Special Feature Solar Cells : Materials for Solar Cells

Seeking to extend the lives of solar cell modules

Social Imperative Enhance weatherability to encourage greater use of renewable energy

To help prevent global warming and the depletion of fossil fuels, steps are being taken worldwide to further the use of renewable energy. Solar cells are seen as a particularly promising option, owing to ease of installation, and manufacturers are working to enhance generating efficiency and reduce associated costs. However, degradation as a result of ultraviolet (UV) rays, heat, humidity, wind and rain lowers the generating efficiency and shortens the lifespan of solar cell modules. Accordingly, enhancing the weatherability of these modules is a key challenge.

To encourage the use of solar power, it is essential to safeguard modules’ vital solar cells from natural damage and to extend replacement cycles, thereby enhancing resource efficiency and enabling users to swiftly recoup their investments. Another challenge is to lower the weight of solar cell modules, thereby reducing the burden on structures that have had modules installed.

DIC’s Response Leverage the outstanding weatherability of DIC adhesives to increase backsheet durability.

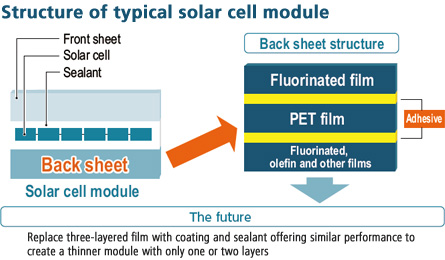

Solar panel back sheets protect solar cells against heat, UV rays and humidity. Crucial to the reliability and lifespan of solar cells, these back sheets are made from multiple layers of polyethylene terephthalate (PET) film and fluorinated film bonded together with an adhesive, ensuring excellent weatherability and resistance to humidity. However, depending on the environment in which panels are installed, general-purpose adhesives may weaken quickly after use, preventing back sheets from functioning effectively and negatively affecting both the performance and lifespan of solar cell modules.

DIC overcame this problem in 2009 by developing an adhesive specially for solar panel back sheets that leverages its hydrolysis-inhibiting resin design and additive-mixing technologies to deliver outstanding resistance to weathering. The adhesive’s ability to ensure stable adhesion for various types of film draws on DIC’s technologies for manufacturing multilayer laminates for packaging, while its resistance to heat and humidity capitalize on the Company’s experience in the production of building materials. Having performed well over more than 3,000 hours (equivalent to 20 years’ consecutive use) in testing at 85°C and 85% humidity, this adhesive surpasses the standards of many solar cell module manufacturers. In 2013, DIC developed a weather-resistant coating that absorbs UV rays and a highly heat- and moisture-resistant sealant. Used together, the coating and sealant enhance back sheet durability and help extend the lifespan of solar cell modules.

KEY PERSON of DIC

The two major themes guiding our development efforts are to enhance weatherability and reduce costs.

Accelerating general acceptance of solar power is largely dependent on manufacturers’ ability to simultaneously improve performance and reduce costs. There is considerable potential in this field for us to maximize DIC’s resin design and dispersion technologies. For example, if we can develop a coating and sealant offering the same weatherability as film, it would contribute to weight reduction and lower costs. We recognize that the road ahead is not an easy one, but we are confident that by integrating DIC’s multiple core technologies we will find success.

Group Manager, Dispersion Technical Group 2,Dispersion Technical Div.1 Masami Hozumi

Solar cell modules are a treasure house of DIC technologies.

Our highly rated back sheet adhesive represents a key application of coating technologies accumulated in the field of packaging materials. In fact, the integration of core DIC technologies has helped improve many aspects of solar cell performance. Going forward, we will continue working to develop materials and components that not only further enhance weatherability and reduce weight but also help improve electric power conversion efficiency, and in so doing to contribute to the evolution of solar power generation.

Head Researcher, Dispersion Technical Group 2,Dispersion Technical Div.1 Tatsuya Koyama

The age of solar power—from systems for homes to megasolar power plants—is on the horizon.

While Germany, Spain and Japan have already introduced feed-in tariff programs to promote wider public acceptance of solar power, the age of solar power is on the horizon. In areas such as North America, the Middle East, India, the People’s Republic of China (PRC) and Africa, the potential of distributed generation, which does not require the construction of long power lines, is attracting particular attention. Driven by related market needs, DIC is promoting the development of a broad range of related proprietary materials with the aim of contributing to the expanded use of clean energy.

High-Performance Chemicals Development Dept., Advanced Polymer Sales Div. Masaru Imai

Special Topics 2014

Ceranate® : Hybrid Resin for Coatings

Seeking to shield houses and other structures from UV rays and air pollution

Hybranch® : Hyperbranched Polystyrene

Enhancing the environmental performance of food containers, electrical appliance components and insulating materials

Solar Cells : Materials for Solar Cells

Seeking to extend the lives of solar cell modules

Lithium Ion Batteries : Materials for Lithium-Ion Batteries

Contributing to the evolution of high-performance batteries is essential in a smart technology-based society

Printed Electronics : Materials for Printed Electronics

Making today’s advanced information society easier to navigate and more environment-friendly

TOPICS

Sun Chemical Revamps its Website

The Sun Chemical Group, a core member of the DIC Group with operations in North America and Europe, recently revamped its website, improving search capability and simplifying navigation.

DIC Expands Supply Capabilities for Linablue® Natural Blue Food Coloring

Rising concern for the health benefits and safety of food is accelerating a shift toward using natural, rather than synthetic, colorings in the food products industry. As the world’s largest manufacturer of one of the few natural blue colorants in existence, the DIC Group intends to bolster its supply capabilities by building a new plant in the United States.