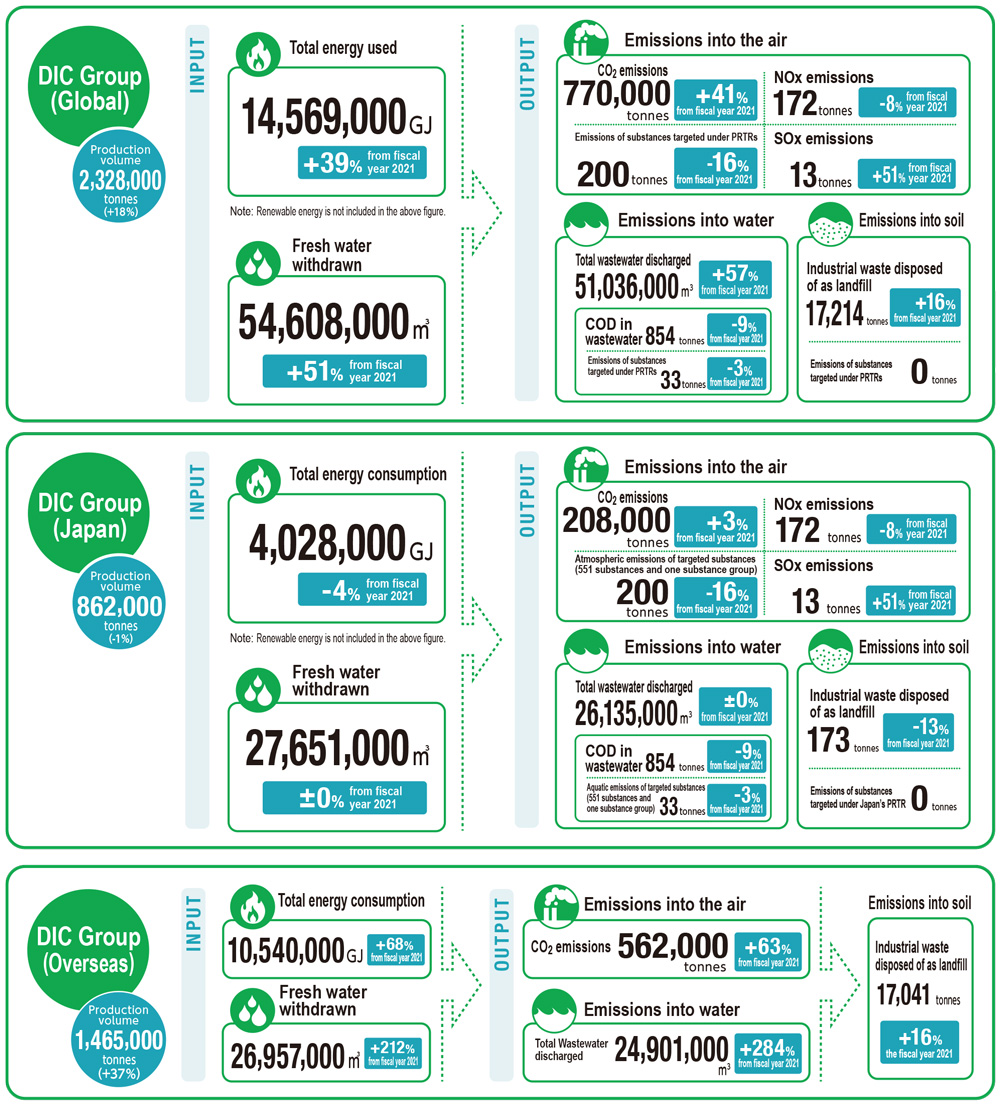

Groupwide Environmental Performance

The DIC Group quantifies the environmental inputs (consumption of energy and other resources) and outputs (emissions into the environment) of its operating activities, and uses its findings to formulate far-reaching and efficient strategies for reducing its environmental footprint. The chart below is a comprehensive illustration of the environmental impact of the Group’s operating activities in Japan and in other countries and territories. The chart below shows environmental impact for two key items (total energy consumption and total water consumption) and three output items (emissions into the air, emissions into water and emissions into soil) in two categories: CO₂ emissions, total wastewater discharged and industrial waste disposed of as landfill. (Data for the DIC Group in Japan also includes emissions of targeted substances into the air, water and soil of NOx and SOx, as well as COD in wastewater.) Beginning in fiscal year 2022, data for the DIC Group in other countries and territories includes that for the Colors & Effects pigments business, which joined the DIC Group in July 2021.

- Note: A PRTR is a scheme for assessing, aggregating and disseminating data on the source of hazardous chemicals, amounts released into the environment and amounts transferred off-site from industrial establishments via waste products.