Special Feature DIC: Shaping a New Era

India: A Land of Colors Where the Past Meets the Future

DIC, which has declared “Color & Comfort” as its brand slogan, enjoys a leading share of the global markets for printing inks, organic pigments and polyphenylene sulfide (PPS) compounds. Since its establishment in 1908, the Company has sought, through constant innovation, to create enhanced value, as well as to contribute to sustainable development for its customers and society. In this special feature, we take a future-oriented look at some of DIC’s efforts to shape a new era.

A huge country and Asia’s fastest-growing economy, India overflows with color. Vibrant saris billow gently in the dusty roads. Temples are adorned with marigolds in vivid shades of orange. Multihued spices spill out from shops lining Old Delhi’s market streets, while neat rows of brightly colored packages beckon from shiny new shopping malls. The coexistence of the past and the present in this land as it hurtles toward the future is both exhilarating and inspiring.

Traditional Indian Colors and Shapes

A Region Famous for Block Printing

Approximately an hour and 20 minutes by plane from the Indian capital of Delhi, the northwestern state of Rajasthan remains synonymous even today with textile printing and dyeing, metal work, pottery and numerous other traditional arts that depend on skilled hands and craftsmanship. The rulers of Rajasthan were patrons of the arts and created villages specializing in different art forms, thus helping to preserve the region’s artistic heritage.

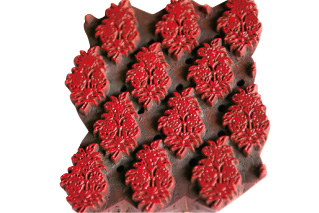

Rajasthani block-printed textiles are exported around the world and have become one of India’s best-known artisanal handicrafts. Block printing on fabric uses intricately carved wooden blocks coated with dye to stamp designs onto fabric. A painstaking process of repeated printing with a series of blocks yields the region’s famous soft, exquisitely patterned textiles.

“Block printing originally used black dyes only,” says Jitendra Chaturvedi, a supervisor at the Anokhi Museum of Hand Printing, which documents the history of block printing and houses an extensive collection of textiles. The emergence of more diverse colors and patterns resulted from the need to produce original block prints for individual villages and occupations.

“In the city of Balotra, near Jodhpur, for example, for about half a century each village had its own set textile pattern, with different occupations, such as gardeners and cowherds, having their own standardized color schemes. Footprint designs were used in Hindu temples, while intricate patterns were produced for the nobility.”

Even more interesting is the passing down of techniques through a back-and-forth process of efforts to modernize and return to tradition. In the 1970s, a turning point in the history of the craft, the arrival of British expats following the “hippie trail” to India led to the creation of clothing using never-before-seen patterns and styles. For instance, artisans in the state capital of Jaipur and surrounding towns traditionally specialized in patterns inspired by local plants and flowers. In the 1970s, however, local designers were suddenly freed of such constraints and began to create bold new patterns inspired by modern motifs.

In the 1990s, rising exports prompted a resurgence of traditional patterns. Sanganer, a textile dyeing and printing center near Jaipur, boasts hundreds of studios, each with its own distinctive patterns. Designers at one such studio, Shilpi, speak of the popularity of innovative offerings created by, among others, block printing on dyed fabrics and combining block printing with embroidery. Jaipur-based Anokhi, founded by an Indian man and his British designer wife, has gained considerable popularity as a fashion label using traditional techniques to create products that appeal to contemporary tastes, from garments such as dresses and shirts to tote bags and cosmetics pouches.

Today, students from many countries come to Rajasthan to learn block-printing technologies, leading to the creation of strikingly original patterns for overseas markets. Block printing thus remains an art in which the meeting of time-honored skill and new sensibilities continues to yield innovation and drive evolution.

Patterns based on natural motifs such as flora, including mango leaves and vines,

and fruit, are typical of block-printed textiles from Jaipur and Sanganer.

the perfect choice for blocks,which are used repeatedly.

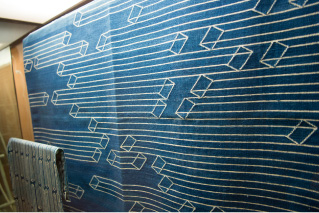

Sanganeri textile dyeing and printing studio, silkscreen

prints a 50 meter-plus length of fabric.

printing artisan at the Anokhi Museum of

Hand Printing

Anokhi Museum of Hand Printing can

view artisans at work up close.

Cities of Color that Convey India’s Energy and Handicrafts in Colors that Resonate With Its People

India’s cities have their own unique colors. This is particularly true in the northwest of the country, home to multiple cities with nicknames referencing color, including Jaipur, the Pink City; Jodhpur, the Blue City; and Jaisalmer, the Golden City. Jaipur, in particular, is known for the beautiful terracotta pink buildings of its historic center, which glow against the bright blue sky. A walk through the city’s Tripolia Bazaar, a popular shopping area organized by shop type, gives one a glimpse of bright saris swishing through the narrow streets. Visual delights awaiting visitors to the magnificent City Palace, home of the Maharaja of Jaipur, include unique, ornately decorated emerald-colored doors and proud, white-clad, red-turbaned royal guards.

Jaipur is also home to exquisite artisanal handicrafts. The eye-catching color of the city’s traditional blue pottery is said to have originated in Persia. The pottery begins with a soft “dough” made from quartz powder and silicate glass, among others, which is molded, painted and glazed, and then fired in a kiln at approximately 800ºC, a low temperature for porcelain ware, causing the painted colors to change, with terracotta turning sky blue and lavender turning a vivid cobalt.

The Pink City’s Hawa Mahal (“Palace of Winds”)

Neerja Corporation, which originally used this technique to make surahi (narrow-necked jugs) and later expanded its focus to include items for export markets, including door knobs, accessories and soap dishes, is said to have changed the course of blue pottery’s history. Seeing the resurrection of blue pottery, the popularity of which had faded, as a way to help impoverished fellow Rajasthanis, entrepreneur Leela Bordia founded Neerja and established the village of Kot Jewar as a community to house and train artisans. Given the fragility of blue pottery, Mrs. Bordia also set up the world’s first recycling system for broken porcelain, an initiative that has earned numerous awards. Although the company product lineup also features pottery in a variety of colors, including yellow and gray, Mrs. Bordia declares with pride that Neerja’s identity is synonymous with blue pottery.

Kalpana Handmade Paper Industries, another company engaged in a traditional Rajasthani artisanal handicraft, namely, the making of cotton paper and paper products, has also benefited from recycling. Cotton paper is handmade paper the raw material for which is cotton. Made using scraps from discarded cotton T-shirts, underwear and other items, cotton paper, which is bound with a natural cotton adhesive, is thick and rough to the touch, giving it a bold character not seen in industrial products.

Handmade cotton paper from Kalpana is used in packaging for perfumes and other aroma products, as well as in notebooks and gift boxes. In addition, it is also favored for calendars used by first-class hotels and wedding invitations. Kalpana’s lineup also includes paper featuring embedded marigold or basil seeds. Add a bit of dirt and some water and the seeds might just germinate! A company established with the aim of preserving an ancient artisanal handicraft, Kalpana continues to bring joy to everyday life for people around the world and to light a path forward for India.

in Jaipur’s blue pottery.

paint bright blue.

cotton paper.

indispensable for ceremonial occasions

in India.

descendants of the last titular Maharaja of

Jaipur.

Strategies and Technologies for Reproducing the Colors of Modern India

DIC India’s Business Development

Print test samples using gravure inks

DIC India Ltd. provides printing inks and technologies that help its customers reproduce the myriad colors of this diverse and vibrant country. Established in 1947 as Coates of India Limited, the company was acquired by DIC in 1999. A listed company, DIC India is currently the leading provider of products and services for India’s printing industry. CEO Shailendra Singh outlined the strategies the company is implementing to further grow its business in India, which in 2024 is expected to overtake the People’s Republic of China (PRC) as the world’s most populous country.

“As you know, the Indian economy continues to grow rapidly in tandem with the country’s population,” Mr. Singh explained. “In addition to population growth, it is important to keep in mind that India has a huge middle class that is expected to continue expanding. Accordingly, it is important that we focus on this market at the same time as we strive to create solutions tailored to the needs of the wealthy and of the general public.”

Mr. Singh describes the Indian market as a whole as an isosceles triangle. “You have the top less-than-1%. Below that you have the middle class, which has grown significantly in recent years. Finally, forming the base of the triangle, you have what we call the “large local” stratum, namely, the general public.”

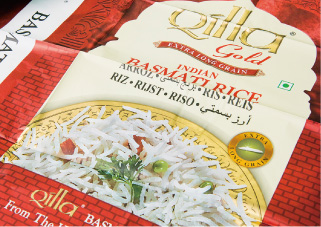

Among the wealthy and the middle class, demand is particularly high for flexible packaging. “The prevailing format for sales of grains and cereals, milk and other food products is shifting from bulk to packaged, so we are at a real turning point,” Mr. Singh explains. “Until now, there has not really been an established packaging industry in India, but we now expect to see a billion-dollar market emerge within the next five years.”

One example of a product for which demand is soaring is vacuum-filled packaging for beverages manufactured by UFLEX Ltd., India’s largest provider of flexible packaging solutions. While still seen as a high-end item, the creation of a distribution infrastructure will facilitate the delivery of perishable juices, milk and other beverages across India regardless of the weather with no negative impact on freshness.

a type of rotary letterpress printing

all machinery is computer-operated

supplied by DIC India, that features a

sumptuous glossy finish with matte portions.

packaging products, boasts cutting-edge

technologies that it is leveraging to

develop environment-friendly and

other offerings.

product development at UFLEX, says that

he looks forward to reinforcing his

company’s relations with DIC India

DIC India supplies news inks in response to the needs of India’s massive “large local” market. Bolstered by rising literacy rates in farming communities and greater disposable income, demand for newspapers is rising. “Farming villages today buy one newspaper and pass it around,” Mr. Singh says. “If, for example, each household was to begin buying its own newspaper then consumption of newspapers would soar.” The company is currently exploring the idea of expanding its operations in the high-growth western state of Gujarat. “Whatever happens, it is critical for us to remain a step ahead of the competition, as well as to ensure a firm grasp of our customers’ needs,” Mr. Singh emphasizes when asked about business strategies, “because companies around the world recognize the opportunities that exist in this market. We must also be flexible in considering collaboration with other companies,” he continues. “If we are active in addressing the challenges ahead, I am confident that we will be able to capitalize fully on the tremendous potential of the Indian market.”

“My motto is ‘Move fast!’” Mr. Singh says. “I believe in working efficiently and always having a smile on my face. If we hesitate even for a moment, the market changes and we fall behind!”

CEO

DIC India Ltd.

Shailendra Singh

Joined DIC India in 2015.

Committed not only to supplying India’s printing

industry with a broad range of high-grade products

but also to working with brand owners to develop

solutions to social imperatives in the growing and

changing Indian market. Sees his mission as being

to drive DIC India’s evolution into one of India’s

leading companies.

DIC in South Asia: Looking Beyond

Expanding Focus from India to the Muslim World

According to the International Monetary Fund (IMF), a rising gross domestic product (GDP), which rose 7.1% in 2017—the third consecutive year of 7.0%-plus growth—and infrastructure development continue to make India a target of significant attention, in both name and substance. What do people who live and work in this exciting market see?

Naoyoshi Furuta, Deputy Managing Director (South Asia) at DIC Asia Pacific Pte Ltd, has worked to develop DIC’s nongraphic arts business in South Asia since being dispatched to India in fiscal year 2015*. The first thing he says is, “You really have to be here to understand the incredible vitality of this place. I think it is important to see and experience India firsthand, especially for those in positions of leadership.”

South Asia, the area supervised by Mr. Furuta, is a dazzling cultural mosaic. In addition to India, an ethnically and linguistically varied nation that is home to people of many different religions, including Hindu, the area includes Sri Lanka, which is predominantly Buddhist, and Islamic Pakistan. Going forward, rapid economic advancement is expected to further drive diversity across the region as a whole.

Skyscrapers in the Cyber City

commercial park in Gurgaon, near Delhi

With the aim of encouraging the efficient sharing of information and know-how, Mr. Furuta established a team comprising members from each country in the region and launched the SANGA Project. At present, more than 70 such projects focusing on coating resins and materials, PPS compounds and packaging films for food, among others, have been rolled out. “SANGA” is an acronym for South Asia Non Graphic Arts,” Mr. Furuta explains. “Project members communicate with each other daily via group email. This greatly enhances collaboration. For example, if one says, ‘I am working on this idea,’ the others respond promptly by sending materials that might be of use. Looking at progress reports also stimulates a healthy rivalry, making teammates realize, for example, where they need to step up efforts and where market similarities mean business strategies implemented elsewhere can be imitated.”

Mr. Furuta’s motto, which reflects his extensive experience overseas, is “Trial and error.” “The DIC Group has some truly unique technologies,” he says. “If you worry too much about keeping it all in-house, investment costs mount and valuable time is lost. In business, being first off the mark is crucial. If you start small, losses will be minimal even if issues arise. Depending on circumstances, collaboration is a good option. What is important is having the guts to take a chance and being confident that what you are doing is right. You may have hit a lot of balls before you get a home run, but it’s all good as long as it works out in the end.”

Mr. Furuta is currently exploring the business potential of Pakistan, which serves as a doorway to the Muslim world. At present, DIC is working through its joint venture with Packages Limited in the eastern city of Lahore to expand the DIC Group’s presence in Pakistan while contributing to the country’s economic development. In so doing, DIC will work to secure access to the Muslim world, home to an estimated 1.6 billion people. Many in the world have turned their focus to India. Mr. Furuta is already looking beyond to the next challenge.

*Position held from 2015 to 2017

the Indian market for passenger cars,

on display at Indira Gandhi International Airport(Delhi)

popular manufacturers include Samsung Electronics Co., Ltd.

of the Republic of Korea (ROK) and Xiomi Corp. of the PRC.

DIC India is located and DIC Asia Pacific has an office

Deputy Managing Director (South Asia)

DIC Asia Pacific Pte Ltd. (2015–2017)

Naoyoshi Furuta

Joined DIC in 1981.After stints in printing inks and corporate planning,

assisted in DIC’s acquisition of the Coates Group. Has held positions in

DIC’s core printing inks, polymers and pigments business. Previous

overseas assignments included Sun Chemical Corporation in the United States.

Assigned to India in 2015. Appointed executive officer and general manager of

the Production Management Unit, effective from January 2018.

Deputy Managing Director (South Asia) effective from January 2018

Chief Representative, DIC Asia Pacific Pte Ltd

Masahiro Kikuchi

Joined DIC in 1986. Worked initially in reprographic products.

On assignment overseas for 12 consecutive years (DIC Europe GmbH,

DIC (Guangzhou) Co., Ltd. and DIC (Taiwan) Ltd.) before returning to

Japan in 2013. Involved in new business development as general

manager of the Life & Living Marketing Department and the Marketing

Division from January 2014 to December 2017. Dispatched to DIC Asia

Pacific as Deputy Managing Director (South Asia) effective from January 2018.

- Links

- DIC India Ltd.