DIC and FPCO Begin Collaborating to Deploy the World’s First Dissolution and Separation Recycling Technology for the Closed-Loop Recycling of Plastic Food Trays —The two companies will launch “tray-to-tray” recycling of colored foamed polystyrene food trays to achieve the closed-loop recycling of all plastic food trays—

- Management & IR

- News Release

Tokyo, Japan—DIC Corporation announced today that it has begun collaborating with Hiroshima-based FP Corporation (FPCO) to deploy the world’s first dissolution and separation recycling technology for polystyrene, the raw material used in plastic trays for food products, to facilitate the closed-loop recycling of these trays. The two companies are aiming for practical implementation in fiscal year 2023.

In November 2020, DIC and FPCO announced plans to collaborate in the practical implementation of a closed-loop recycling system for polystyrenethat maximizes the technologies, as well as the collection and recycling systems, of both companies. This initiative aims to realize the closed-loop recycling that uses chemical recycling technology to recycle polystyrene to styrene monomer, which is the raw material for polystyrene.

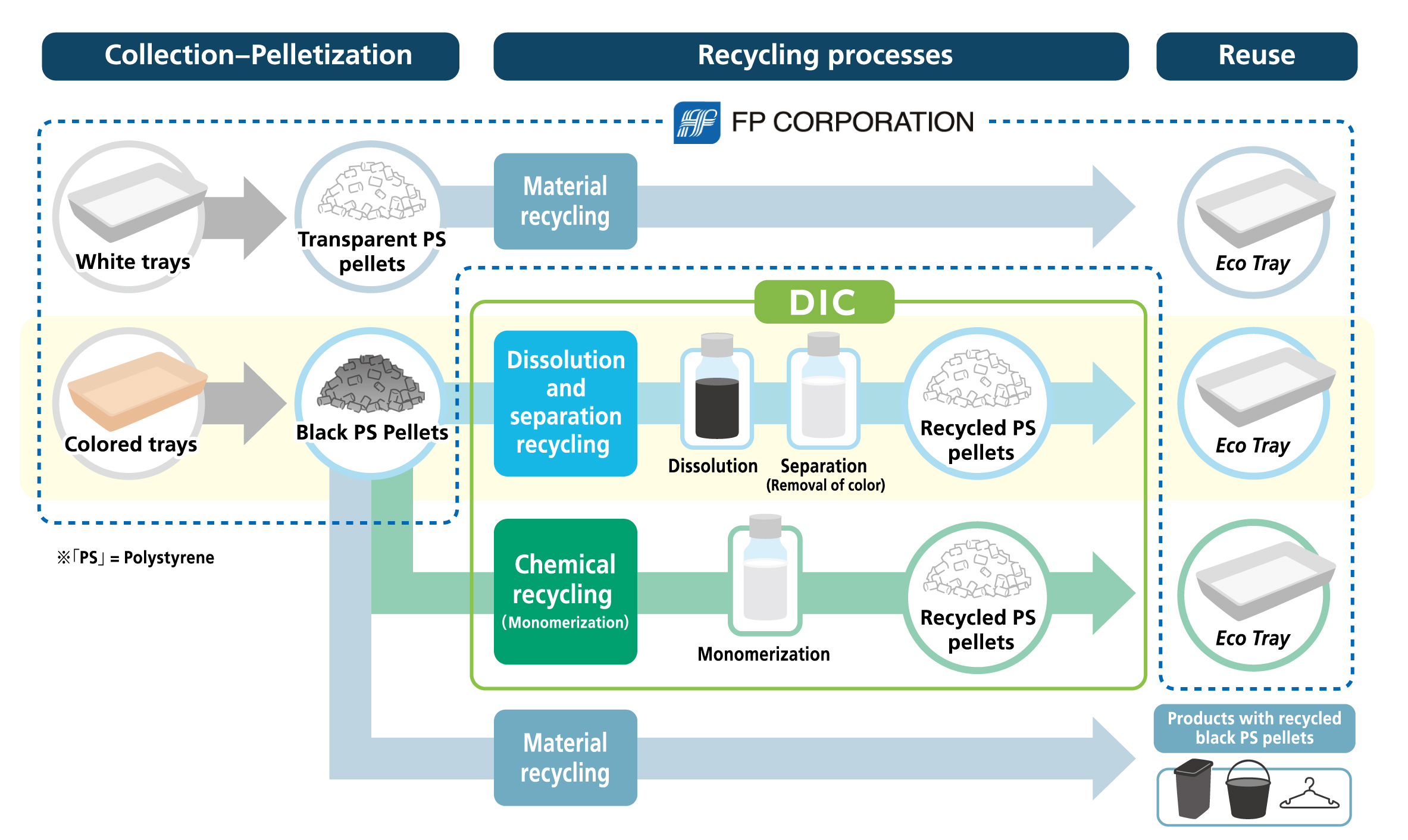

FPCO promotes “tray-to-tray” recycling, collecting post-consumer foamed polystyrene food trays from approximately 10,000 collection bases at supermarkets and other locations across Japan, and then recycling them into new food trays. Foamed polystyrene food trays can be either white or colored, depending on use. The used white trays that are discarded by households can be recycled into new food trays. However, because pulverizing colored foamed polystyrene trays yields black pellets which usage is limited due to its color; and therefore, these trays are generally recycled into materials for clothes hangers and other household items.

To resolve this issue, DIC has developed a new dissolution and separation recycling technology specifically for colored trays. This technology, which makes use of the technologies and polymer design capabilities DIC has cultivated as a manufacturer of inks to eliminate colored elements from black pellets, will be adopted at polystyrene production facilities, enabling “tray-to tray” recycling of colored foamed polystyrene food trays as of white trays.

We are proceeding with industrial verification of this process at DIC’s Yokkaichi Plant. DIC and FPCO intend to launch recycling of collected post-consumer colored foamed polystyrene food trays in fiscal year 2023, as well as to combine this technology with chemical recycling, which the companies are promoting simultaneously, to create a hybrid recycling process.

In its DIC Vision 2030 long-term management plan, DIC identifies responding to a circular economy as a central sustainability strategy and as a challenge critical to the realization of a sustainable society. Looking ahead, the DIC Group will continue collaborating with customers and suppliers across its supply chain with the aim of achieving greater circularity in the important market for food packaging.

The FPCO Group has pursued as a manufacturer the three basic pillars of “creating superior, environment-friendly products”,” manufacturing them at competitive prices”, and “delivering them to our clients when they need them”. The FPCO Group makes every effort to reduce its environmental impact across the entire value chain, including in procurement, product development, manufacturing, logistics and recycling, with the goal of helping to create a recycling-oriented and sustainable society.

– Ends –

FPCO Method Circular Recycling

DIC Corporation is one of the world’s leading fine chemicals companies and the core of the DIC Group, a multinational organization comprising over 190 companies, including Sun Chemical Corporation, in more than 60 countries and territories. The DIC Group is recognized as a global leader in the markets for a variety of products essential to modern lifestyles, including packaging materials, display materials such as those used in television and computer displays, and high-performance materials for smartphones and other digital devices, as well as for automobiles. Through such products, the Group endeavors to deliver safety and peace of mind, and color and comfort, to people everywhere. The DIC Group also seeks to contribute to a sustainable society by developing innovative products that respond to social change and which help address social imperatives. With annual consolidated net sales currently in excess of ¥800 billion and 22,000-plus employees worldwide, we pledge to continue working in close cooperation with our customers wherever they are.https://www.dic-global.com/en/

FP Corporation (FPCO) is a Japan’s leading manufacturer of food containers used for items sold at supermarkets, convenience stores and other retailers. Since its establishment, the company has dedicated itself to developing and providing products that respond to the needs of its customers. FPCO also endeavors to contribute to the realization of a sustainable society by promoting its proprietary FPCO-method “tray-to-tray” and “bottle-to-tray” recycling, which contributes to the reduction of waste and CO2 emissions, as well as by developing resource-efficient containers with a reduced environmental impact.

Company name: FP Corporation

Representative officers: Mikimasa Sato, Chairman and Representative Director; Kazuyuki Yasuda, President and Representative Director

Headquarters: 13-15 Akebono-cho, 1-chome, Fukuyama, Hiroshima 721-8607, Japan

Date of establishment: July 1962

URL: https://www.fpco.jp/en.html

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.